Patents

Literature

74results about How to "Lower the electrolysis temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

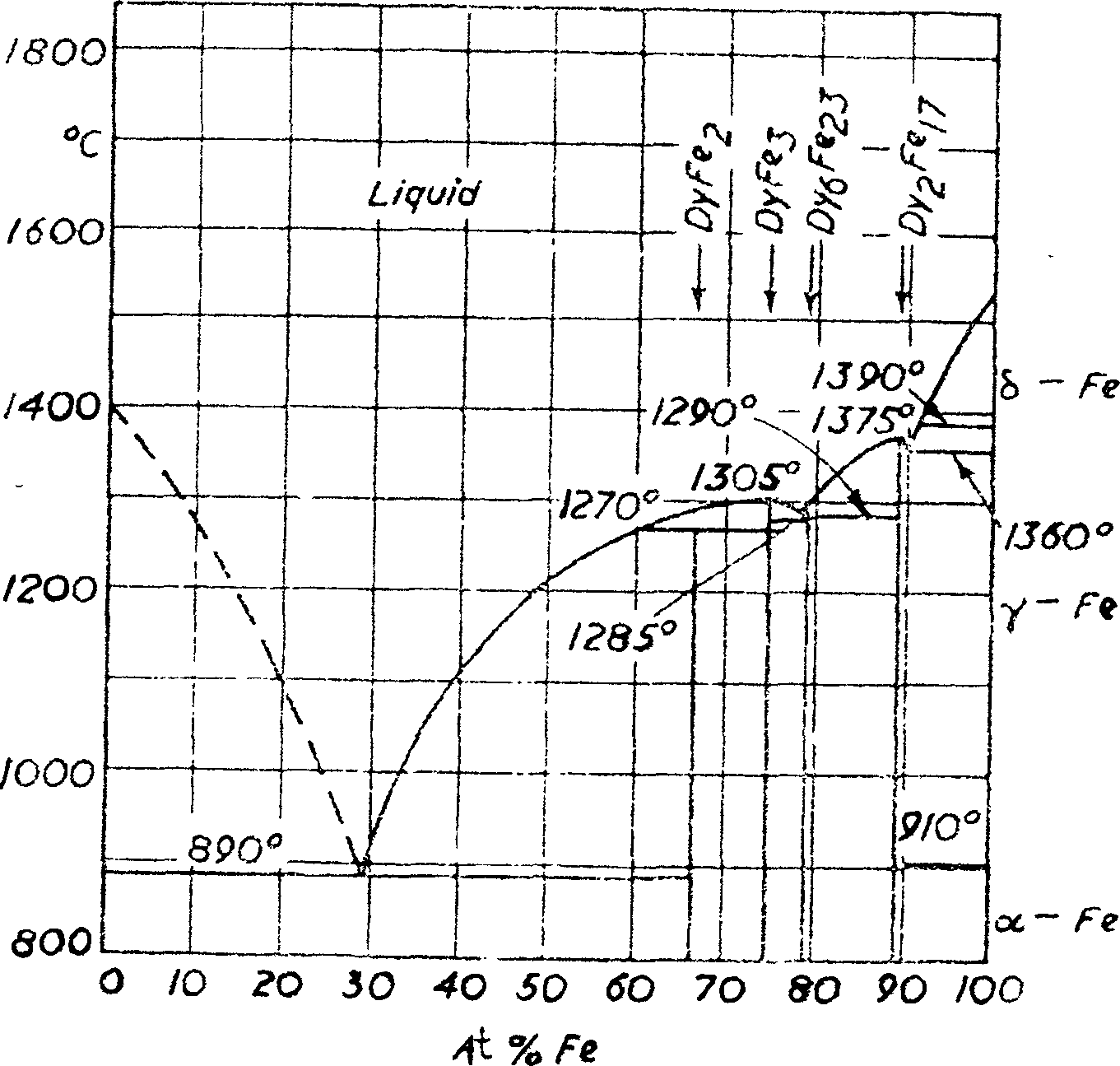

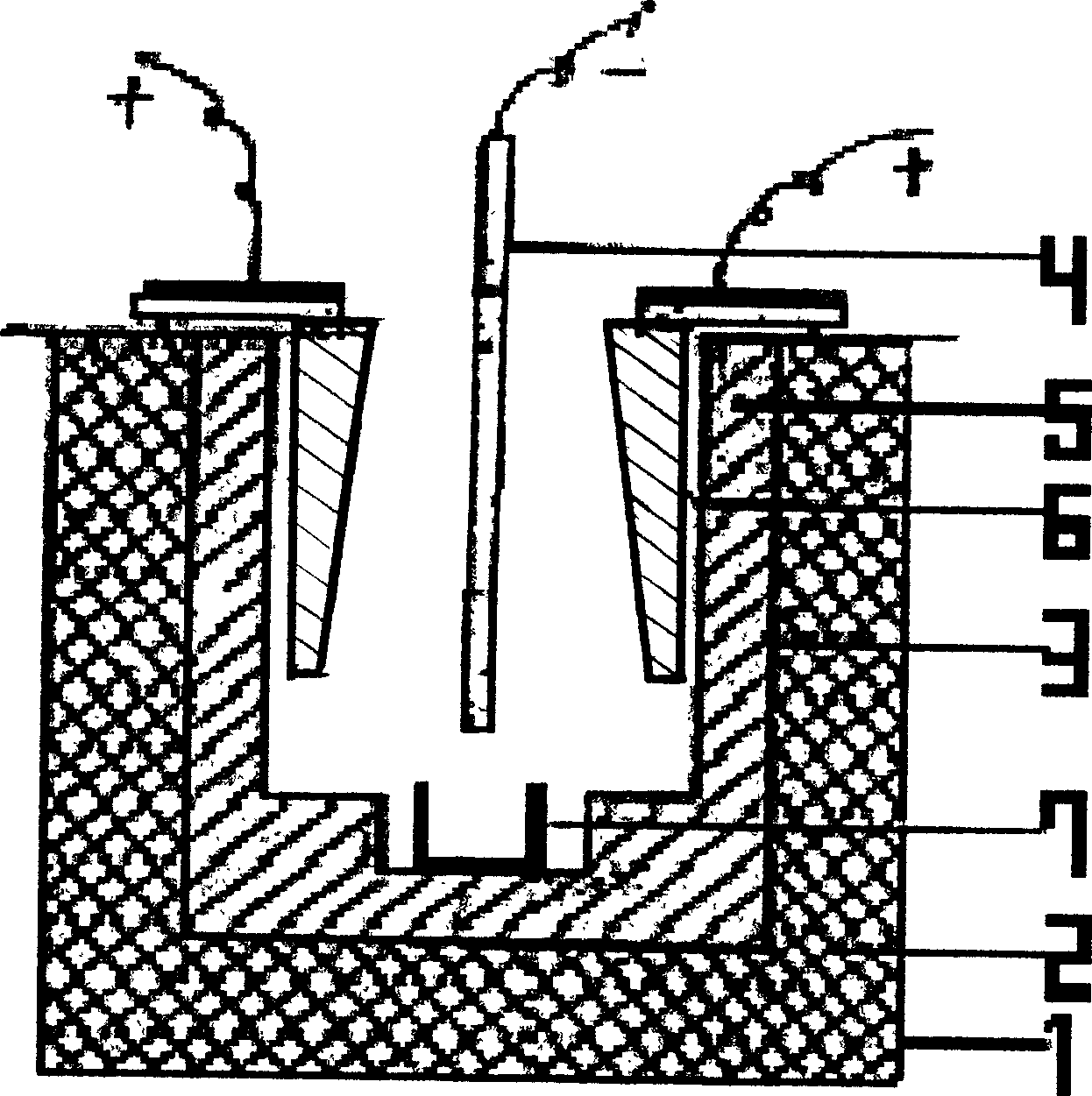

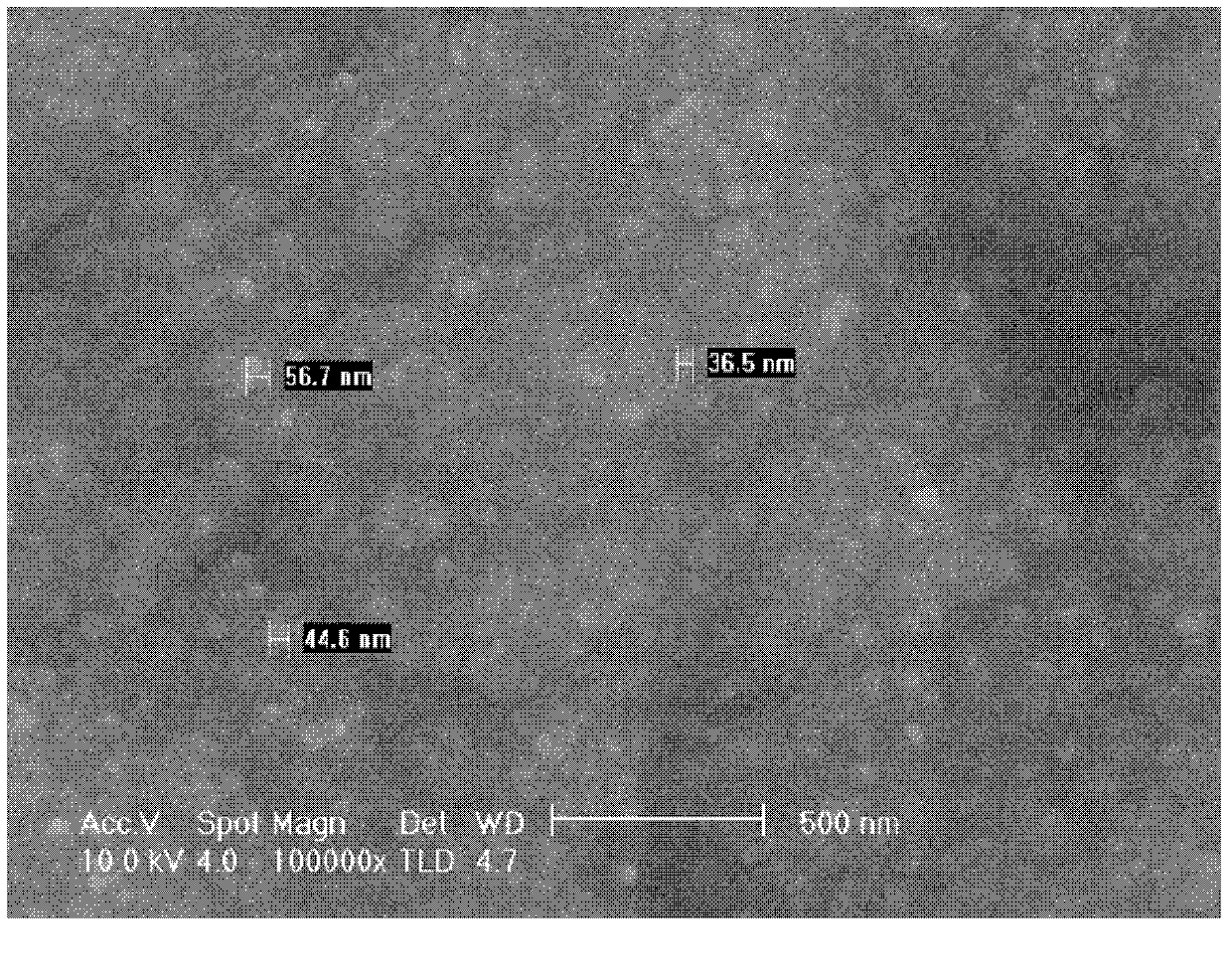

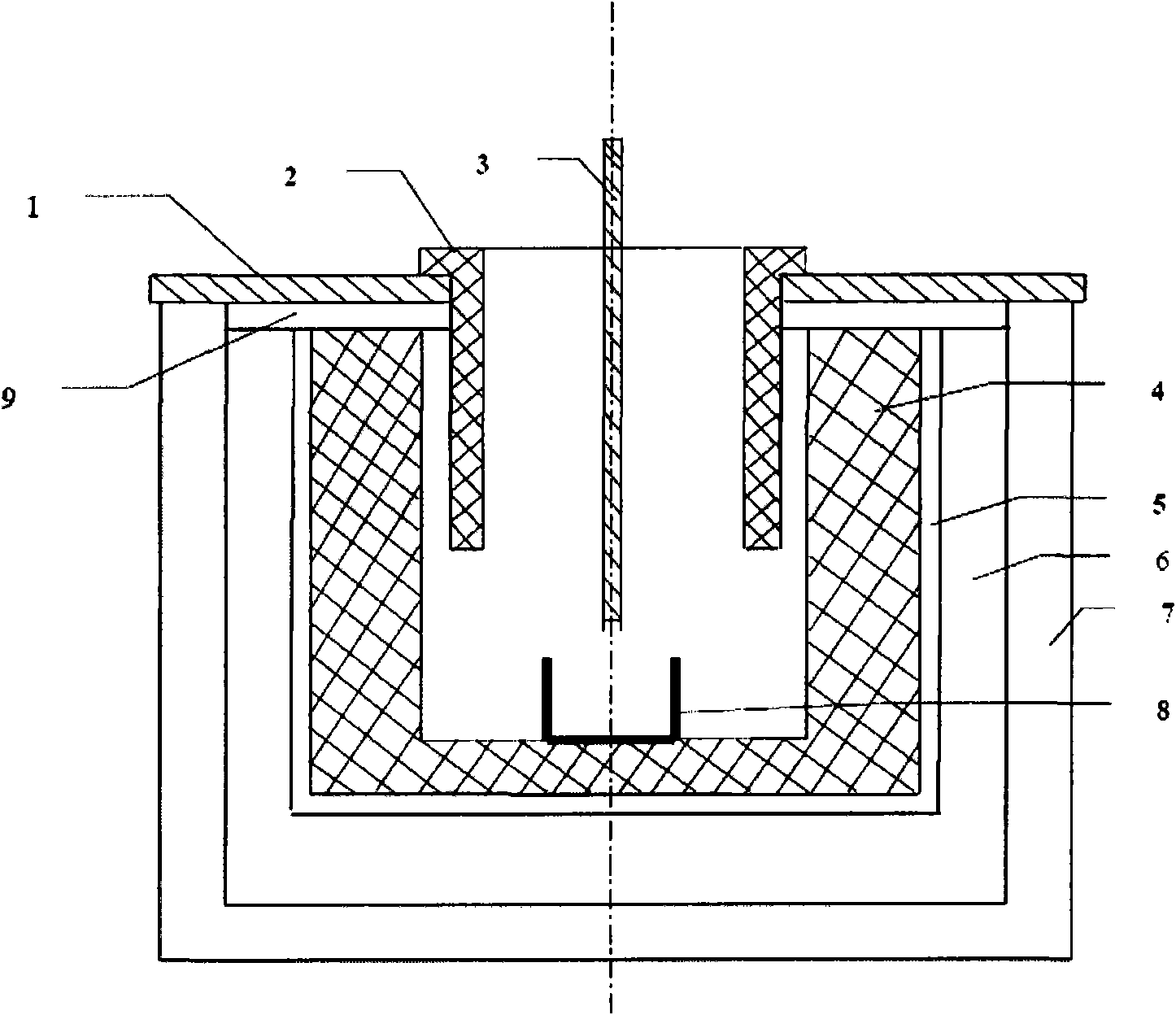

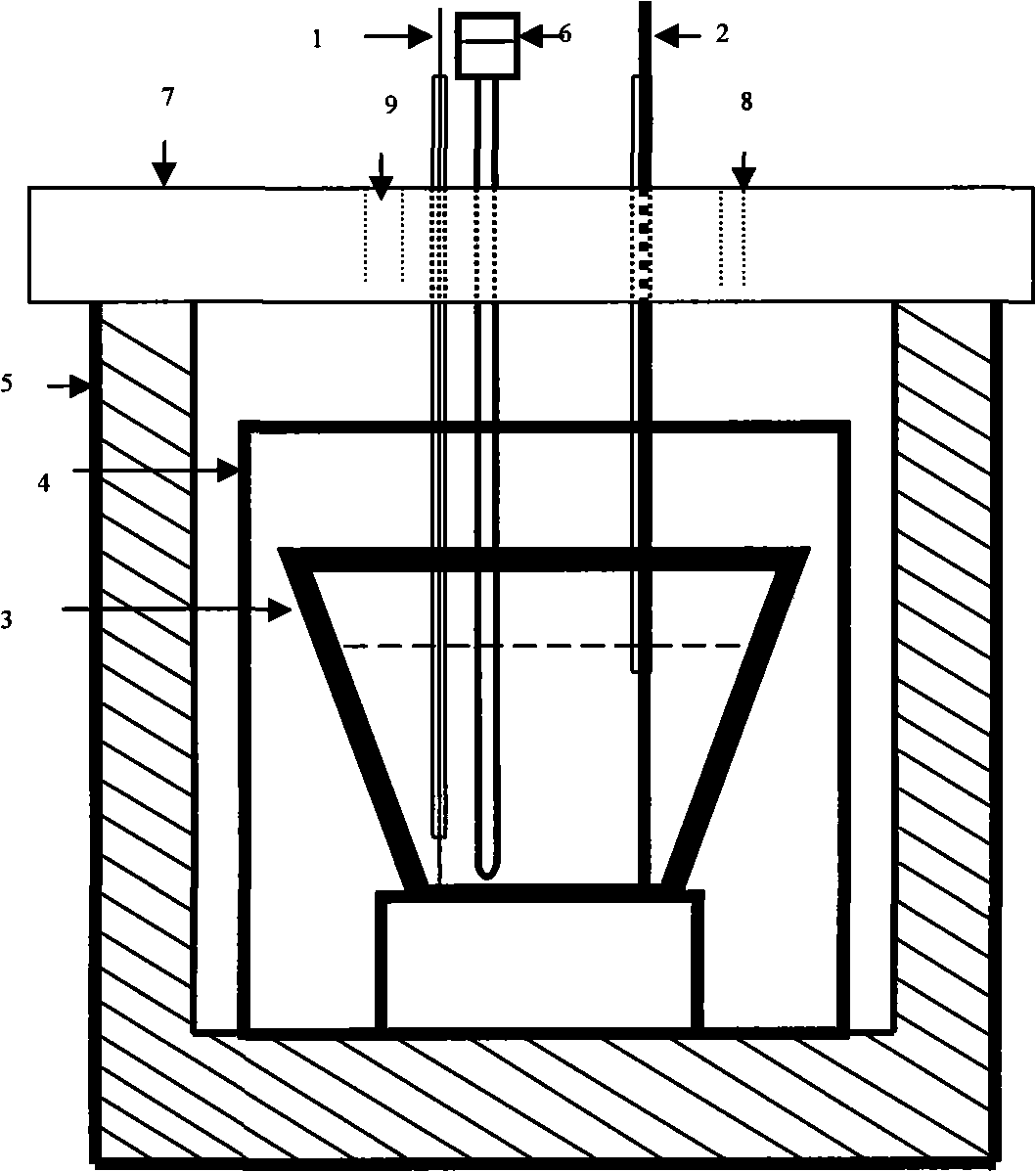

Process and apparatus for producing Dy-Fe alloy by molten salt electrolysis method

The invention relates the dysprosium-iron alloy technology with fused salt electrolysis process and device, belonging to rare-earth products preparing field. The method comprises the following steps: at high temperature, dysprosium oxide melting at fluoride, dysprosium oxide beginning ionizing; at the condition of 95V / M direct current field, separating out Dy3+ on the surface of iron cathode, deacidizing Dy3+ to Dy, and alloying Dy and Fe to form Dy-Fe. O2- is oxygenated to O2 on the surface of graphite cathode, and it reacts with carbite to form CO2. The melting point of dysprosium-iron (20úÑFe) is 1046Deg.C, and the melting point of Dy is 1407Deg.C, so the electrolyzation is carried out at 1050Deg.C. The invention has the advantages of low investment, low cost, simple technology, continuous production and low impurity content.

