Low-doping-amount and high-performance alkali-free and chlorine-free liquid setting accelerator and preparation method thereof

A high-performance, quick-setting agent technology, applied in the field of building materials, can solve the problems of non-marketability, productization, small 28d strength ratio, narrow cement application range, etc., and achieve high early strength, favorable viscosity, and remarkable coagulation-accelerating effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

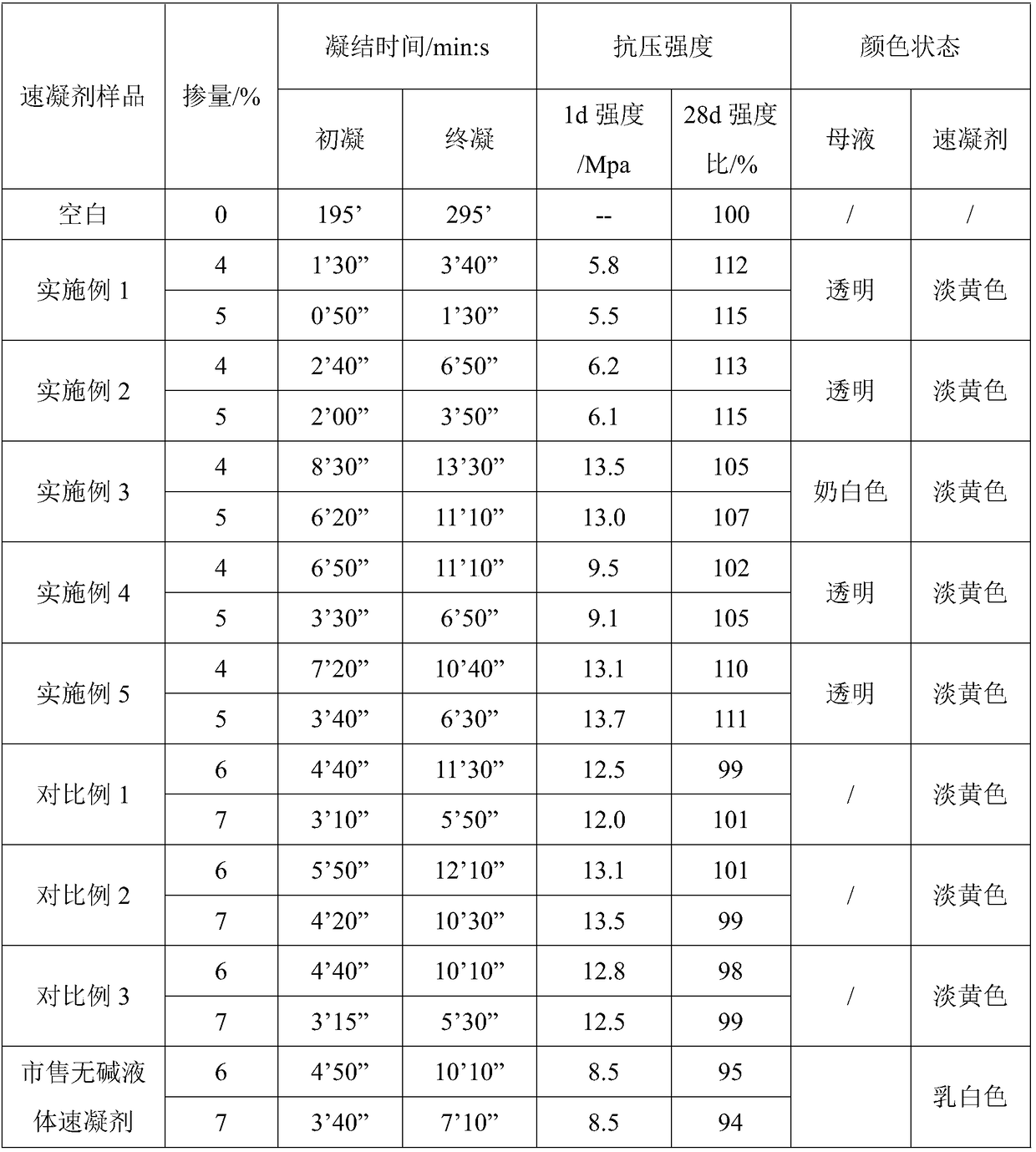

Examples

Embodiment 1

[0031] This embodiment provides a non-alkali and chlorine-free liquid quick-setting agent for sprayed concrete. Its components and the mass parts of each component are as follows: 30 parts of aluminum sulfate, 10 parts of magnesium sulfate, 0.5 parts of precipitated hydrated magnesium silicate 0.5 parts of magnesium oxide, 1 part of magnesium fluorosilicate, 2 parts of triethanolamine, 1 part of polyacrylamide, 0.5 parts of citric acid, 40 parts of mother liquor (aluminum hydroxide, hydrofluoric acid, complexing agent) and 30 parts of water .

[0032] The mother liquor is 69 parts by weight of hydrofluoric acid, 23 parts by weight of aluminum hydroxide and 8 parts by weight of a complexing agent.

[0033] The preparation method comprises the steps of:

[0034] (1) Preparing mother liquor at normal temperature: First, the hydrofluoric acid of 30 parts by weight is stirred at normal temperature, then the aluminum hydroxide of said parts by weight is added and mixed and stirred ...

Embodiment 2

[0038]This embodiment provides a non-alkali and chlorine-free liquid quick-setting agent for sprayed concrete. Its components and the mass parts of each component are as follows: 60 parts of aluminum sulfate, 0.8 part of precipitated hydrated magnesium silicate, 1 part of magnesium oxide 2 parts of magnesium fluorosilicate, 3 parts of diethanolamine, 1.5 parts of polyacrylamide, 0.8 parts of oxalic acid, 30 parts of mother liquor (aluminum hydroxide, hydrofluoric acid, complexing agent) and 40 parts of water.

[0039] The mother liquor is 61 parts by weight of hydrofluoric acid, 30 parts by weight of aluminum hydroxide and 9 parts by weight of a complexing agent.

[0040] The preparation method comprises the steps of:

[0041] (1) Preparing mother liquor at normal temperature: First, the hydrofluoric acid of 30 parts by weight is stirred at normal temperature, then the aluminum hydroxide of said parts by weight is added and mixed and stirred for 10 min, and the hydrofluoric ac...

Embodiment 3

[0045] This embodiment provides a non-alkali and chlorine-free liquid quick-setting agent for sprayed concrete, its components and the mass parts of each component are as follows: 50 parts of aluminum sulfate, 7 parts of magnesium sulfate, 1 part of precipitated hydrated magnesium silicate 2 parts of magnesium oxide, 2 parts of magnesium fluorosilicate, 1.5 parts of diethanolamine, 1 part of polyacrylamide, 1 part of citric acid, 10 parts of mother liquor (aluminum hydroxide, hydrofluoric acid, complexing agent) and 35 parts of water .

[0046] The mother liquor is 56 parts by weight of hydrofluoric acid, 37 parts by weight of aluminum hydroxide and 7 parts by weight of a complexing agent.

[0047] The preparation method comprises the steps of:

[0048] (1) Preparing mother liquor at normal temperature: First, the hydrofluoric acid of 30 parts by weight is stirred at normal temperature, then the aluminum hydroxide of said parts by weight is added and mixed and stirred for 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com