Synthetic mica prepared from calcined talcum and preparation method and processing method of fluorophlogopite powder and fluorophlogopite pearlescent pigment

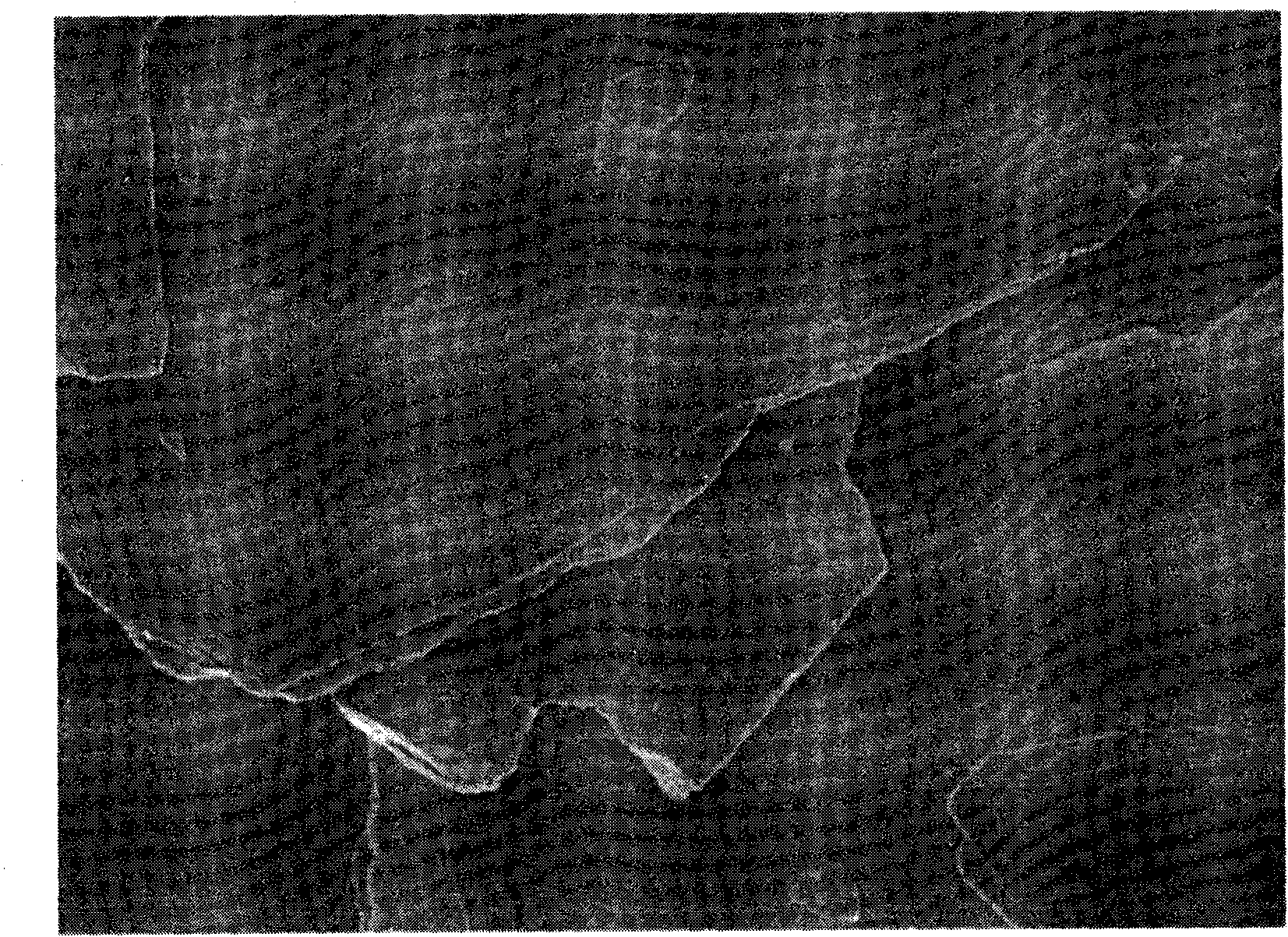

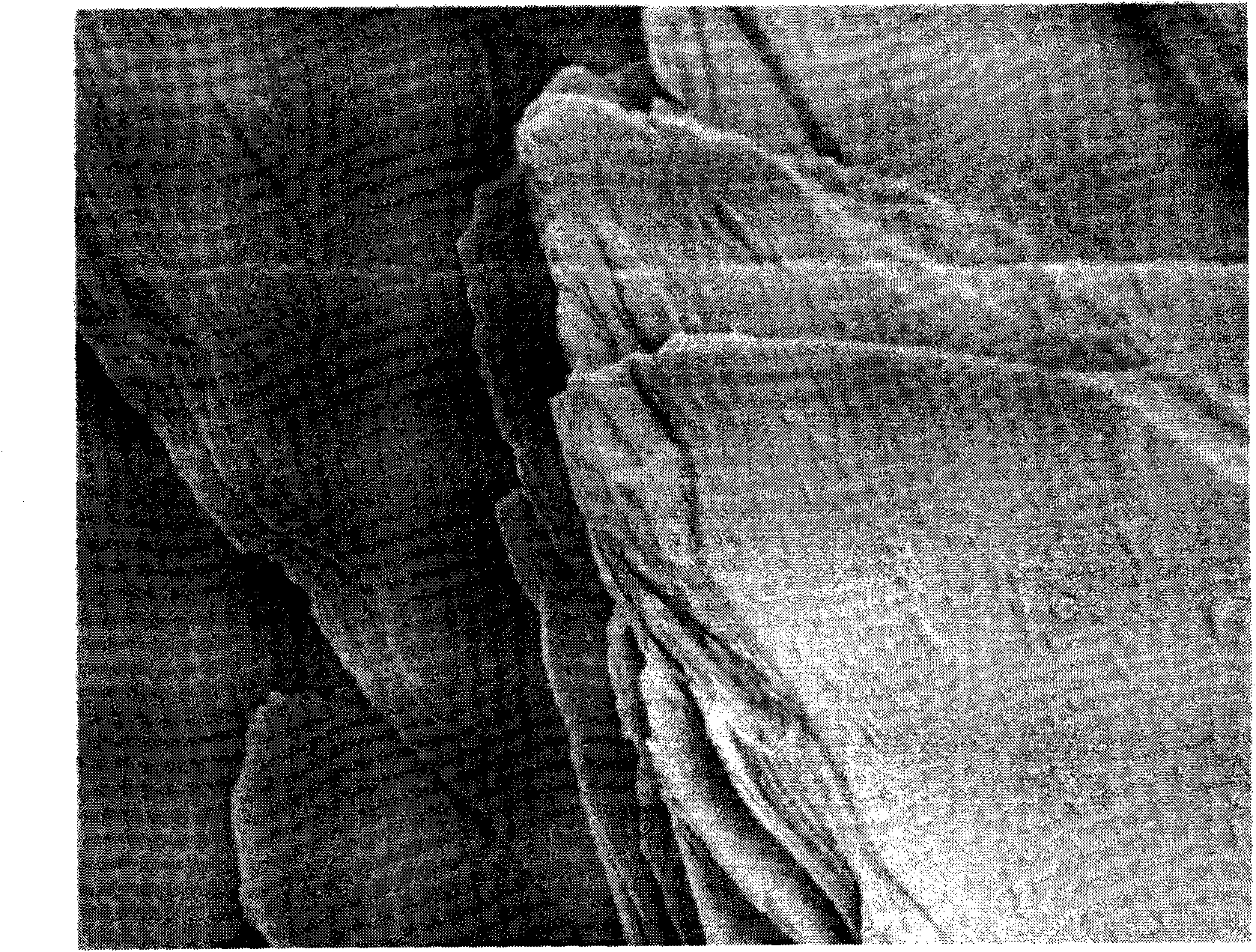

A technology of fluorophlogopite powder and synthetic mica, which is applied in the field of artificial synthetic mica products and processing, and achieves the effects of less impurities, smooth surface and thin cleavage layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

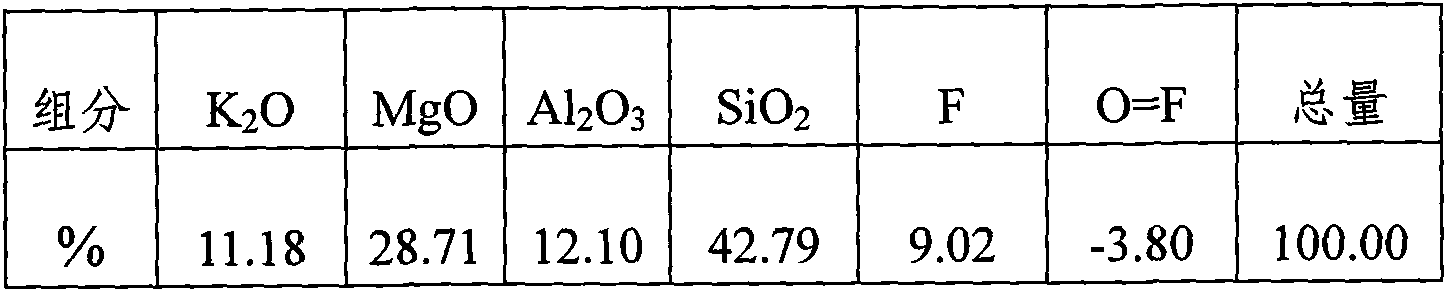

[0049] A synthetic mica prepared by using high-purity calcined talc instead of fused magnesia. The synthetic mica is produced by melting calcined talc, heavy magnesium oxide, potassium fluorosilicate, aluminum oxide and potassium carbonate.

Embodiment 2

[0051] On the basis of Example 1, a preferred embodiment of the present invention is that among the five raw materials, the weight percentages of each raw material are respectively configured as follows: the content of calcined talc is 55%, and the content of heavy magnesium oxide is 9%, the content of potassium fluorosilicate is 20%, the content of aluminum oxide is 12%, and the content of potassium carbonate is 4%. When the purity of raw materials changes, the proportioning ratio should be adjusted.

Embodiment 3

[0053] On the basis of Example 2, a preferred embodiment of the present invention also includes that the five kinds of raw materials are selected from raw materials with a purity greater than 98.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com