Molecular sieve acidity and pore structure composite modulation method

A technology of molecular sieve and pore structure, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, silicates, etc., can solve the problems of molecular sieve dissolution and microporous structure damage, loss of strong acid centers of molecular sieves, and raising the treatment temperature of soda ash solution, etc., to achieve The microporous structure is well maintained, the center density is increased, and the center density is complete.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

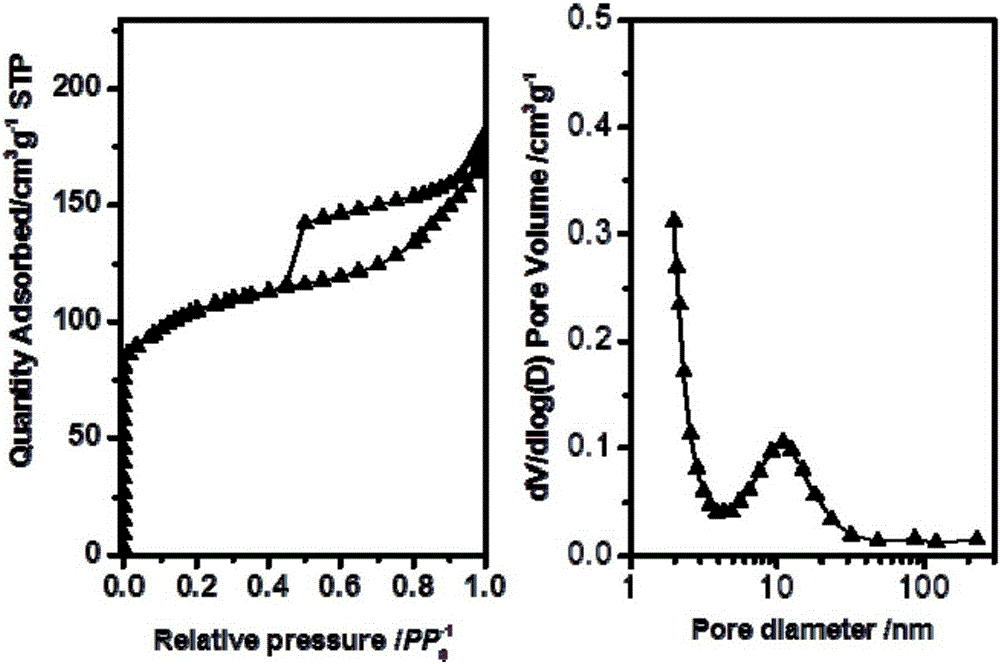

[0025] Take 10g ZSM-5 molecular sieve (Si / Al=35, Na 2 O content 3 ) 3 In the solution, magnetically stirred at 65°C for 35 minutes, then filtered and washed to neutrality, dried at 120°C for 12 hours, and calcined in a muffle furnace at 550°C for 3 hours. The obtained molecular sieve was added to 0.8mol / L ammonium nitrate solution, solid-liquid ratio was 1:10, magnetically stirred at 85°C for 2 hours, then filtered and washed, dried at 120°C for 12 hours, and then placed in a muffle furnace It is calcined at 550°C for 6 hours. Table 1 shows the structure data of molecular sieve treated with aluminum-containing compound alkaline medium. In this example, the secondary pore distribution curve of the ZSM-5 molecular sieve sample treated with aluminum-containing alkaline medium is as follows figure 1 Shown.

