A method for setting the shape of nylon fishing net

A technology for fishing nets and meshes, applied in fiber types, elongation of fabrics, processing of textile materials, etc., can solve problems such as non-continuous production, unreliable nodule setting, and unstable chemical structure of nylon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

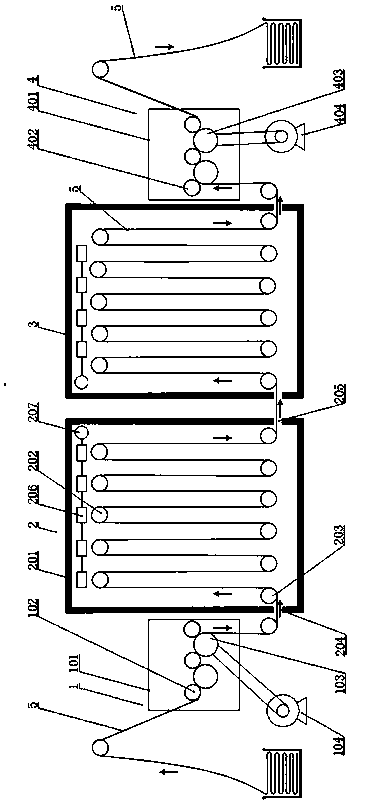

Image

Examples

Embodiment Construction

[0027] A method for setting the shape of a nylon fishing net sheet, which undergoes the following process steps:

[0028] a. Consolidation treatment

[0029] Inject the consolidation solution into the FRP immersion tank of length×width×depth=5.80m×0.25m×0.35m. The consolidation solution is a water-based acrylic resin solution with a concentration of 20% to 40%, and the liquid level is slightly higher than The stacking height of the mesh shall prevail; the FRP soaking tank is placed under the weaving machine, and the nylon fishing nets woven by the weaving machine are directly sent to the FRP soaking tank for stacking and soaking treatment for 5-10 minutes; After the sheet is processed, it can improve the anti-slip resistance of the mesh nodules, enhance the firmness of the nodules, reduce the internal stress at the bend of the mesh knot, and increase the tensile strength of the mesh. It should be pointed out that the soaking time of the mesh can be determined according to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com