Patents

Literature

32results about How to "Ease of noise reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

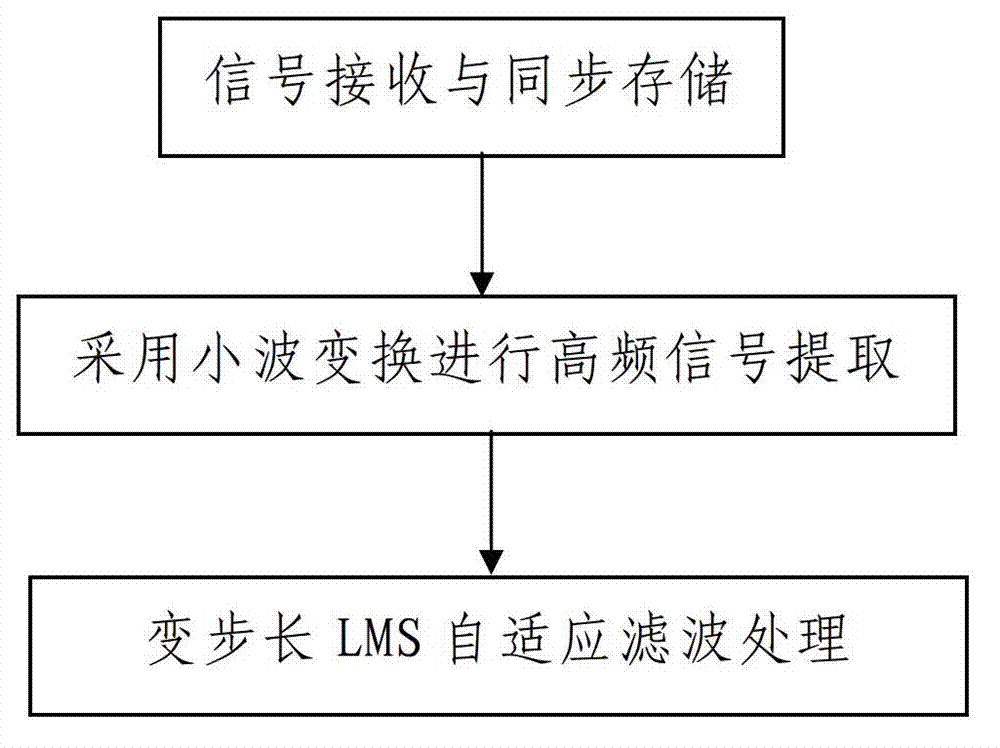

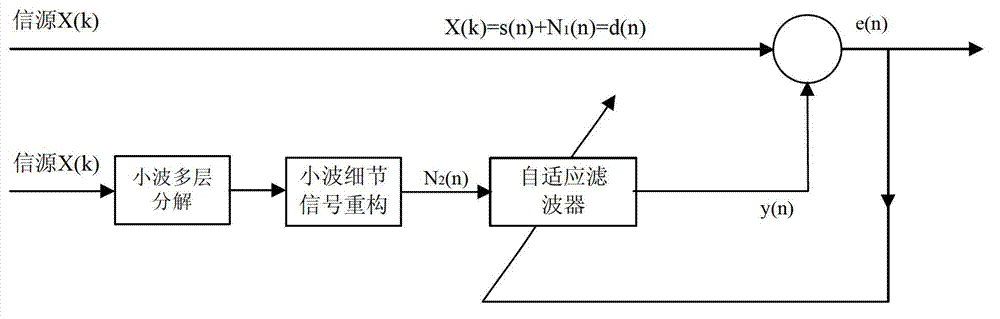

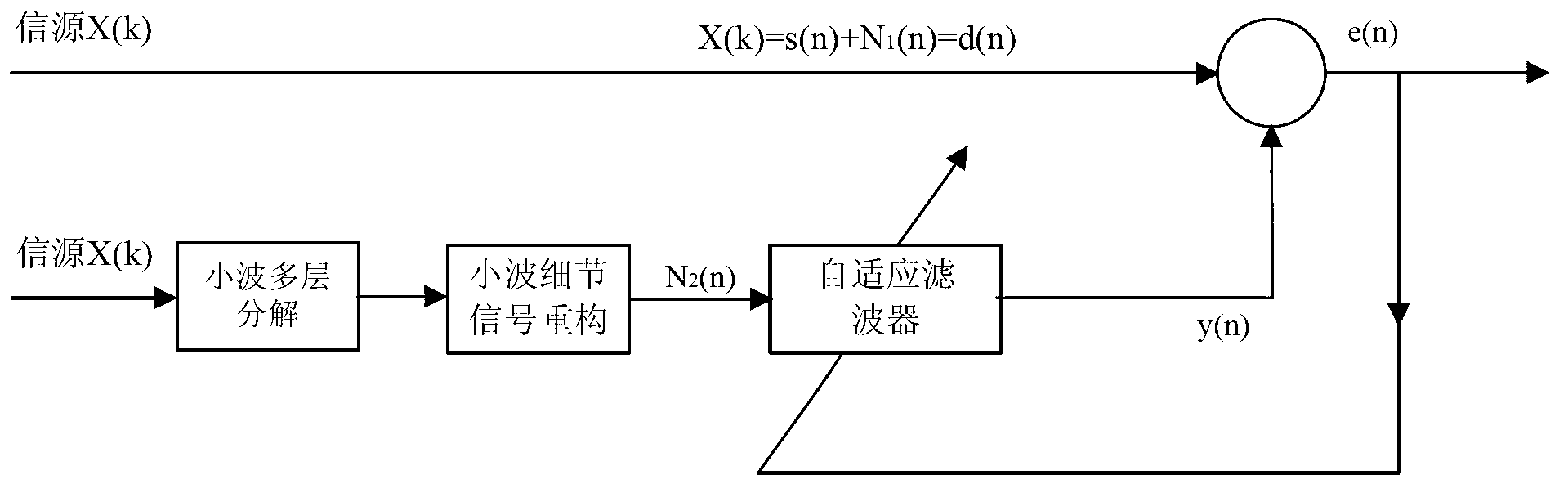

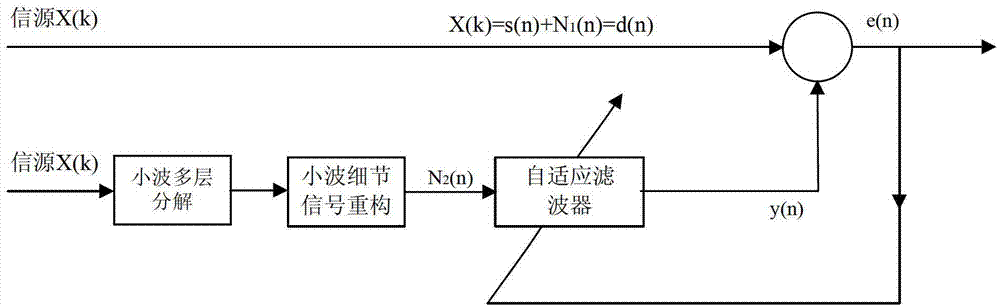

Wavelet transform and variable-step-size LMS (least mean square) adaptive filtering based signal denoising method

ActiveCN102832908ASimple stepsReasonable designAdaptive networkDigital technique networkPattern recognitionAdaptive filter

The invention discloses a wavelet transform and variable-step-size LMS (least mean square) adaptive filtering based signal denoising method which comprises the following steps that: 1, signal receiving and synchronous storage: a data processor synchronously stores received signals into a data memory so as to obtain a sampling sequence X (k) which is a one-dimensional signal; 2, high-frequency signal extraction: the data processor carries out wavelet transform on the currently received one-dimensional signal X (k) and extracts high-frequency signals; and 3, LMS adaptive filtering: the data processor invokes the high-frequency signals extracted by an LMS adaptive filter to carry out LMS error calculation so as to obtain output signals subjected to filtering, and carries out adjustment on the parameters of the filter according to error signals, so that the output signals tend to interference signals. The method disclosed by the invention is simple in steps, reasonable in design, convenient to realize, and good in denoising effect; and the denoising process is performed through the combination of wavelet transform and variable-step-size LMS adaptive filtering, so that the filtering effect and the tracking speed are effectively increased.