Owner:包头市稀土应用技术研究所

Method for preparing Al-Ti alloy or plated Al-Ti alloy by low-temperature electrolytic deposition of ionic liquid

InactiveCN101994128AReduce material requirementsLower the electrolysis temperatureElectrolysis componentsPhotography auxillary processesIonAluminium

The invention relates to a method for preparing Al-Ti alloy or plated Al-Ti alloy by low-temperature electrolytic deposition of ionic liquid, which is characterized by synthesizing an ionic liquid from an organic material and anhydrous aluminium trichloride, adding a right amount of titanium salt to prepare an ionic liquid electrolyte, taking a substrate which is pre-treated as a deposition cathode and preparing Al-Ti alloy or plated Al-Ti alloy by direct current electrolytic deposition, wherein the titanium content within the alloy can be as high as 30%. The method provided by the invention has the advantages that the ionic liquid used therein has wide resource, low price and wide electrochemical window, the electrical conductivity is high, the ionic liquid is friendly to environment and the titanium salt can be effectively dissolved, the temperature of electrolytic deposition and cell voltage can be effectively reduced by using low-temperature electrolytic deposition process of ionic liquid to prepare Al-Ti alloy and the plating thereof, the energy consumption is reduced, the corrosion of the device is greatly reduced, the properties of the deposition layer which is obtained thereby are high and the thickness of the deposition layer and the titanium content of the alloy are easy to be controlled.

Owner:KUNMING UNIV OF SCI & TECH

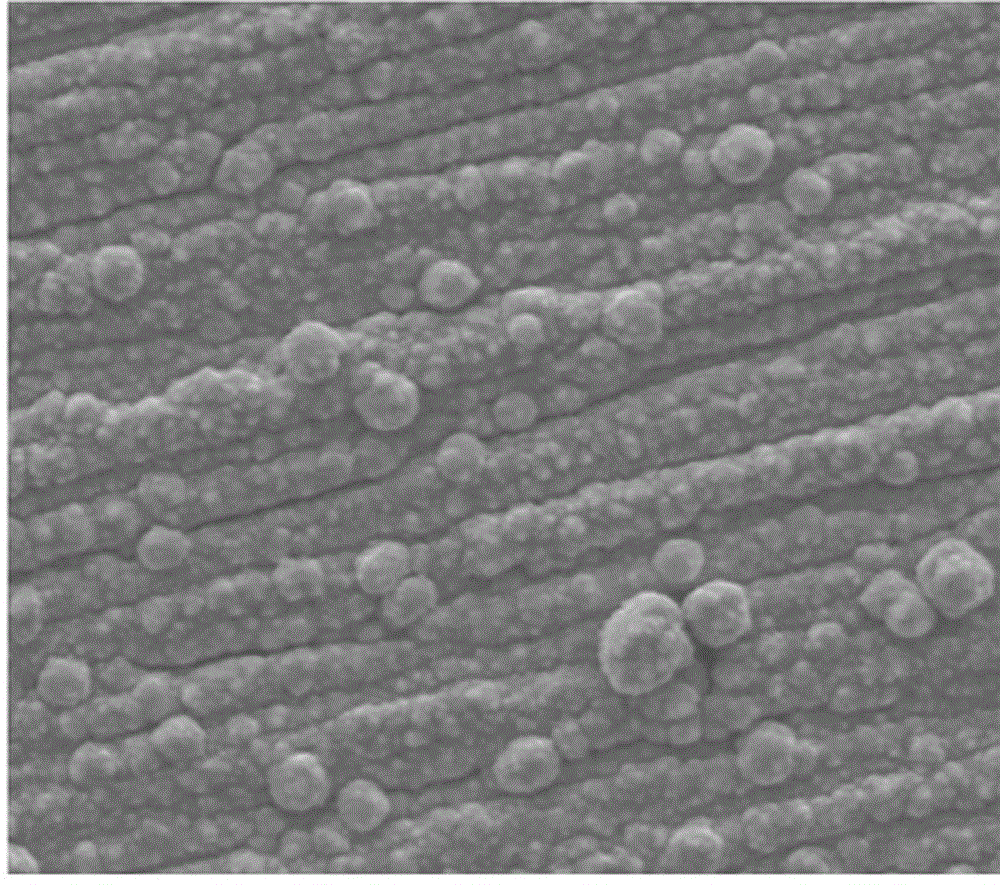

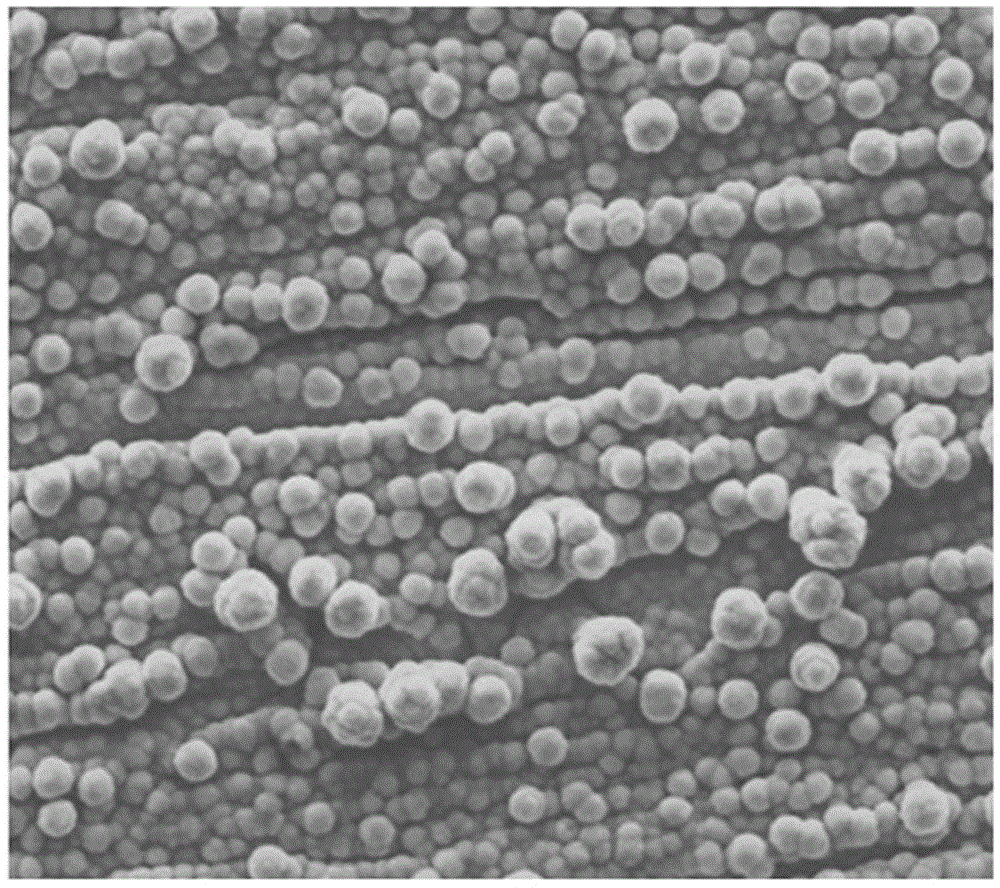

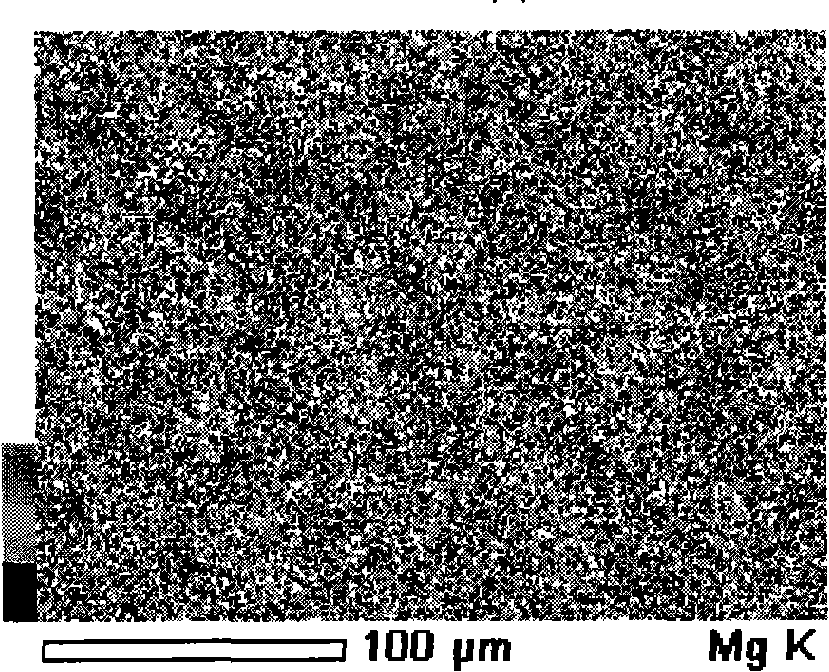

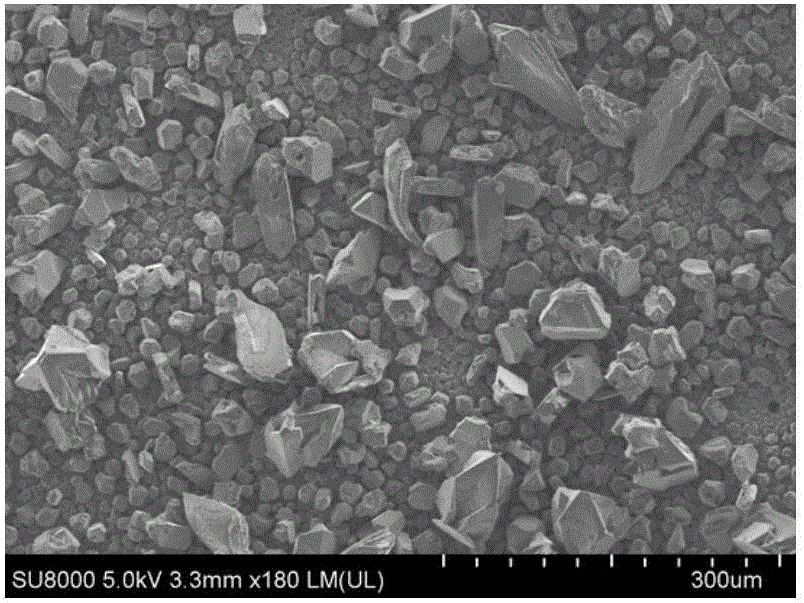

Method for preparing nanometer aluminum or nanometer aluminum coating in low-temperature electro-deposition form by using ion liquid/additive system

ActiveCN102888630AHigh purityWide variety of sourcesMaterial nanotechnologyElectrochemical windowIonic liquid

The invention designs a method for preparing nanometer aluminum or nanometer aluminum coating in an electro-deposition form by using an ion liquid / additive system. The method is characterized in that: ion liquid and anhydrous aluminum trichloride are mixed into a low-temperature electrolyte and suitable additives are added for preparing the ion liquid / additive system. A processed substrate is taken as a deposition cathode; the direct current electro-deposition is adopted for preparing the nanometer aluminum or nanometer aluminum coating; and the size of the aluminum grains is adjusted according to requirements. According to the method, the problems of high cost and small output of the present technology for producing the nanometer aluminum are solved; the adopted ion liquid is conventional ion liquid and is characterized by wide source, low cost, high conductivity, wide electrochemical window and being non-volatile and environment-friendly; the suitable additives are used, so that the high-quality nanometer aluminum or nanometer aluminum coating obtained in the conventional ion liquid is realized; the obtained aluminum deposited coating is compact, smooth and flat; a nanometer material can be obtained by using the ion liquid / additive system at lower temperature; the reaction is easy to control; the energy consumption is low; the obtained nanometer aluminum is high in quality and high in current efficiency; the size of the nanometer aluminum can be effectively controlled by adjusting the dosage and formula of the additives; the process is simple; the cost is low; and the application prospect is better.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for preparing aluminium and aluminium alloy by low temperature molten-salt electrolysis

The invention relates to a low temperature salt smelting electrolytic preparation aluminum and aluminum alloy that uses metal chloride or metal chloride mixture as electrolyte that has melting point lower than 800 degree centigrade, uses carbon material or noble electrode as anode, puts cathode on the bottom of graphitic cell groove and puts electrolyte on the upper of cathode, electrifying and heating, after electrolyte smelting, inserting the anode into molten salt, taking fusion electrolysis under the conditions of over A1203 decomposition voltage and lower electrolyte decomposition voltage, inter-pole gap over 0.1cm, temperature below 800 degree centigrade, electrolyzing to current lower than 1.0A, taking out cathode into smelter, smelting aluminum and casting under the condition of over 660 degree centigrade; using liquid aluminum and alumina mixture as cathode electrolyzing, and the temperature is over 660 degree centigrade, taking out aluminum from cathode, adding alumina, continuously taking electrolyzing process. The method sharply decreases electrolyzing temperature and saves electric energy.

