Double-arm multi-head placement machine

A placement machine and multi-head technology, which is applied in the manufacture of printed circuits, electrical components, printed circuits, etc., can solve problems such as inconvenience, and achieve the effects of large design, increased suction speed, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0025] Relevant definitions involved in this article: X direction is the direction of PCB transmission, Y direction is the direction perpendicular to the PCB transmission direction, Z direction is the direction perpendicular to the XY plane, and R direction is the rotation direction of the patch axis.

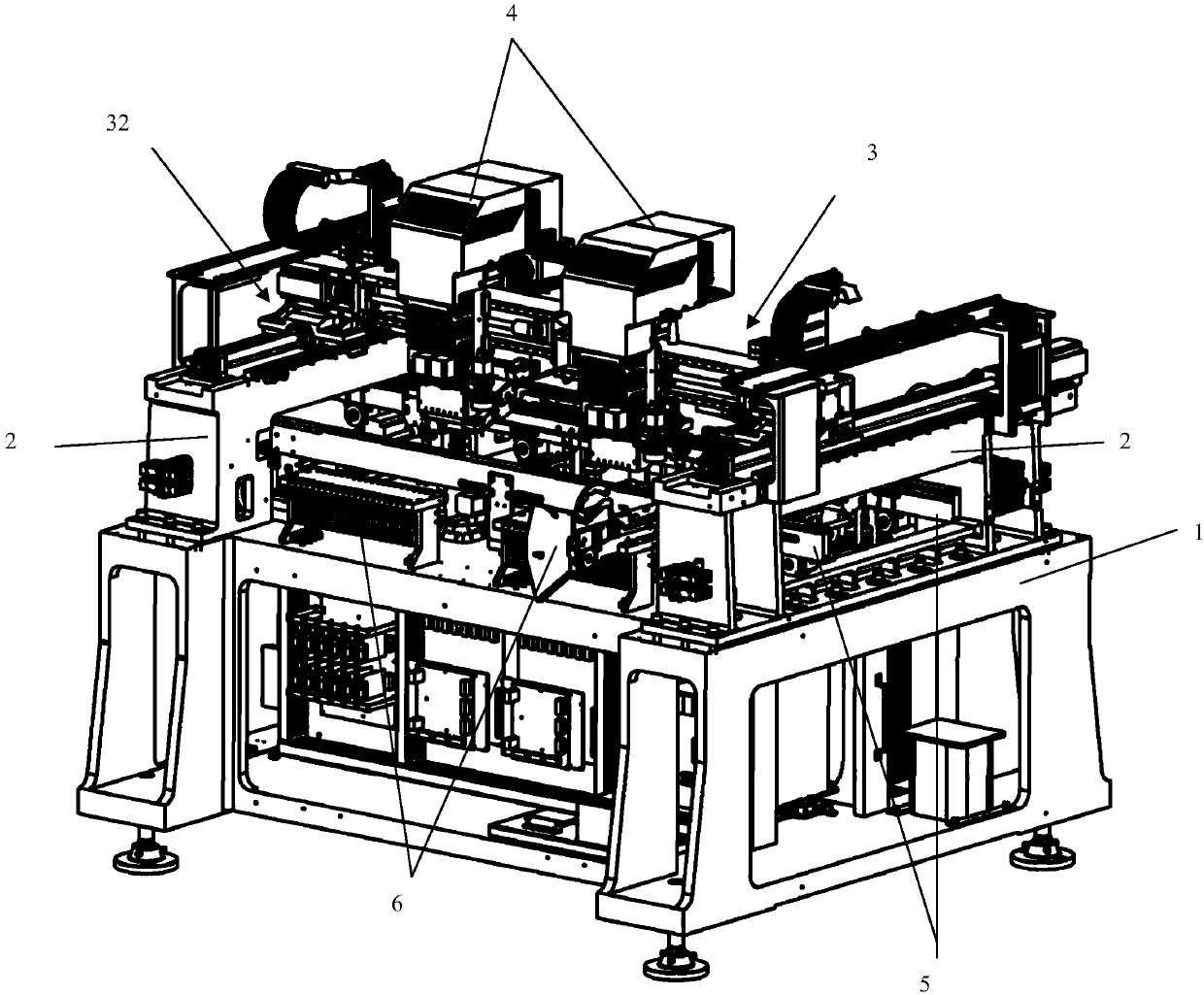

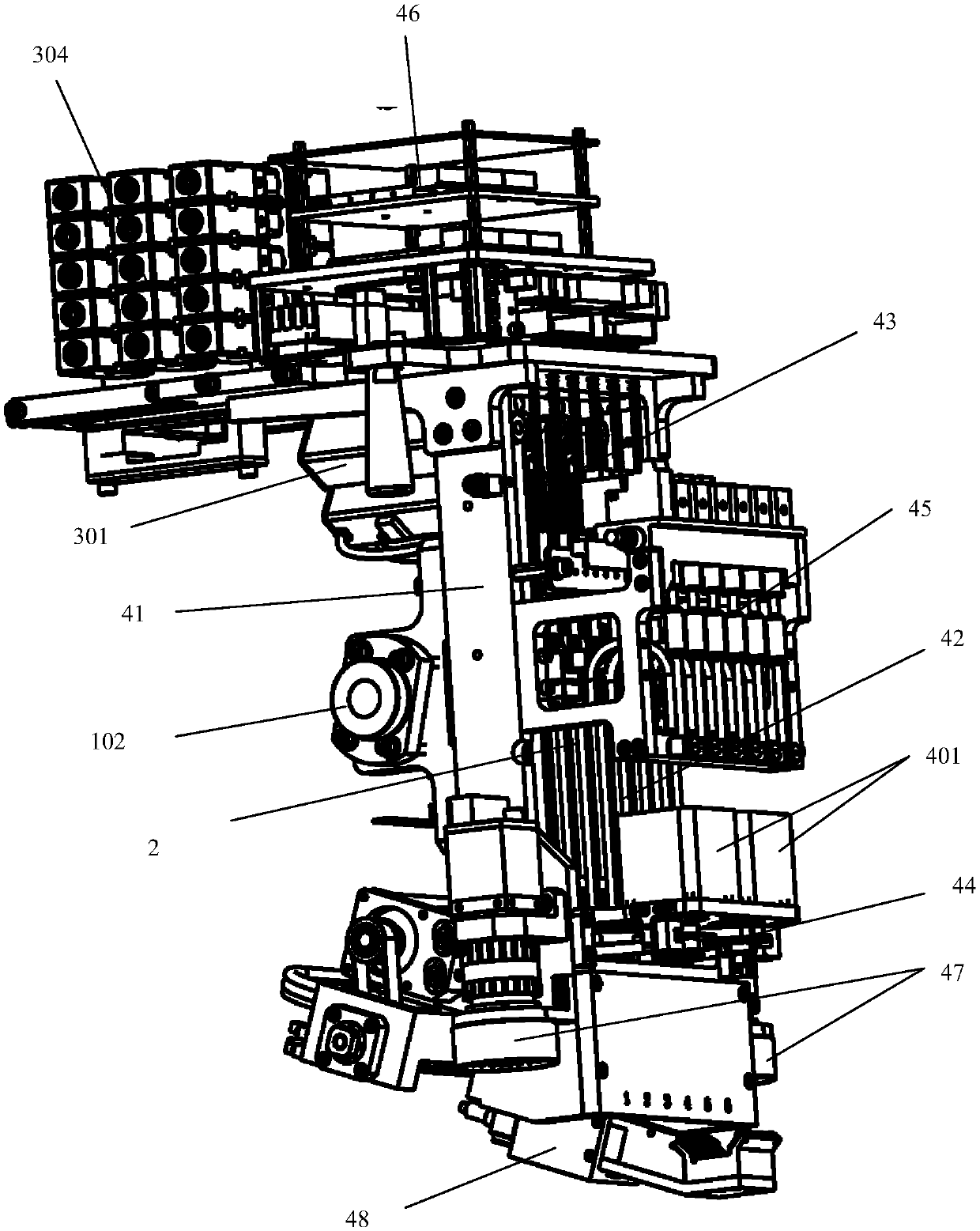

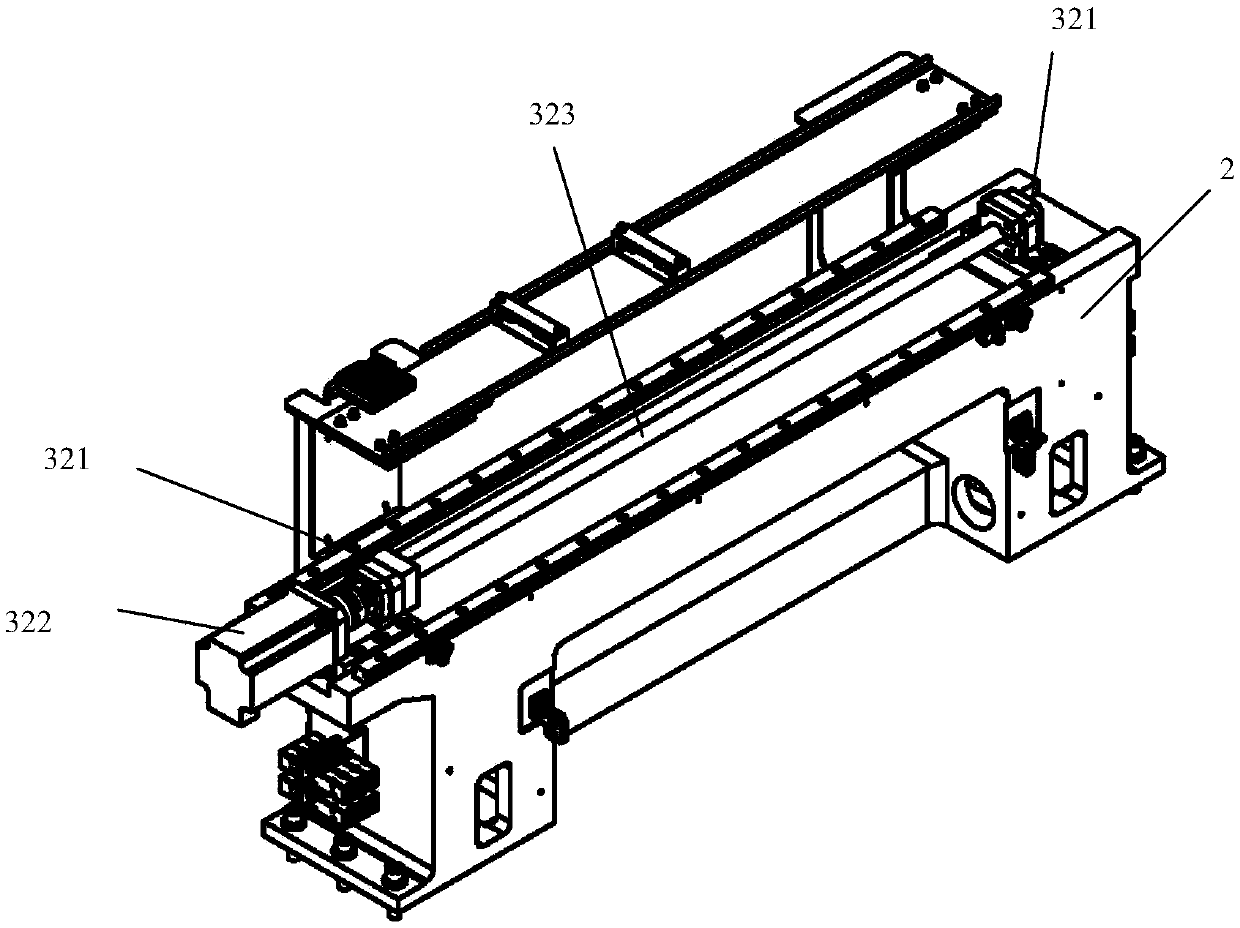

[0026] Such as Figure 1-6 As shown, the dual-arm multi-head placement machine includes two sets of single-arm multi-head placement devices, two Y-axis positioning arches 2, a feeding device 5 and a board feeding device 6, and the two Y-axis positioning arches 2 are respectively installed on The main frame 1 of the inlet and outlet of the board feeding device 6 is perpendicular to the direction of board feeding. Move; the single-arm multi-head placement device 3 is composed of a translation base assembly 32 moving in the Y direction, a moving arm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com