Owner:XIAN UNIV OF SCI & TECH

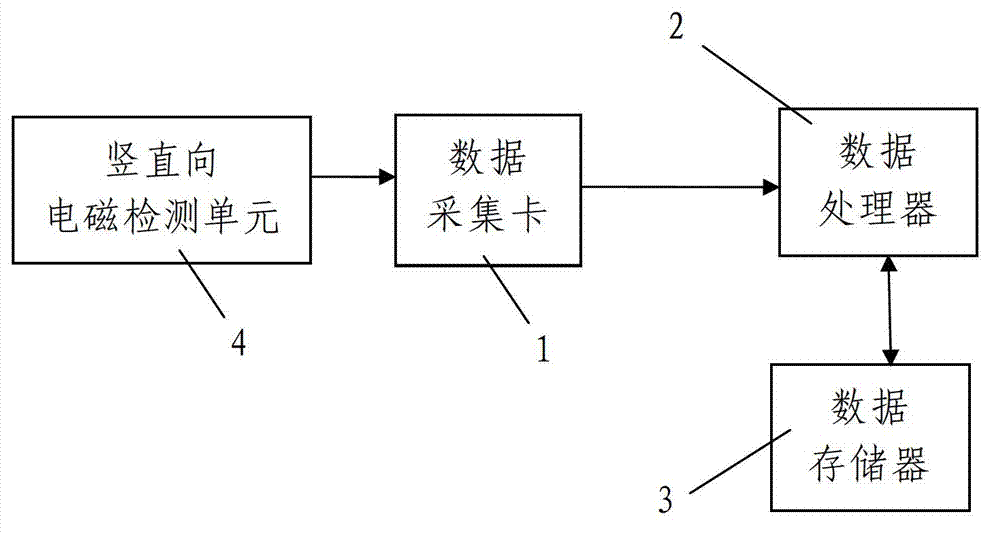

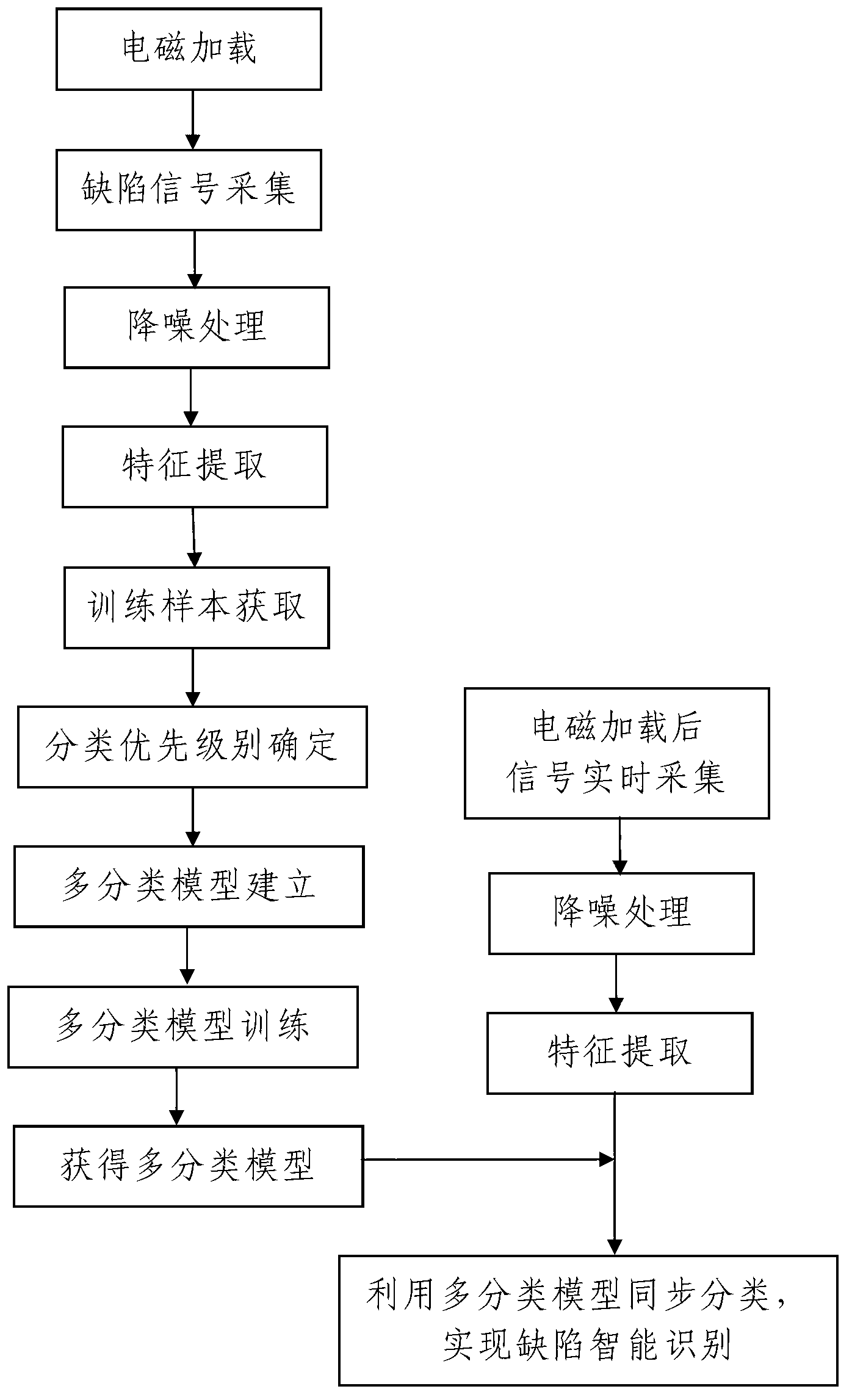

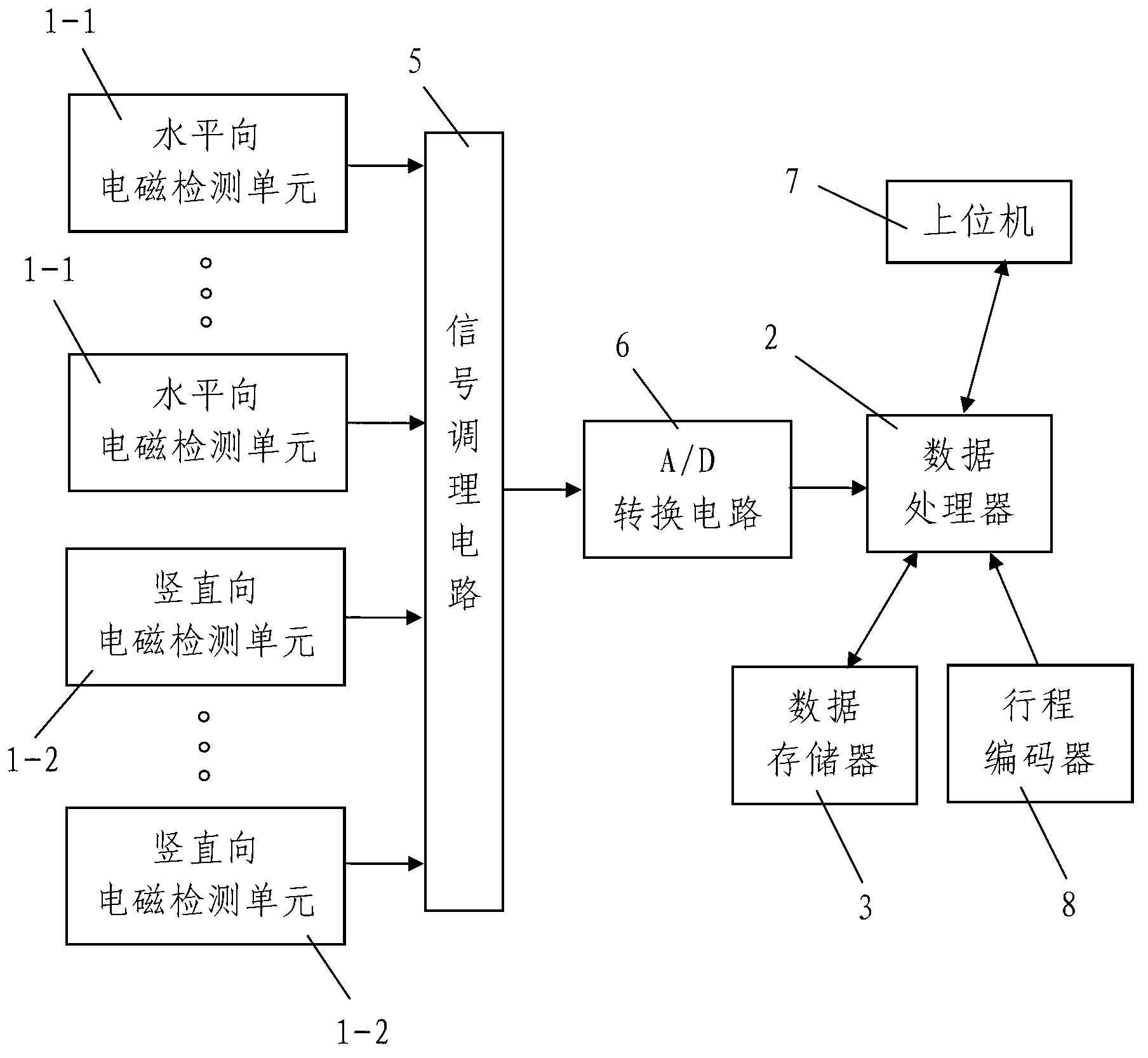

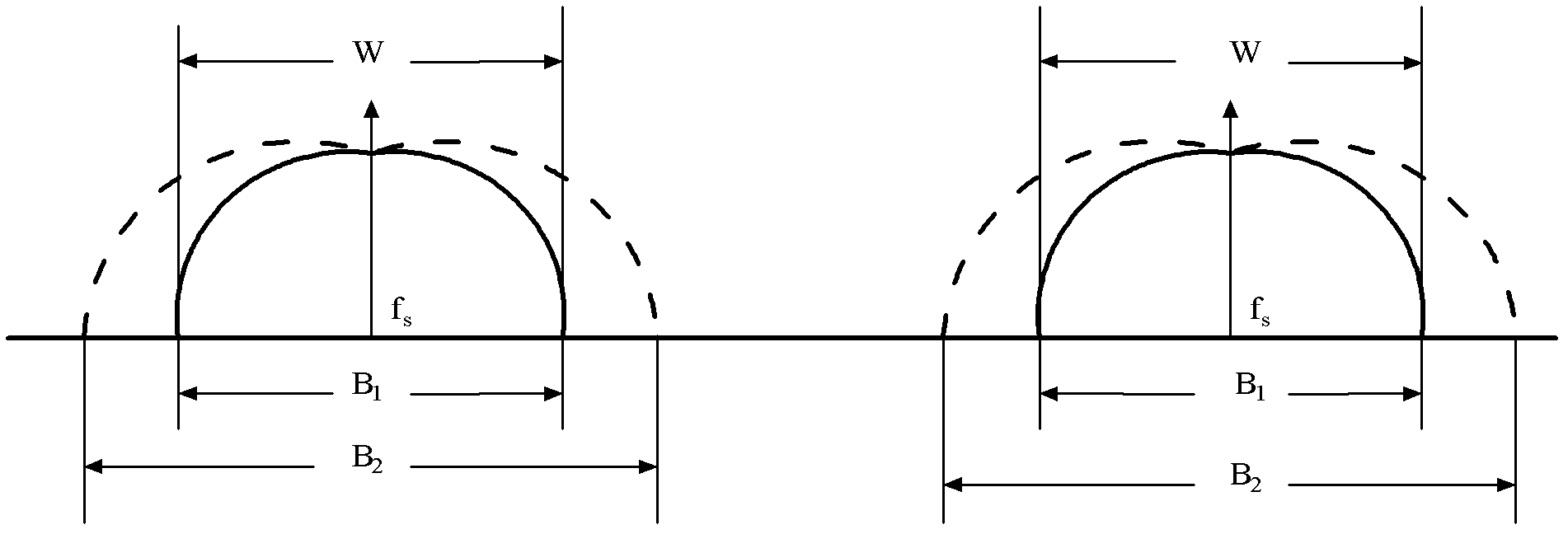

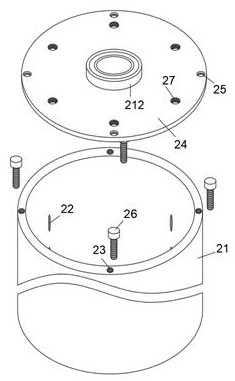

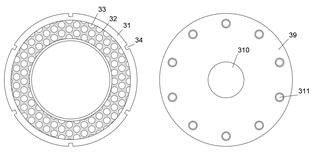

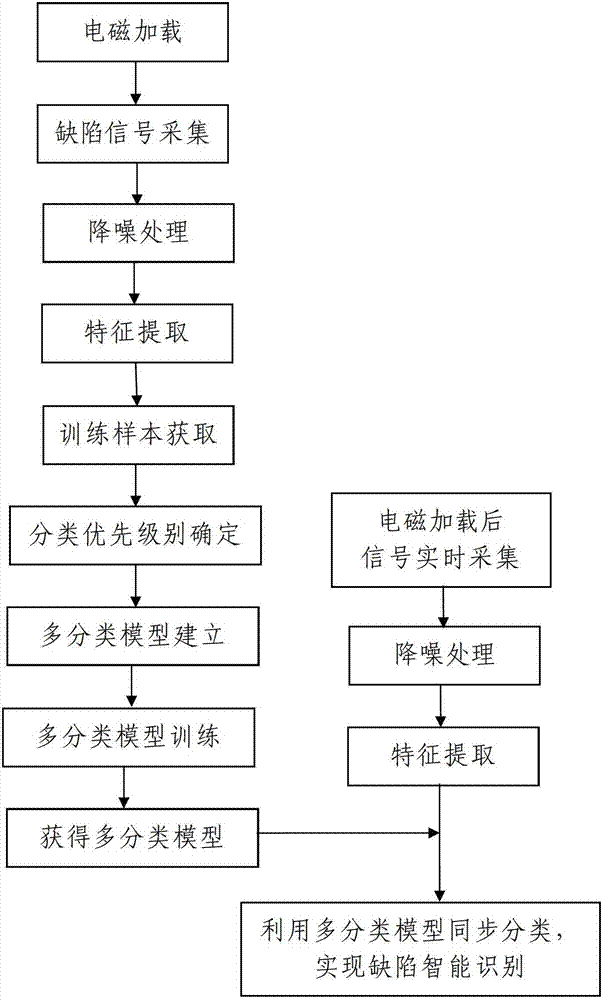

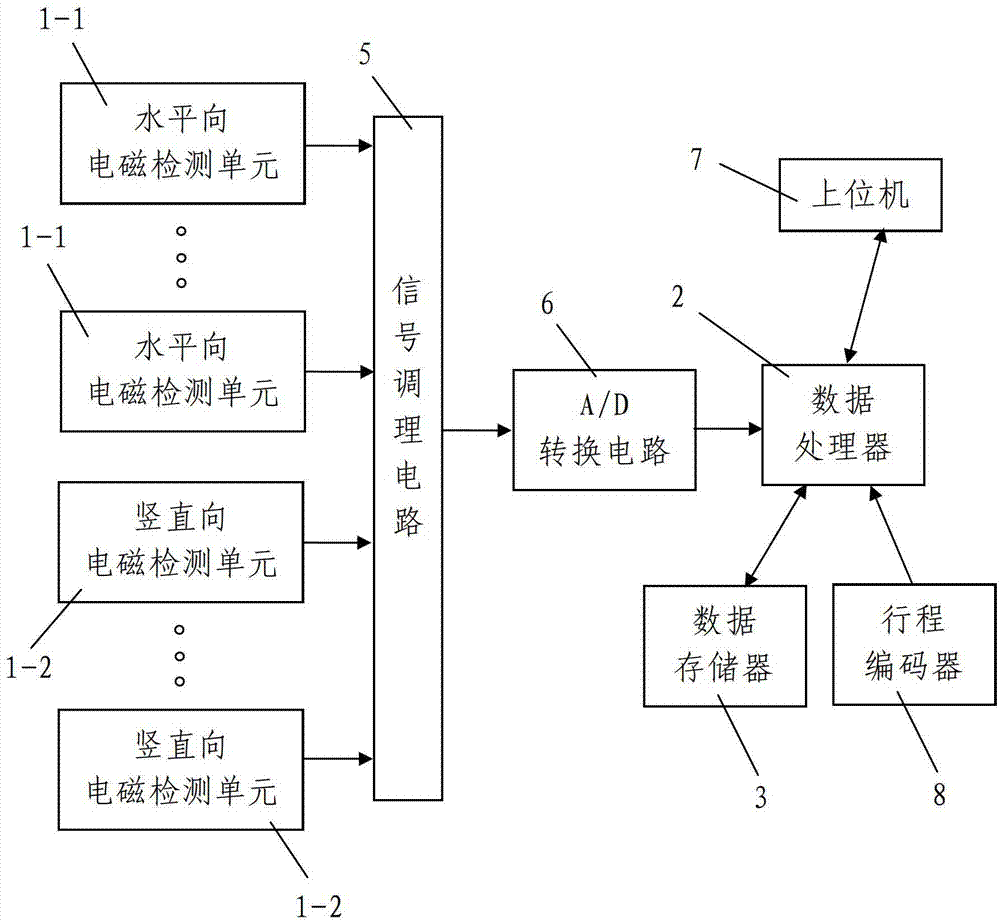

Intelligent steel cord conveyer belt defect identification method and intelligent steel cord conveyer belt defect identification system

ActiveCN102841131AReasonable designEasy installation and layoutMaterial magnetic variablesFeature extractionClass model

The invention discloses an intelligent steel cord conveyer belt defect identification method and an intelligent steel cord conveyer belt defect identification system. The identification method includes the following steps: (1) electromagnetic loading; (2) defect signal acquisition; (3) feature extraction; (4) training sample obtainment; (5) class priority determination; (6) multi-class model establishment; (7) multi-class model training; (8) real-time signal acquisition and synchronous class: electromagnetic detection units are adopted for real-time detection, detected signals are synchronously inputted into a data processor, features are extracted and then sent into established multi-class models, and the defect class of a detected conveyer belt is automatically outputted. The identification system comprises an electromagnetic loader, a plurality of electromagnetic detection units, the data processor and an upper computer, the data processor can automatically output the defect class of the detected conveyer belt, and the upper computer bidirectionally communicates with the data processor. The design of the invention is reasonable, the invention is easy to operate and convenient to put into practice, moreover, the using effect is good, the practical value is high, the reliability of conveyer belt defect detection is enhanced, and the efficiency of defect identification is increased.

