Method for processing potassium-containing rocks

A technology of potassium rock and potassium fluorosilicate, which is applied in the field of comprehensive utilization of non-metallic minerals, can solve the problems of high energy consumption, large volume of absorption equipment, large amount of catalyst, etc., and achieve the effect of saving energy consumption and shortening the processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

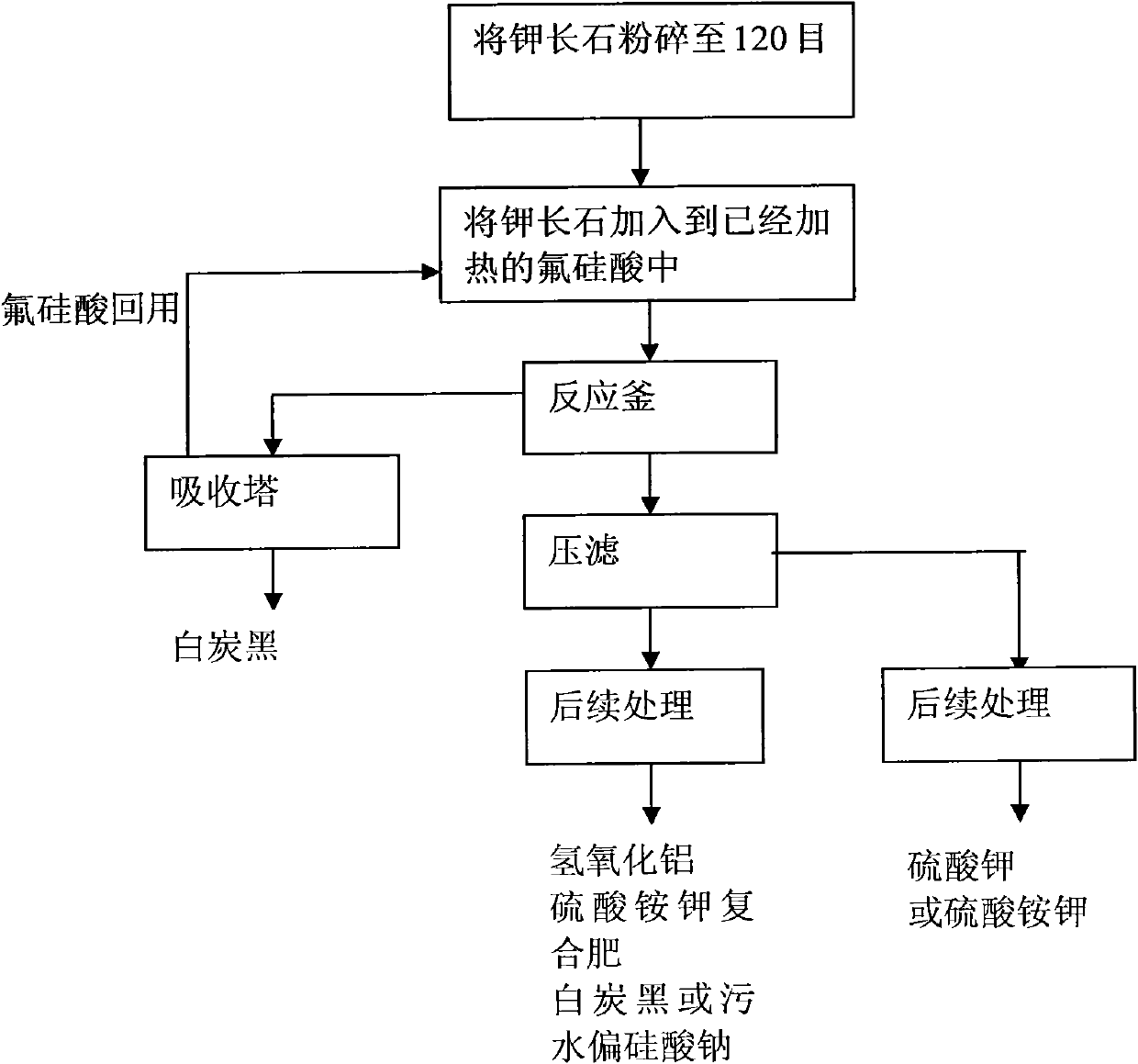

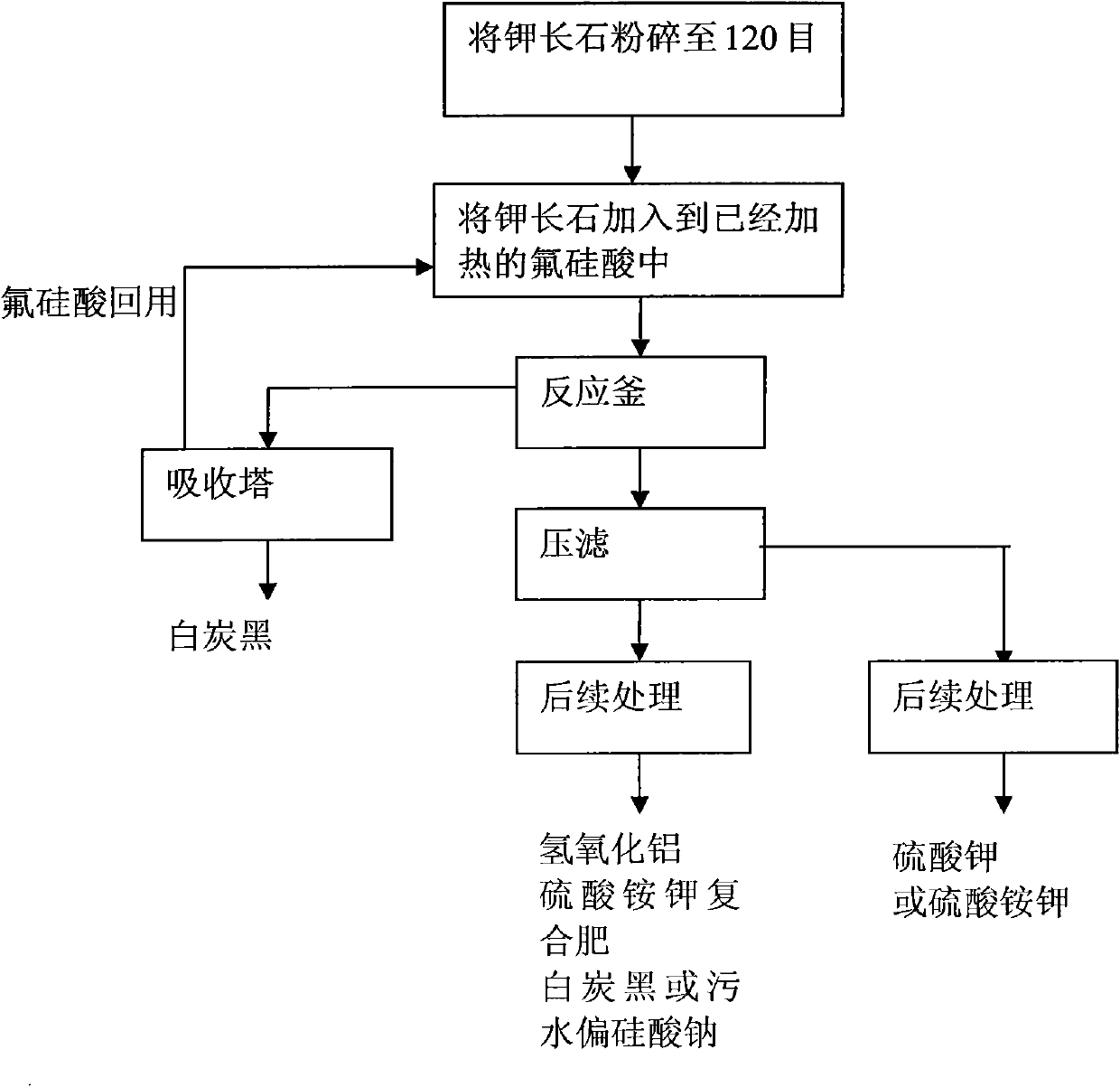

[0034] Such as figure 1 As shown, in the reaction kettle, add 1 cubic meter of 30% fluosilicic acid, heat the fluosilicic acid to 90°C with a heat conduction oil furnace, and slowly add potassium feldspar powder that has been crushed to 200 mesh by Raymond mill under stirring state 200 kg, heated with a heat-conducting oil furnace, so that the temperature in the reactor reaches 130 ° C, and the temperature is stable for 1 hour to complete the reaction. The gas produced by silicon tetrafluoride is absorbed through the absorption tower and transformed into white carbon black by sodium method , and the obtained mixed suspension including potassium fluorosilicate, aluminum fluorosilicate and silica gel enters the subsequent processing unit in the form of suspension. In this treatment process, heating the fluosilicic acid to 90°C first, and then heating it to 130°C is the most optimal solution. Only about 20 kg of standard coal with a heat content of 5,000 kcal is used, which great...

Embodiment 2

