High activity, high medium oil selective hydrocracking catalyst and preparation thereof

A hydrocracking and catalyst technology, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of low catalyst hydrocracking activity, high catalyst hydrocracking activity, and high selectivity of medium oil, etc. Achieve the effects of reducing metal loss, excellent performance, and improving medium oil selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

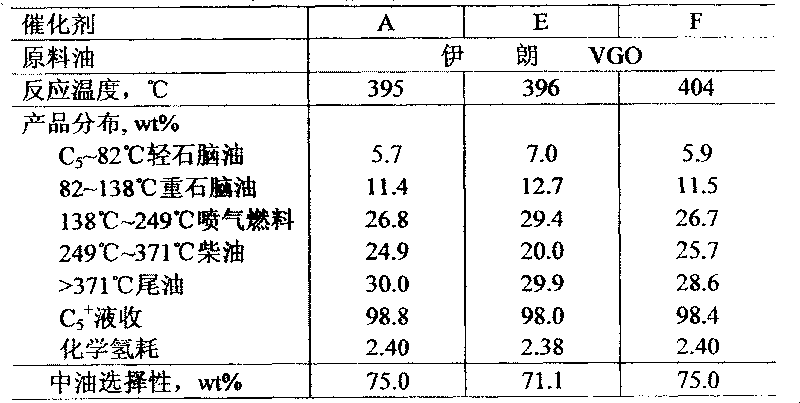

[0022] Catalyst A is the catalyst prepared by the inventive method, and catalyst weight is composed of: WO 3 22.0%, NiO 9.0%, ZrO 2 7% SiO 2 33%, Al 2 o 329%, of which the molecular sieve content is 20%, and the specific surface area is 240m 2 / g, the pore volume is 0.34ml / g.

[0023] Concrete preparation steps are as follows:

[0024] (1) Prepare Al-containing 2 o 3 600 ml of aluminum chloride solution with a concentration of 90 g / l, containing NiO 200 ml of nickel chloride solution with a concentration of 140 g / l, containing ZrO 2 150ml of 140g / l zirconium oxychloride solution was mixed in a 5 liter container and diluted with 2000ml of clean water.

[0025] (2) Prepare dilute water glass solution, containing SiO 2 550 milliliters of water glass solution of 75g / l, under stirring situation, (2) is added in (1);

[0026] (3) Add ammonia water to the mixture of (1) and (2) under stirring until the pH value is 5.2;

example 2

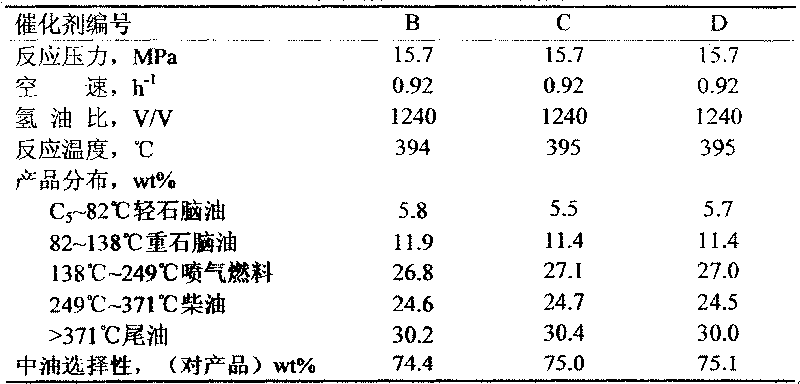

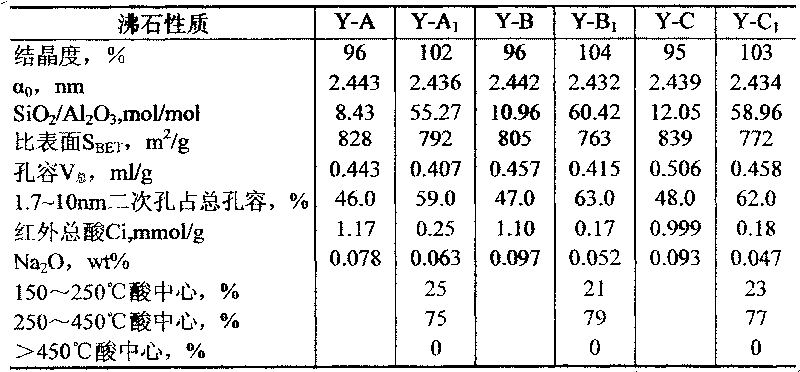

[0035] It is the hydrocracking catalyst B of the present invention, and the preparation method is the same as that of Example 1, except that 25% of the Y-type molecular sieve modified by hydrothermal treatment is added before aging, and the molecular sieve Y-B prepared by ZL96119840.0 Example 2 is used as a raw material for the molecular sieve, and the Hydrothermal treatment, hydrothermal treatment conditions are temperature 700 ° C, pressure 0.3 MPa, time 22 hours, then acid treatment, using 0.5M sulfuric acid 3000 ml, sulfuric acid and molecular sieve weight ratio is 1: 2, temperature 30 ° C, time 1 hour, Obtain modified molecular sieve Y-B 1 , Y-B and Y-B 1 The properties are shown in Table 3. Catalyst weight composition is: WO 3 21.0%, NiO 7.5%, ZrO 2 6.5% SiO 2 30%, Al 2 o 3 35%, the specific surface is 260m 2 / g, the pore volume is 0.36ml / g.

example 3

[0037] It is the hydrocracking catalyst C of the present invention, and the preparation method is the same as Example 1, except that the Y-type molecular sieve modified by hydrothermal treatment is added before aging to be 17%, and the molecular sieve Y-C prepared by ZL96119840.0 embodiment 3 is used as a raw material for the molecular sieve, and the Hydrothermal treatment, hydrothermal treatment conditions are temperature 650 ° C, pressure 0.2 MPa, time 28 hours, then acid treatment, use 3.0 M hydrochloric acid 8500 ml, hydrochloric acid and molecular sieve weight ratio is 1: 18, temperature 60 ° C, time 3 hours , to get modified molecular sieve Y-C 1 , Y-C and Y-C 1 The properties are shown in Table 3. Catalyst weight composition is: WO 3 23.6%, NiO 7.4%, ZrO 2 7% SiO 2 31%, Al 2 o 3 31%, the specific surface is 270m 2 / g, the pore volume is 0.31ml / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com