Embodiment 2

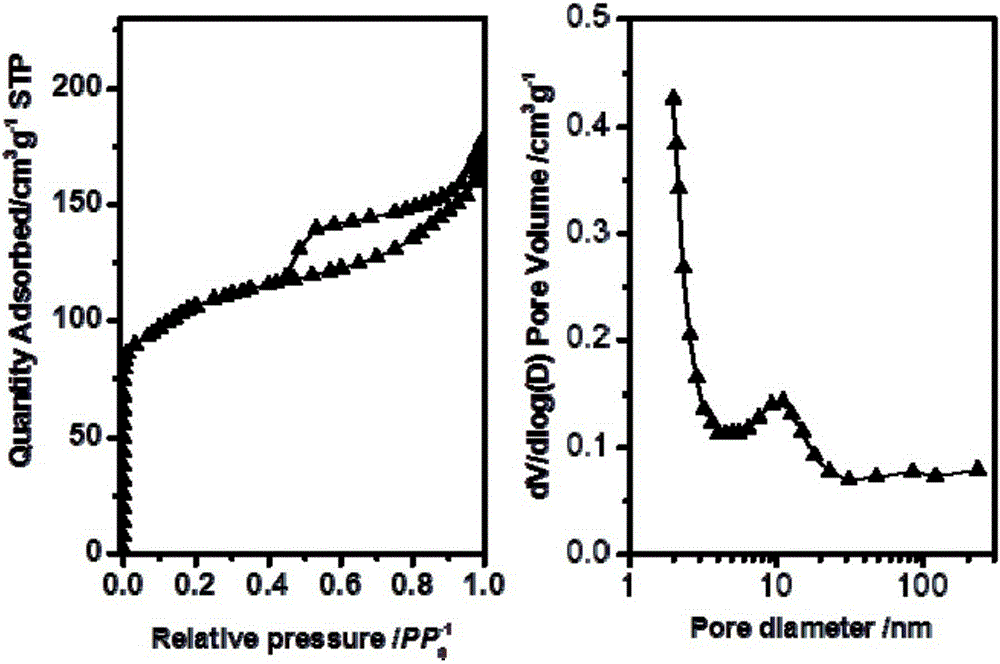

[0027] Take 15g ZSM-5 molecular sieve (Si / Al=38, Na 2 O content 0.15wt%) added to 200ml containing 0.25mol / L KOH-0.005mol / L AlF 3 In the mixed solution, magnetically stirred at 65°C for 60 minutes, then filtered and washed to neutrality, dried at 110°C for 12 hours, and calcined in a muffle furnace at 540°C for 3 hours. The obtained molecular sieve was added to 1.0mol / L ammonium nitrate solution with a solid-to-liquid ratio of 1:20, magnetically stirred at 85°C for 2 hours, then filtered and washed, dried at 120°C for 12h, and then placed in a muffle furnace for 550 Calcined at ℃ for 6 hours, denoted as B. Table 1 shows the structure data of molecular sieve treated with aluminum-containing compound alkaline medium. The secondary pore distribution curve of the sample after ZSM-5 molecular sieve treatment with aluminum-containing alkaline medium in this example is as follows: figure 2 Shown.

Embodiment 3

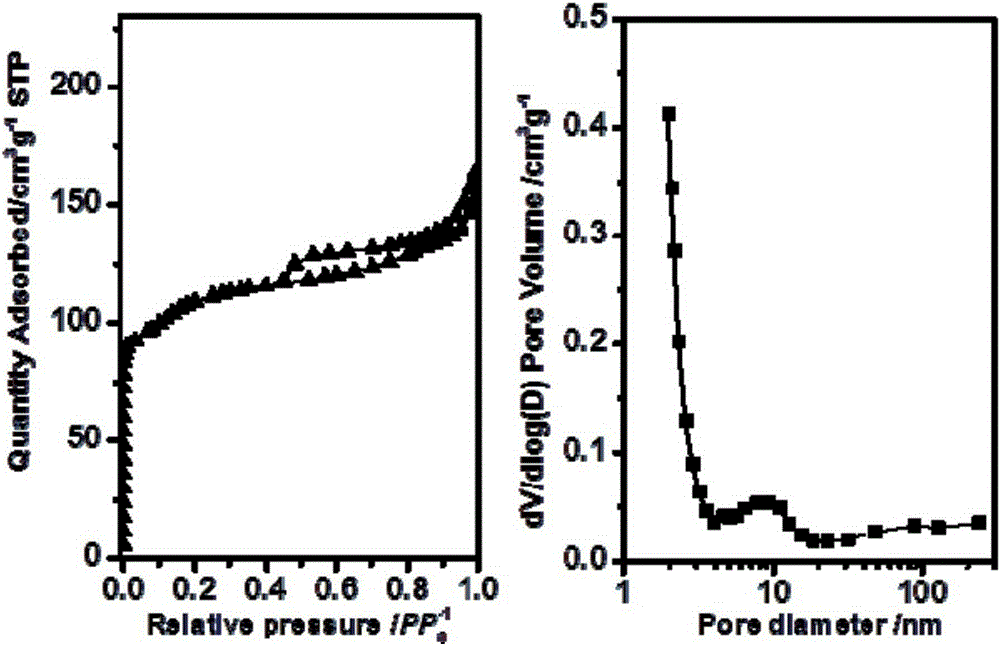

[0029] Take 10g ZSM-5 molecular sieve (Si / Al=34, Na 2 O content 0.15wt%) was added to 200ml mixed solution containing 0.25mol / L NaOH-0.009mol / L aluminum isopropoxide, stirred magnetically at 75°C for 55 minutes, then filtered and washed to neutrality, dried at 110°C for 12 hours Firing in a muffle furnace at 540°C for 3 hours. The obtained molecular sieve was added to 1.0mol / L ammonium nitrate solution with a solid-to-liquid ratio of 1:20, magnetically stirred at 85°C for 2 hours, then filtered and washed, dried at 120°C for 12h, and then placed in a muffle furnace for 550 Calcined at ℃ for 6 hours, denoted as C. Table 1 shows the structure data of molecular sieve treated with aluminum-containing compound alkaline medium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com