Nano-suspension concrete early strength accelerator and preparation method thereof

A nano-suspension and concrete technology, applied in early-strength concrete admixtures, concrete early-strength admixtures based on nanotechnology and their preparation fields, can solve the problems of increasing cracking risk, increasing the dosage of admixtures, deteriorating the workability of concrete, etc. , to achieve the effect of being conducive to active activation, accelerated early hydration, and excellent early strength performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation of embodiment 1 thixotropic solution

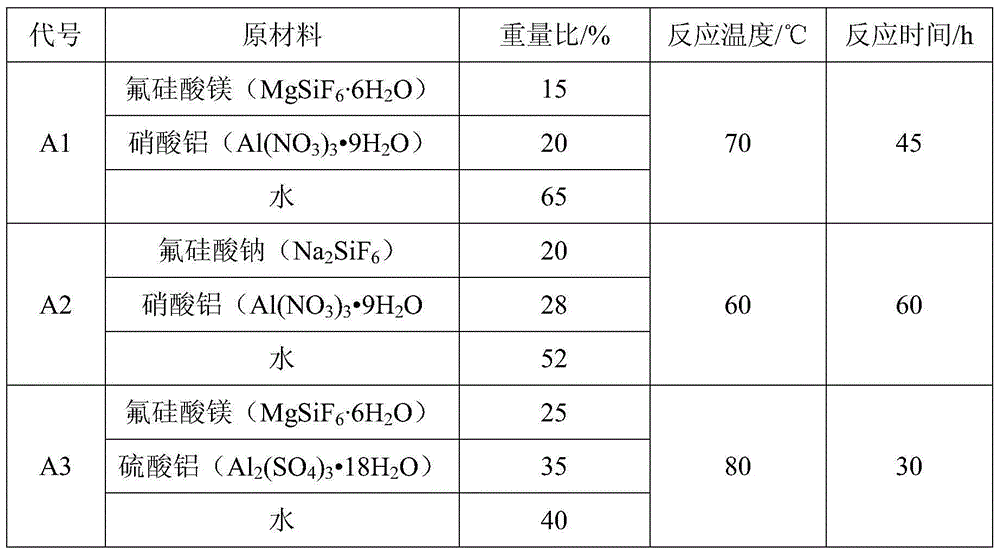

[0029] The preparation of the thixotropic solution is prepared according to the formula shown in Table 1. The preparation method is as follows: first dissolve the soluble fluorosilicate and the soluble aluminum salt in water respectively, mix and stir the reaction, and then cool to room temperature for storage; the selected raw materials All are commercially available raw materials for industrial products.

[0030] Table 1 Preparation of thixotropic solution

[0031]

Embodiment 2

[0032] The preparation of embodiment 2 nano calcium silicate suspension

[0033] Prepare a mixed aqueous solution with a total dosage of 40-60% of high molecular polymer and soluble silicate, and then slowly add the soluble calcium salt solution and the remaining high molecular polymer aqueous solution to the In a mixed aqueous solution; or prepare a mixed aqueous solution with a total dosage of 40-60% of high molecular polymer and soluble calcium salt, and then put the aqueous solution of soluble silicate and the remaining high molecular polymer aqueous solution at 20-30°C were slowly added dropwise to the mixed aqueous solution.

