Method for preparing nanoclay/styrene-butadiene rubber powder modified asphalt by adopting spray drying method

A spray-drying, styrene-butadiene rubber technology, applied in building components, building insulation materials, buildings, etc., can solve the problems of insignificant high-temperature stability of asphalt, reduced service performance of asphalt pavement, and impaired low-temperature performance of asphalt, etc. Excellent road performance, improved interaction, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

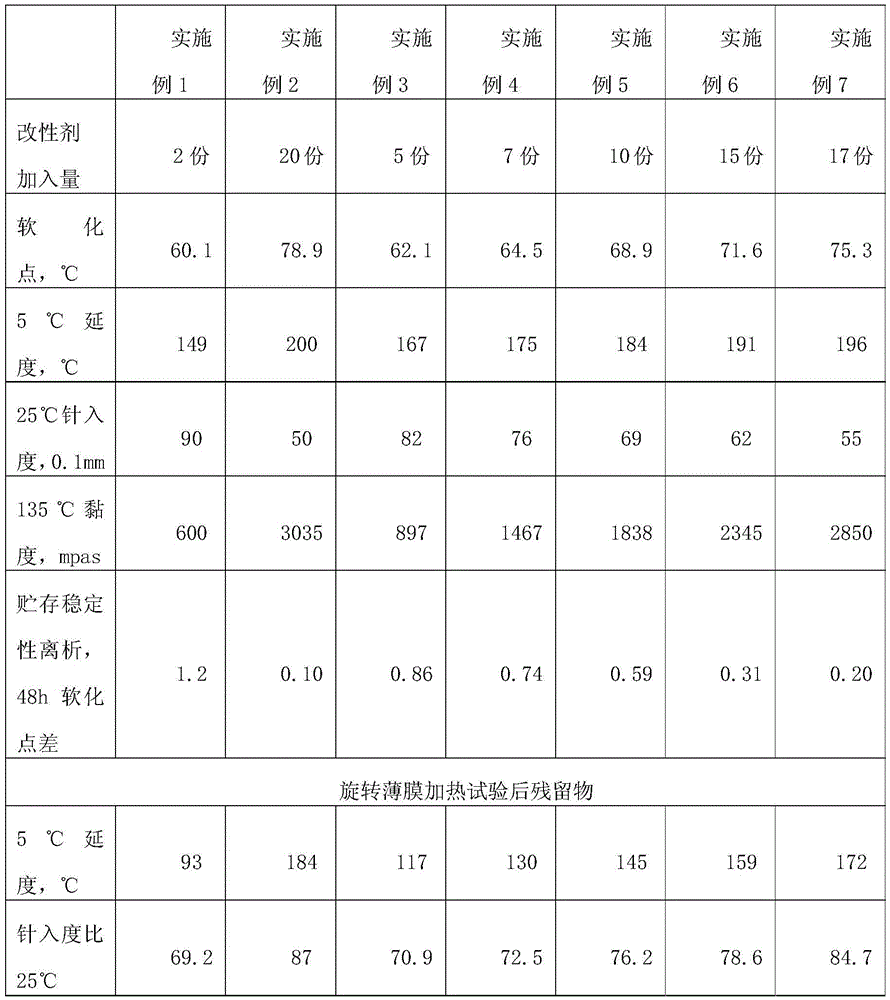

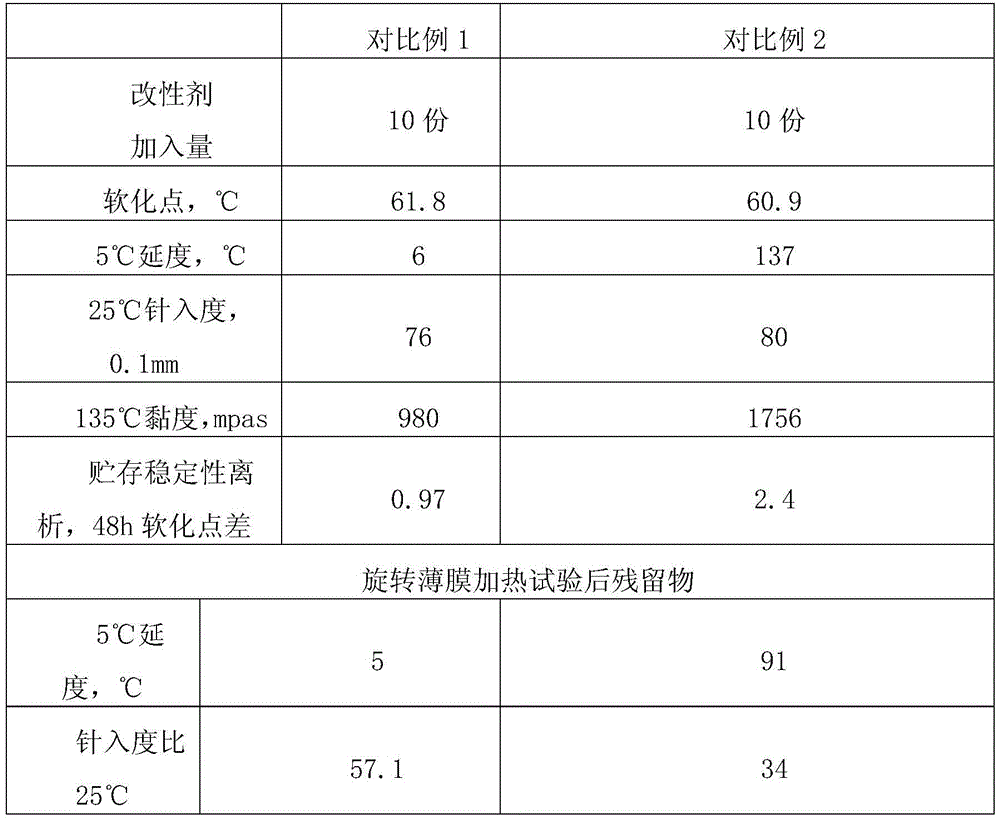

Examples

Embodiment 1

[0023] Get 60g montmorillonite, add 1140g water, stir 180min under the stirring speed of 300r / min and obtain the clay suspension that solid content is 5%, get 1200g solid content and be that 5% clay suspension joins 500g mass fraction and be 20% butane Mix evenly with benzene latex to obtain a mixed solution, and spray-dry to obtain 160g of clay / styrene-butadiene rubber powder with a particle size of 33μm. Take 160g of clay / styrene-butadiene rubber powder and 8000g of No. 70 petroleum asphalt at 160 ° C for 15 minutes, and then mix it at 2000rr / min shearing machine for 60min to obtain nano-clay / styrene-butadiene rubber modified asphalt.

Embodiment 2

