Production method of sodium fluosilicate

A technology of sodium fluorosilicate and production method, which is applied in the direction of silicon halide compounds, etc., can solve the problems of human hazards, waste of resources, and unutilized fluorine, and achieve the effect of eliminating hazards and increasing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

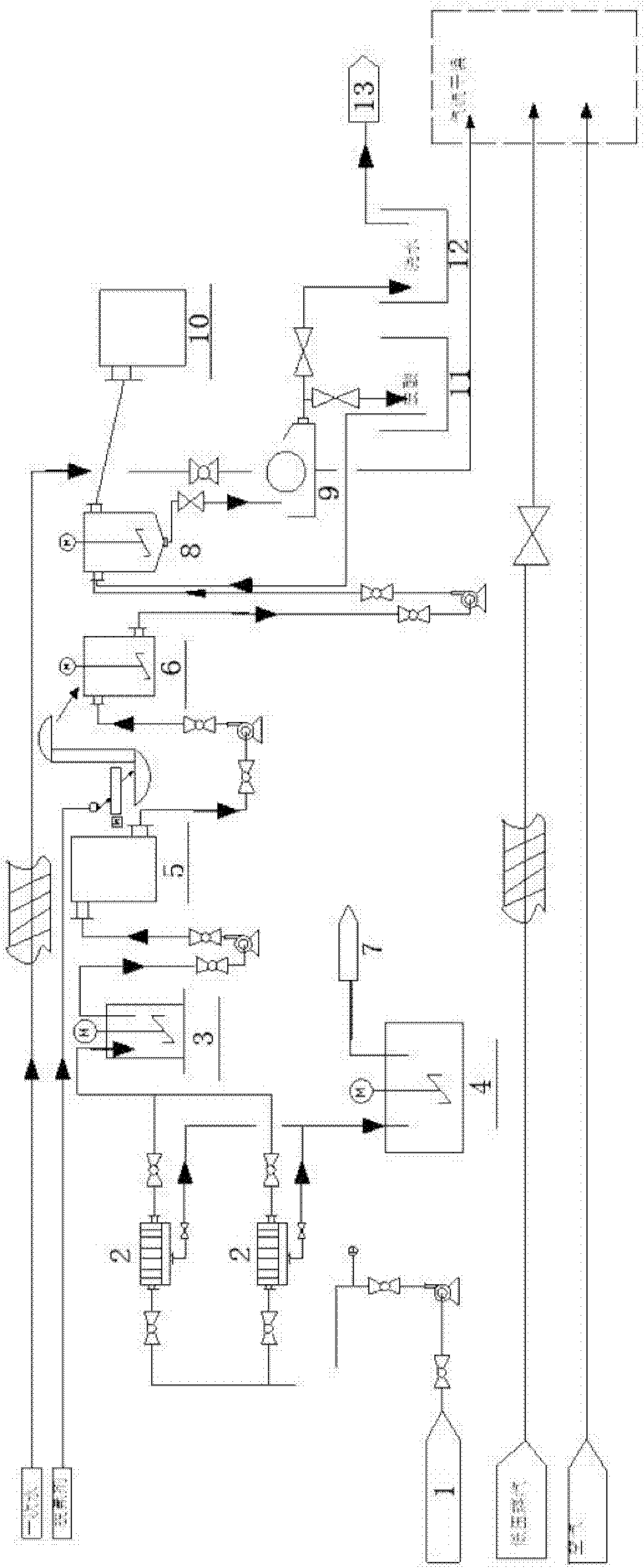

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0017] The method for producing sodium fluorosilicate by using fluorine-containing phosphoric acid in the phosphoric acid workshop, including the production process of phosphoric acid, phosphoric acid filtrate tank 3, reaction tank 6, settling tank 8, scraper centrifuge 9, airflow drying device, etc., specifically includes The following steps:

[0018] 1) After the phosphoric acid tank 1 in the phosphoric acid workshop, add two phosphoric acid purification devices (i.e., filter press 2) to purify the phosphoric acid produced in the phosphoric acid workshop, and control it by adjusting the amount of phosphoric acid washing water added and the specific gravity of the extracted acid. The concentration of phosphoric acid is controlled at 18%-25%, and the pressure of the purification device is less than 0.45Mpa (the crude phosphoric acid is pumped into the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com