Owner:XIAN UNIV OF SCI & TECH

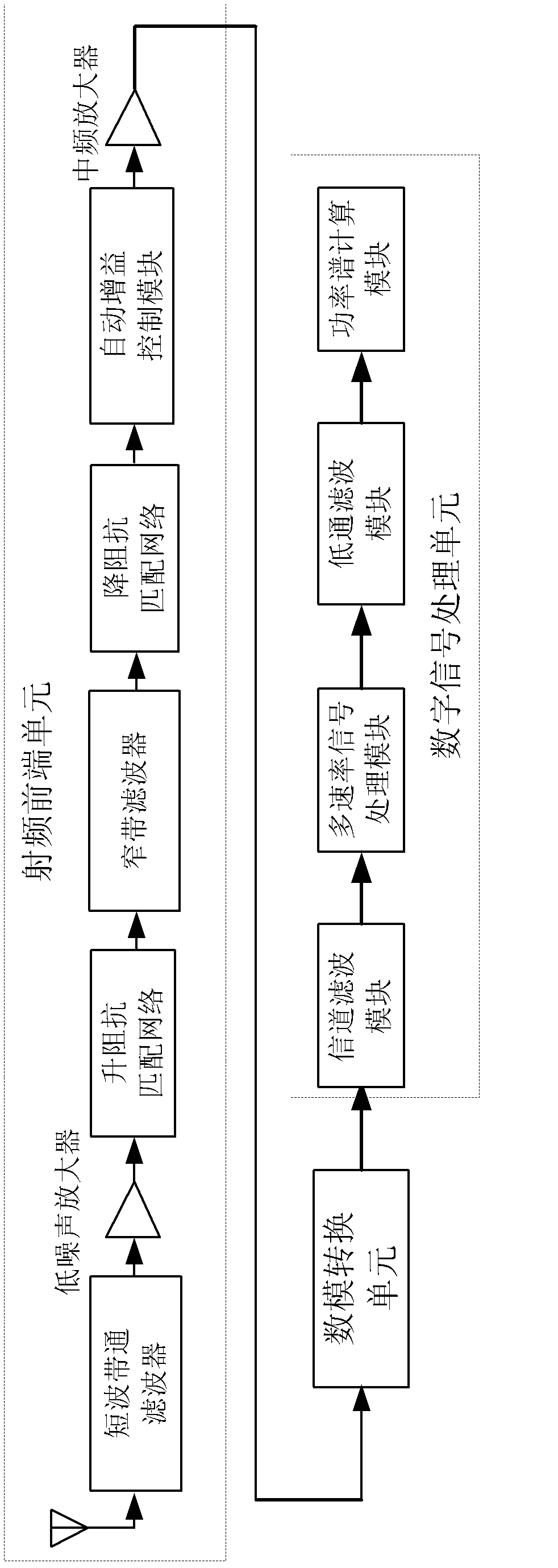

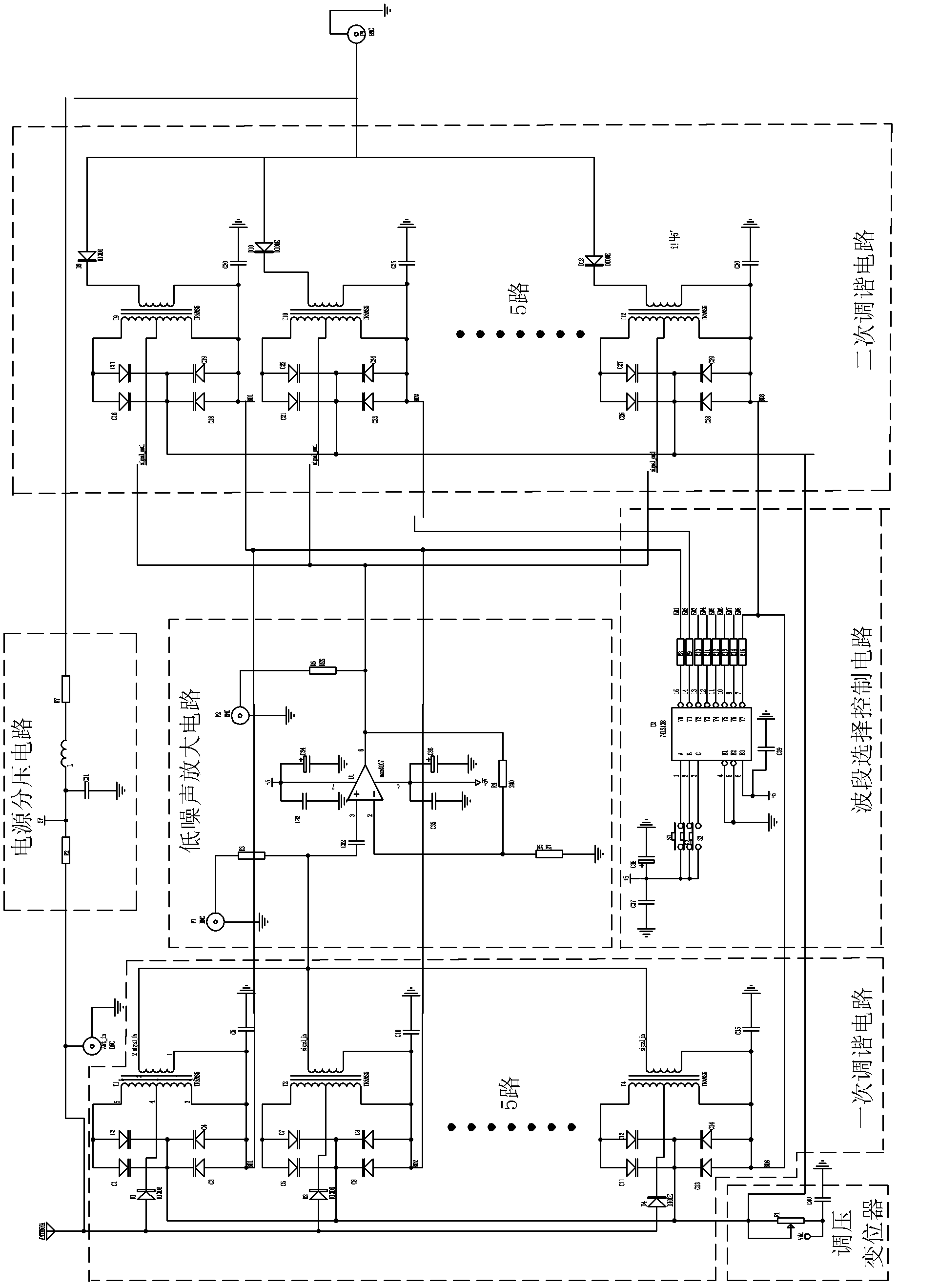

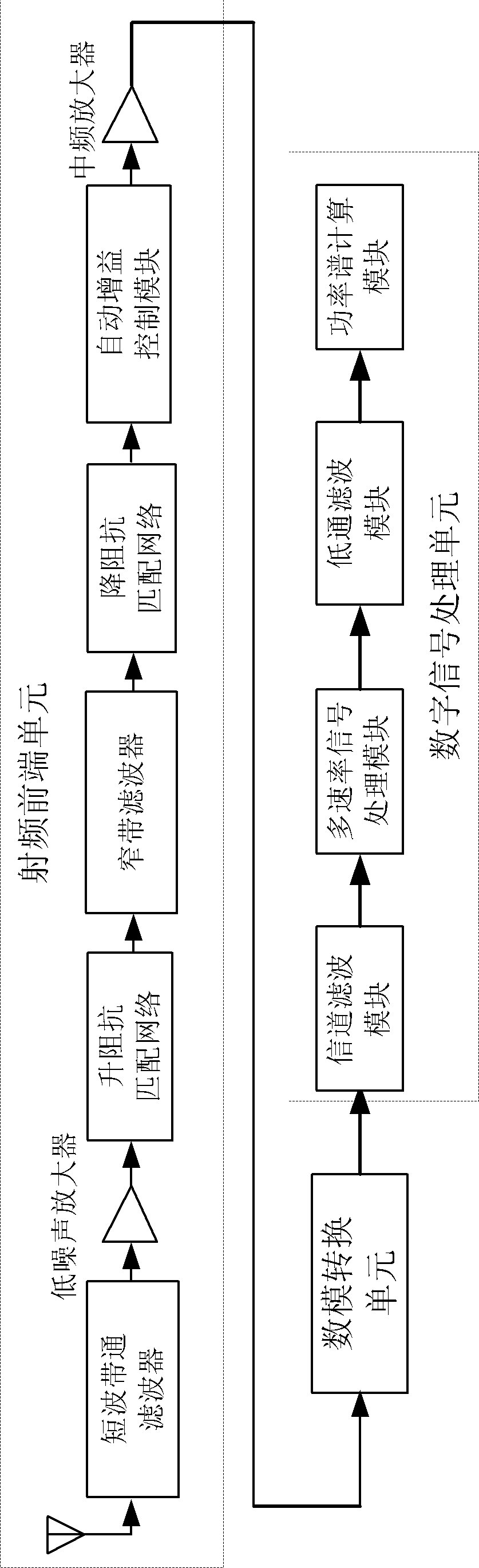

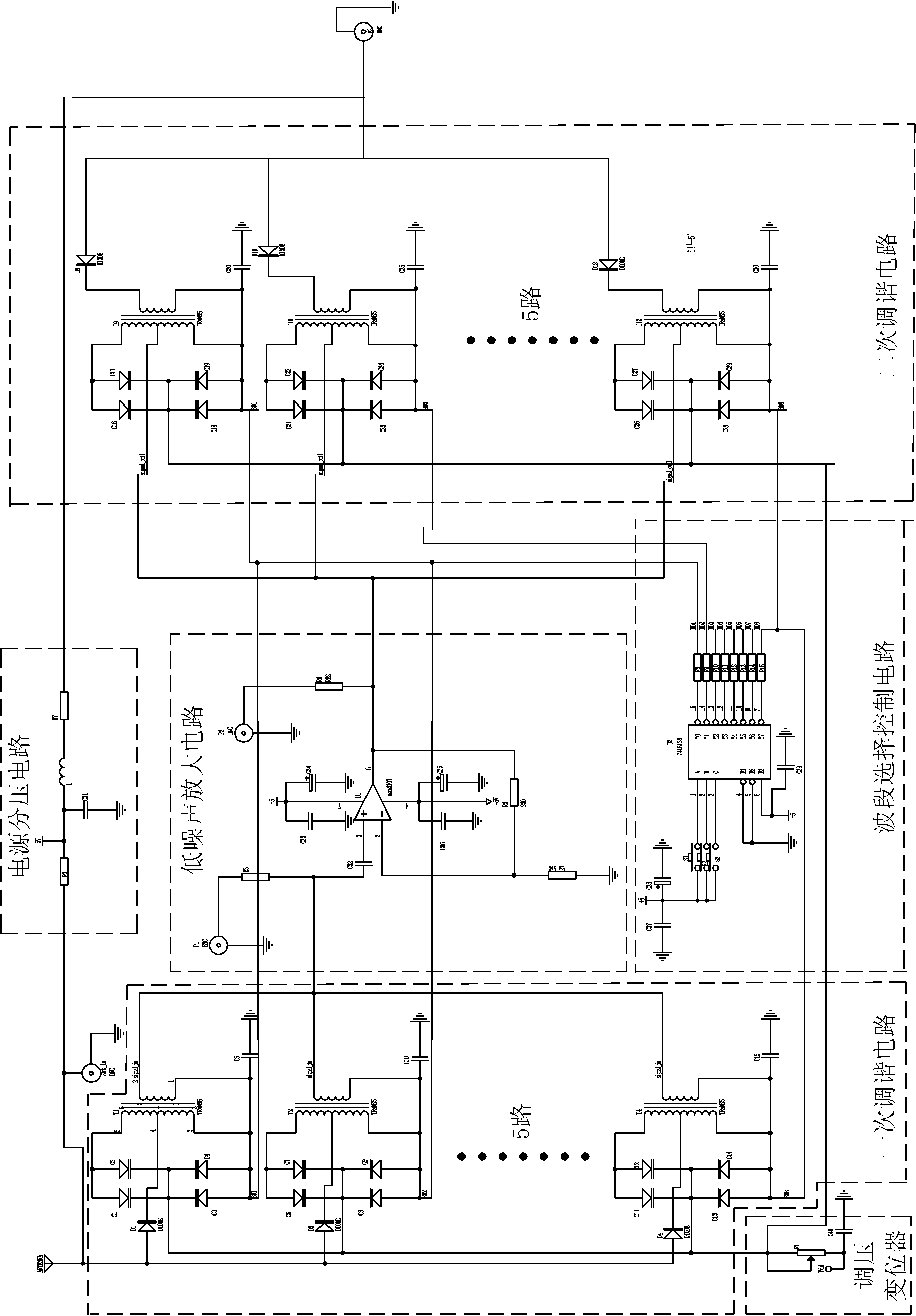

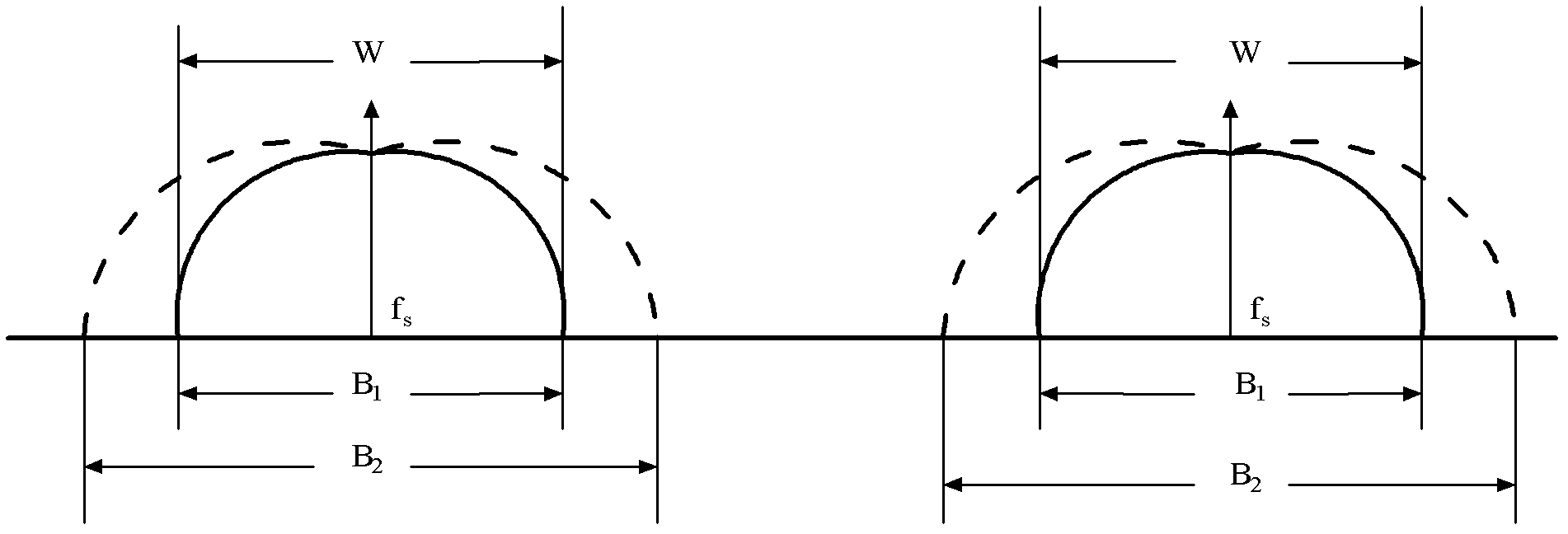

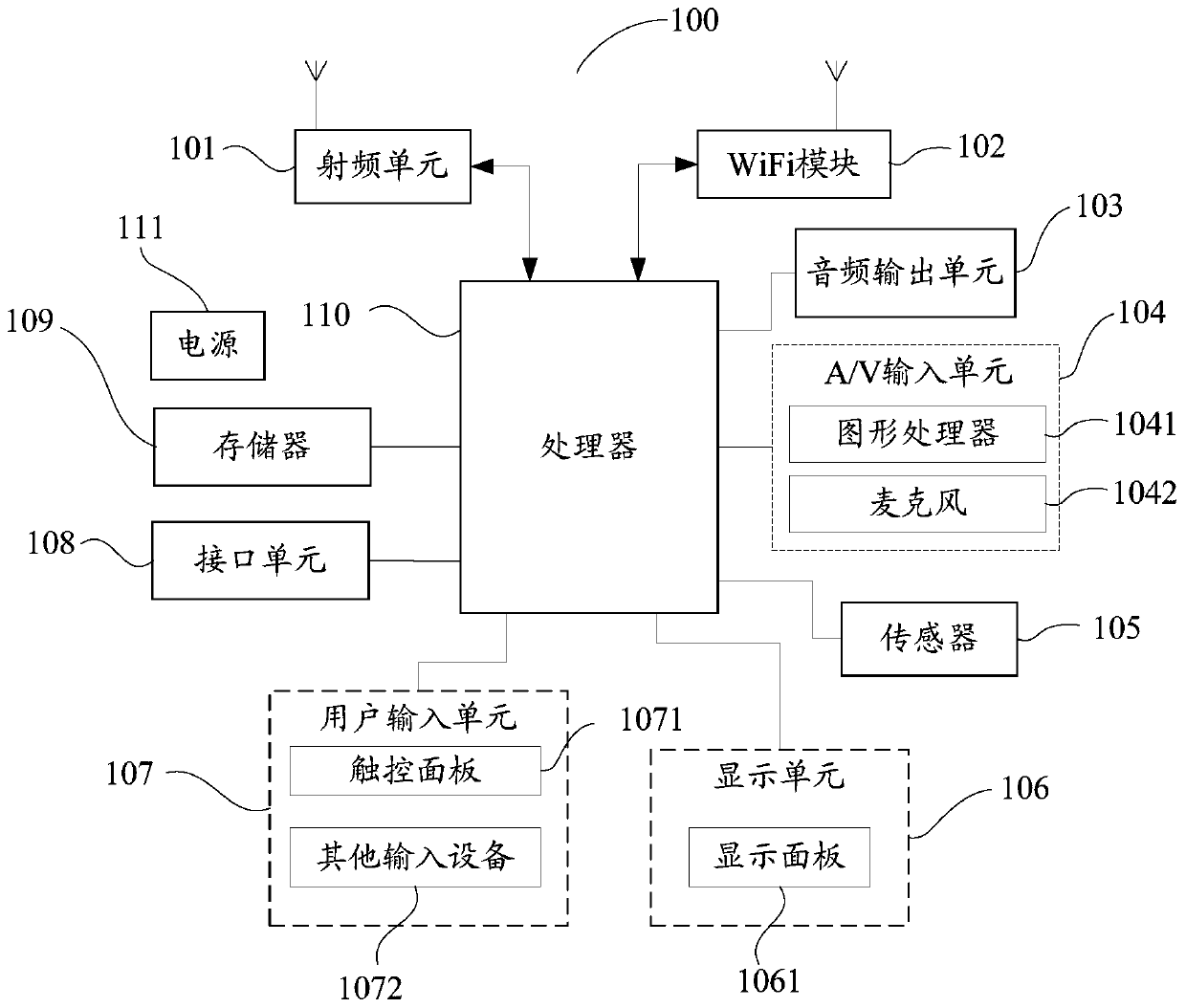

Short-wave spectrum sensing method and system

InactiveCN102594468AIncrease coverageImprove signal-to-noise ratioTransmission monitoringDigital signal processingMulti band

The invention discloses a short-wave spectrum sensing method and a short-wave spectrum sensing system. An RF (radio-frequency) front-end unit dynamically adjusts the center frequency of a narrow-band electric tuning filter for multi-band short-waves at an RF analog front-end, and the Q value of a tuned loop is improved through an effective impedance matching network, thereby controlling the bandwidth of a filter to be fixed at a communication channel bandwidth or slightly greater than the communication channel bandwidth; after carrying out sampling on a signal, an analog-to-digital conversion module converts an analog short-wave signal in a pass band into a digital short-wave signal, and a digital signal processing unit realizes the sensing on the power spectrum of a received signal by using an energy detection algorithm. The method and system disclosed by the invention have the characteristics that the frequency band covering of short-waves is comprehensive, no image interference is introduced, and the method and the system are easy to implement.

Owner:GUILIN UNIV OF ELECTRONIC TECH

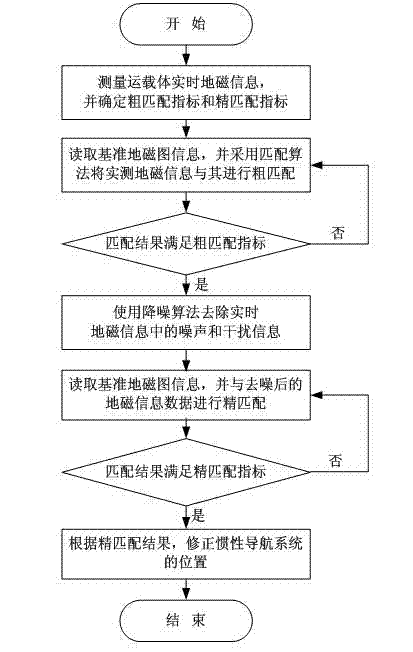

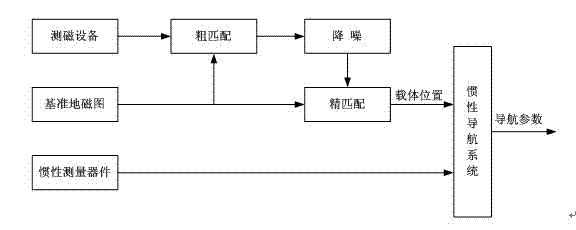

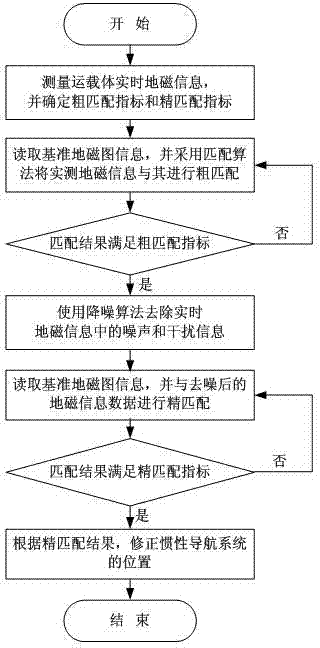

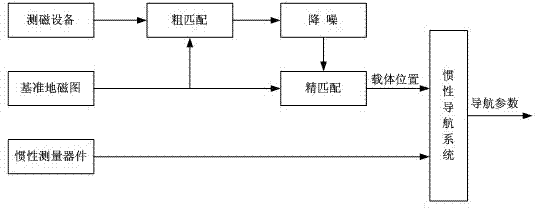

Geomagnetic aided inertial navigation method

InactiveCN102829782AImprove noise reduction efficiencySave fine matching timeNavigation by terrestrial meansNavigation by speed/acceleration measurementsNoise reductionMarine navigation

The invention relates to the navigation and guidance technologies and provides a technical scheme of a geomagnetic aided inertial navigation method. According to the scheme, at least more than one magnetic measuring apparatus is used for simultaneously measuring real-time geomagnetic information of transporters; and a geomagnetic matching navigation mode is adopted to conduct rough matching, noise reduction and precise matching on the measured real-time geomagnetic information sequentially. The magnetic