[0025] Get 100g of kaolin, add 300g of water, stir at a stirring speed of 800r / min for 240min to obtain a clay suspension with a solid content of 25%, take 400g of a solid content of 25% clay suspension and join 250g of styrene-butadiene latex with a mass fraction of 40% Mix uniformly in the medium to obtain a mixed solution, and spray-dry to obtain 200g of clay / styrene-butadiene rubber powder with a particle size of 100μm. Take 200g of clay / styrene-butadiene rubber powder and 1000g of No. 100 petroleum asphalt at 200°C for 30min, and then mix it at 6000r / min shear 120min in a special shearing machine to obtain nanoclay / styrene-butadiene rubber modified asphalt.

Embodiment 3

[0027] Get 70g of silica, add 630g of water, stir at a stirring speed of 300r / min for 100min to obtain a clay suspension with a solid content of 10%, take 700g of a solid content of 10% clay suspension and join 500g of styrene-butadiene latex with a mass fraction of 20% Mix uniformly in the medium to obtain a mixed solution, and spray-dry to obtain 170g of clay / styrene-butadiene rubber powder with a particle size of 39μm. Take 170g of clay / styrene-butadiene rubber powder and 3400g of No. 90 petroleum asphalt at 165°C for 15min, and then mix it at 3000r / min Shearing for 60 minutes in a special shearing machine to obtain nanoclay / styrene-butadiene rubber modified asphalt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com