Aluminum-lithium-samarium alloy and fused salt electrolysis preparation method thereof

A molten salt electrolysis and alloy technology, applied in the field of alloys, can solve the problems of harsh preparation conditions and high equipment requirements, and achieve the effects of reducing production costs, simple process and shortening production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

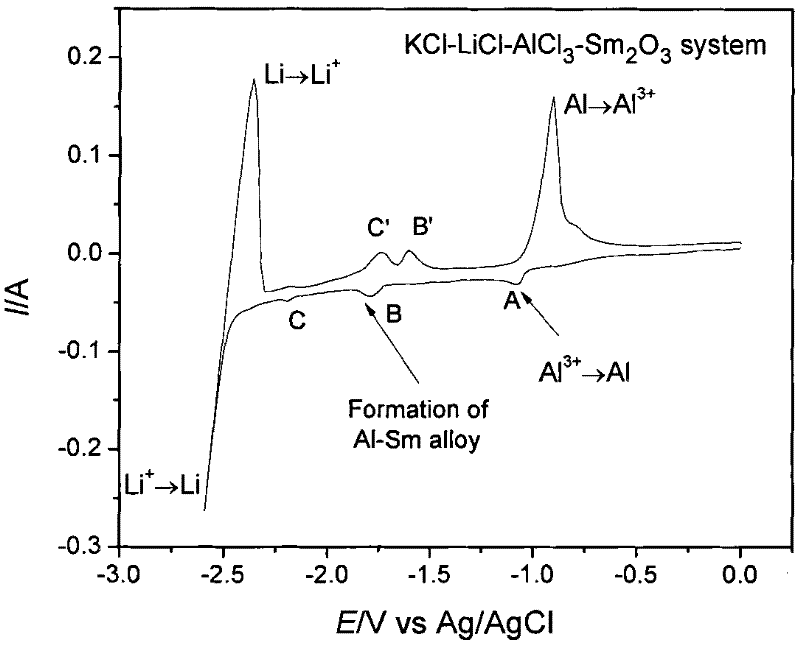

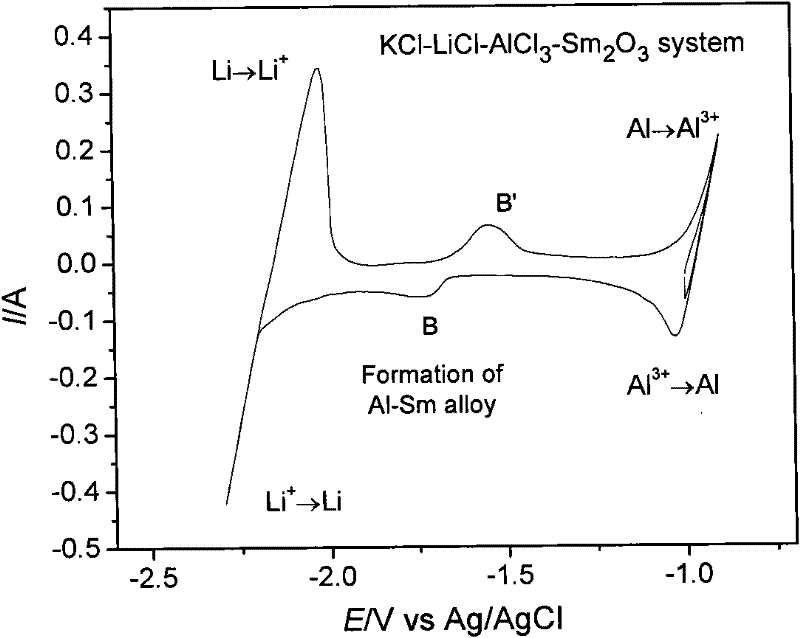

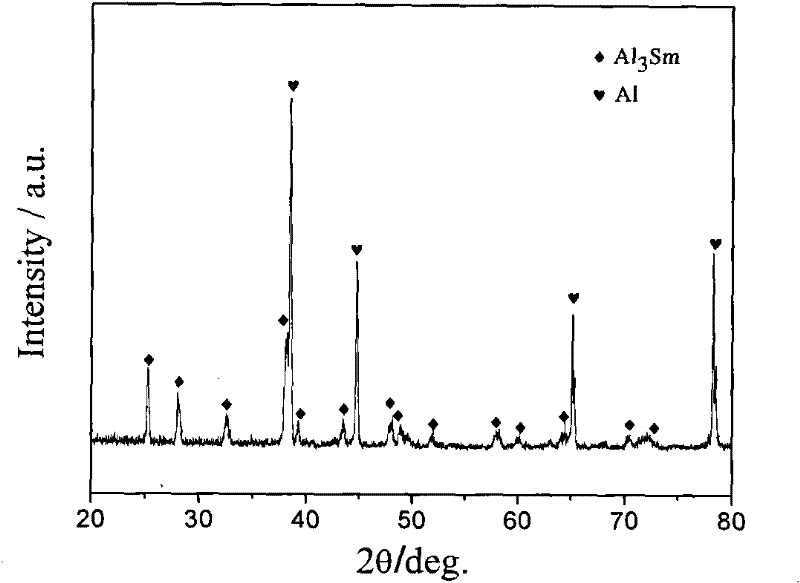

Method used

Image

Examples

Embodiment 1

[0028] Example 1: In the electrolytic furnace, using LiCl+KCl as the electrolyte system, heated to 630 ° C to melt, and Sm 2 o 3 Powder and AlCl 3After mixing evenly, press it into tablets, and add it to the molten salt in the form of granules at one time. The mass ratio of each electrolyte in the system is AlCl 3 :LiCl:KCl=6.2%:46.9%:46.9%, Sm 2 o 3 The amount of addition is 1% of the weight of molten salt, with inert metal molybdenum (Mo) as the cathode, graphite as the anode, the electrolysis temperature is 630 ° C, and the cathode current density is 6.4A / cm 2 , anode current density 0.5A / cm 2 , after 120 minutes of electrolysis, the Al-Li-Sm alloy was deposited near the cathode of the molten salt electrolytic cell. The contents of aluminum, lithium, and samarium in the alloy are 20.9%, 68.2%, and 10.9%, respectively.

Embodiment 2