measuring manner reduces the error of the apparatus and ensures the reliability of the measured value. By adopting the matching mode, the non-matching points with the reference geomagnetic map are eliminated and the range of the noise reduction and the precise matching is reduced, thereby improving the noise reduction efficiency of the real-time geomagnetic information and saving the precise matching time of the non-matching points; and meanwhile, the speed of the precise matching is improved and the precision of the navigation is ensured, thereby further promoting the quality of the geomagnetic aided inertial navigation.

Owner:BINZHOU UNIV

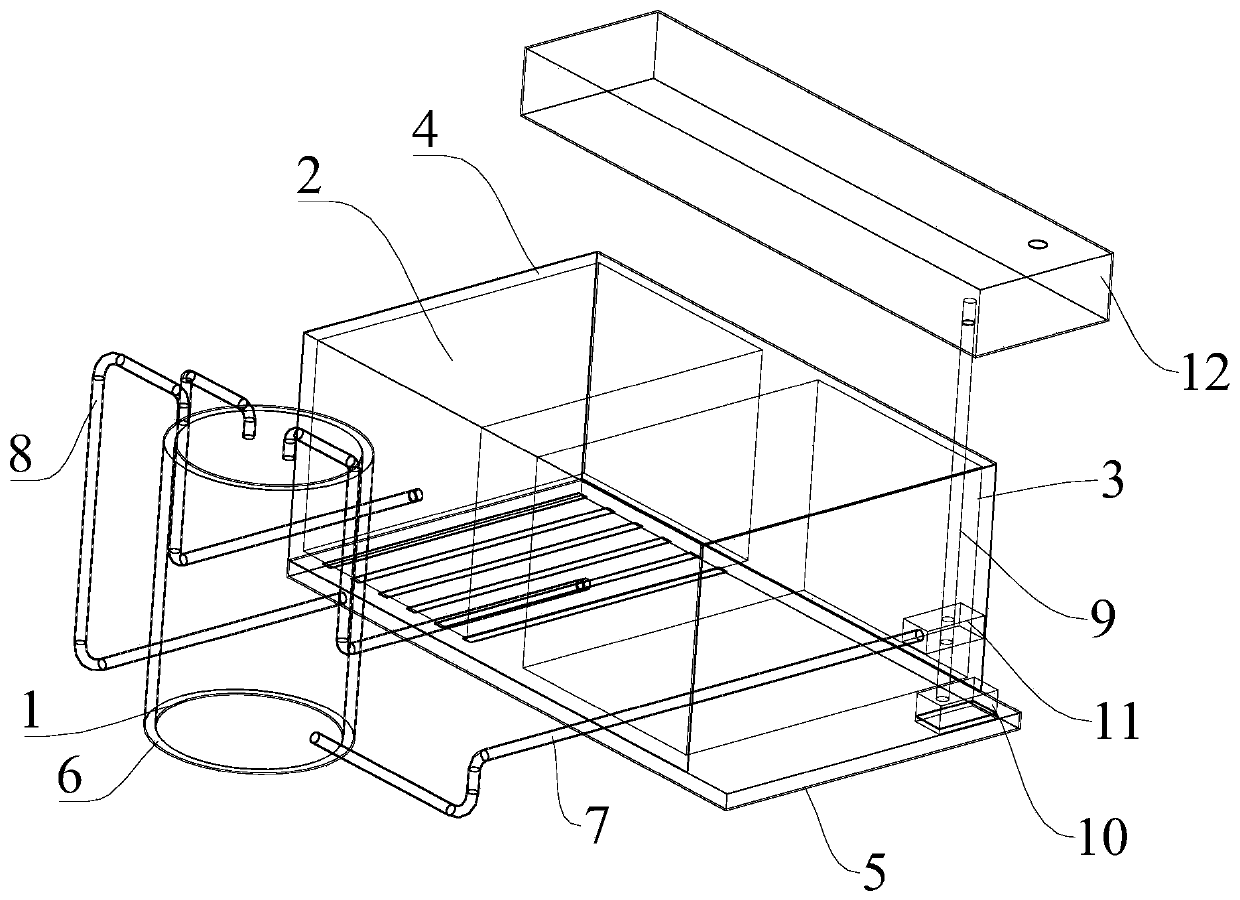

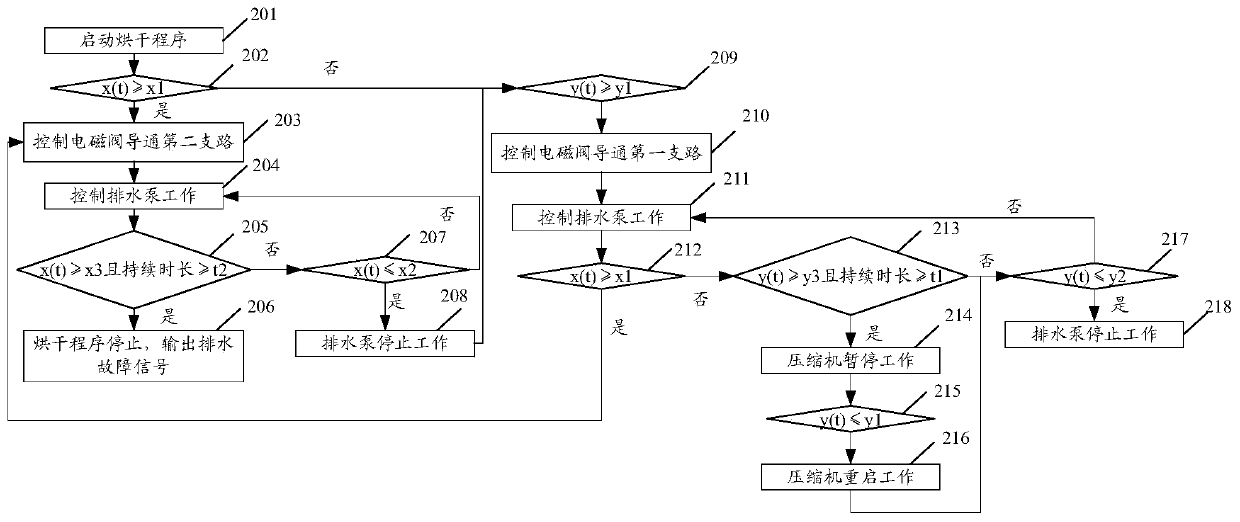

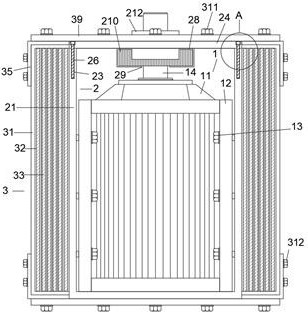

Cooling device for clothes treatment equipment and clothes treatment equipment

ActiveCN110284308AReduce noiseEase of noise reductionTextiles and paperLaundry driersCooling effectEngineering

The embodiment of the invention discloses a cooling device for clothes treatment equipment and the clothes treatment equipment. The cooling device comprises a collection container used for collecting condensate water obtained through condensation by an evaporator of the clothes treatment equipment, and a cooling structure arranged on the outer wall of a compressor of the clothes treatment equipment and communicated with the collection container, wherein the cooling structure is used for cooling the compressor and dissipating heat for the compressor through flowing of the condensate water. According to the cooling device for the clothes treatment equipment, the condensate water generated from the clothes treatment equipment is adopted for water cooling, introduction of an external cold source is not needed, and arrangement of a cooling fan is not needed, which is beneficial for reducing cost; in addition, the cooling structure is adopted for cooling the outer wall of the compressor and dissipating heat for the outer wall of the compressor, the situation is not influenced that the exterior of the cooling structure is wrapped by a sound absorption material, noise reduction treatment is conveniently conducted on the compressor, and the contradiction between cooling and noise reduction in the prior art is overcome, which is beneficial for ensuring the cooling effect and reducing noise of the clothes treatment equipment.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