[0036]In the reaction kettle, add 1 cubic meter of 40% fluosilicic acid, heat the fluosilicic acid to 80°C or 100°C with a heat-conducting oil furnace, and slowly add 200 grams of potassium feldspar powder that has been crushed to 200 mesh by Raymond mill while stirring. kg, heated with a heat-conducting oil furnace, so that the temperature in the reactor reaches 120°C, and the temperature is stable for 3 hours to fully react. The gas produced by silicon tetrafluoride is absorbed through the absorption tower, and is transformed into white carbon black through the sodium method, and the The obtained mixed suspension including potassium fluorosilicate, aluminum fluorosilicate and silica gel enters the subsequent processing unit in the form of suspension. In this treatment process, about 40 kg of standard coal with a heat content of 5,000 kcal needs to be used, which reduces energy consumption compared with the existing technology, and provides a good raw material for the subseque...

Embodiment 3

[0038] After finely crushing 10 grams of potassium-containing shale minerals to 120 mesh, add 60 ml of 30% fluosilicic acid into the reaction kettle, start heating to 90°C in an oil bath, and add 10 grams of potassium-containing shale powder into the The reaction kettle is heated with a heat-conducting oil furnace, so that the temperature in the reaction kettle reaches 140°C, and it is kept warm for 1.5 hours to fully react. The gas produced by silicon tetrafluoride is absorbed by the absorption tower and transformed into self-carbon black by sodium method. , and the obtained mixed suspension including potassium fluorosilicate, aluminum fluorosilicate and silica gel enters the subsequent processing unit in the form of suspension.

[0039] It can be seen from the above description that after the process of the present invention, potassium-containing rocks such as muscovite and nepheline can be completely opened by using only fluorosilicic acid to obtain a mixed suspension contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com