Owner:NORTHEASTERN UNIV

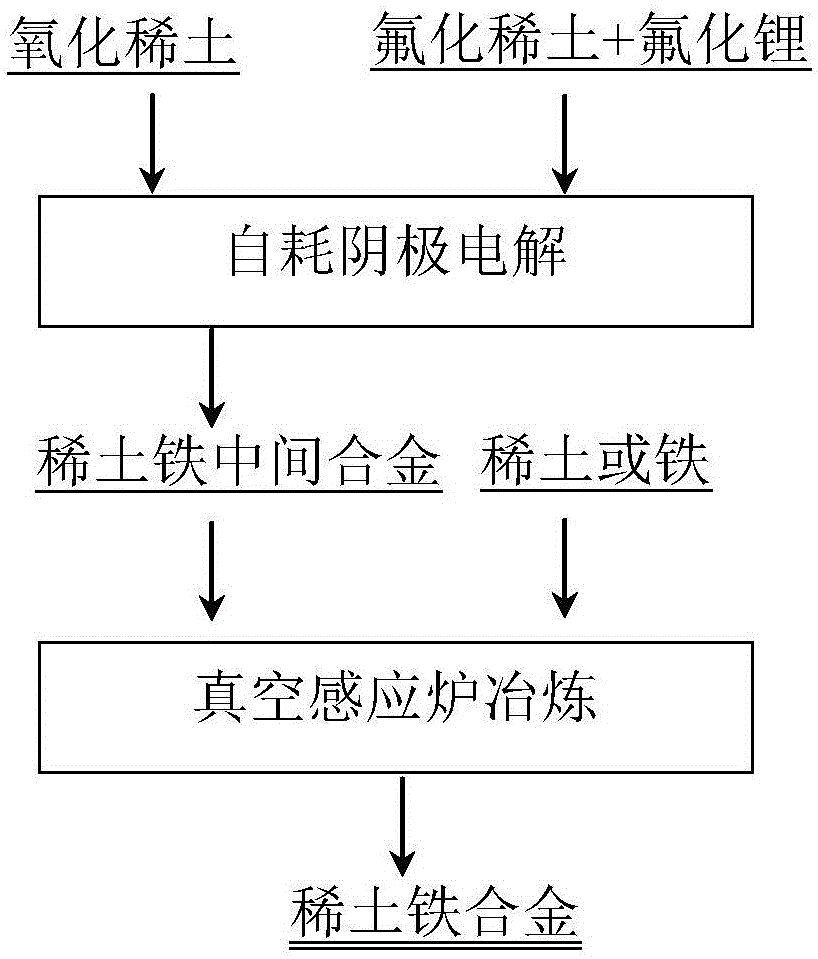

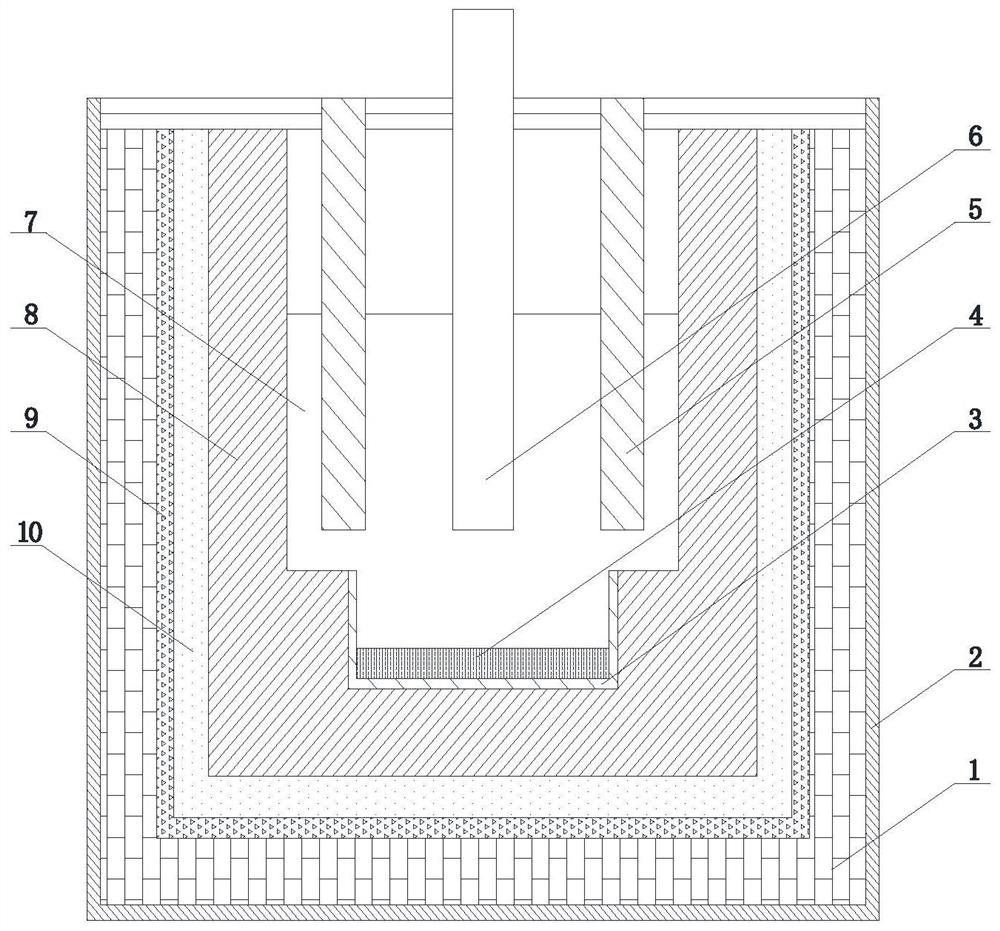

Rare-earth ferroalloy and preparation process thereof

The invention relates to a rare-earth ferroalloy for producing a rare-earth permanent magnetism material with high performance and a preparation process thereof. The ferroalloy comprises the contents according to the weight percentage: 30-90 of neodymium or didymium rare earth, and the balance ferrum and less than 1 of unavoidable impurities, wherein the O content is less than or equal to 0.1, the C content is less than or equal to 0.1 and the N content is less than or equal to 0.05. The alloy is prepared by an electrolytic method of fluoride molten salt system oxide, and an electrolyte of the alloy comprises rare-earth fluoride and lithium fluoride.

Owner:LESHAN YOUYAN RARE EARTH NEW MATERIAL CO LTD

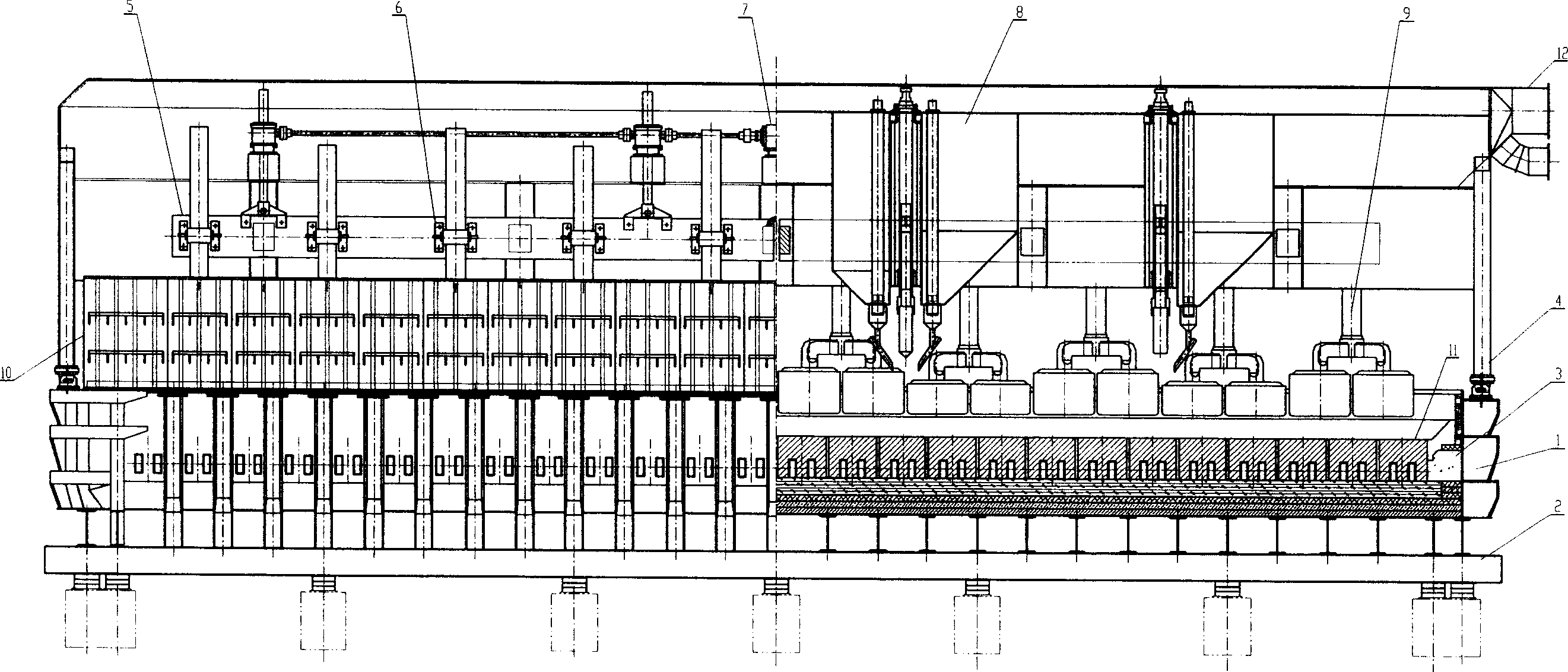

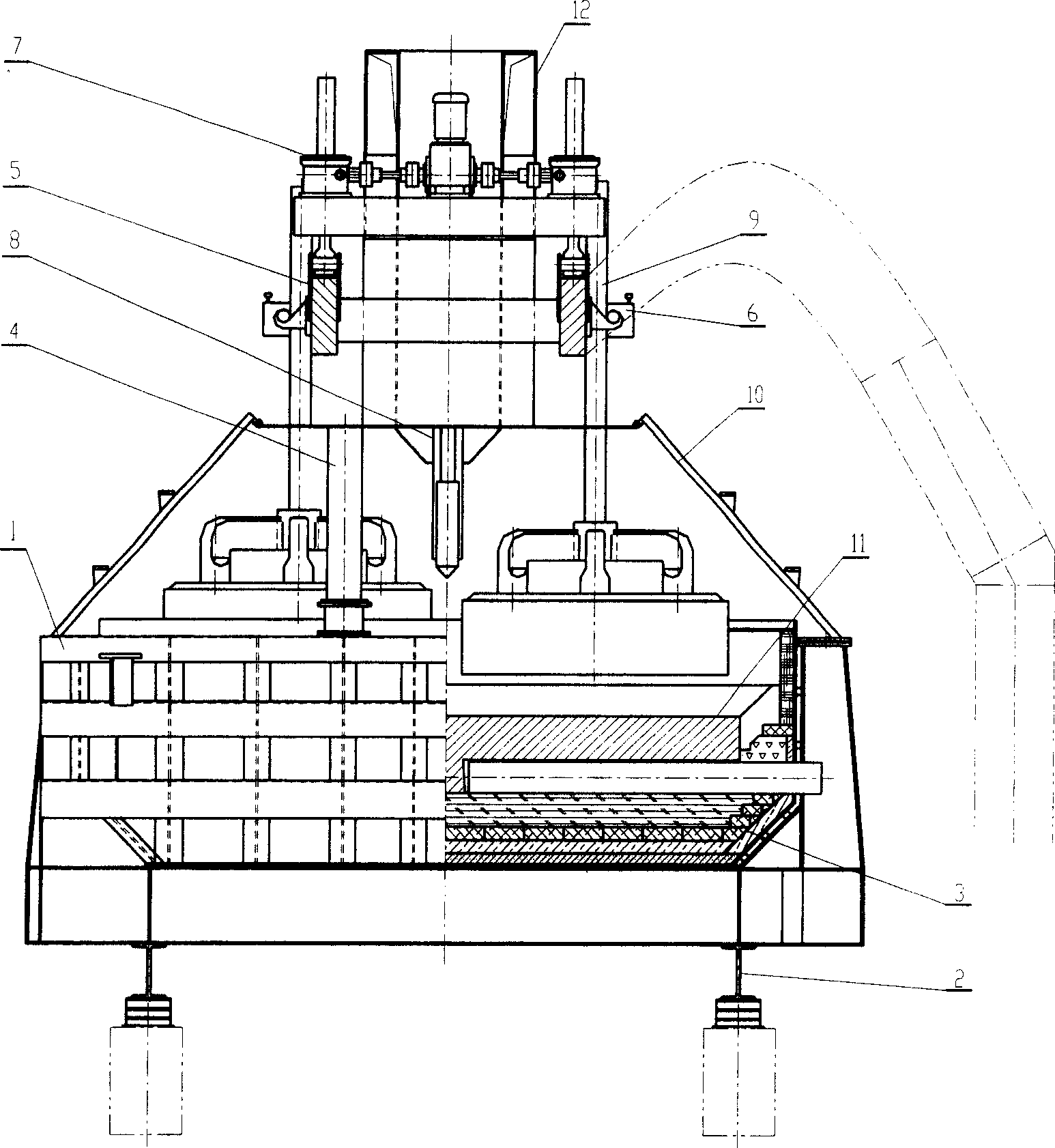

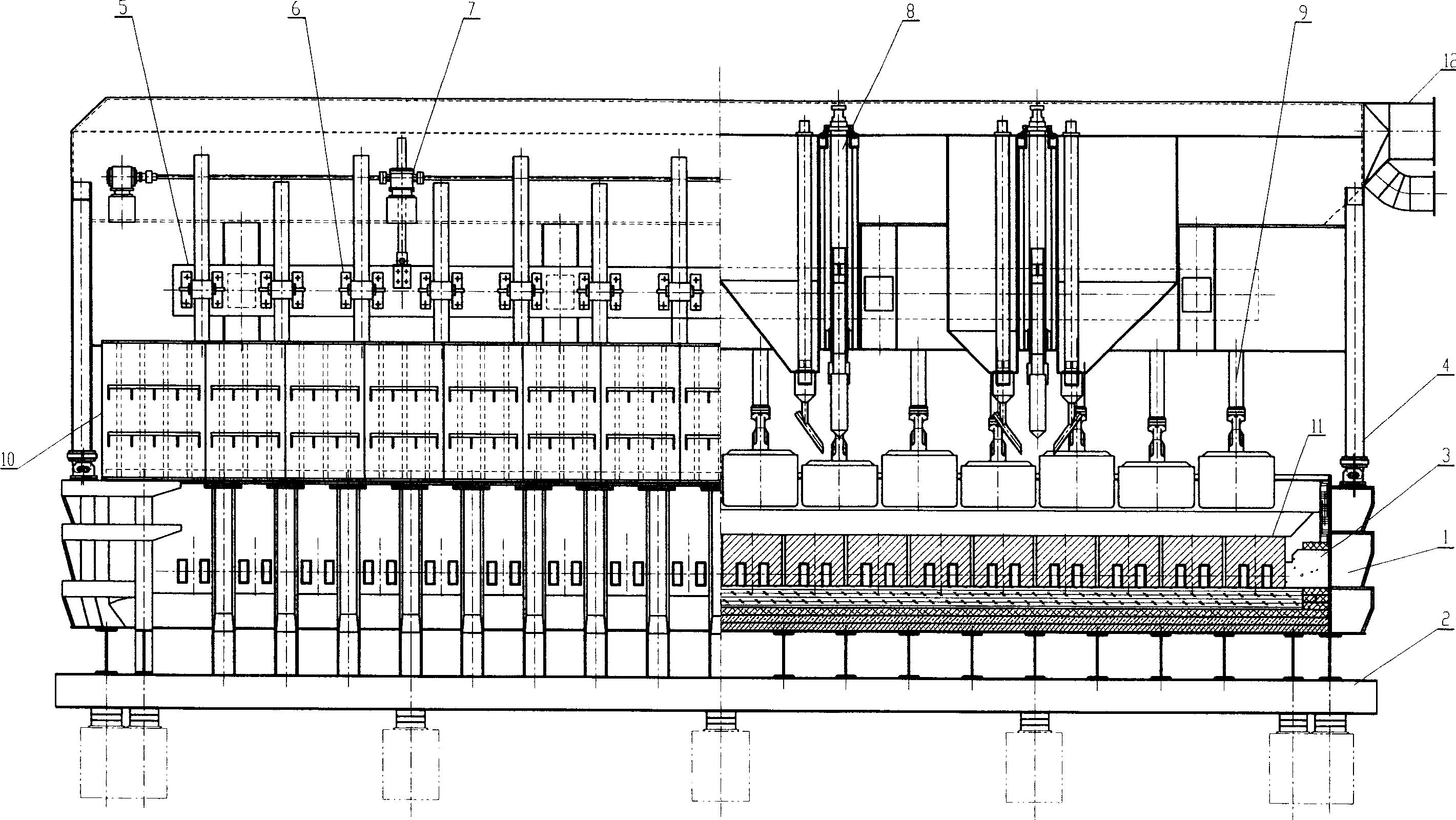

Large-scale aluminium electrolysis pre-baking tank

The large aluminum electrolyzing pre-roasting tank includes anode carbon block combination, anode bus, breaking and feeding unit, anode elevating mechanism, crossbeam and portal upright, tank sealing air exhaust system, tank casing, cathode structure and bottom heat insulating structure. It features the double anode structure comprising two anode carbon blocks assembled through aluminum rod and steel pawl; the elevator installed below the top surface of the crossbeam; the tank sealing air exhaust system set inside the crossbeam; and the cathode with surround casing, carbon block with bottom composite heat insulating layer, side silicon nitride to combine silicon carbide blocks and surrounding cast material. The present invention has improved structure resulting in raised fume collecting efficiency, reasonable gas flow distribution and smooth aluminum electrolyzing process.

Owner:NORTHEASTERN UNIV ENG & RES INST CO LTD

Rare earth alloy, preparation technique and application thereof

The invention relates to a light rare earth base heavy rare earth alloy, a preparation technology and application thereof. The alloy contains 1-40wt% heavy rare earth, and is prepared by oxide fused salt electrolysis process in fluoride molten salt. The electrolyte is composed of rare earth fluoride, lithium fluoride and magnesium fluoride, the compositions are: 65 to 87wt% of base fluoride in rare earth fluoride, 5 to 25wt% of heavy rear earth fluoride, 5-12wt% of lithium fluoride and 0.5 to 3wt% of magnesium fluoride. Since the electric efficiency is larger than 75%, the metal recovery rate is large than 90%, the preparation technology is especially suitable for industrialized mass production.

Owner:LESHAN YOUYAN RARE EARTH NEW MATERIAL CO LTD

Method for low-temperature electrolysis of aluminum oxide for producing aluminum adopting ion liquid

InactiveCN101265588AStable in natureImprove conductivityPhotography auxillary processesProcess efficiency improvementElectrolysisDecomposition

The invention relates to a method for producing aluminum by adopting ionic liquid to directly electrolyze alumina at a low temperature, and is characterized in that the HSO4<-> type anionic ionic liquid dissolves alumina and is taken as a low temperature electrolyte, alumina is taken as raw material and is directly electrolyzed by the direct current, the tank voltage is higher than the decomposition voltage of alumina but lower than that of the electrochemical window of the ionic liquid, aluminum is separated out from the cathode, and CO2 is generated from the anode. The ionic liquid adopted by the invention has wide source, low price, good stability, high conductivity, and wide electrochemical window; the good stability is environmental friendly and can efficiently dissolve alumina at a low temperature; adopting the ionic liquid as the low temperature electrolyte greatly reduces the temperature of electrolysis and the tank voltage; the capacity usage ratio is high and the erosion of equipment is greatly reduced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for producing aluminium-lithium alloy with high lithium content by low-temperature molten salt electrolysis

The invention provides a method for producing an aluminium-lithium alloy with high lithium content by low-temperature molten salt electrolysis. In an electrolytic furnace, aluminium is taken as a cathode, a cathode sleeve is sheathed thereon, graphite is taken as an anode, an electrolyte system is formed from LiCl and KCl, wherein, the weight ratio of LiCl: KCl is equal to 45: 55, the electrolysistemperature is 380-450 DEG C, the self-consumption cathode method is adopted for carrying out electrolysis, the current density of the cathode is 1-3.0A / cm<2>, the current density of the anode is 0.5A / cm<2>, the cell voltage is 4.1-5.6V, LiCl is supplemented during the electrolysis process for leading the mixing ratio of LiCl: KCl of the electrolyte to be in the vicinity of an eutectic point, theliquid aluminium-lithium alloy with high lithium content is deposited in the vicinity of the cathode in a molten salt electrolytic cell by 1-4 hours of electrolysis, and the solid aluminium-lithium alloy is prepared by solidification. The method can obtain the liquid aluminium-lithium alloy with evenly distributed alloy components at low temperature. The method can avoid the defects of burning loss of lithium during the doping process and the like, simultaneously save energy consumption of doping, mixing and melting process, avoid cracking of the cathode and uneven components, and avoid the defects of burning loss of the lithium caused by higher temperature and volatilization loss of LiCl.