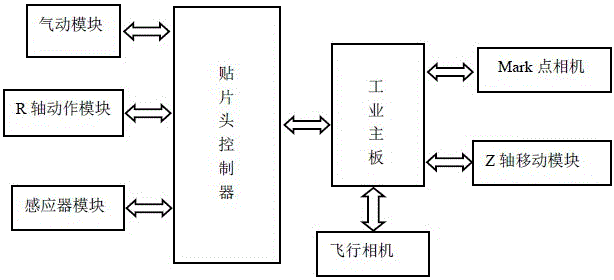

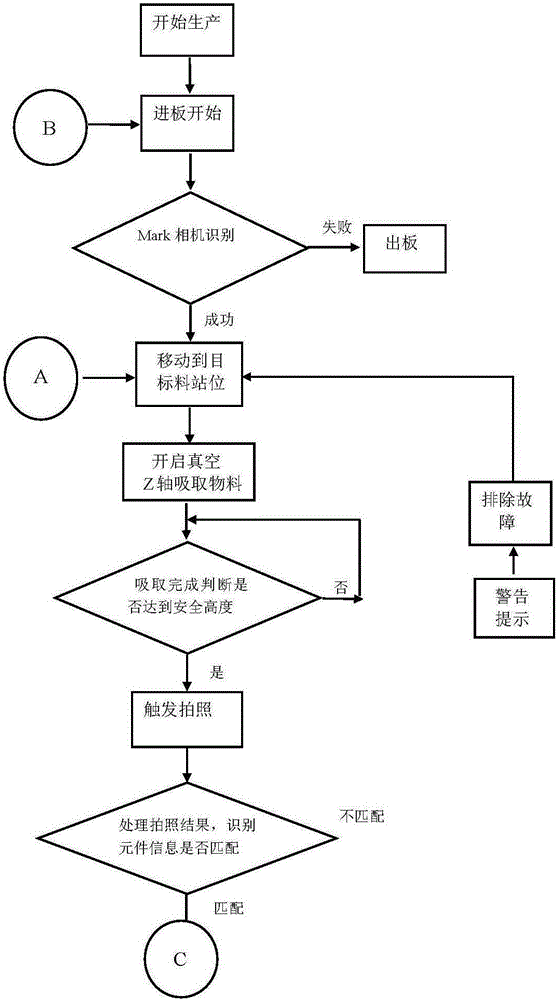

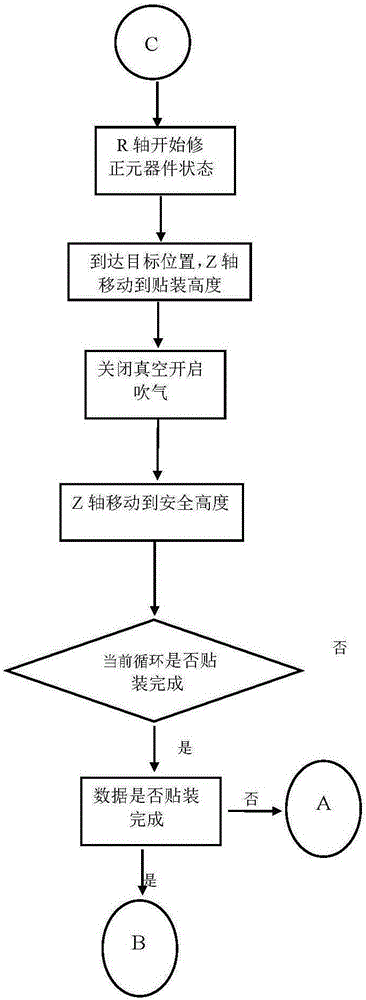

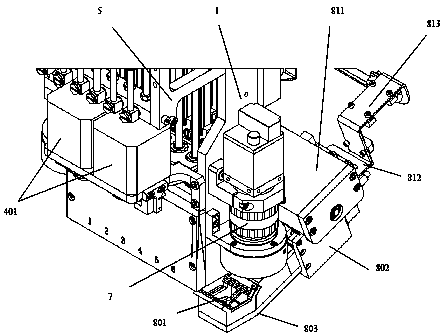

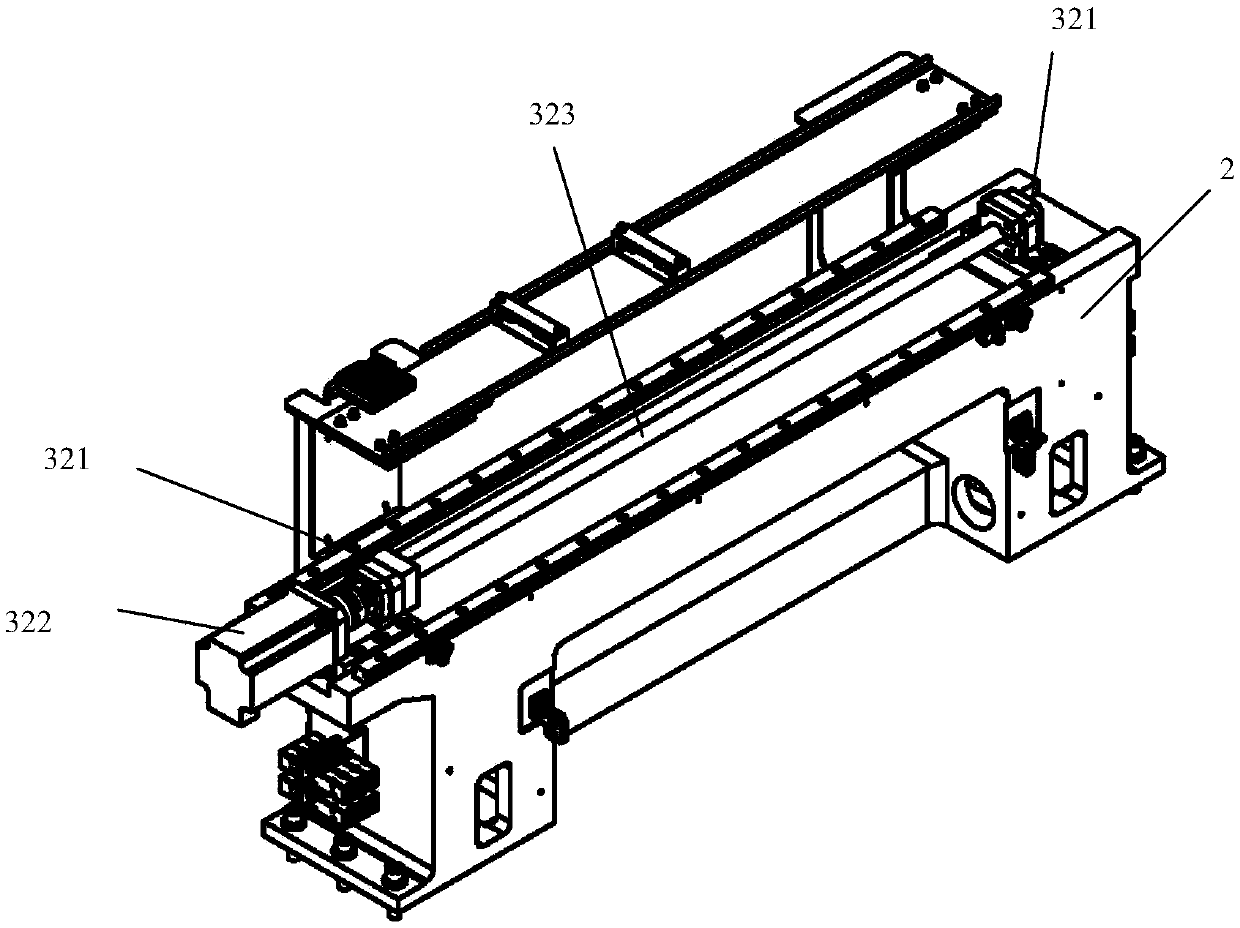

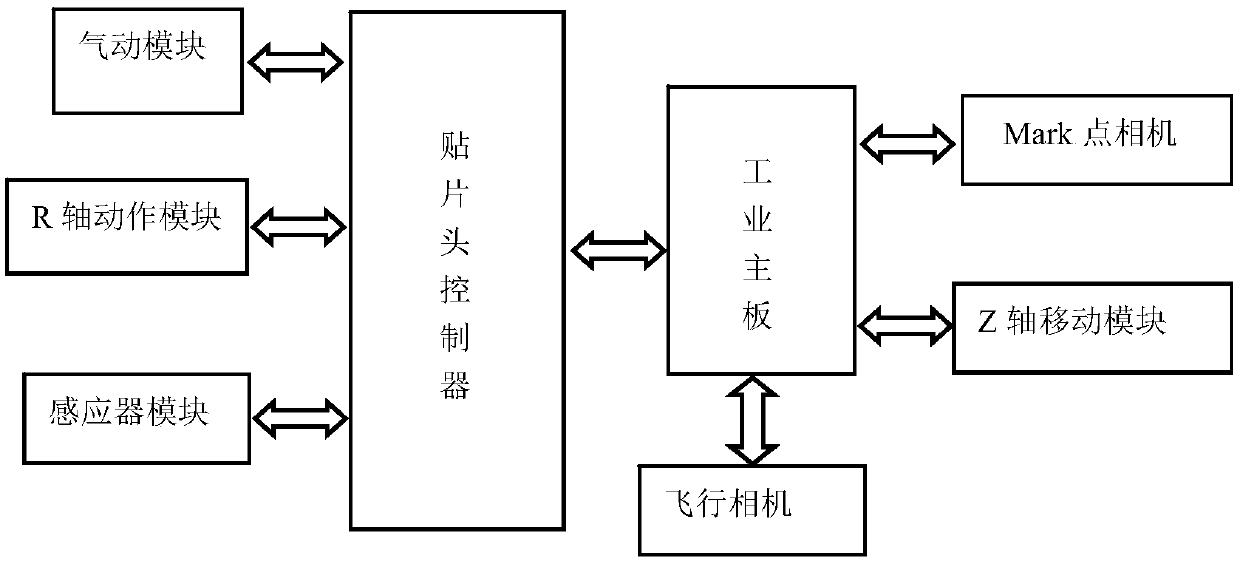

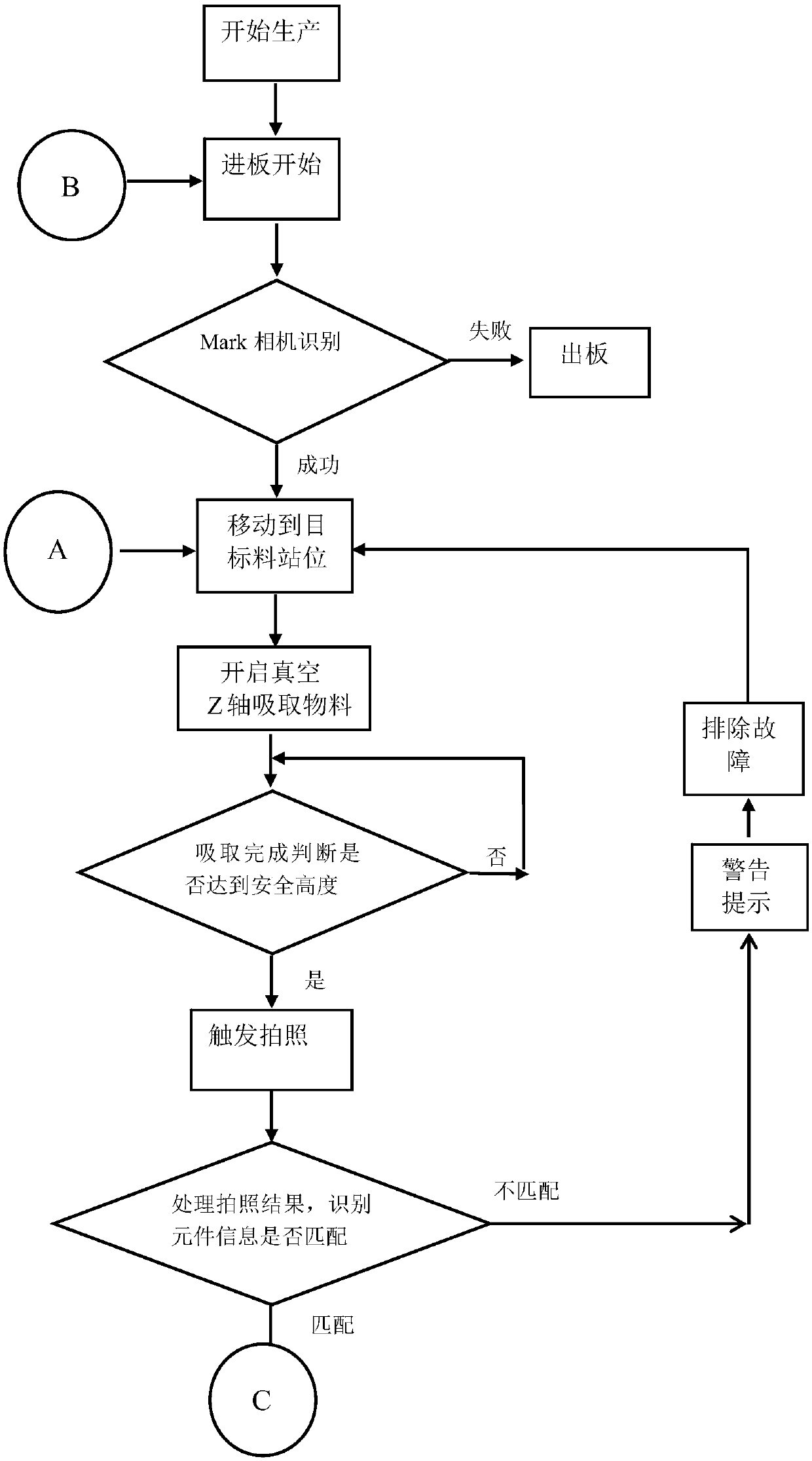

Mounting head control system and method

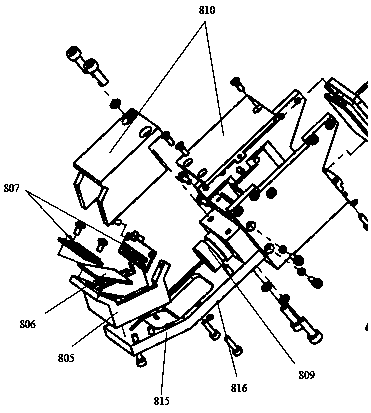

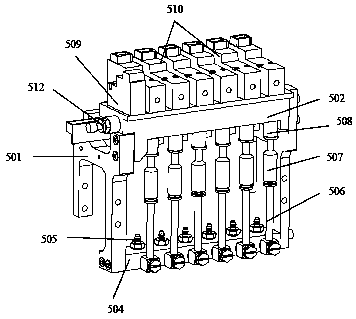

ActiveCN106304675ARealize R rotationEase of noise reductionPrinted circuit assemblingModularityInductor

The invention provides a mounting head control system. The mounting head control system consists of a mounting head controller, an industrial mainboard, a Mark point camera, a Z axis moving module, a flight camera, a pneumatic module, an R axis motion module and an inductor module. The mounting head control system is characterized in that the Mark point camera, the Z axis moving module and the flight camera are connected to the industrial mainboard; the mounting head controller is connected to the pneumatic module, the R axis motion module and the inductor module; and the mounting head controller is connected to the industrial mainboard. The mounting head control system and method use a modularization idea and use a mounting head controller to be connected to the industrial mainboard, independently take charge for data processing of the pneumatic module, the R axis motion module and the inductor module, realize material absorbing and discharging of a mounting shaft, and member rotation in an R direction; the inductor is in charge of data collection of the pneumatic module and the R axis motion module and is in communication with the industrial mainboard through a CAN bus, which makes the whole system faster and more efficient. The mounting head control system and method effectively improve a material absorbing speed, reduce vacuum detection fluctuation and provide convenience to noise reduction processing of a detection signal of a simulation pressure sensor.

