Large-scale aluminium electrolysis pre-baking tank

A technology of aluminum electrolysis and pre-baking tank, which is applied in the field of electrolytic tank structure, which can solve the problems of unbalanced negative pressure, difficulty in forming the furnace side, and large air leakage area, so as to eliminate gaps, uniform negative pressure and improve gas collection efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

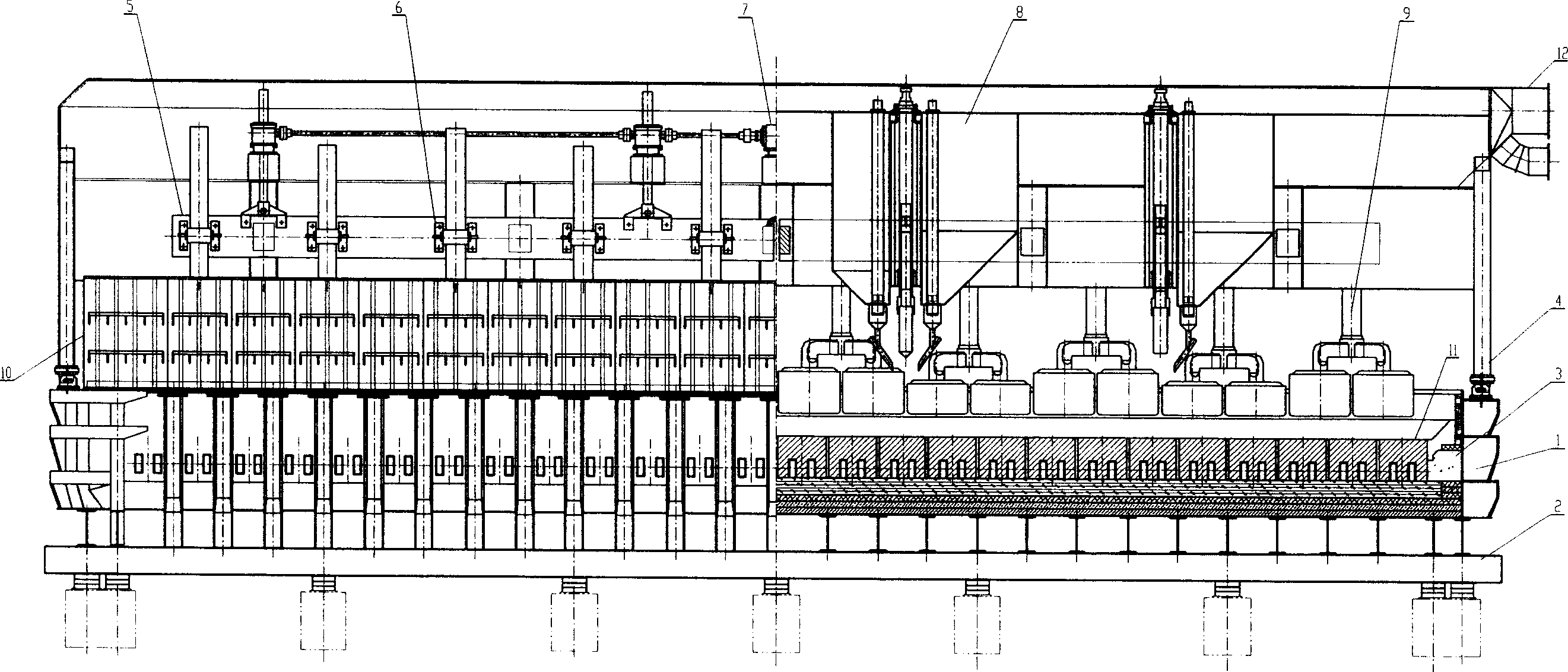

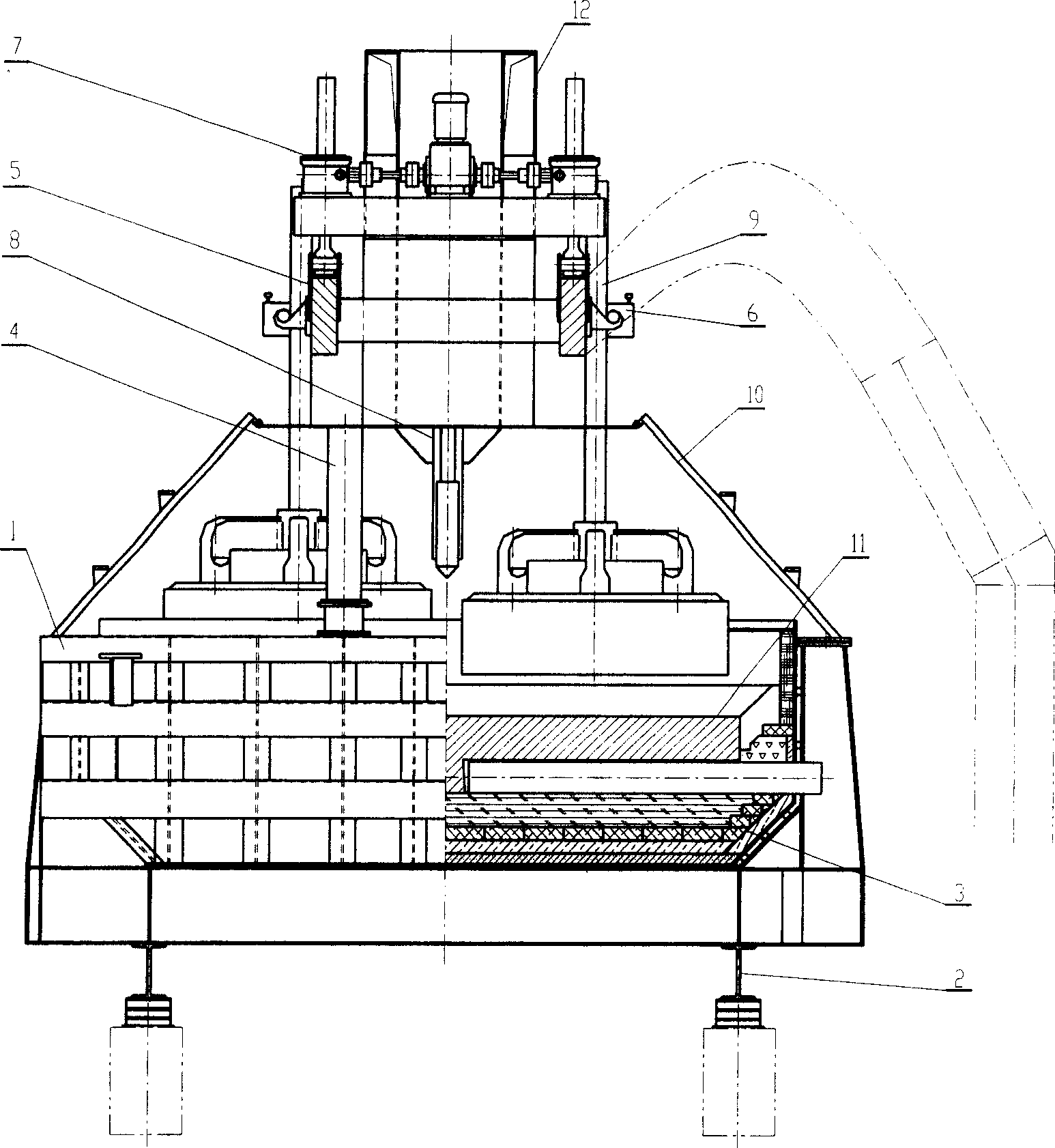

