USY molecular sieve modification method

A molecular sieve and modification technology, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of large crystallinity drop and achieve high crystallinity and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

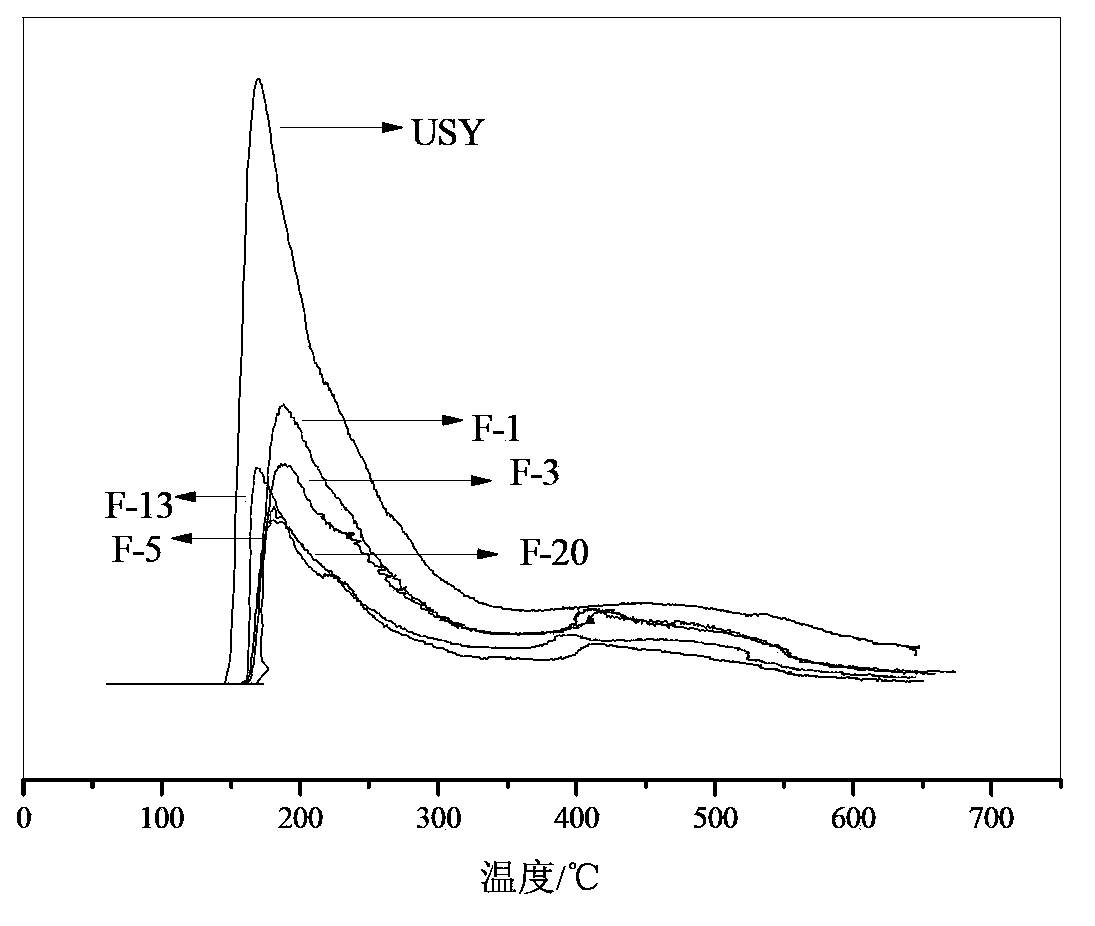

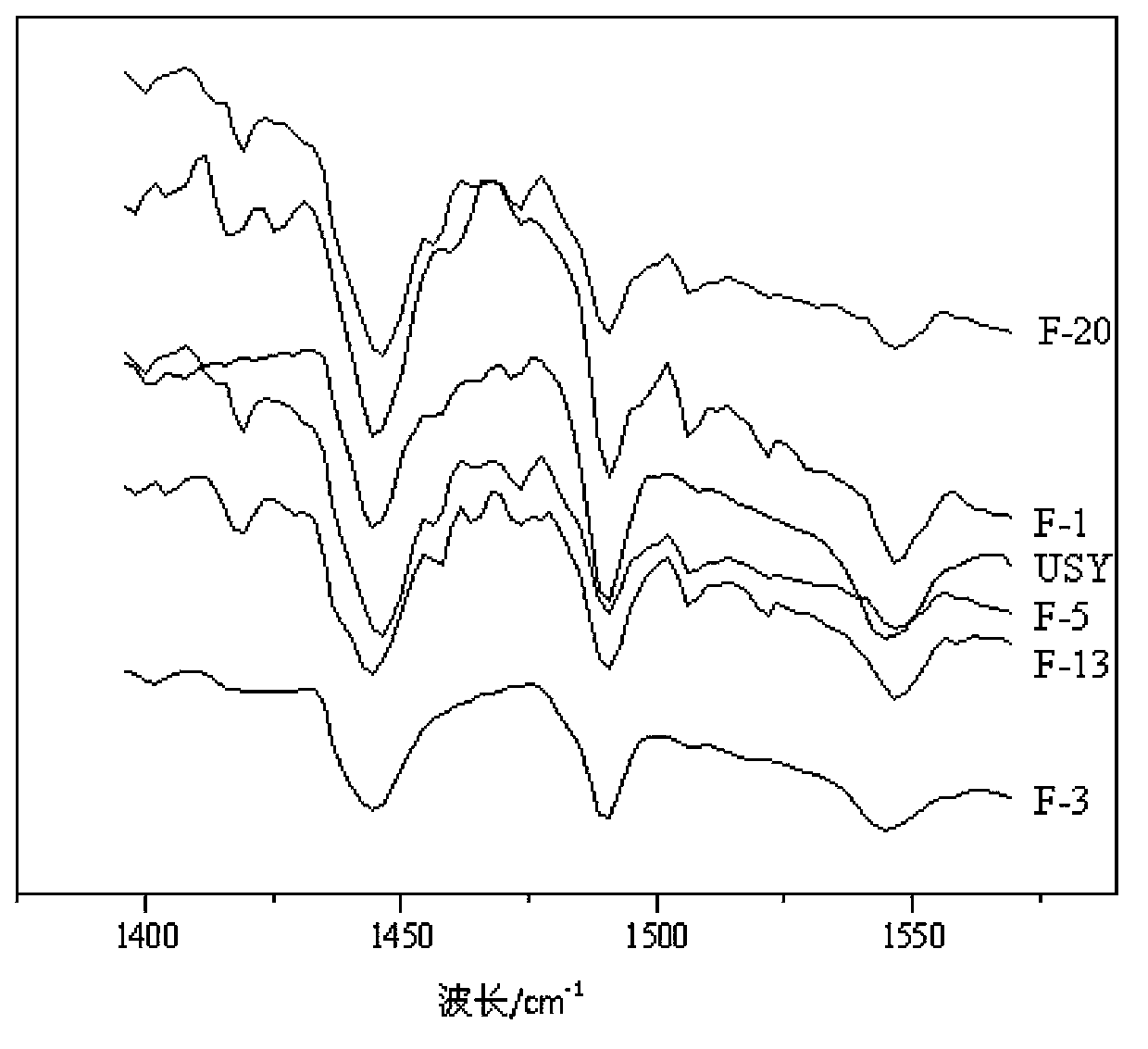

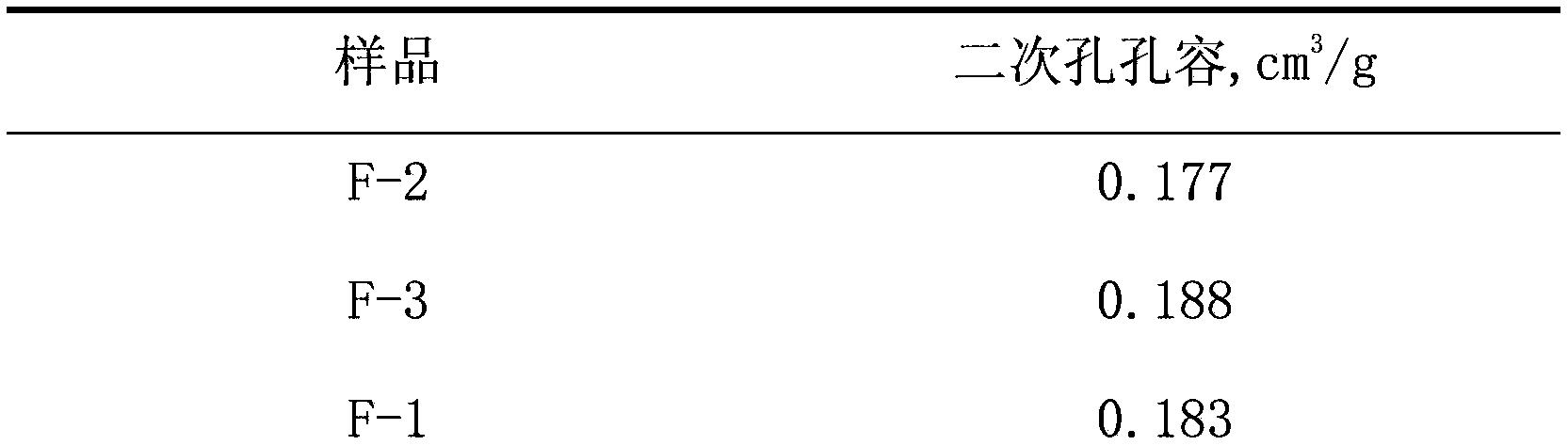

[0022] This example investigates the influence of citric acid concentration on the effect of industrial USY modification.

[0023] (1) Prepare citric acid solutions with different concentrations (0.10mol / L, 0.15mol / L, 0.20mol / L and 0.25mol / L);

[0024] (2) Weigh 4 parts of industrial USY, 12g each, and put them into 250ml three-necked flasks respectively;

[0025] (3) Add 60ml of citric acid solution with different concentrations in turn, stir, and heat up to 70°C;

[0026] (4) When the temperature rises to 70°C, continuously add 60ml of 0.10mol / L ammonium fluorosilicate solution at a rate of 1ml / min;

[0027] (5) After the feeding is completed, continue to react for 3 hours;

[0028] (6) The obtained product was washed with deionized water until neutral, and dried at a constant temperature of 110°C for 16 hours to obtain modified samples, which were labeled as F-2, F-3, F-1, and F-4.

Embodiment 2

[0030] This example investigates the effect of ammonium fluorosilicate feeding rate on the modification of industrial USY molecular sieves. The modification method is the same as in Example 1, except that the fixed citric acid concentration is 0.15mol / L, and the feed rate of ammonium fluorosilicate is changed to 0.75ml / min, 1ml / min, 1.25ml / min and 1.5ml / min respectively, The obtained modified samples are marked as F-8, F-3, F-9, and F-10.

Embodiment 3

[0032] This example investigates the effect of reaction time on the modification effect of industrial USY molecular sieves. The modification method is the same as in Example 2, except that the feeding rate of ammonium fluorosilicate is fixed at 1ml / min, and the reaction time is changed to 2h, 3h, 4h and 5h respectively, and the modified samples obtained are marked as F-11, F- 3, F-12 and F-13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com