Owner:广东木几智能装备有限公司

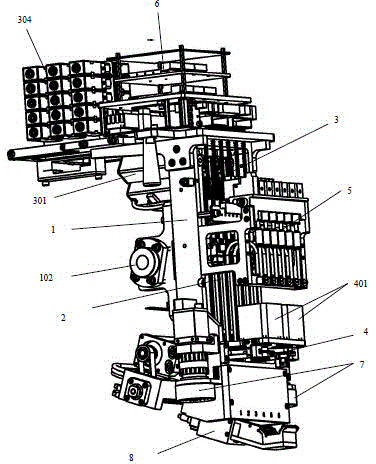

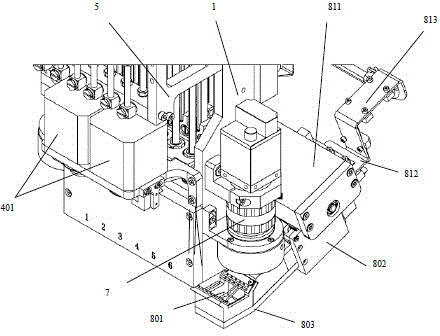

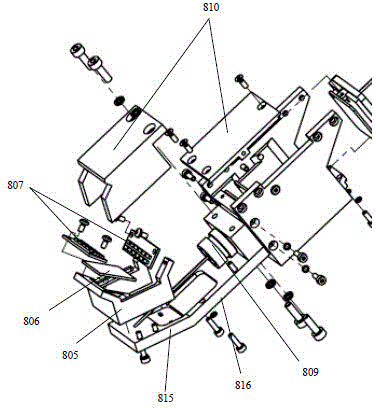

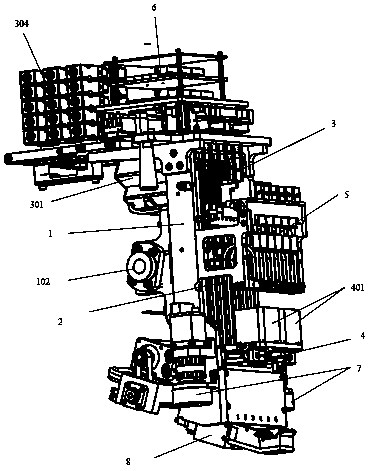

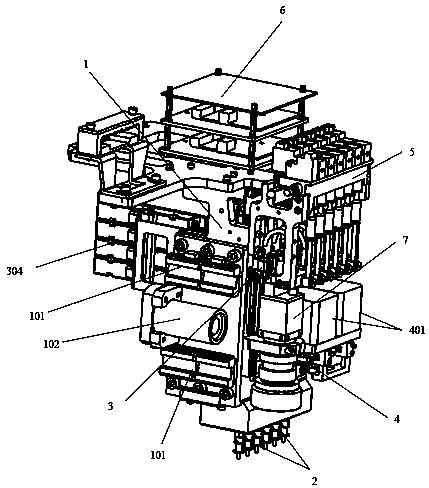

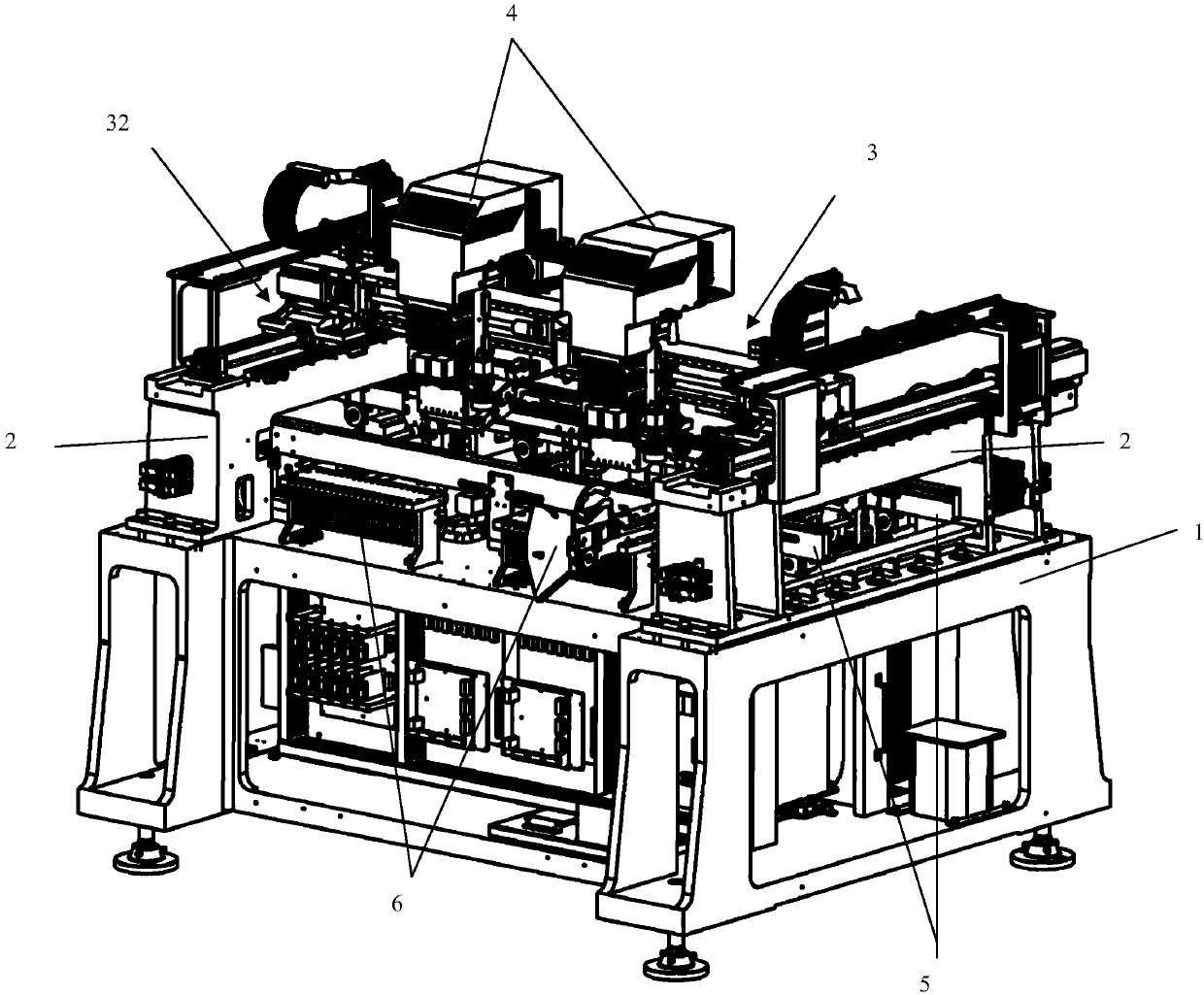

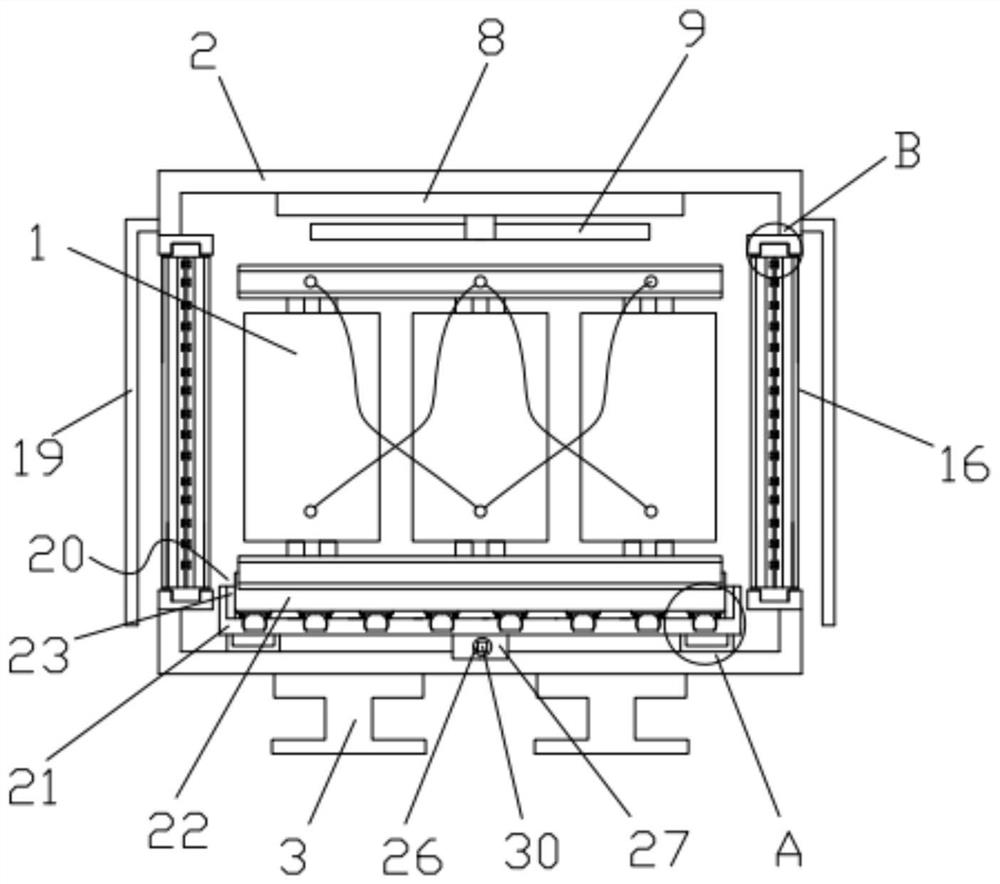

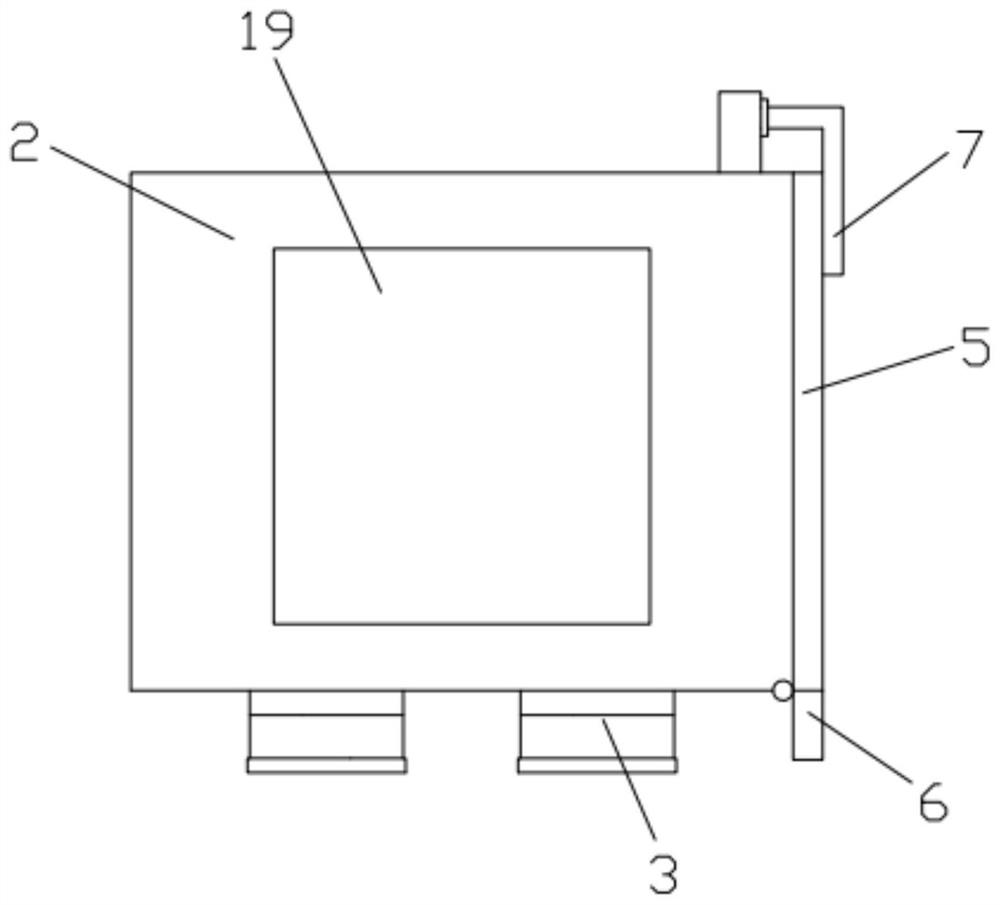

High-precision chip mounting head capable of flight identification

ActiveCN106304673AReduce deflectionGuaranteed uptimePrinted circuit assemblingAcute angleMiniaturization

The invention provides a high-precision chip mounting head capable of flight identification. The chip mounting head comprises a chip mounting head support, chip mounting shafts mounted in the chip mounting head support, a direction-Z elevation mechanism, a direction-R turning mechanism and a vacuum module group; the chip mounting head is characterized in that an integrated control assembly is mounted in the back side of the upper portion of the chip mounting head support, the vacuum module group is mounted in the front side of the upper portion of the support, a direction-R stepping motor which drives the direction-R turning mechanism and a CCD camera collecting images are mounted in the middle of the front side of the support, direction-Z driving motors are mounted in the back side of the support, and the directions of output shafts of the direction-Z driving motors are vertical to the axis-Z; and a flight camera device is mounted in the lower portion of the back side of the chip mounting head support, and comprises a light source assembly below a nozzle, a camera assembly, a camera support provided with the light source assembly and the camera assembly and a driving mechanism which enables the camera support to move along the axis-X, and an acute angle is formed between the direction of a lens of the camera assembly and the vertical direction in the XY plane. The chip mounting head is minimized and low-cost, and stable, accurate, rapid and high-precision chip mounting is realized.

