Separation method of nickel in sulfate solution

A separation method, sulfate technology, applied in the direction of improving process efficiency, etc., can solve the problems of difficult to achieve continuous operation, cumbersome operation process, etc., and achieve the effect of low equipment requirements, low reagent consumption, and short operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

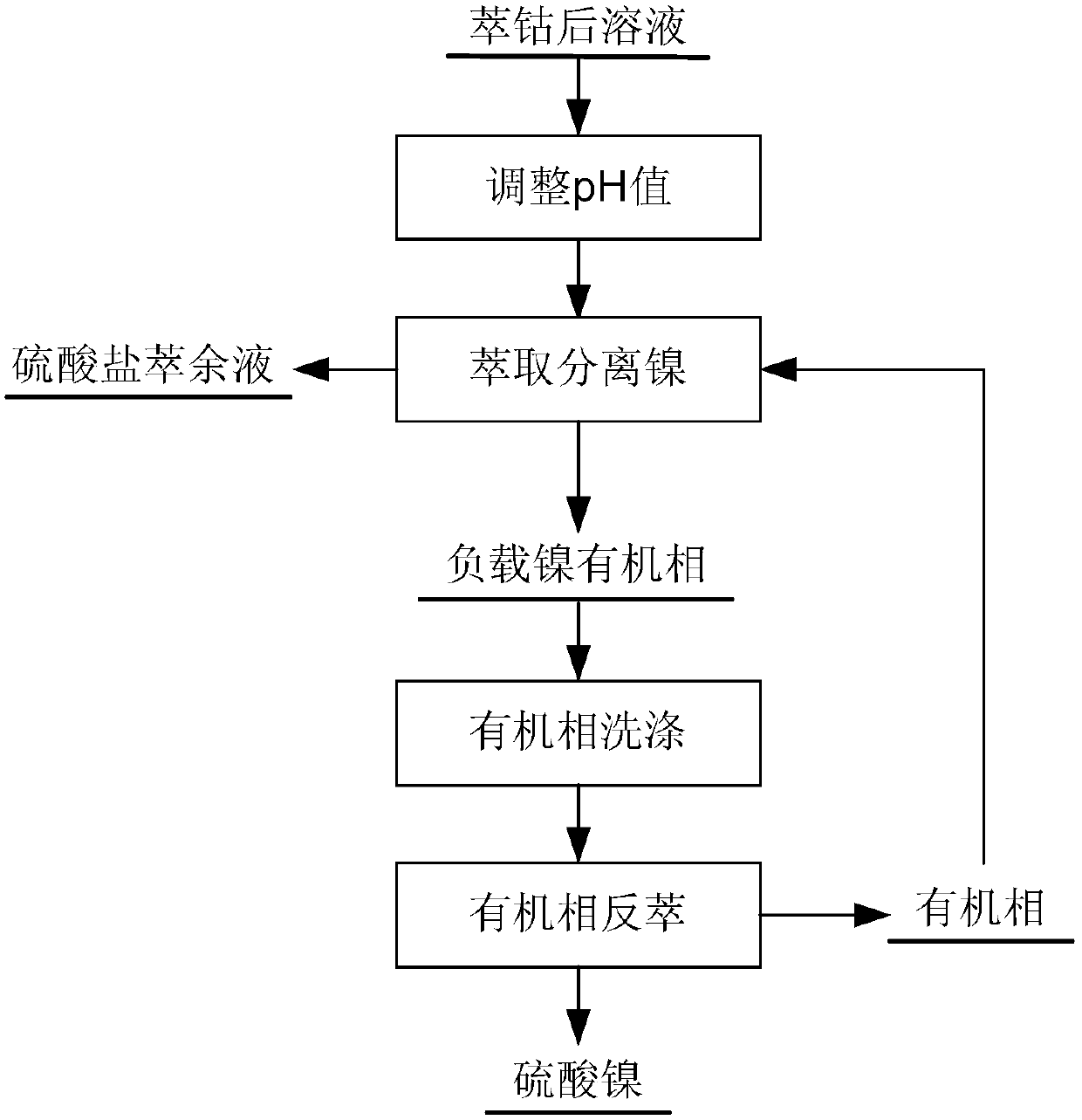

[0036] Such as figure 1 Shown, a kind of separation method of nickel in sulfate solution is used for processing the solution after cobalt extraction, and the concentration of ammonium sulfate in the solution after cobalt extraction is 200g / L, and the concentration of nickel ions is 2.5g / L. The method may include the steps of:

[0037]Step a1, using ammonia water to adjust the pH value of the cobalt-extracted solution to 9-10, then using No. 260 solvent oil as a diluent, and using nickel extractant LIX984 as an organic phase to extract and separate nickel. The volume concentration of nickel extractant LIX984 is 10 %, the extraction ratio O / A=1:1, the number of extraction stages is 3, and the mixing time is 3min, thereby obtaining a nickel-loaded organic phase and an ammonium sulfate raffinate containing 0.9mg / L of nickel.

[0038] Step b1, washing and back-extracting the nickel-loaded organic phase, the washing ratio O / A=15:1, the number of washing stages is 2, the back-extrac...

Embodiment 2

[0040] Such as figure 1 Shown, the separation method of nickel in a kind of vitriol salt solution is used for processing the solution after a certain cobalt extraction, and the concentration of ammonium sulfate in the solution after the extraction of cobalt is 20g / L, sodium sulfate concentration 150g / L, nickel ion concentration is 1.5g / L, the separation method may comprise the following steps:

[0041] Step a2, using ammonia water to adjust the pH value of the cobalt-extracted solution to 9-10, then using No. 260 solvent oil as the diluent, and using nickel extractant LIX984 as the organic phase to extract and separate nickel, the volume concentration of the nickel extractant LIX984 is 10 %, the extraction ratio O / A=2:1, the number of extraction stages is 3, and the mixing time is 3min, thereby obtaining a nickel-loaded organic phase and an ammonium sulfate raffinate containing 0.7mg / L of nickel.

[0042] Step b2, washing and back-extracting the nickel-loaded organic phase, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com