Method for directly preparing aluminum foil through low temperature electrolysis

An aluminum foil, direct technology, applied in the field of electrolysis, which can solve problems such as difficult electrolysis or refining process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

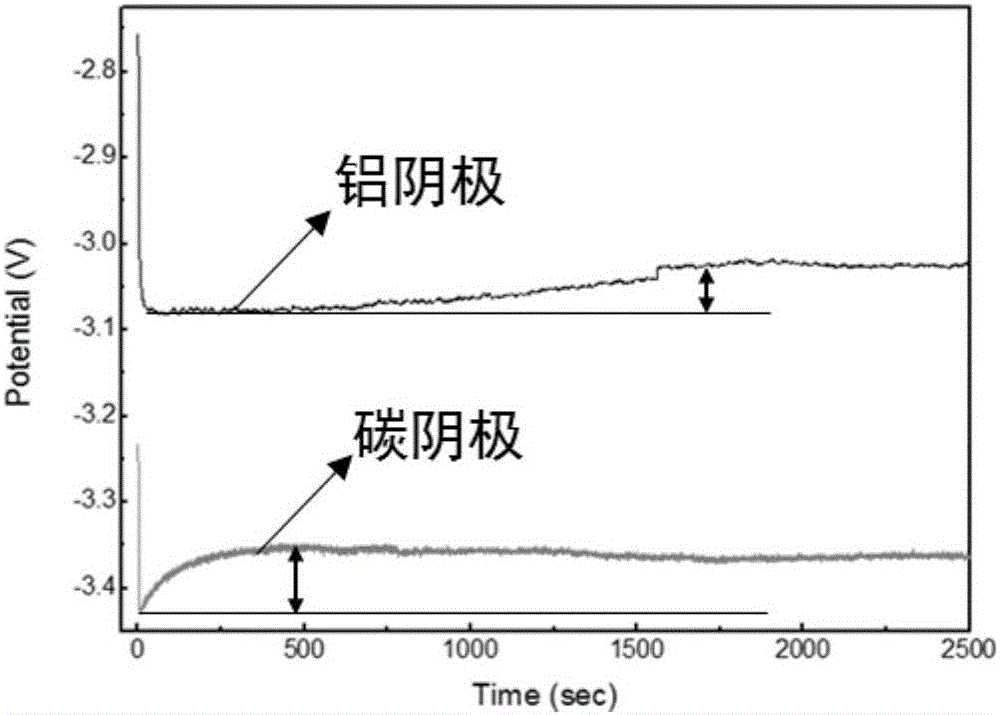

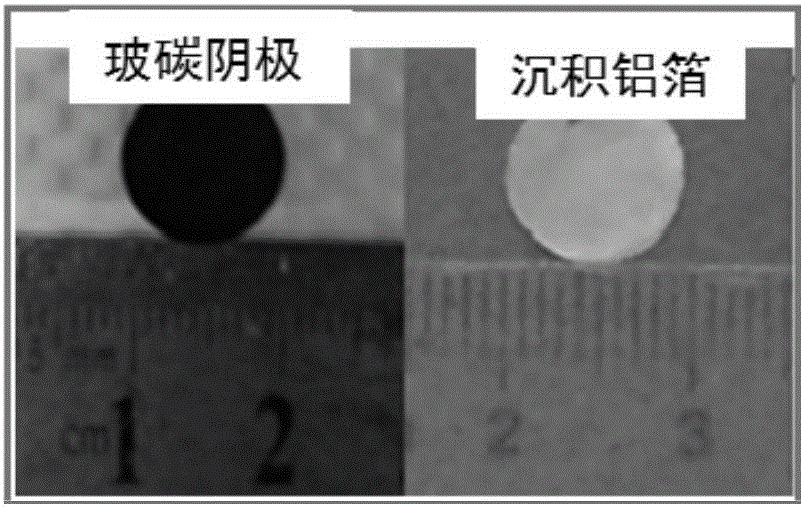

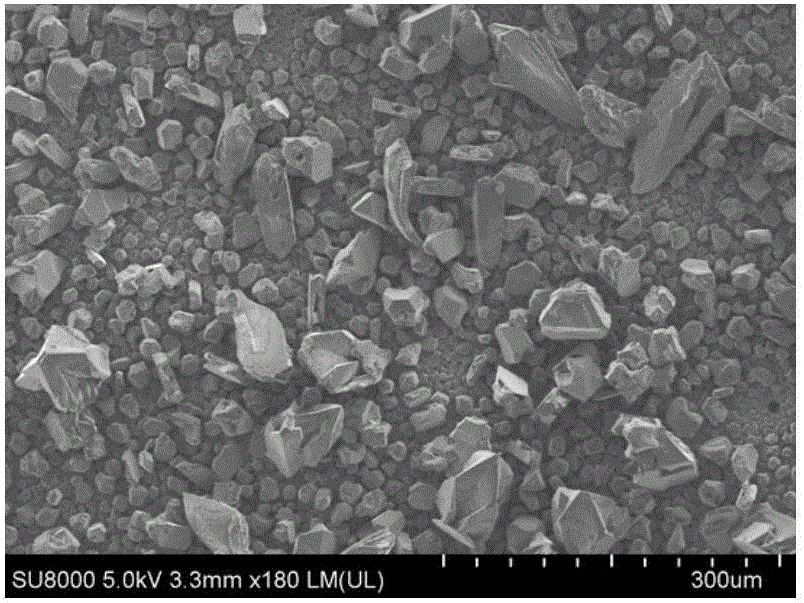

[0020] AlCl 3 Dissolved in [BMIMCl] ionic liquid, the active material concentration is 0.9M, the cathode is a glassy carbon disc electrode with a diameter of 3mm, the anode is an inert glassy carbon electrode, and the reference electrode is an aluminum wire. Constant voltage electrodeposition, the working voltage is -1.5V, the temperature is 25°C, after 3 hours of electrodeposition on the surface of the cathode to obtain dense aluminum foil, after the electrodeposited aluminum foil is peeled off from the surface of the cathode, it is washed with dichloromethane for many times to ensure the cleaning of the ionic liquid Clean, then dry the product with cold nitrogen.

Embodiment 2

[0022] AlCl 3 dissolved in [PP 14 Cl] in the ionic liquid, the active substance concentration is 1.3M, the cathode is a glassy carbon disc electrode with a diameter of 3mm, the anode is an inert glassy carbon electrode, and the reference electrode is an aluminum wire. Constant voltage electrodeposition, the working voltage is -1.8V, the temperature is 50°C, after 3 hours of electrodeposition on the surface of the cathode to obtain dense aluminum foil, after the electrodeposited aluminum foil is peeled off from the surface of the cathode, it is washed with dichloromethane for many times to ensure the cleaning of the ionic liquid Clean, then dry the product with cold nitrogen.

Embodiment 3

[0024] AlCl 3 dissolved in [N 2222 Cl] in the ionic liquid, the active substance concentration is 1.5M, the cathode is a glassy carbon disc electrode with a diameter of 3mm, the anode is an inert glassy carbon electrode, and the reference electrode is an aluminum wire. Constant voltage electrodeposition, the working voltage is -2.3V, the temperature is 25°C, after 2 hours of electrodeposition on the surface of the cathode to obtain dense aluminum foil, after the electrodeposited aluminum foil is peeled off from the surface of the cathode, it is washed with dichloromethane for many times to ensure the cleaning of the ionic liquid Clean, then dry the product with cold nitrogen.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com