Owner:江苏华志珹智能科技有限公司

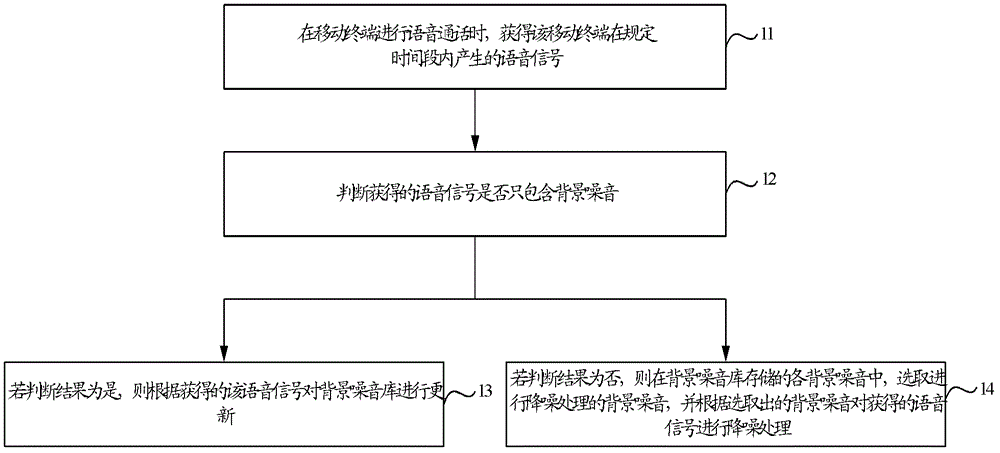

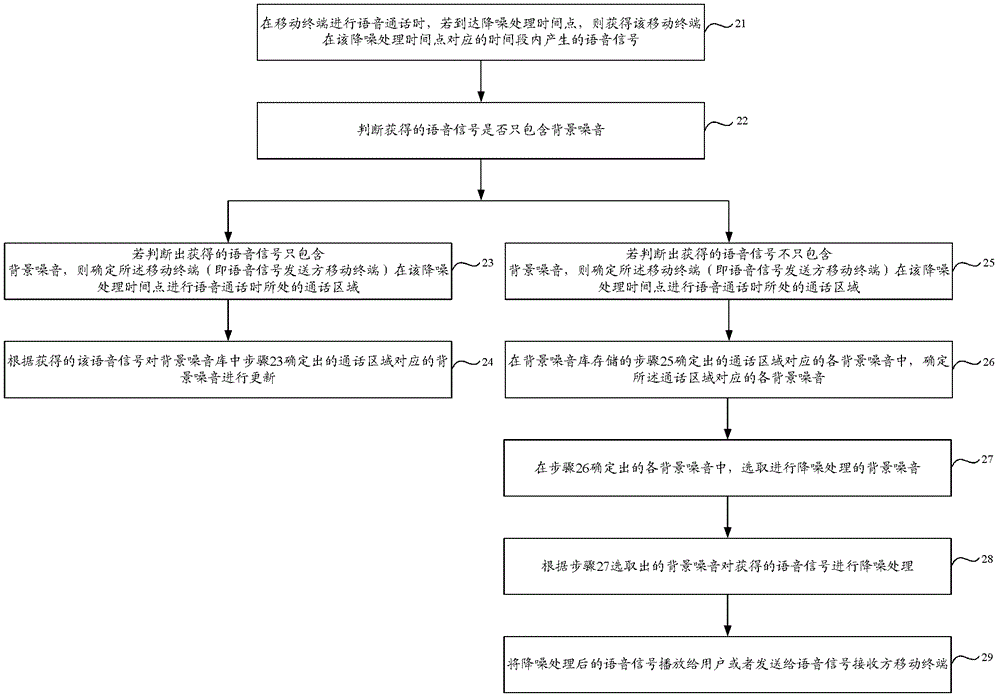

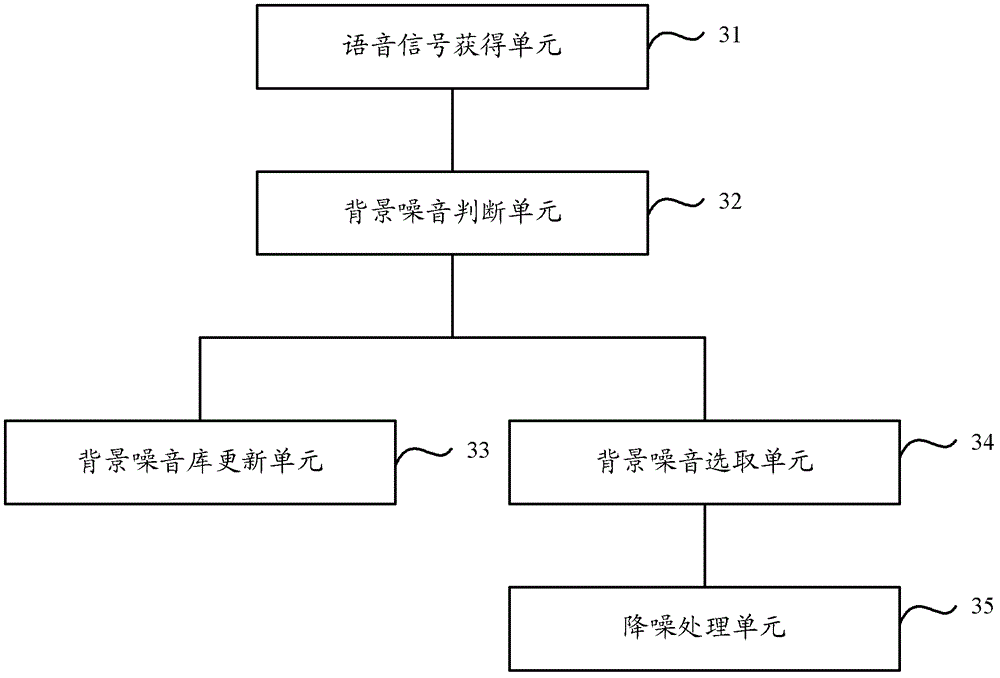

Speech signal noise reduction processing method and device

ActiveCN103177728BImprove voice call qualityEase of noise reductionSpeech analysisCommunication qualityNoise reduction

The invention discloses a method and a device for conducting noise reduction on speech signals. The method comprises the steps of obtaining speech signals generated by a mobile terminal in a specified time period when the mobile terminal conducts speech communication; judging whether obtained speech signals only contain background noises or not; if obtained speech signals only contain background noises, updating a background noise library according to obtained speech signals; and if obtained speech signals do not only contain background noises, selecting background noises to be subjected to noise reduction from all background noises stored in the background noise library, and conducting noise reduction on obtained speech signals according to selected background noises. By the aid of the technical scheme, the problems that the speech communication quality of users is affected due to the fact that the good noise reduction effect can not be achieved when the mobile terminal in the prior art conducts noise reduction on speech signals according to background noises stored in advance can be solved.

Owner:中国移动通信集团广西有限公司

Novel explosion-proof motor noise reduction device

InactiveCN111969774AImprove seismic performanceAvoid the problem of falling apartMagnetic circuit rotating partsSupports/enclosures/casingsElectric machineStructural engineering

The invention discloses a novel explosion-proof motor noise reduction device in the field of motors. The device comprises a motor mechanism, and the motor mechanism comprises an explosion-proof motor,a base, a positioning bolt and a rotor. Compared with the prior art, the device has the beneficial effects that the motor mechanism is conveniently limited in the anti-explosion motor through the arranged fixing mechanism, and the noise generated in the rotating process of the rotor of the anti-explosion motor can be greatly reduced through the use of the first honeycomb plate in the noise reduction box to achieve the noise reduction effect; the noise reduction mechanism is arranged outside the fixing mechanism in a sleeving manner; noise generated in the working process of the explosion-proof motor can be well reduced; good noise reduction treatment is carried out through the second honeycomb plate and the inorganic fiber plate; and the honeycomb plate has a good anti-vibration effect, the problem that the noise reduction mechanism falls apart due to vibration generated in the working process of the explosion-proof motor is avoided, and the connectivity of the connecting position between the fixing mechanism and the noise reduction mechanism can be better made more compact through the top cover and the fixing bolts.

Owner:JIANGSU HENGKANG ELECTRICAL

Intelligent steel cord conveyer belt defect identification method and intelligent steel cord conveyer belt defect identification system

ActiveCN102841131BReasonable designEasy installation and layoutMaterial magnetic variablesFeature extractionClass model

The invention discloses an intelligent steel cord conveyer belt defect identification method and an intelligent steel cord conveyer belt defect identification system. The identification method includes the following steps: (1) electromagnetic loading; (2) defect signal acquisition; (3) feature extraction; (4) training sample obtainment; (5) class priority determination; (6) multi-class model establishment; (7) multi-class model training; (8) real-time signal acquisition and synchronous class: electromagnetic detection units are adopted for real-time detection, detected signals are synchronously inputted into a data processor, features are extracted and then sent into established multi-class models, and the defect class of a detected conveyer belt is automatically outputted. The identification system comprises an electromagnetic loader, a plurality of electromagnetic detection units, the data processor and an upper computer, the data processor can automatically output the defect class of the detected conveyer belt, and the upper computer bidirectionally communicates with the data processor. The design of the invention is reasonable, the invention is easy to operate and convenient to put into practice, moreover, the using effect is good, the practical value is high, the reliability of conveyer belt defect detection is enhanced, and the efficiency of defect identification is increased.

Owner:XIAN UNIV OF SCI & TECH

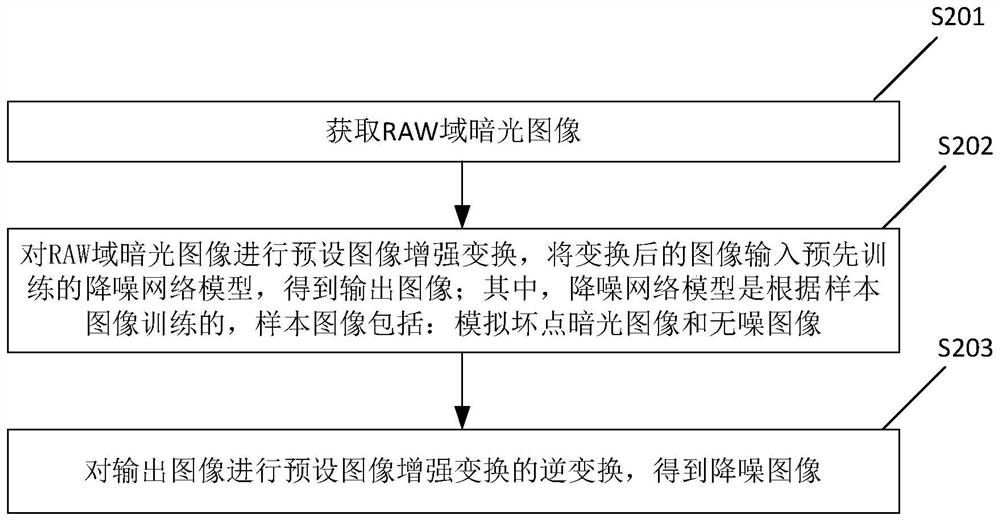

Dark light image noise reduction method and device

ActiveCN114418873AReduce the effect of noise reductionQuality improvementImage enhancementImage analysisImage noise reductionSample image

The embodiment of the invention provides a dark light image noise reduction method and device. The method comprises the following steps: acquiring a RAW domain dark light image; performing preset image enhancement transformation on the RAW domain dark light image, and inputting the transformed image into a pre-trained noise reduction network model to obtain an output image; wherein the noise reduction network model is trained according to sample images, and the sample images comprise a simulation dead pixel dark light image and a noise-free image; and performing inverse transformation of preset image enhancement transformation on the output image to obtain a noise-reduced image. The influence of image dead pixels on the dark light image noise reduction process can be remarkably reduced, and the noise reduction quality of the dark light image is improved.