[0029] Example 2: In the electrolytic furnace, use LiCl+KCl as the electrolyte system, heat to 630 ° C to melt, and Sm 2 o 3 Powder and AlCl 3 After mixing evenly, press it into tablets, and add it to the molten salt in the form of granules at one time. The mass ratio of each electrolyte in the system is AlCl 3 :LiCl:KCl=7.2%:46.4%:46.4%, Sm 2 o 3 The addition amount is 1% of the molten salt weight, with the inert metal molybdenum (Mo) as the cathode, graphite as the anode, the electrolysis temperature is 660 ° C, and the cathode current density is 6.4A / cm 2 , anode current density 0.5A / cm 2 , after 120 minutes of electrolysis, the Al-Li-Sm alloy was deposited near the cathode of the molten salt electrolytic cell. The contents of aluminum, lithium, and samarium in the alloy are 26.8%, 31.6%, and 41.6%, respectively.

Embodiment 3

[0030] Example 3: In the electrolytic furnace, using LiCl+KCl as the electrolyte system, heated to 630 ° C to melt, the Sm 2 o 3 Powder and AlCl 3 After mixing evenly, press it into tablets, and add it to the molten salt in the form of granules at one time. The mass ratio of each electrolyte in the system is AlCl 3 : LiCl: KCl=9.0%: 45.5%: 45.5%, Sm 2 o 3 The addition amount is 1% of the molten salt weight, with the inert metal molybdenum (Mo) as the cathode, graphite as the anode, the electrolysis temperature is 720 ° C, and the cathode current density is 6.4A / cm 2 , anode current density 0.5A / cm 2 After 120 minutes of electrolysis, an Al-Li-Sm alloy was deposited near the cathode of the molten salt electrolytic cell. The contents of aluminum, lithium, and samarium in the alloy were 71.4%, 2.4%, and 26.2%, respectively. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com