Process for decomposing potassium feldspar by adopting low-temperature semidry method for comprehensive utilization

A process method, the technology of potassium feldspar, which is applied in the field of comprehensive utilization of potassium feldspar, can solve the problems of high energy consumption, pollution, and high requirements on equipment materials, and achieve the effect of mild reaction conditions and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The process method of the present invention is described in conjunction with the given examples, but does not constitute any limitation to the present invention.

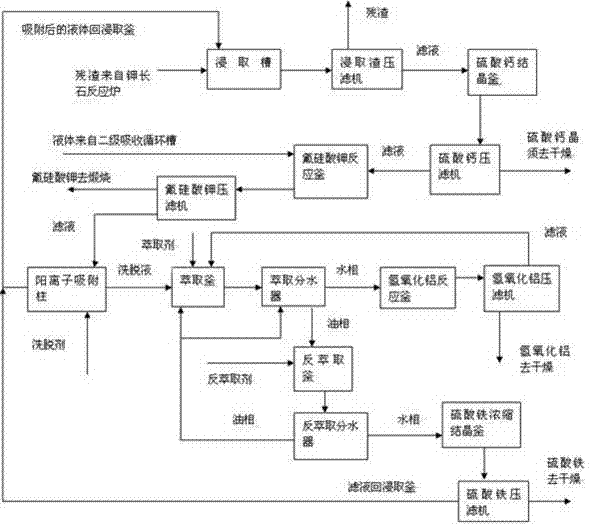

[0024] A kind of processing method that adopts low-temperature semi-dry method to decompose potassium feldspar, the processing steps of described processing method are:

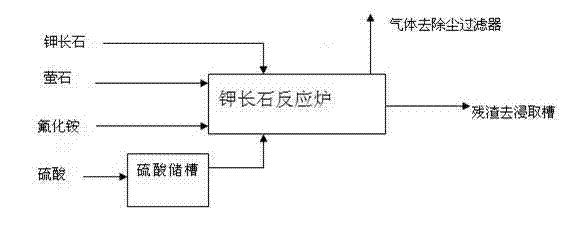

[0025] (1) Reaction: Potassium feldspar (SiO 2 content 62.86%), fluorspar (CaF 2 content 97%), ammonium fluoride, and 98% sulfuric acid in a mass ratio of 1:0.3:1.5:1.6. After being fully mixed through the feeding screw, they are added to the converter reactor and reacted at 180-250°C and autogenous pressure for 2.0 ~4.5 hours; the reaction principle is:

[0026] CaF 2 + H 2 SO 4 = 2HF + CaSO 4

[0027] 2K[AlSi 3 o 8 ] + 24HF + 4H 2 SO 4 =K 2 SO 4 +Al 2 (SO 4 ) 3 + 6SiF 4 ↑+16H 2 o

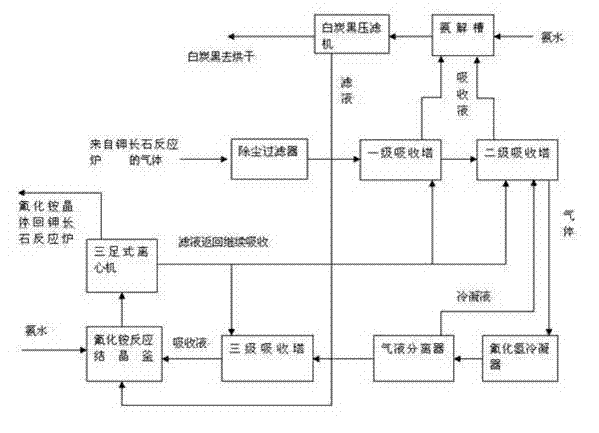

[0028] (2) Gas absorption: introduce the gas generated by the reaction into the dust removal filter to remove dust; the gas after dust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com