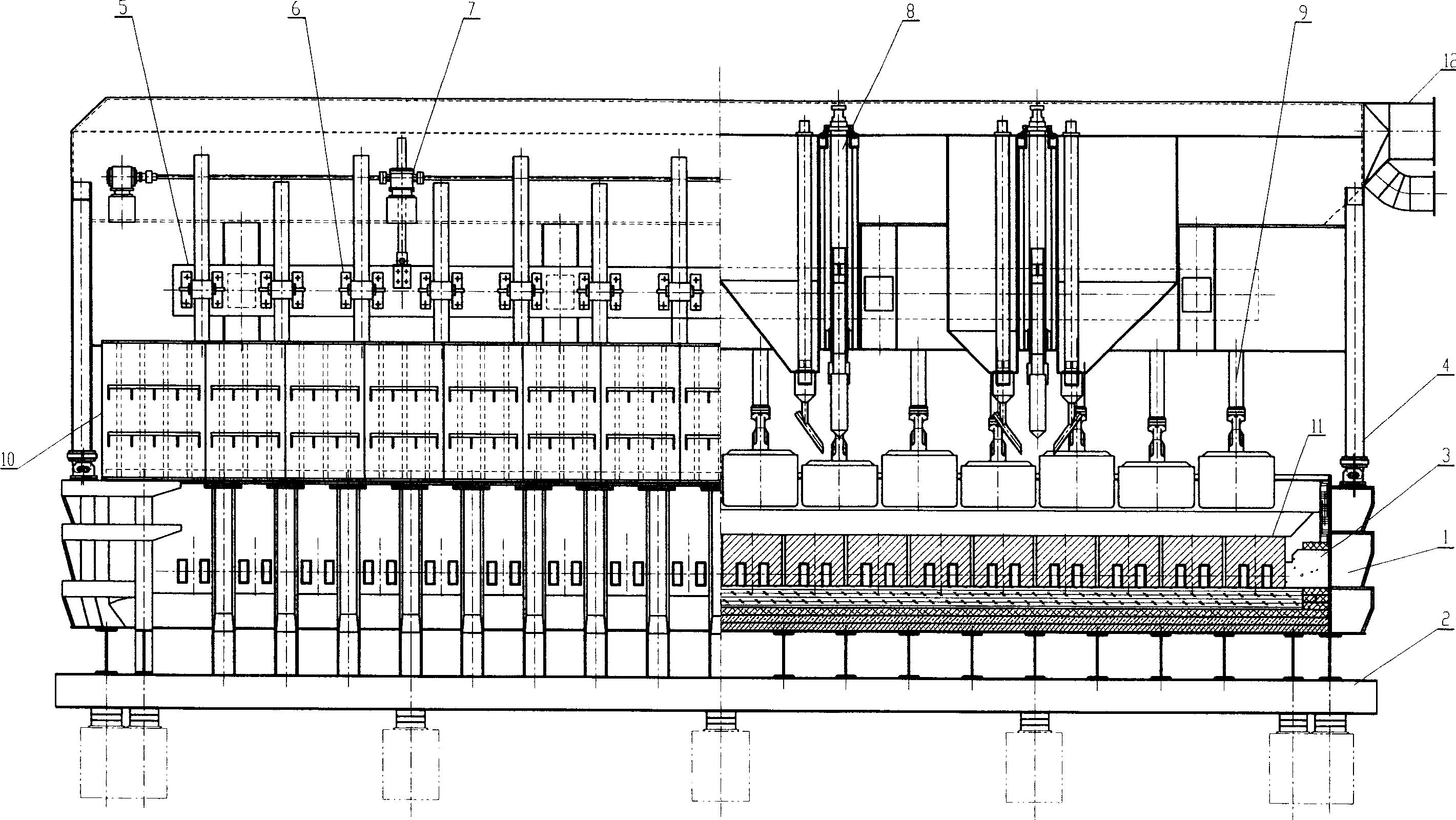

[0032] Below in conjunction with accompanying drawing and embodiment, content of the present invention is further described and supplemented:

[0033] The upper structure of the electrolytic cell of the present invention is composed of an anode carbon block group 9, an anode bus bar 5, a shelling and feeding device 8, an anode lifting mechanism 7, a column girder 4, and a cell airtight exhaust system 10 and 12.

[0034] like figure 1 , 2 As shown, the following uses a 300KA electrolytic cell as an example to describe in detail. In fact, this design scheme can also be applied to large-scale aluminum electrolytic prebaked cells of 280KA to 330KA.

[0035] 1. The upper structure of the electrolytic cell:

[0036] 1) Anode carbon block group 9

[0037] The anode carbon block group consists of aluminum conductive rods, steel claws and anode carbon blocks. The double anode form is adopted, which is characterized in that two anode carbon blocks are assembled together by an alumin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com