Owner:HARBIN ENG UNIV

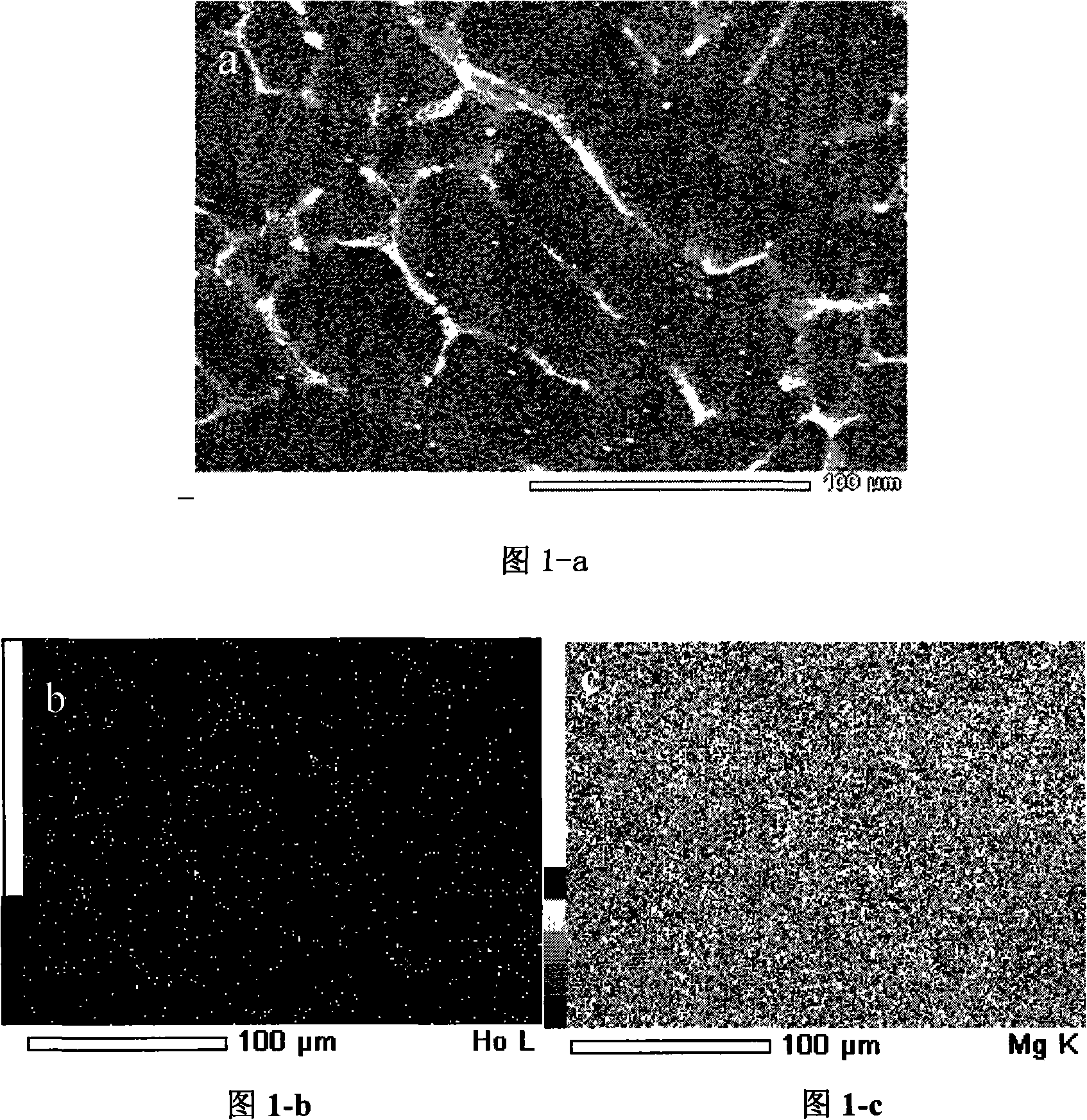

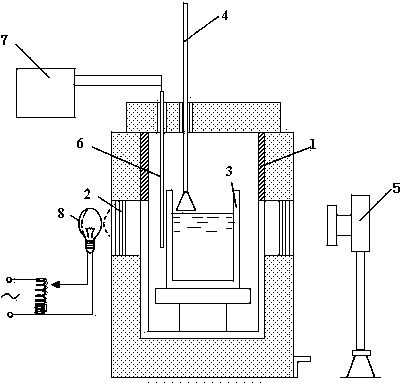

Mg-Li-Ho alloy, and fused salt electrolysis preparation and apparatus thereof

The invention provides a Mg-Li-Ho alloy and a method for preparing the same by molten salt electrolysis. The method comprises the following steps of: adding Ho2O3 in an electrolytic furnace by taking MgCl2 plus LiCl plus KCl plus KF as an electrolyte system, and heating up the mixed electrolyte system to fuse at a temperature of 650 DEG C; depositing the Mg-Li-Ho alloy in a molten salt bath close to a cathode via electrolyzing for 1 to 2 hours with a sunk cathode method with metal molybdenum (Mo) as the cathode, graphite as an anode, cathode current density between 12 and 16 A / cm<2>, anode current density between 0.5 and 0.6 A / cm<2> and bath voltage between 4.6 and 7.6V. The method completely uses metal compounds as raw materials to directly prepare the Mg-Li-Ho alloy through molten salt electrolysis, without using metal magnesium, lithium or metal holmium. Therefore, the method greatly shortens the production flow, simplifies the process, decreases the electrolysis temperature, and can reduce the production cost of the alloy.

Owner:HARBIN ENG UNIV

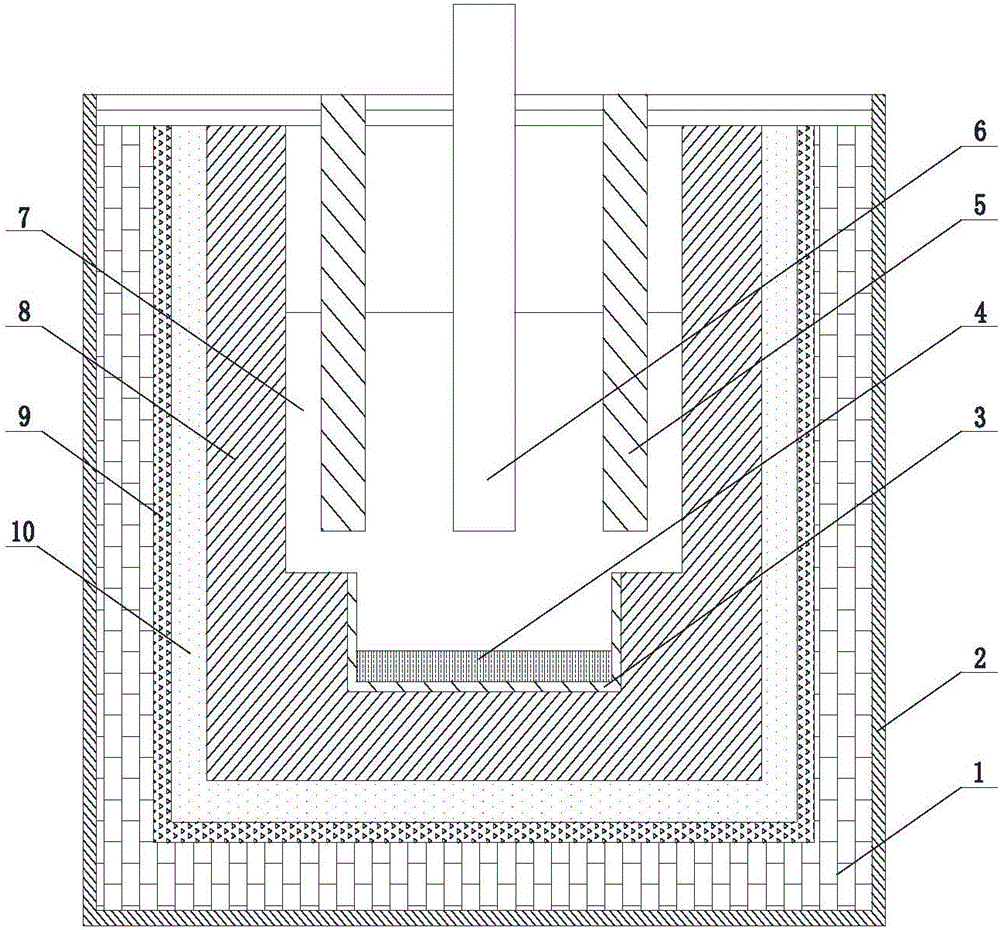

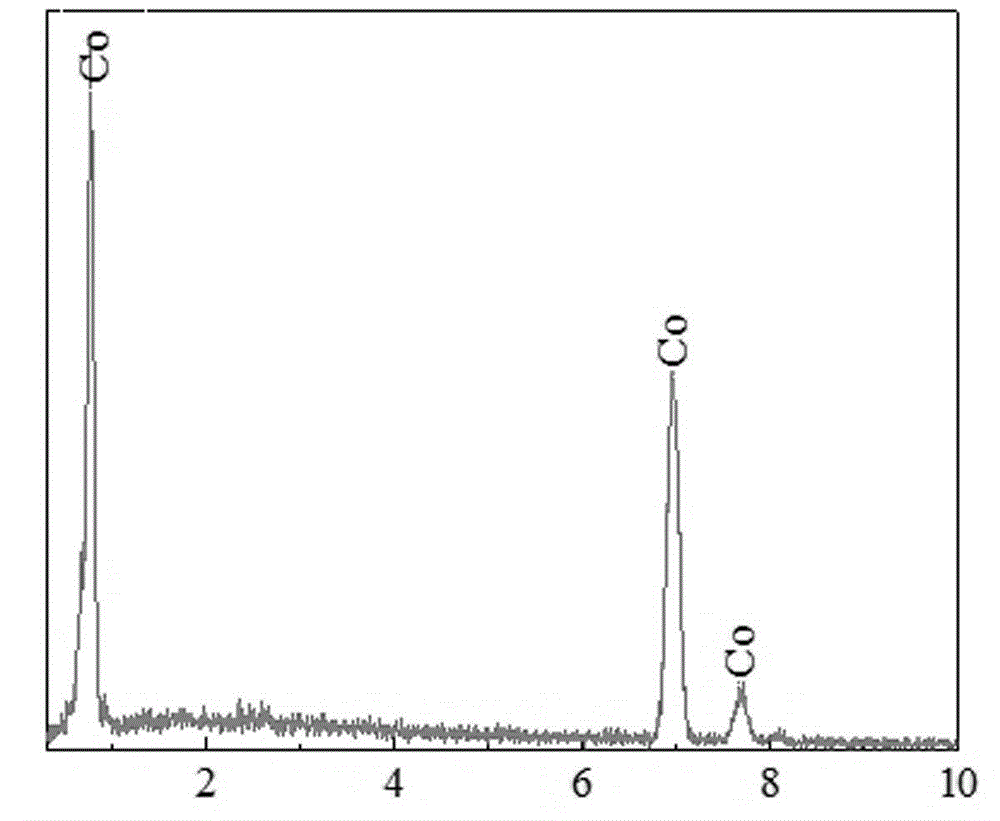

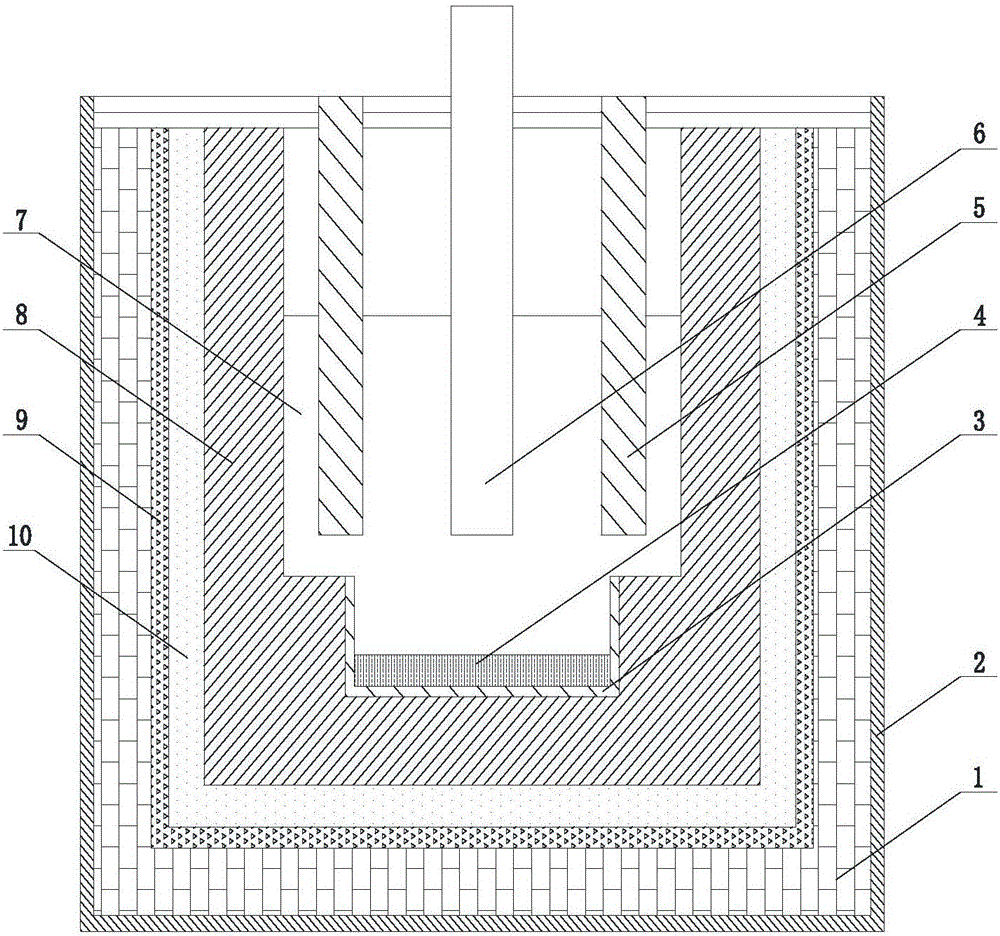

Rare earth iron alloy and preparation method thereof

The invention discloses a rare earth iron alloy. The content of rare earth is 0-95 wt%; and the balance is iron and inevitable impurities with the total quantity of less than 0.5 wt%, wherein oxygen is not more than 0.01 wt%, carbon is not more than 0.01 wt%, phosphorus is not more than 0.01 wt%, and sulfur is not more than 0.005 wt%. The invention further discloses a preparation method of the rare earth iron alloy. The prepared rare earth iron alloy is uniform in component, low in segregation, low in impurity content, high in rare earth yield, low in cost and free of pollution, is applied to the rare earth steel, and is high in rare earth yield, prominent in effect and suitable for large-scale industrial production.

Owner:BAOTOU RES INST OF RARE EARTHS +1

Method for preparing silicon from composite molten salt electrolyte

InactiveCN101967649AImprove current efficiencyImprove direct yieldElectrolysis componentsMass contentSilicon dioxide

The invention provides a method for preparing silicon from a composite molten salt electrolyte. The method comprises the following steps of: adding calcium oxide-calcium chloride (CaO-CaCl2) serving as the molten salt electrolyte into silica or silicon dioxide (SiO2) serving as a raw material until the mass ratio of the SiO2 to the CaO in the mixture is 2-30:1, wherein the CaO mass content of the CaO-CaCl2 molten salt electrolyte accounts for 1 to 15 percent of that of the CaO-CaCl2 molten salt electrolyte; and raising the temperature to 600 to 1,000 DEG C under a protective gas environment and performing electrolytic reduction so as to obtain elementary substance silicon. The silica or the silicon dioxide serving as the raw material is not under the control of shapes and can be in the form of blocks, particles or powder; and the electrolyte CaO-CaCl2 serves as a mixed molten salt system for silicon electrolysis, so that the silicon dioxide can be dissolved directly, silicon yield is increased, current efficiency in an electrolytic process is improved, electrolysis temperature and energy consumption are low, product recovery is high and greenhouse gases and impurities are not produced.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of silicon particles by inert anode molten salt electrolysis

The invention relates to a preparation method of silicon particles by inert anode molten salt electrolysis. The method comprises the following steps of: carrying out cathodic electrolysis by using a cryolite molten salt system as the electrolyte, molten aluminum or Al-Si alloy as the cathode and silicon dioxide or silicate as electrolysis raw materials to prepare a liquid Al-Si alloy and carrying out condensation treatment to obtain the silicon particles with purity more than 99.72wt%. According to the invention, NiFe2O4-based cermet or Cu-Ni-Fe alloy is used as the inert anode, thus reducing the boron, phosphorus and other impurities in the cathode caused by anode consumption; the liquid Al-Si alloy is used as the actual cathode, thus avoiding the poor electrical conductivity of electrolytic cell caused by solid silicon deposition on the cathode, easily taking out the cathode product from the electrolytic cell and maintaining electrolysis continuity; and the electrolysis temperature is low, thus reducing the pollution of the electrolyte and the wall material of the electrolytic cell to the cathode product. The process method provided by the invention is simple and convenient to operate and environmentally-friendly, has the advantages of long anode life, low electrolysis temperature, high purity of electrolysis product and low production cost and, and is suitable for industrial application.

