Method for preparing lithium metal through low-temperature melting electrolysis

A molten salt electrolysis, metal lithium technology, applied in the direction of electrolysis components, electrolysis process, electrodes, etc., can solve the problems of large environmental pollution, high preparation cost, large energy consumption, etc., and achieve energy saving, power reduction, and electrolysis voltage reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

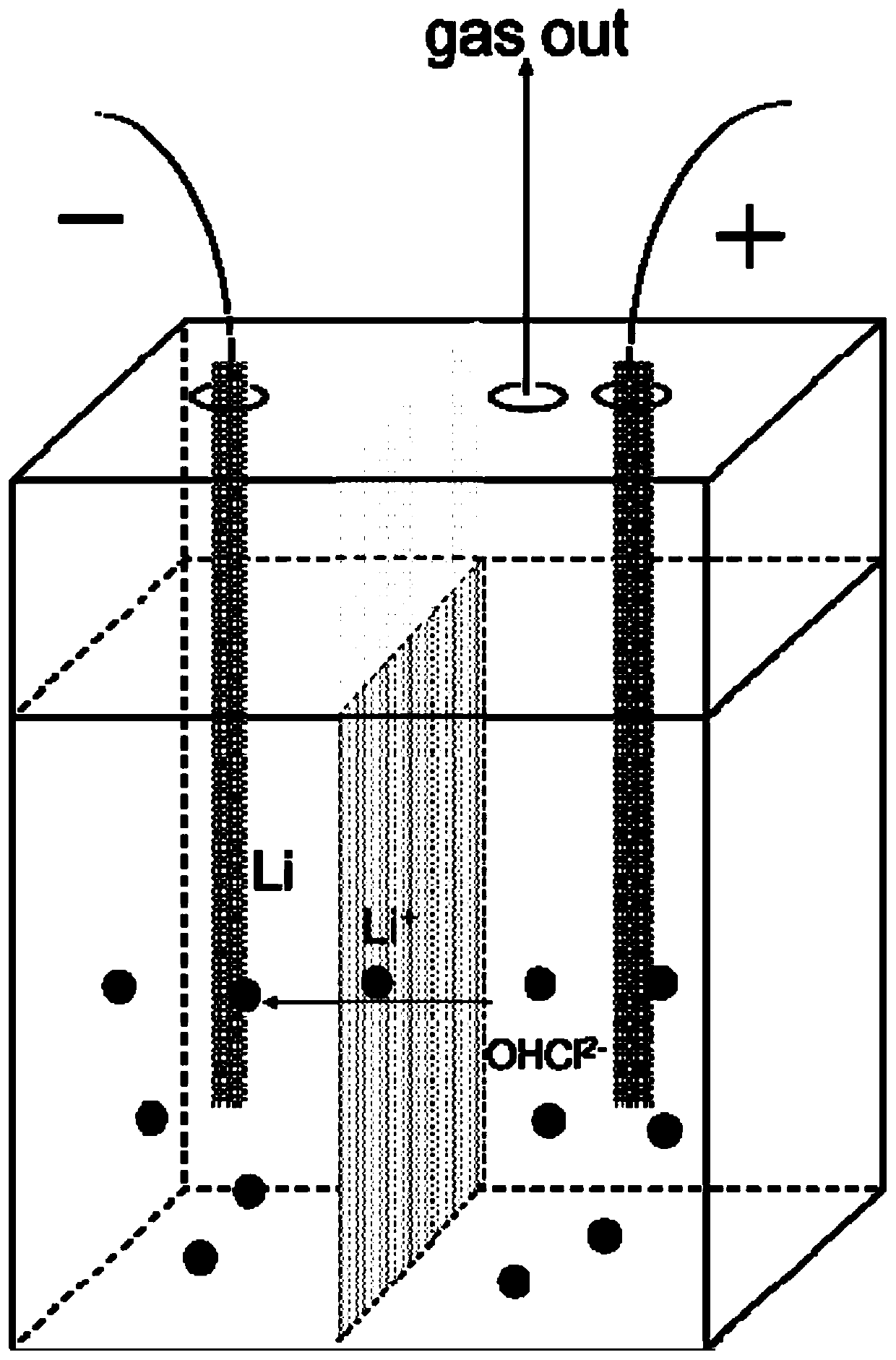

[0027] The present invention forms Li by electrolytic melting lithium chloride and lithium hydroxide 2 OHCl is used as the raw material for electrolysis, the positive side (OHCl) 2- It is oxidized to generate oxygen and hydrogen chloride gas, and lithium ions on the negative electrode side are reduced and deposited on the surface of the negative electrode current collector, thereby obtaining high-purity metallic lithium.

[0028] In the present invention, both the negative electrode chamber and the positive electrode chamber are Li 2 OHCl molten salt, the positive and negative chambers in the electrolytic cell are separated by a porous diaphragm or lithium-ion ceramic electrolyte to prevent the oxygen and hydrogen chloride gas generated by the positive electrode from contacting and re-reacting with the negative metal lithium. At the same time, a gas absorption device is connected to the electrolyzer system, and the generated oxygen and hydrogen chloride gas are recovered and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com