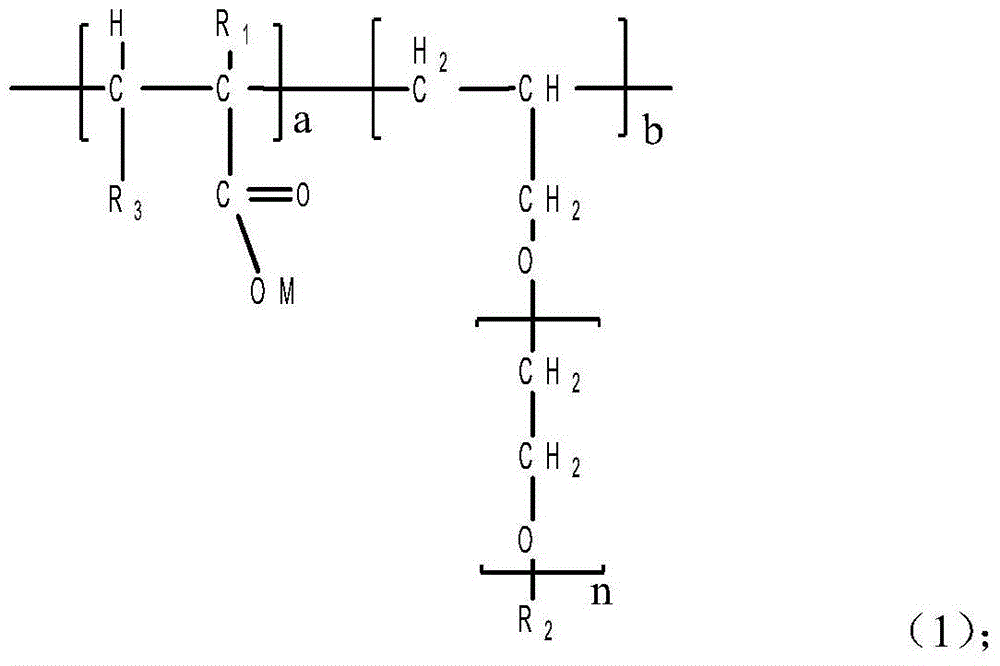

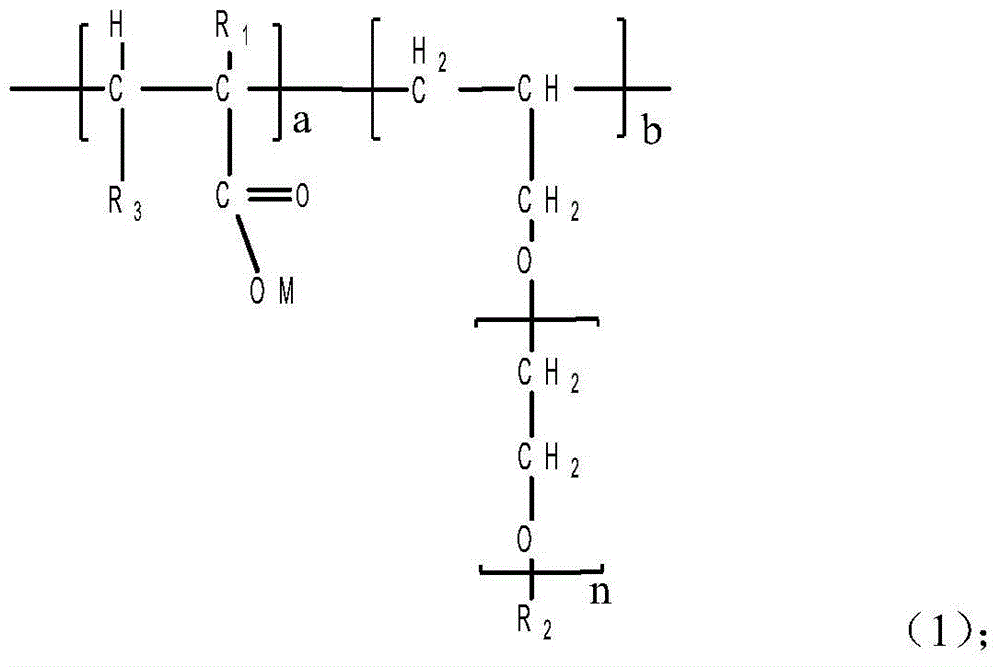

[0034] Wherein, the selected macromolecular polymer in the preparation process of nano-calcium silicate is an aqueous solution with a solid content of 40%, and its molecular formula is:

[0035]

[0036] The structural parameters and corresponding codes are shown in Table 2.

[0037] Table 2 Polymer parameters and codes

[0038]

[0039] T...

Embodiment 3

[0046] The preparation of embodiment 3 nano-suspension concrete early strength agent

[0047] Mix the thixotropic solution prepared in Example 1 with the nano-calcium silicate prepared in Example 2 and stir for 10-30 minutes to obtain the solution. The reaction conditions and product properties are shown in Table 5. At the same time, the stability of up to 60 days was compared with the suspension of nano-calcium silicate without adding thixotropic components.

[0048] Table 5 Reaction conditions and product properties of nano-suspension concrete early strength agent

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com