Owner:CENT SOUTH UNIV

Method of preparing transition metal and alloy thereof through low temperature molten salt electro-deposition

A method of preparing transition metal and alloy thereof through low temperature molten salt electro-deposition is characterized by comprising the steps of (1) mixing anhydrous urea, acetamide and anhydrous LiX uniformly and heating and stirring the mixture to form a colorless uniform liquid molten salt; (2) dissolving a transition metal chloride TMCl2 in low temperature molten salt and stirring and mixing the mixture uniformly to form a low temperature molten salt electrolyte; (3) with a copper sheet or stainless steel as a cathode and graphite as an anode, performing electro-deposition in the low temperature molten salt electrolyte at the electrolyzing temperature of 70-90 DEG C in a manner of constant potential and constant current to control the potential or cathode current density; and (4) when the electrolysis is finished, taking the copper sheet or stainless steel out and cleaning and drying it to obtain the transition metal and alloy thereof deposited on the surface of the cathode. The molten salt is low in price and is low in eutectic temperature so that the method is low in cost, is low in electrolysis temperature, is energy-saving, is less in pollution and is slight in corrosion on equipment.

Owner:NORTHEASTERN UNIV LIAONING

Cerium iron alloy and preparation method thereof

The invention discloses a cerium iron alloy. The content of cerium is 0-95 wt%; and the balance is iron and inevitable impurities with the total quantity of less than 0.5 wt%, wherein oxygen is not more than 0.01 wt%, carbon is not more than 0.01 wt%, phosphorus is not more than 0.01 wt%, and sulfur is not more than 0.005 wt%. The invention further discloses a preparation method of the cerium iron alloy. The prepared cerium iron alloy is uniform in component, low in segregation, low in impurity content, high in rare earth yield, low in cost and free of pollution, is applied to the rare earth steel, and is high in rare earth yield, prominent in effect and suitable for large-scale industrial production.

Owner:BAOTOU RES INST OF RARE EARTHS +1

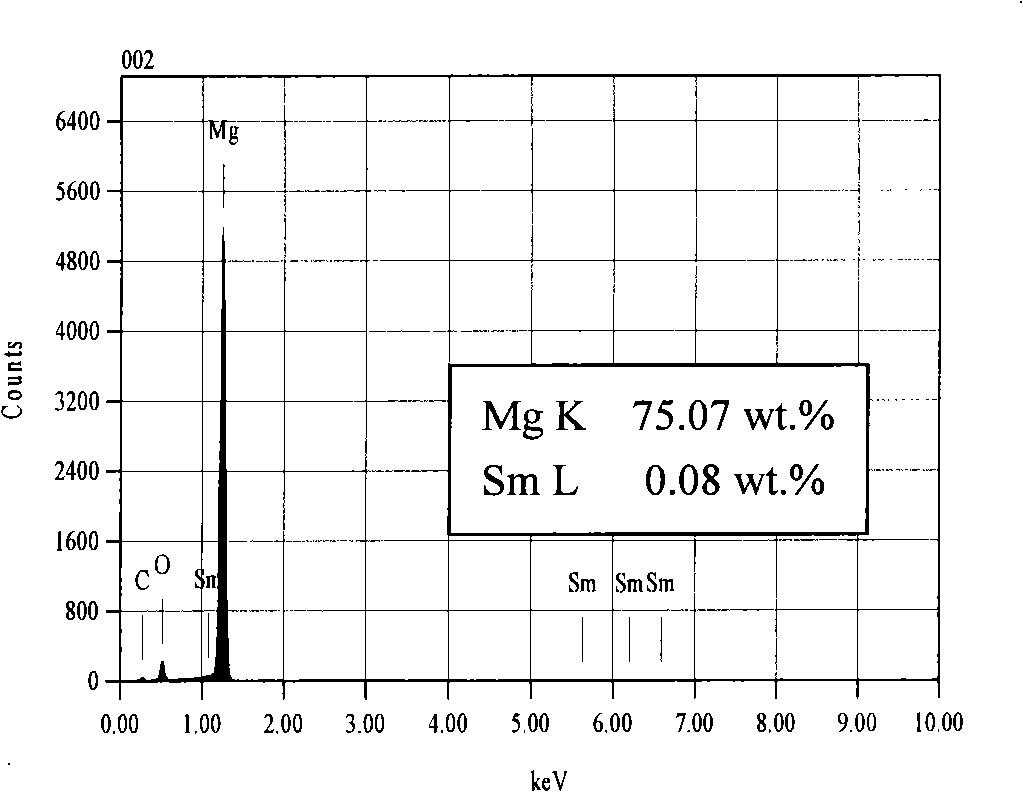

Magnesium-lithium-samarium alloy and preparation method thereof by fused salt electrolysis

The invention provides a Mg Li -Samarium alloy and a method for preparing the same through fusion electrolysis. The method uses MgCl2+LiCl+KCl+KF as an electrolyte system in an electrolytic furnace, then adds anhydrous Sm2O3 powders to heat up to a melting temperature of 680 DEG C or anhydrous SmCl3 powders to heat up to a melting temperature of 630 DEG C, using metal molybdenum (Mo) as a cathode and graphite as an anode at an electrolysis temperature of between 630 and 810 DEG C, and adopts a sinking cathode method, in which a cathodic current density is 6.4 to16.0A / cm<2>,an anodic current density is 0.5A / cm<2> and a cell voltage is 5.1-8.4V, so as to deposit a Mg-Li-Sm alloy nearby the cathode in a fused-salt electrolysis cell after electrolyzing for 40 to 120 minutes. The method does not use metallic magnesium, metal lithium, or metallic samarium, but uses metal compound as raw materials to directly prepare the Mg-Li-Sm alloy through the fusion electrolysis method, thereby having the advantages of greatly shortening production flow and reducing the energy consumption and production cost due to the simple process with low temperature electrolysis.

Owner:HARBIN ENG UNIV

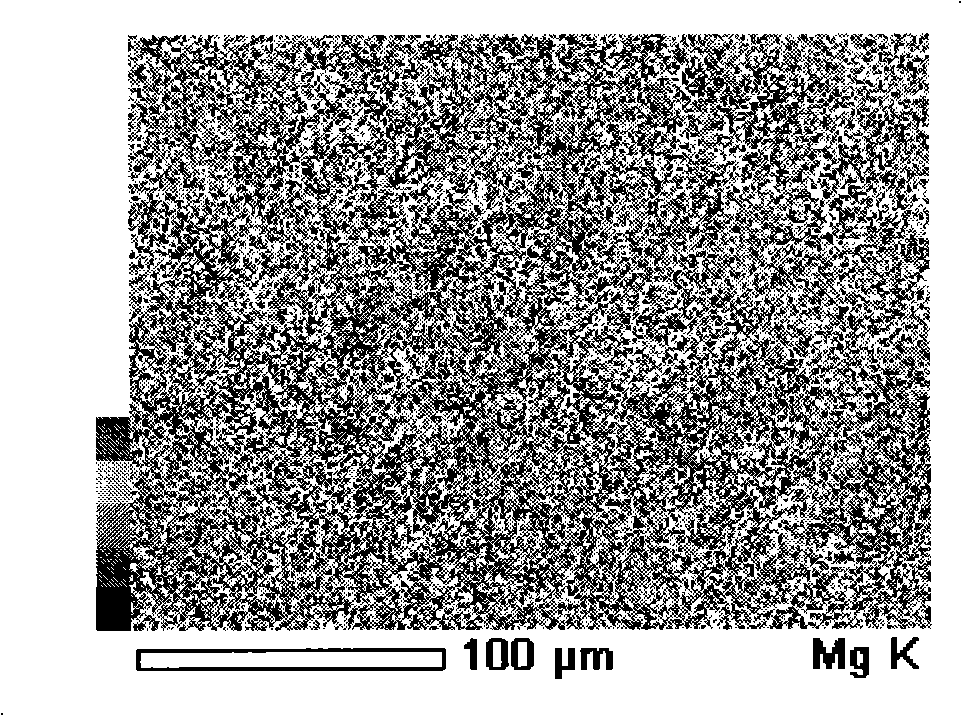

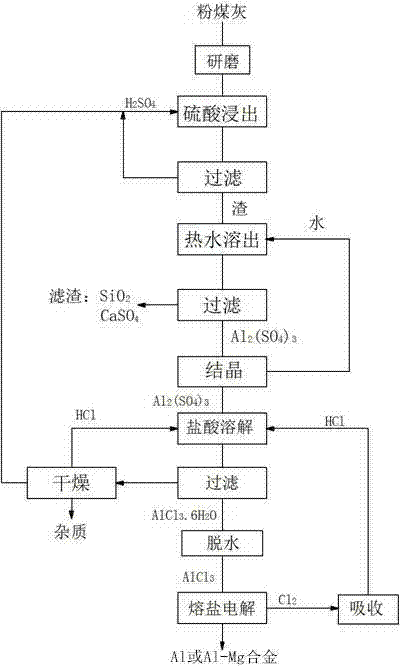

Method for preparing metallic aluminum or aluminum-magnesium alloy by utilizing pulverized fuel ash

ActiveCN104294314AWith green energy saving and environmental protectionReduce the temperatureAluminium chlorideMetallic aluminum

The invention belongs to the field of non-ferrous metallurgy and relates to a method for preparing metallic aluminum or an aluminum-magnesium alloy by utilizing pulverized fuel ash. According to the technical scheme of the invention, the method comprises the following steps: preparing aluminum chloride by adopting acid leaching of pulverized fuel ash, wherein the adopted electrolyte system consists of a flux, a solute and an additive, and the flux comprises the following components in percentage by mass: 0-60 percent of NaCl, 25-75 percent of KCl and 0-66 percent of MgCl2; adding a solute AlCl3 which accounts for 5-50 percent of the mass of the flux, an additive LiCl which accounts for 0-5 percent of the mass of the flux, 0-5 percent of an additive KF, 0-5 percent of an additive MgF2 or 0-5 percent of an additive AlF3, wherein the solute AlCl3 is added from the bottom of the electrolytic cell, the interpolar voltage is controlled to be 2.3-3.3V, the cathode-current density is 0.5-1.5A / cm<2>, and the electrolysis temperature is 450-500 DEG C; and producing chlorine on one side of the anode in the electrolysis process, recycling chlorine, and depositing solid metallic aluminum or the aluminum-magnesium alloy on one side of the cathode. According to the method disclosed by the invention, the power consumption is saved, the electrolysis temperature is low, the production cost is low, the problems of aluminum chloride evaporation and generation of dendritic crystals during electrolysis are solved, the environmental pollution is avoided, and the equipment is easy to realize.

Owner:李景江

Method for improving capability of electrolyte in technique of electrolytic aluminium

InactiveCN1563500AImprove physical and chemical propertiesLow melting pointElectrolyteMaterials science

This invention relates to a method for improving electrolyte performance in the technology of electrolyzing Al which adds weight percentage of 1-10% NaCl in the electrolyte to effectively change the composition of Al electrolyte, improving its chemical and physical performance to reduce its melting point and reduce the electrolyzing temperature by 20deg.C and increase its conductivity and current efficiency over 1%.

Owner:QINYI IND GROUP NINGXIA

Method for preparing Mg-Sr alloy by electrolyzing MgO and SrO in same trough

The invention relates to a method for preparing magnesium- strontium alloy by electrolyzing MgO and SrO in the same electrolyser, belonging to magnesium alloy preparation technique field. It is characterized in that it takes MgO and SrO as suply for alloy, metal halide as electrolyte, decodes magnesium and strontium with electrical deoxidation to get magnesium- strontium alloy, the temperature for electrolysis is 650- 850 Deg. C, and voltage is 2.5- 4.5 V. The invention takes MgO and SrO or precursor material as raw material, prepares magnesium- strontium alloy through electrolytic reduction. It is characterized by shortened process, environment- friendly, low production cost, good economic bebefit, and high- purity magnesium- strontium alloy with strontium content being 0.05-25%wt.

Owner:CHONGQING UNIV

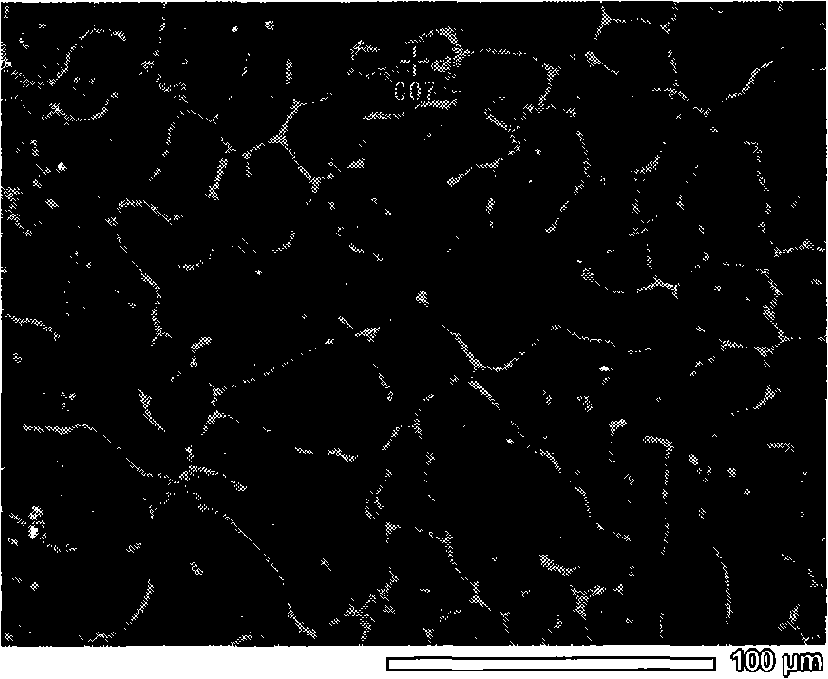

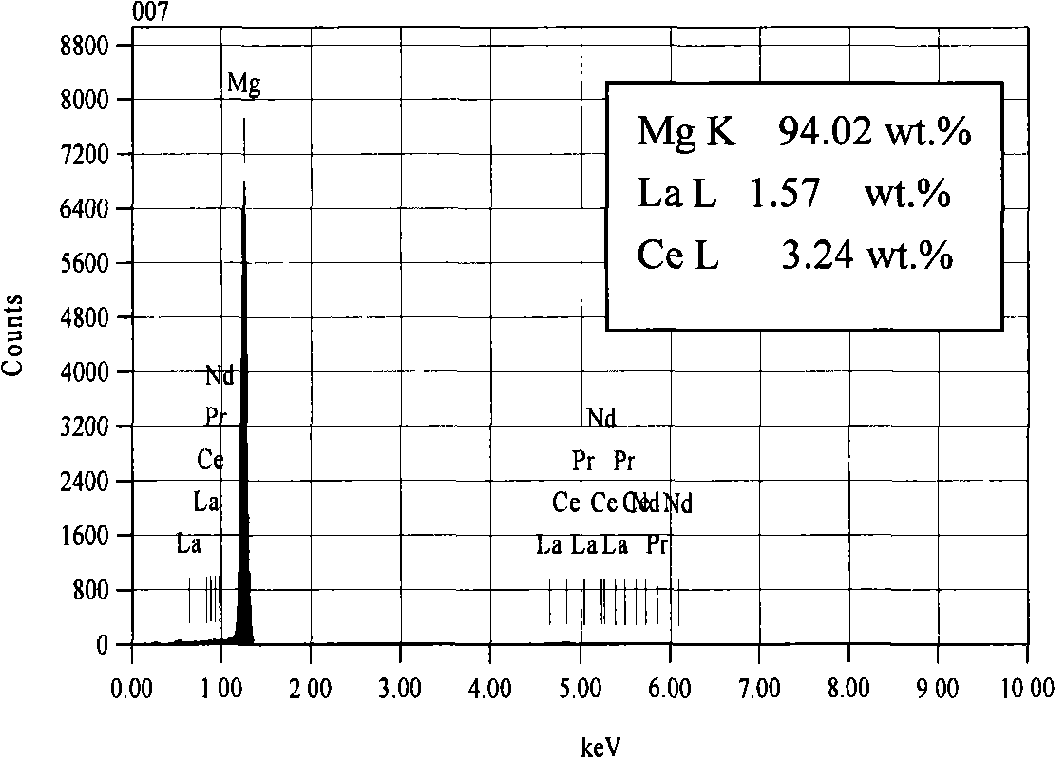

Mg-Li-Ce-La alloy and fused salt electrolysis preparation thereof

The invention provides a Mg-Li-Ce-La alloy and a method for directly preparing the same by molten salt electrolysis. The method comprises the following steps of: fusing at a temperature of between 750 and 800 DEG C after adding Ce-rich rare-earth carbonate (cerous carbonate and lanthanum carbonate) in an electrolytic furnace by taking MgCl2 plus LiCl plus KCl plus KF as an electrolyte system; depositing the Mg-Li-Ce-La alloy in a molten salt bath close to a cathode via electrolyzing for 1 to 2 hours with an inert metal electrode as the cathode and graphite as an anode, a sunk cathode method, at an electrolysis temperature of between 650 and 800 DEG C, with cathode current density between 12 and 20 A / cm<2>, anode current density 0.5 A / cm<2> and bath voltage between 5.5 and 9.0V. The method completely uses metal compounds as raw materials to directly prepare the Mg-Li-Ce-La alloy with uniform compositions and without a segregation phenomenon through molten salt electrolysis, without using metal magnesium, lithium or rare-earth metal, thereby greatly shortening the production flow, simplifying the process, and reducing the production cost of the alloy.

