Low-temperature concrete early strength agent

A technology of concrete and early-strength agent, applied in the field of low-temperature concrete early-strength agent, achieves the effects of small water loss, good anti-corrosion effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

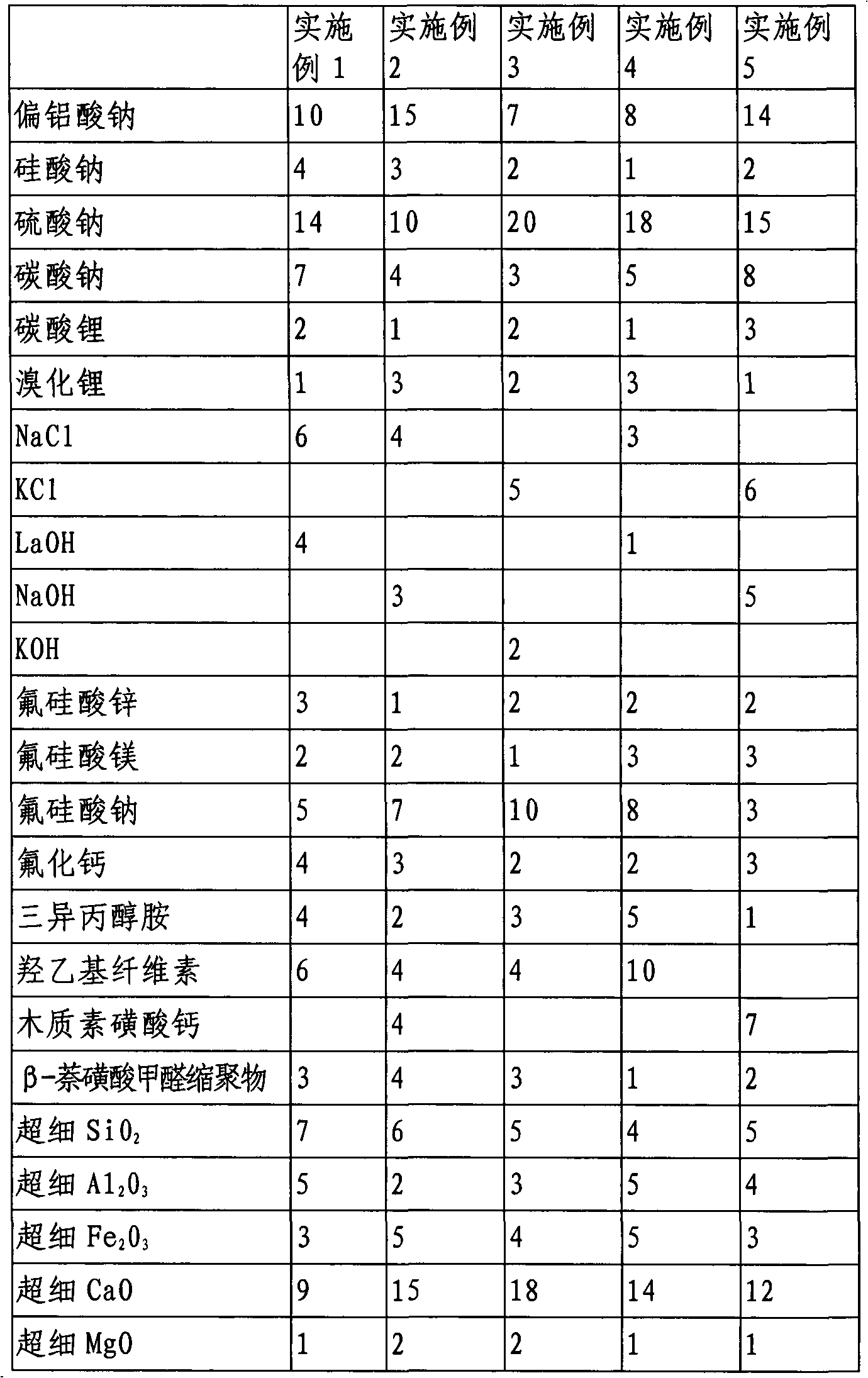

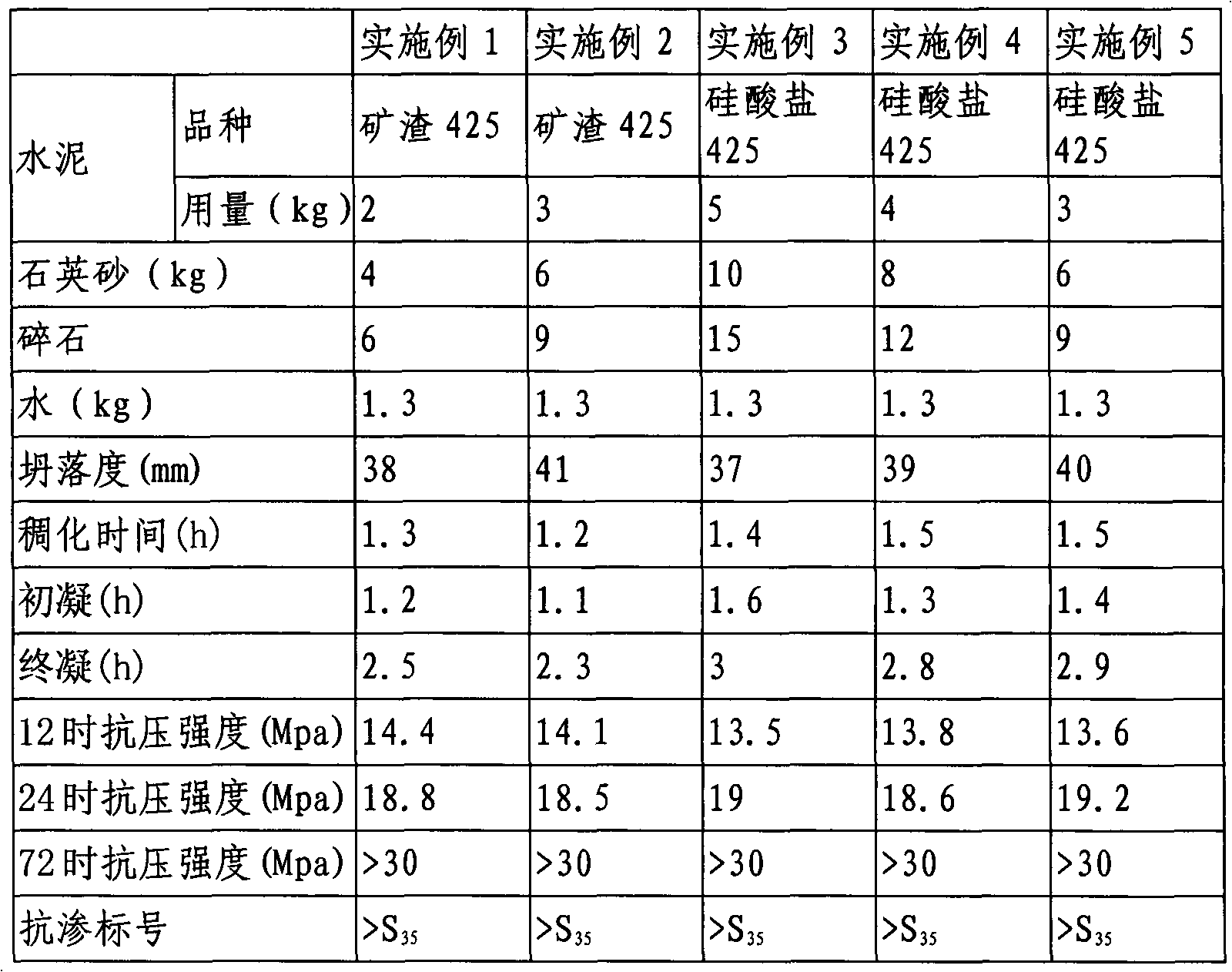

[0022] In the embodiment of the present invention, following table 1 is embodiment, and table 2 is implementation effect.

[0023] Unless otherwise specified, the weight of the average weight ratio is g.

[0024] Table 1

[0025]

[0026] Table 2

[0027]

[0028] The test conditions are a temperature of 4°C and a pressure of 30Mpa.

[0029] It can be seen from the above two tables that the present invention can shorten the thickening time of cement slurry and improve the early compressive strength of cement stone under low temperature conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com