Owner:HARBIN ENG UNIV

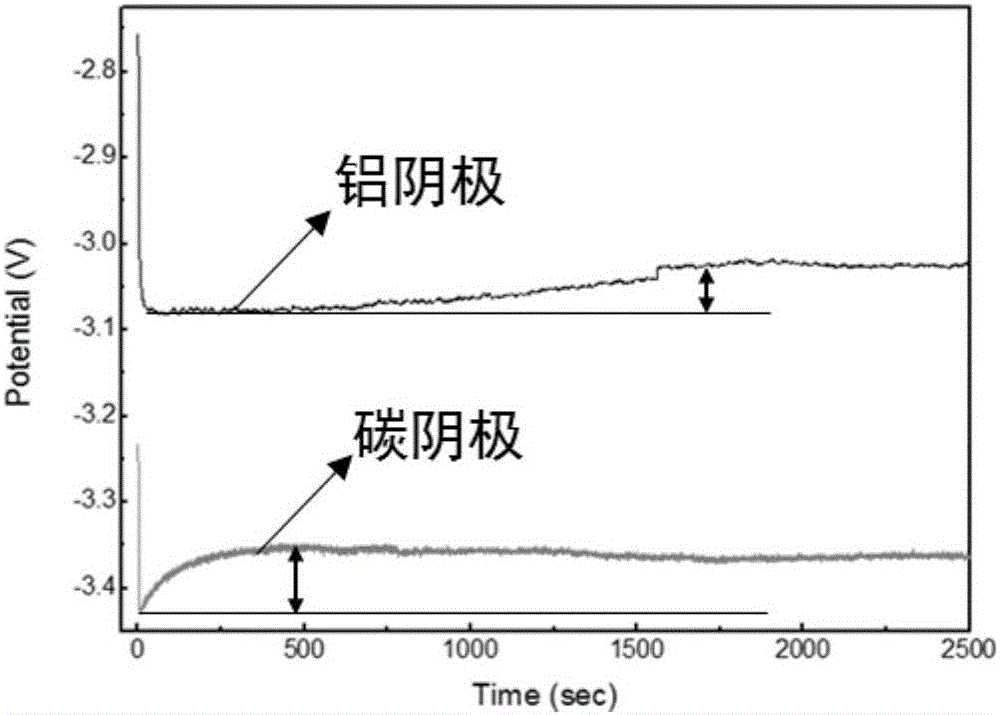

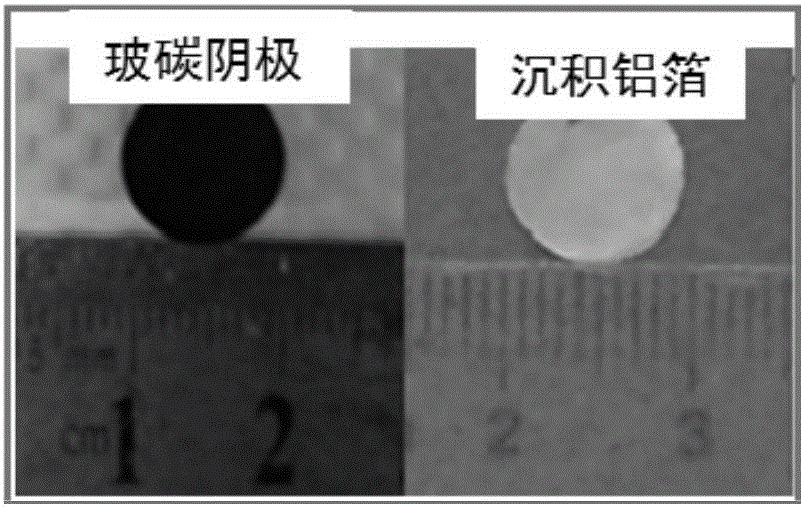

Method for directly preparing aluminum foil through low temperature electrolysis

InactiveCN105671598AEasy to separateReduce adhesionElectroforming processesMetallic aluminumElectrolysis

The invention discloses a method for directly preparing an aluminum foil through electrolysis at low temperature in an ionic liquid medium.Not only is the problem that a compact deposition layer is difficult to strip in the electrodeposition process of metallic aluminum in ionic liquid solved, but also a novel approach is provided for electrochemical preparation of the aluminum foil.The method is characterized in that a higher nucleation overpotential of metallic aluminum on a carbon cathode is utilized, a compact deposition layer is formed, and meanwhile the compatibility between the metallic aluminum and carbon material lattices is poor, so that the compact aluminum foil on the surface of the cathode is easy to strip.According to the method for directly preparing the aluminum foil through electrolysis, the low-temperature ionic liquid serves as the electrolyte, a carbon material with a smooth surface serves as the cathode, and by means of the characteristics that the ionic liquid is low in melting point and not prone to volatilization, the metallic aluminum foil is successfully prepared within the low-temperature range of 25 DEG C-100 DEG C.The method for directly preparing the aluminum foil through electrolysis has the advantages that the operation temperature is low, and the technological steps are simple and easy to operate; continuous production is easy to achieve, and the production energy consumption and cost of the aluminum and the aluminum foil can be significantly reduced.The method has a good application prospect in the aspect of preparation of the metallic aluminum and aluminum foil through low-temperature electrolysis.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Praseodymium-neodymium-iron alloy and preparation method thereof

The invention discloses a praseodymium-neodymium-iron alloy. The praseodymium-neodymium-iron alloy comprises 0-95wt% of praseodymium and neodymium and the balance iron and inevitable impurities of which the total content is less than 0.5wt%, wherein the content of oxygen is less than or equal to 0.01wt%, the content of carbon is less than or equal to 0.01wt%, the content of phosphorus is less than or equal to 0.01wt%, and the content of sulfur is less than or equal to 0.005wt%. The invention further discloses a preparation method of the praseodymium-neodymium-iron alloy. The praseodymium-neodymium-iron alloy prepared through the method is uniform in composition, small in segregation, low in impurity content, high in rare-earth yield, low in cost, and free of pollution; and the praseodymium-neodymium-iron alloy is high in rare-earth yield and remarkable in effect when applied to rare-earth steel, and is suitable for large-scale industrial production.

Owner:BAOTOU RES INST OF RARE EARTHS +1

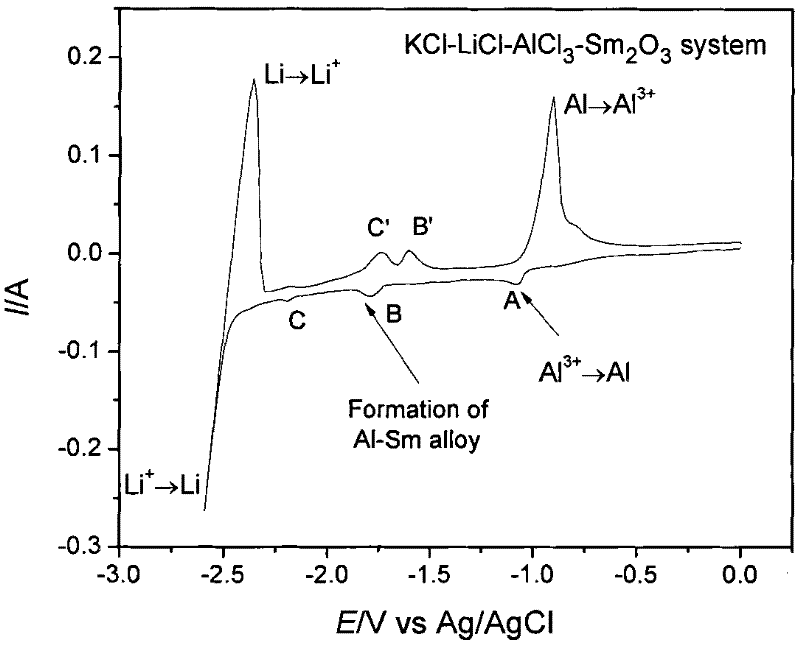

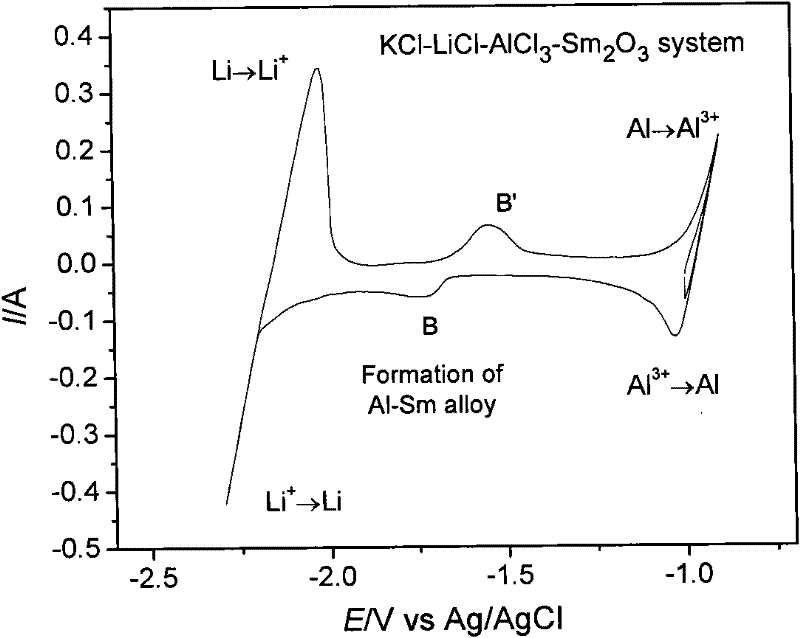

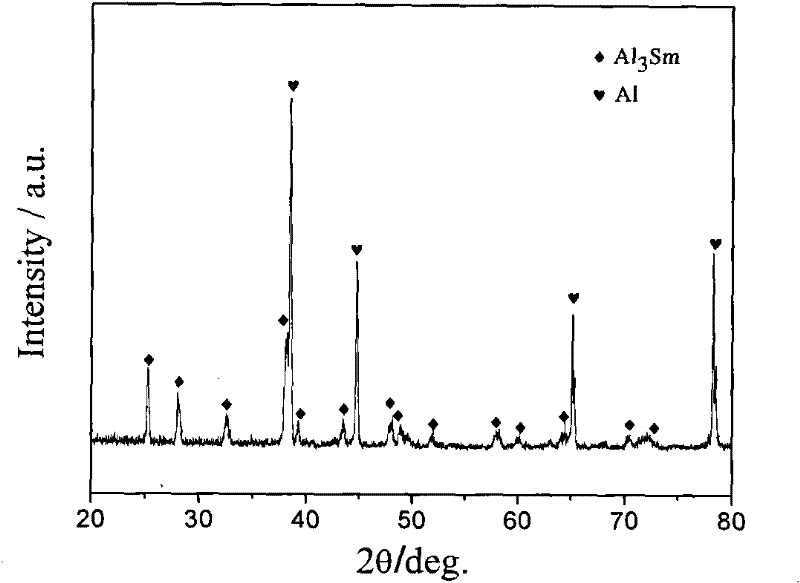

Aluminum-lithium-samarium alloy and fused salt electrolysis preparation method thereof

The invention provides an aluminum-lithium-samarium alloy and a fused salt electrolysis preparation method thereof. The aluminum-lithium-samarium alloy is prepared by the following steps of: heating LiCl and KCl serving as an electrolyte system to 630 DEG C for fusion in an electrolytic furnace; uniformly mixing Sm2O3 powder and AlCl3 and tabletting the mixture, adding the mixture into fused saltin the form of grains to ensure that the mass ratio of the AlCl3, LiCl to KCl is 6.2-11.0 percent to 44.5-46.9 percent to 44.5-46.9 percent, wherein the amount of the added Sm2O3 is 1 percent of the weight of the electrolytic fused salt; and taking metal molybdenum as a cathode and graphite as an anode and performing electrolysis for 2 to 6 hours to deposit the Al-Li-Sm alloy close to the cathodeof the fused salt electrolysis cell, wherein the electrolysis temperature is between 630 and 720 DEG C, the cathode current density is 6.4A / cm<2> and the anode current density is 0.5A / cm<2>. By completely using metal compounds as raw materials and adding aluminum chloride, the chlorination of samarium oxide is realized and the aluminum-lithium-samarium alloys of different components are obtained by controlling the conditions such as the proportion of the electrolytes, the electrolysis time, the temperature, the current density and the like. The alloy and the method have the advantages of simple whole process, low requirements on equipment, low energy consumption and low pollution.

Owner:HARBIN ENG UNIV

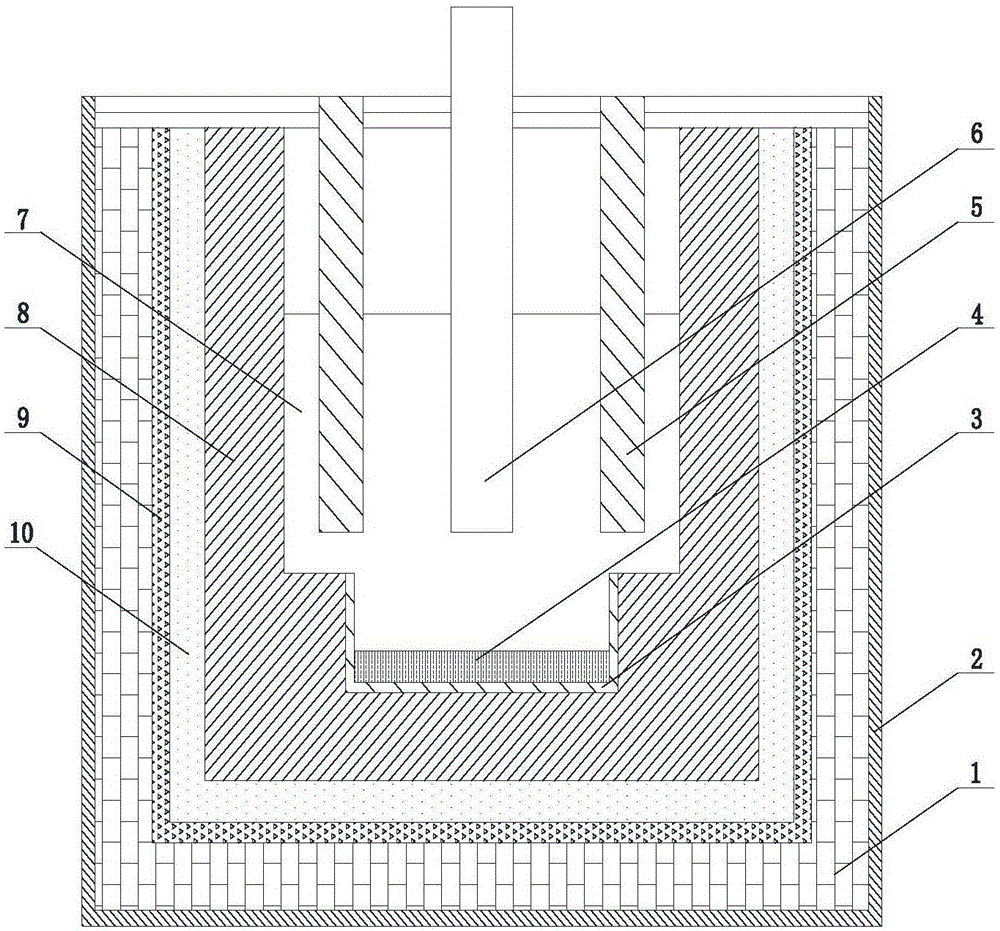

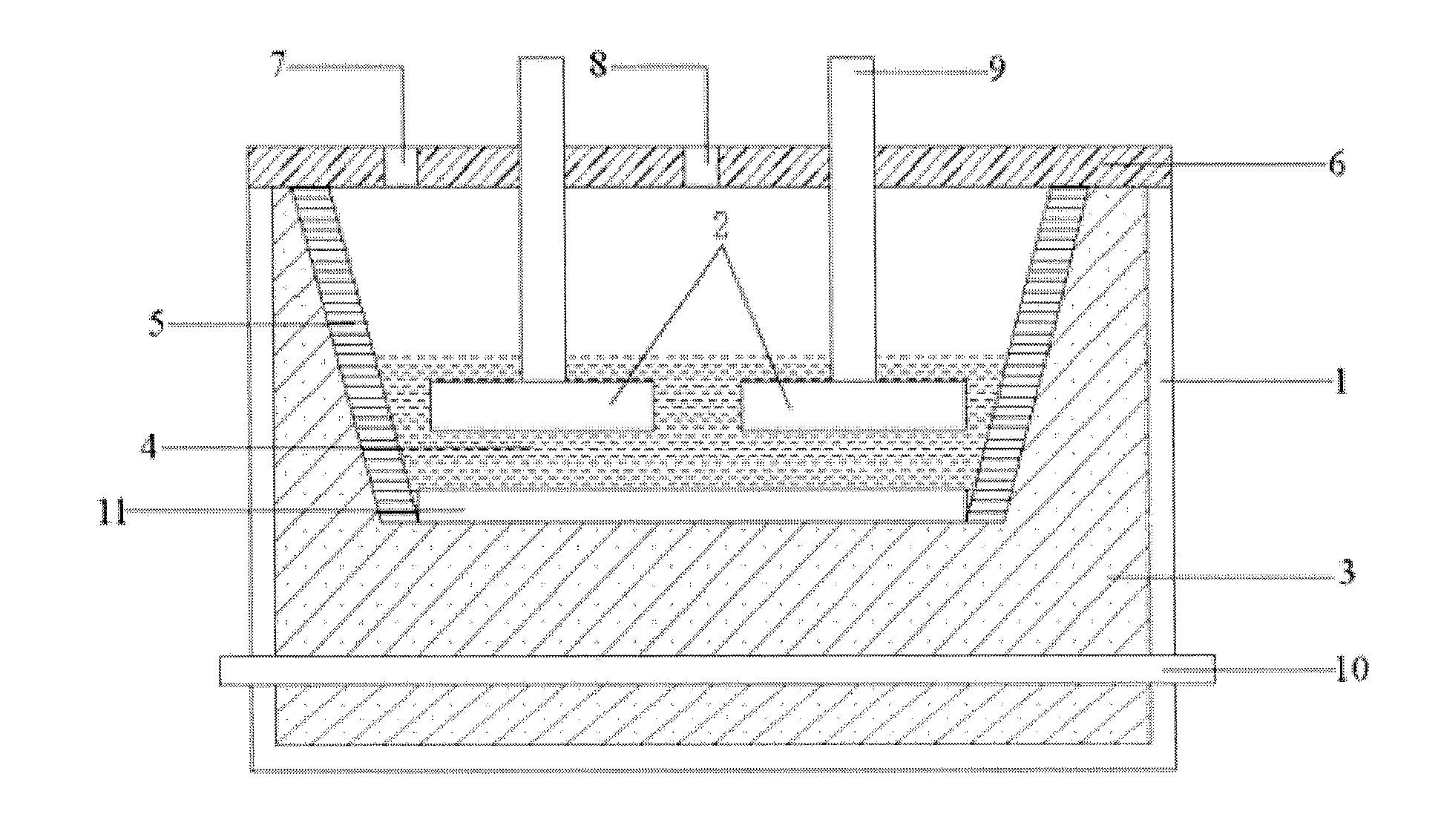

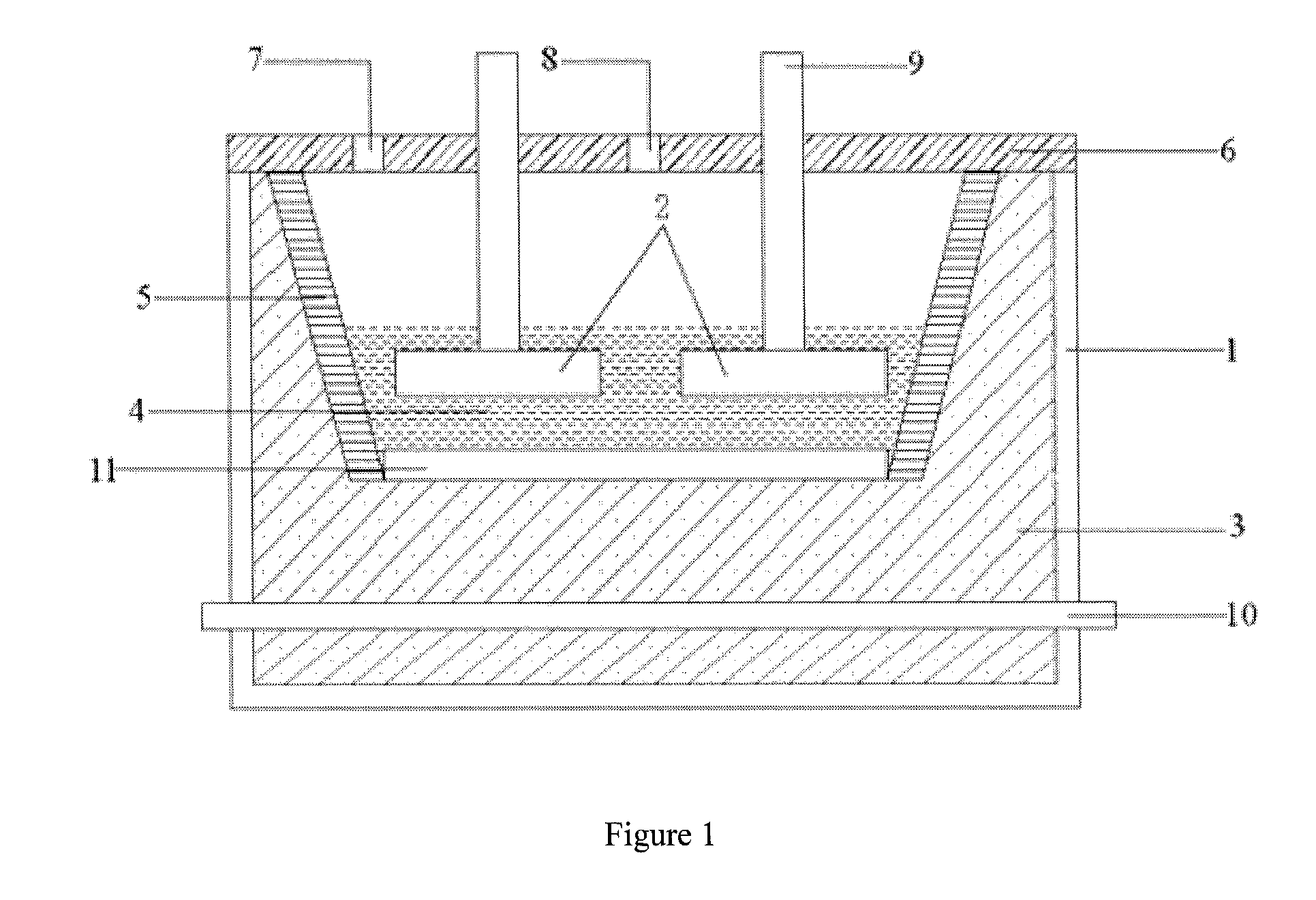

Electrolysis tank used for aluminum electrolysis and electrolysis process using the electrolyzer

InactiveUS20150122664A1Improve conductivityReduce overvoltageIsotope separationOxygenMaterials science

An electrolytic cell for aluminum electrolysis includes a cell body, in which an anode and a cathode are arranged inside the cell body, the cell body is filled with an electrolyte, and at least a part of the anode is immersed in the electrolyte; the anode is arranged above the cell body, the cathode is arranged at the bottom of the electrolytic cell and is covered by aluminum liquid, the electrolyte is located between the anode and the cathode and covers the aluminum liquid; and an insulating layer is arranged on the inner sidewall of the cell body for isolating oxygen or the electrolyte from a carbon block. The anode contains Fe and Cu as primary components; and the electrolyte is composed of 30-38 wt % of NaF, 49-60 wt % of AlF3, 1-5 wt % of LiF, 1-6 wt % of KF and 3-6 wt % of Al2O3, and the molar ratio of NaF to AlF3 is 1.0-1.52.

Owner:INNER MONGOLIA UNITED IND

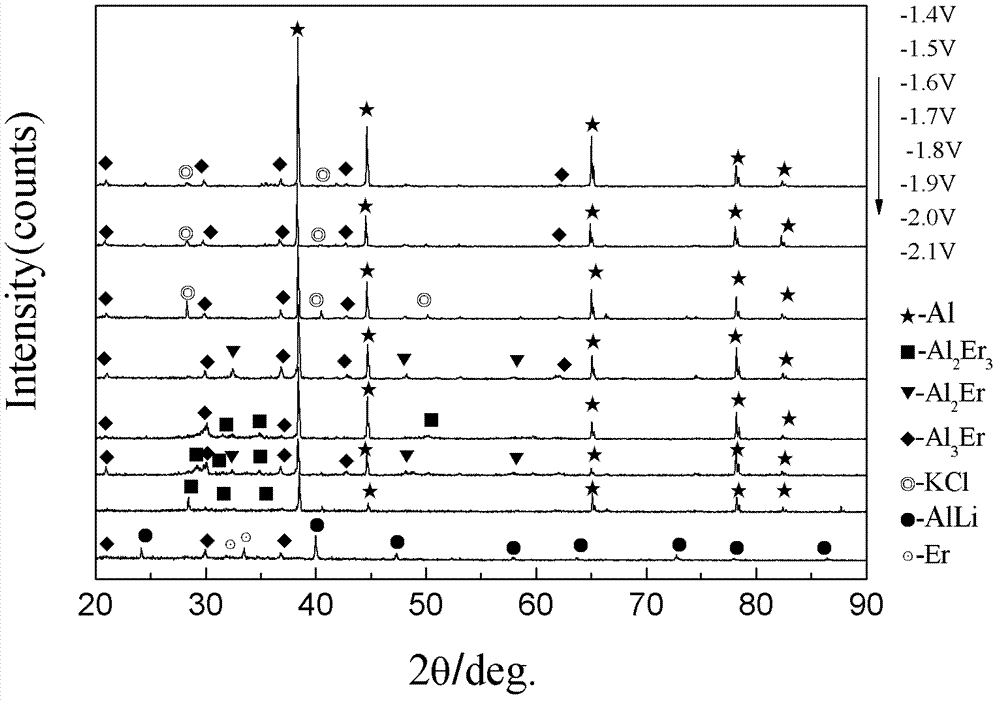

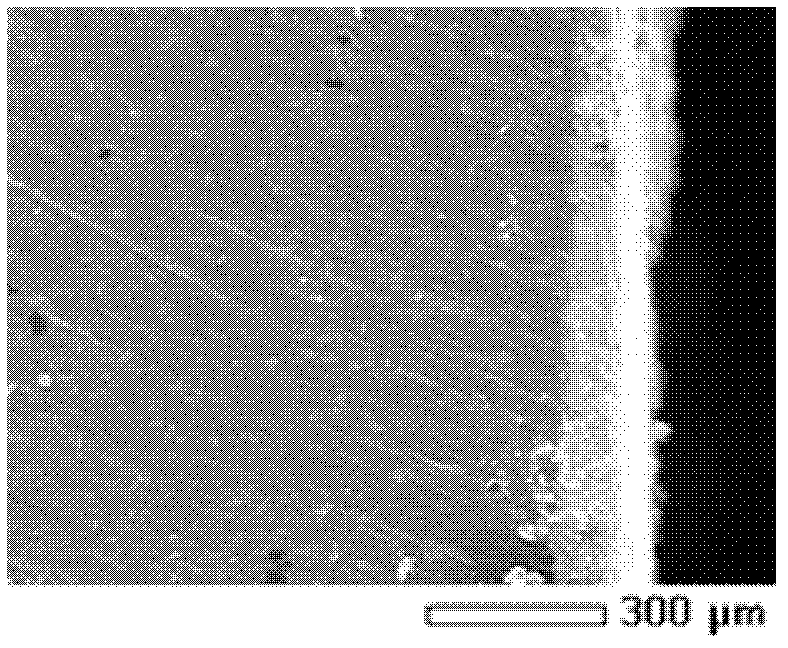

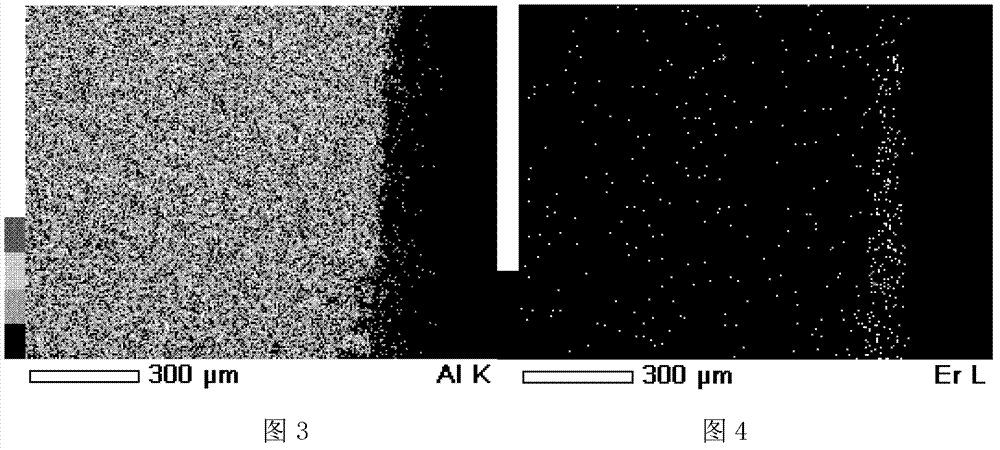

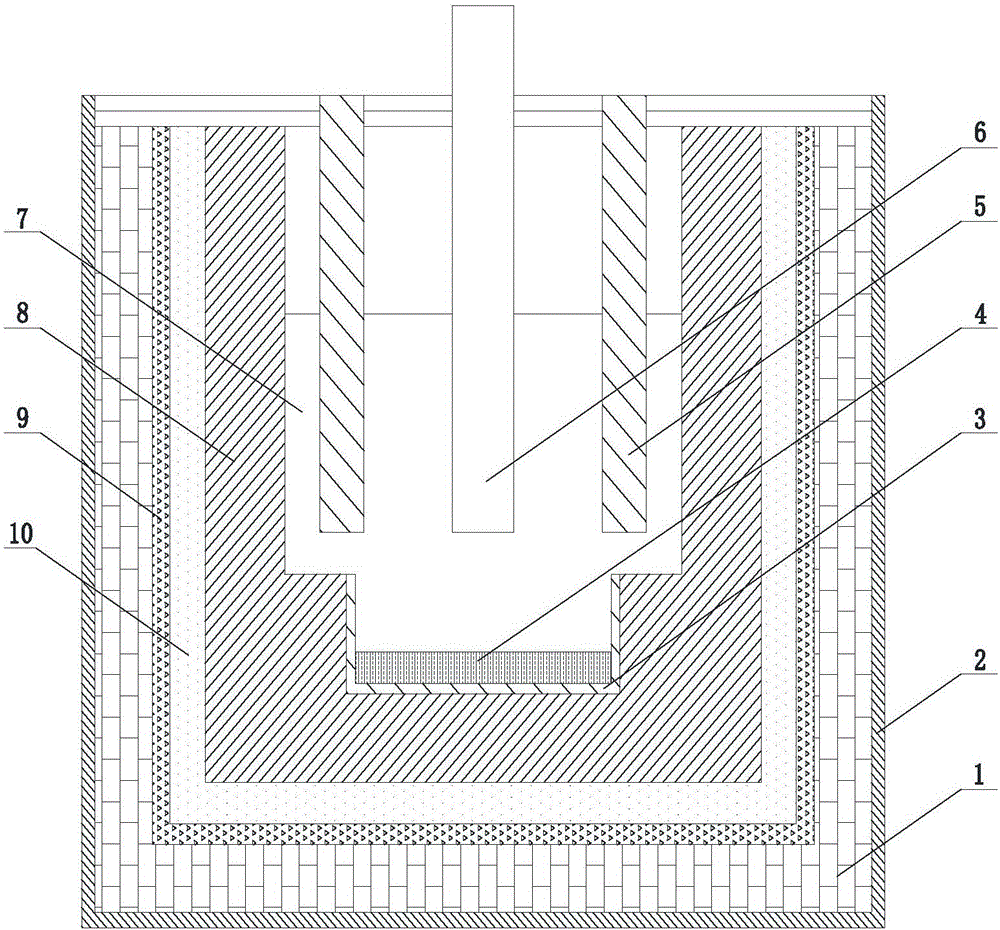

Method for preparing intermetallic aluminum-erbium or aluminum-lithium-erbium alloy by fused salt electrolysis

The invention provides a method for preparing intermetallic aluminum-erbium or aluminum-lithium-erbium alloy by fused salt electrolysis, which is implemented in a way that: in an electrolytic furnace, metallic aluminum is use as a cathode, a graphite rod is used as an anode, and Ag / AgCl is used as a reference electrode; a mixture, which comprises 48.9 wt% of KCl, 48.9% of LiCl and 2.20% of ErCl3,is used as an electrolyte system; electrolysis is carried out at 520 DEG C; and by controlling the cathode potential at -1.4--2.1V, erbium precipitates on the solid-state aluminum cathode and diffuses to the inside of the aluminum cathode to form the aluminum-erbium alloy containing Al3Er, Al2Er and Al2Er3, or aluminum-lithium-erbium alloy containing Al-Li and Al3Er. By controlling the cathode potential, the formed strengthened phase Al3Er has high melting point and stable heat resistance, and can obviously enhance the strength of the aluminum-erbium or aluminum-lithium-erbium alloy. The invention overcomes the actual state that the composition of the aluminum-erbium or aluminum-lithium-erbium alloy prepared by the fused salt electrolysis process can not be controlled.

Owner:HARBIN ENG UNIV

Lanthanum cerium iron alloy for producing rare earth steel and preparation method thereof

The invention discloses a lanthanum-cerium ferroalloy for producing rare earth steel. The content of lanthanum-cerium is 0 to 95wt%, and the balance is iron and unavoidable impurities with a total amount less than 0.5wt%, in which oxygen ≤ 0.01wt%. Carbon ≤ 0.01wt%, phosphorus ≤ 0.01wt%, sulfur ≤ 0.005wt%. The invention also discloses a preparation method of lanthanum-ferrocerium alloy for producing rare earth steel. The lanthanum-ferrocerium alloy prepared by the invention has uniform composition, small segregation, low impurity content, high rare earth yield, low cost and no pollution. It can be applied to rare earth steel with high rare earth yield and significant effect, and is suitable for large-scale industrial production.

Owner:BAOTOU RES INST OF RARE EARTHS +1

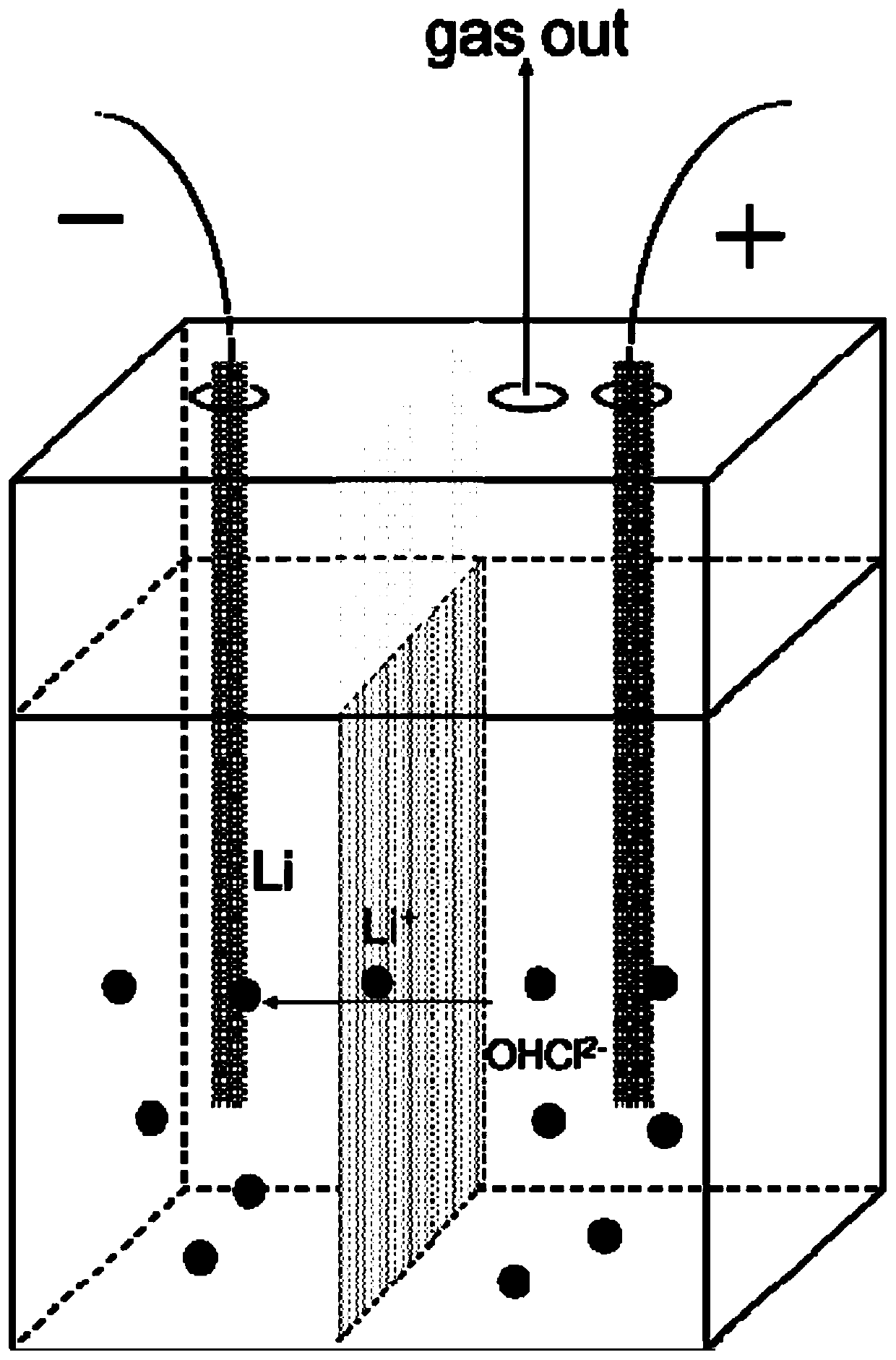

Method for preparing lithium metal through low-temperature melting electrolysis

InactiveCN111088506ALow melting pointLower the electrolysis temperatureDiaphragmsElectrodesMetallic lithiumMolten state

The invention provides a method for preparing lithium metal through low-temperature melting electrolysis. According to the method, the temperature of molten salt (from 450 DEG C to 350 DEG C or below)can be can greatly lowered, the corrosion of chlorine to device materials can be reduced, and therefore the lithium metal is efficiently prepared. The method for preparing the metal lithium through electrolysis comprises the steps that a mixture of LiX (X=Cl, Br and I) and LiOH is heated to be in a 350-DEG C molten state, low-melting-point Li2 (OH) nX2-n is prepared, Li2 (OH) nX2-n serves as an electrolysis raw material, and the metal lithium is prepared through electrolysis in a molten salt state.

Owner:BEIJING UNIV OF CHEM TECH

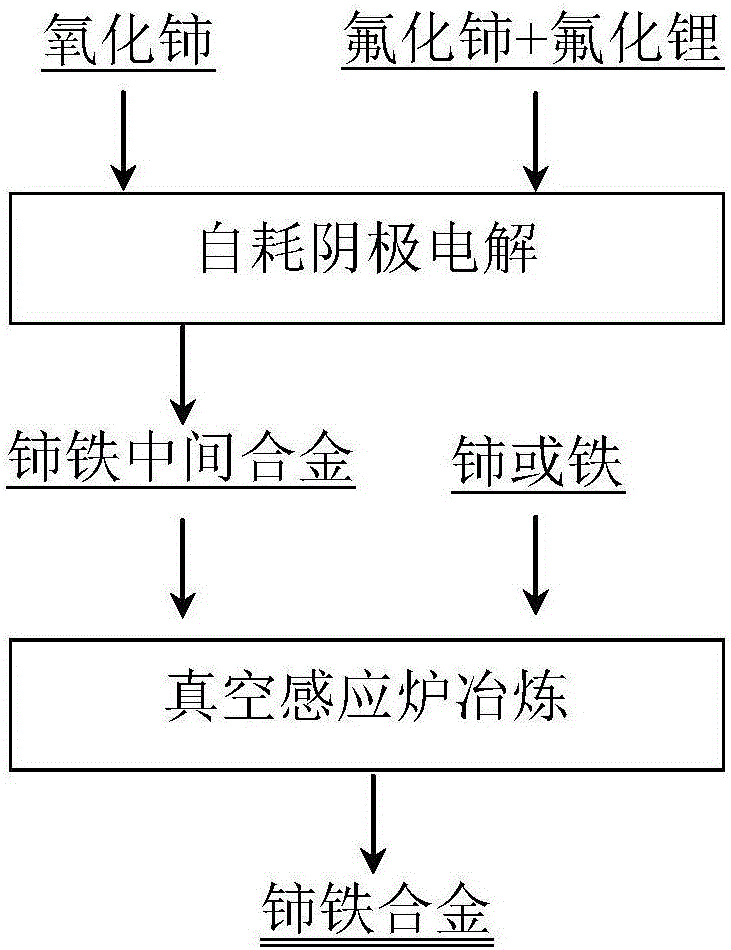

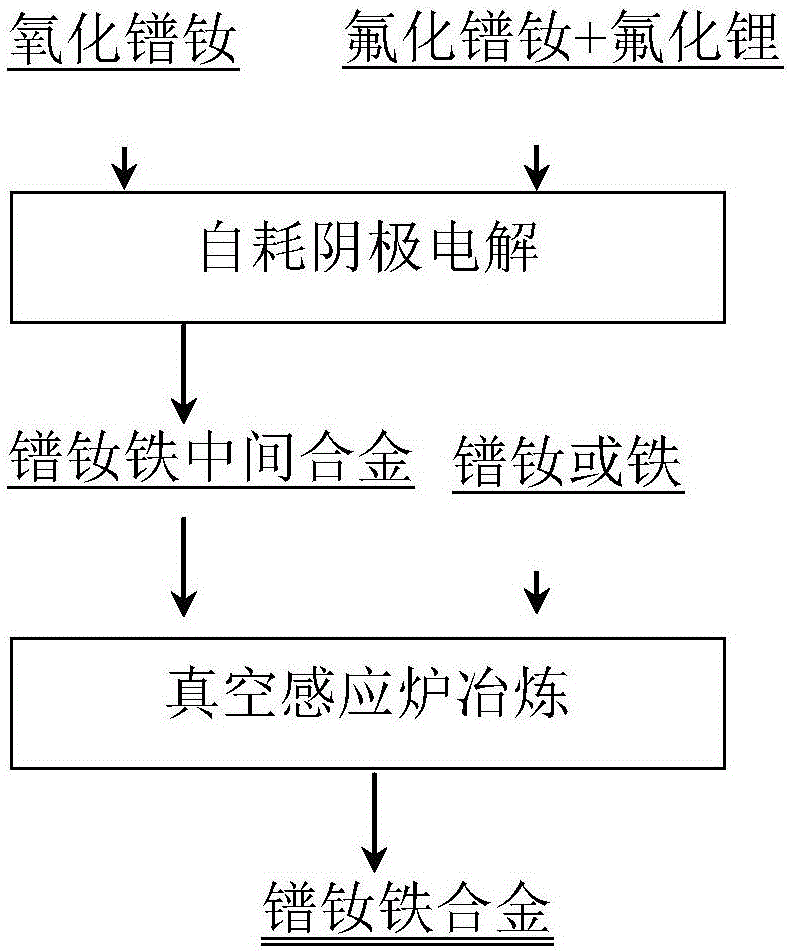

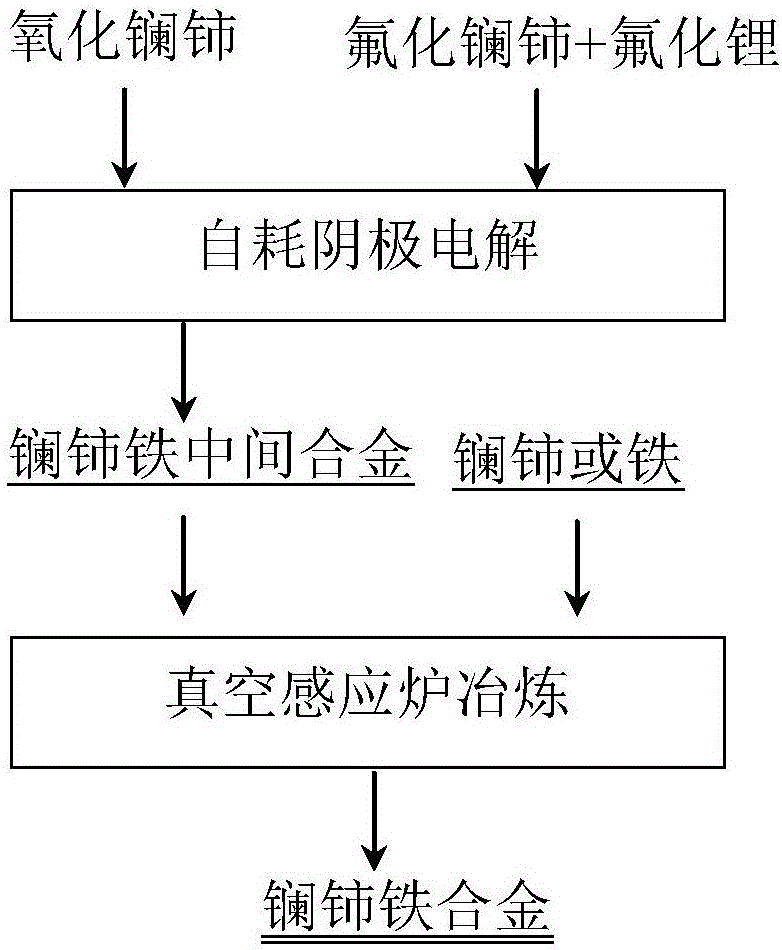

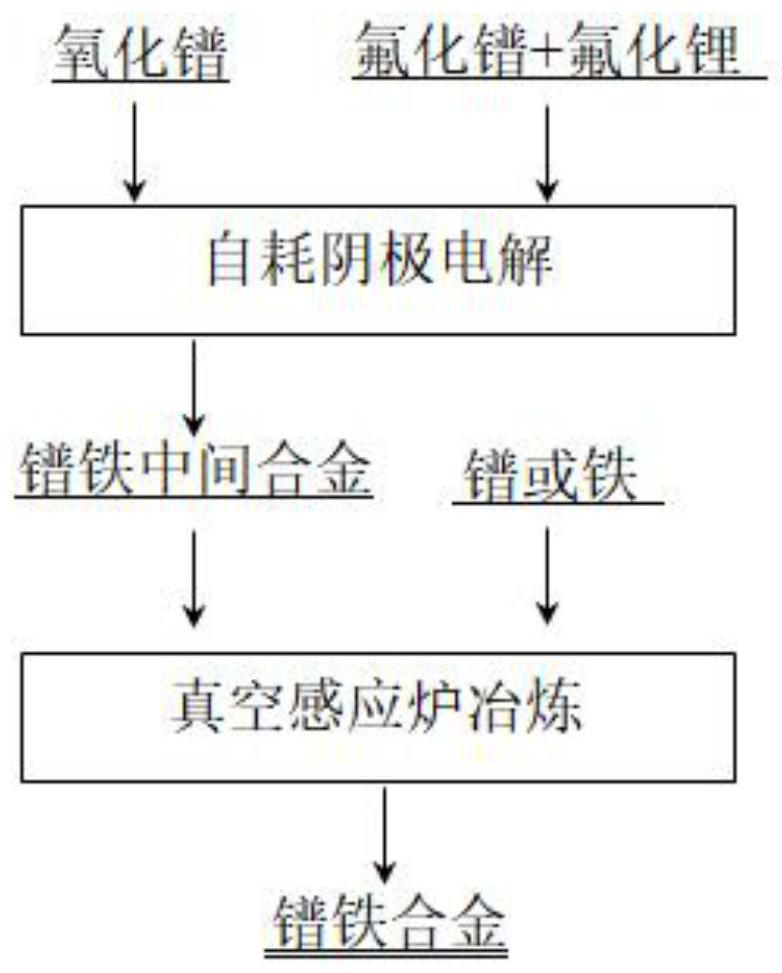

Preparation method of praseodymium-iron alloy

The invention discloses a preparation method of a praseodymium-iron alloy. The preparation method comprises the following steps: in equipment for electrolyzing a praseodymium-iron intermediate alloy, under a fluoride molten salt electrolyte system of praseodymium fluoride and lithium fluoride, direct current is introduced to electrolyze praseodymium oxide serving as an electrolysis raw material to obtain the praseodymium-iron intermediate alloy; and the praseodymium-iron intermediate alloy and iron serve as raw materials, the praseodymium-iron alloy is prepared through a melting and blending method, and the melting and blending process is carried out under the vacuum condition. According to the preparation method of the praseodymium-iron alloy, the praseodymium-iron alloy obtained after the praseodymium-iron intermediate alloy obtained through molten salt electrolysis is subjected to vacuum melting and blending is accurate in component control, due to the fact that melting is conducted under vacuum, the burning loss of rare earth is small, the yield is high, the praseodymium-iron alloy is uniform in component, small in segregation and low in impurity content, and when the praseodymium-iron alloy is applied to rare earth steel, the yield of rare earth is high, and the effect is remarkable.

Owner:BAOTOU RES INST OF RARE EARTHS +1

Method for improving alumina dissolution rate in aluminium electrolysis process

Belonging to the technical field of aluminium electrolysis, the invention specifically relates to a method for improving an alumina dissolution rate in an aluminium electrolysis process. The key points lie in that, fluorinated alumina, high igloss alumina or additive-containing alumina is added into an electrolyzer as an electrolysis raw material, and hydrogen fluoride, water vapour or carbon dioxide that are escaped from an alumina dissolution process can play a stirring role, so that the dissolution rate of alumina in the electrolyzer can be greatly enhanced. With extremely simple process and low cost, the method provided in the invention can effectively improve the dissolution rate of alumina, enhance the current efficiency of the electrolysis process and reduce the electrolysis temperature, thus reducing industry energy consumption and saving energy sources, as well as being able to be widely promoted and applied in industrial production.

Owner:NORTHEASTERN UNIV LIAONING

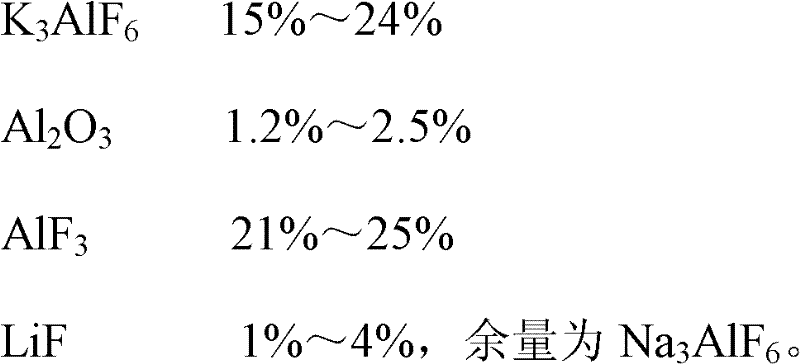

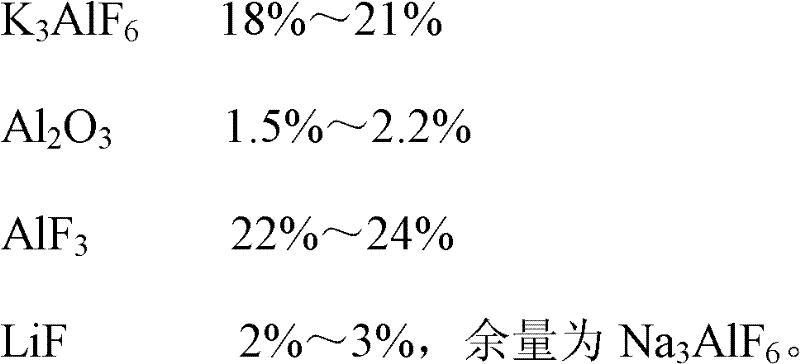

Low-temperature aluminum electrolysis process and electrolyte

InactiveCN101713082BReduced ability to dissolve aluminaIncreased ability to dissolve aluminaAnode effectHeat losses

The invention relates to a low-temperature aluminum electrolysis process and electrolyte. The electrolyte consists of Na3AlF6, K3AlF6, Al2O3, AlF3 and LiF; and the electrolysis temperature is between 850 and 910 DEG C, the coefficient of an anode effect is smaller than 0.1 time / tank day, and the anode current density is 0.5 to 1.2 A / cm2. The primary crystal temperature of the electrolyte adoptingthe component formula is low and changes comparatively slowly along with the changes of the components in favor of solving the problems of uneven tank bottom current, unstable tank voltage and the like caused by sharp raising of the primary crystal temperature of a melt and cathode crusting due to directional migration of Na+ and cathode enrichment. Besides, The K3AlF6 in the electrolyte can effectively increase the capability of the melt for dissolving the aluminum oxide, and solve the problem of deposition of the aluminum oxide at the bottom of a tank. Because the electrolysis temperature is lower, the heat loss of an electrolytic tank can be greatly reduced, and the energy-saving current efficiency is high. The low-temperature aluminum electrolysis process is simple and is easy to operate, the electrolyte has reasonable components, and the low-temperature aluminum electrolysis process can effectively reduce the aluminum electrolysis temperature, inhibit the cathode crusting in the process of aluminum electrolysis, improve the current efficiency of the aluminum electrolysis and reduce the energy consumption of the aluminum electrolysis, is suitable for industrial production, andcan replace the conventional aluminum electrolysis process.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com