Owner:INTELLINDUST INFORMATION TECH (SHENZHEN) CO LTD +1

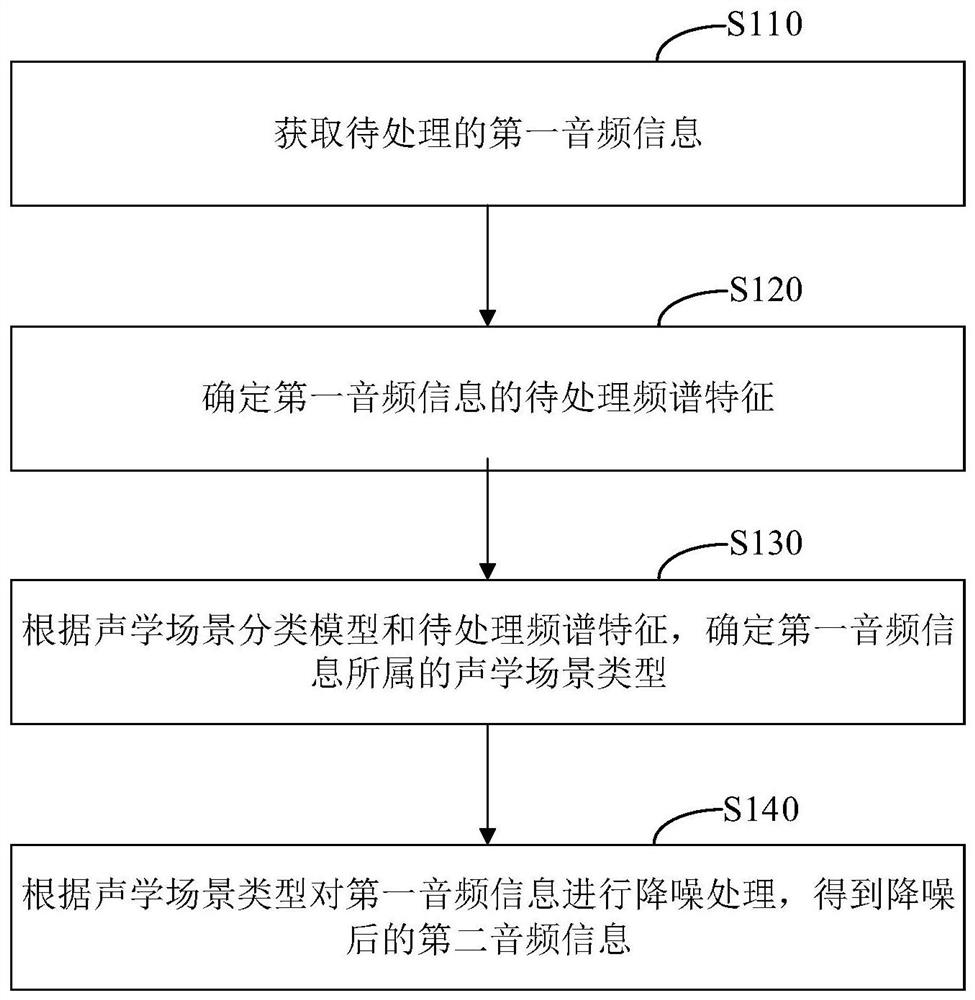

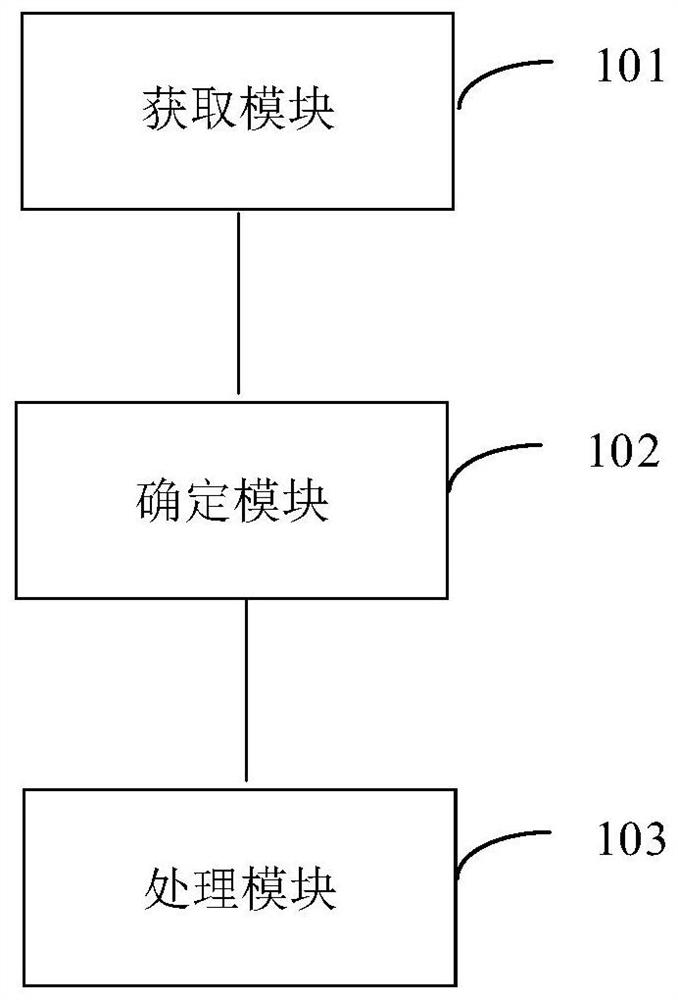

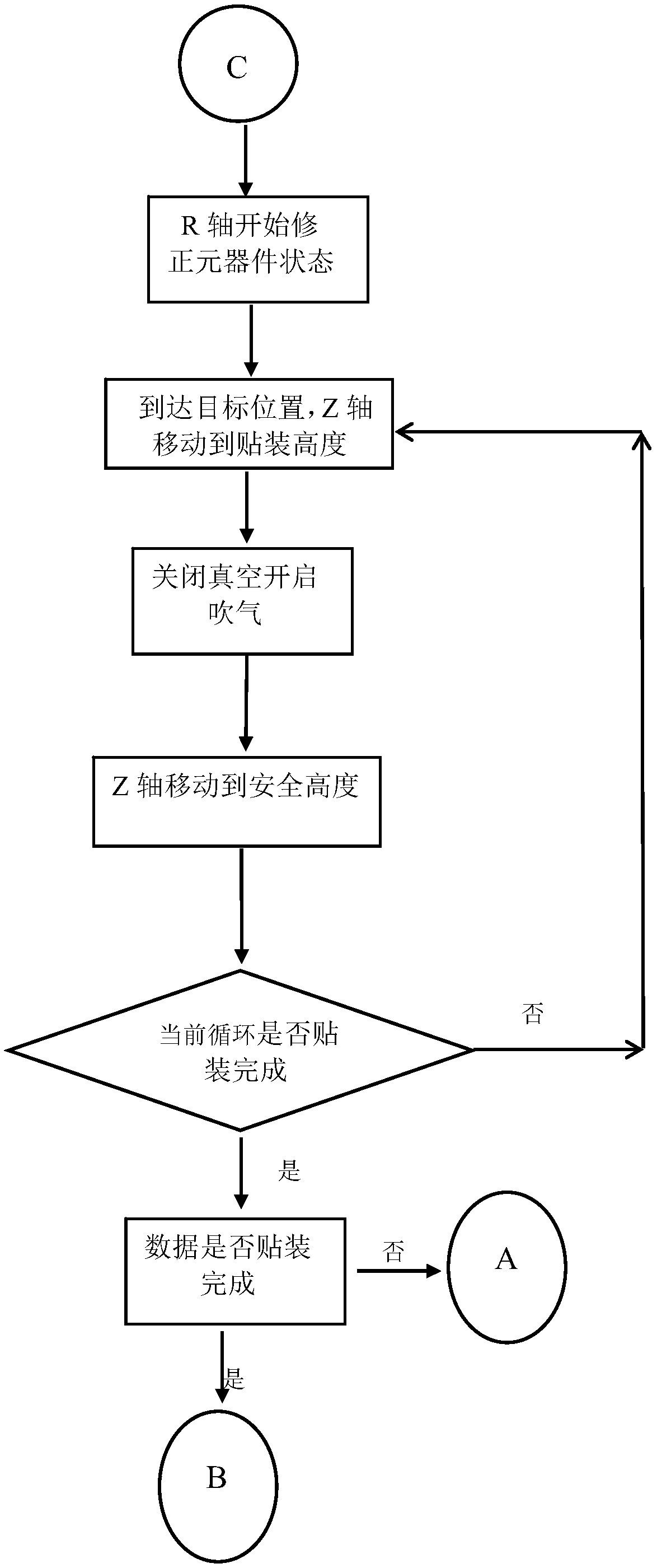

Noise reduction processing method and device, terminal and storage medium

PendingCN114694666AAudio processing is goodVideo processingSpeech analysisEngineeringSpeech recognition

The invention relates to a noise reduction processing method and device, a terminal and a storage medium. The method comprises the following steps: acquiring to-be-processed first audio information; determining a to-be-processed spectrum feature of the first audio information; determining an acoustic scene type to which the first audio information belongs according to an acoustic scene classification model and the to-be-processed spectrum features; and performing noise reduction processing on the first audio information according to the acoustic scene type to obtain second audio information after noise reduction. According to the method, the first audio information is subjected to noise reduction processing in different modes according to the acoustic scene type, so that the noise-reduced audio information after noise reduction is accurately, efficiently and simply obtained, a user does not need to know excessive software operation knowledge and knowledge in the sound field, audio processing can be well achieved, video processing is well achieved, and the user experience is improved. And the use experience of the user is improved.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

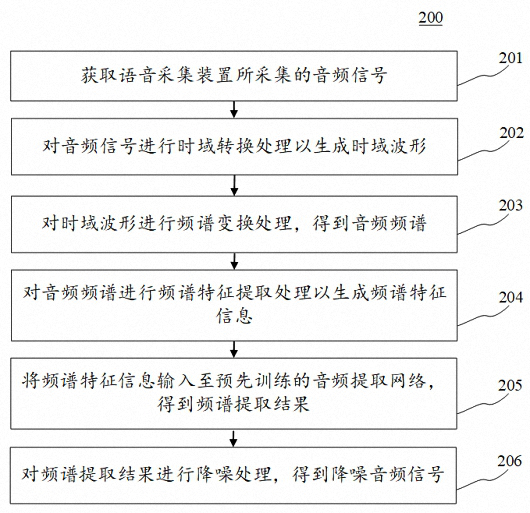

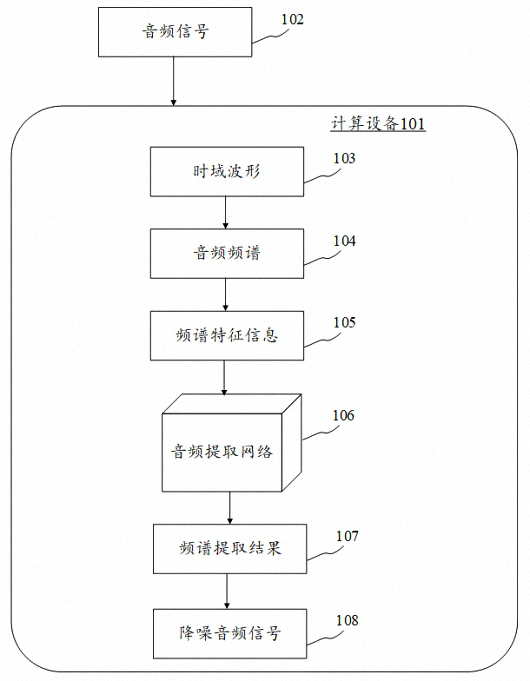

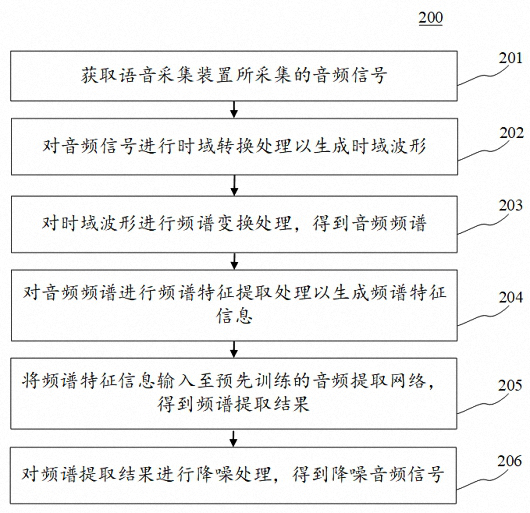

Audio noise reduction transmission method, device, electronic device and computer readable medium

ActiveCN112599147BImplement noise reduction processingEase of noise reductionSpeech analysisNoiseFrequency spectrum

Embodiments of the present disclosure disclose an audio noise reduction transmission method, device, electronic equipment, and computer-readable medium. A specific implementation of the method includes: acquiring the audio signal collected by the speech collection device; performing time-domain conversion processing on the above-mentioned audio signal to generate a time-domain waveform; performing spectrum conversion processing on the above-mentioned time-domain waveform to obtain an audio frequency spectrum; The audio spectrum is subjected to spectral feature extraction processing to generate spectral feature information; the above spectral feature information is input to a pre-trained audio extraction network to obtain a spectrum extraction result; the above spectral extraction result is subjected to noise reduction processing to obtain a noise-reduced audio signal. This embodiment implements noise reduction processing on audio, improves the noise suppression effect, and thus improves the audio transmission efficiency of the earphone.

Owner:北京嘉诚至盛科技有限公司

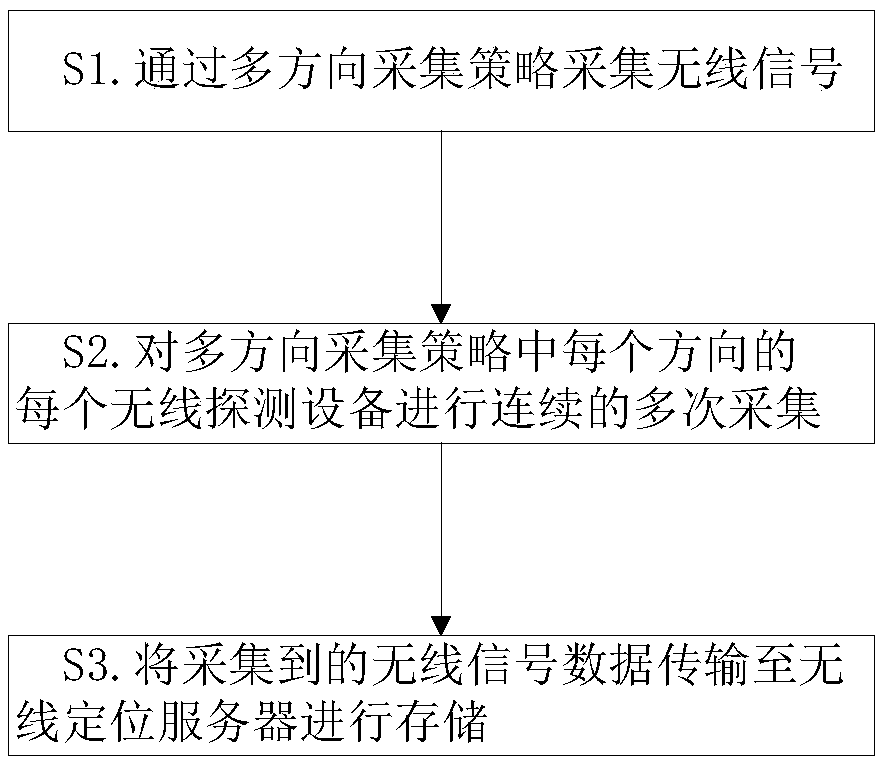

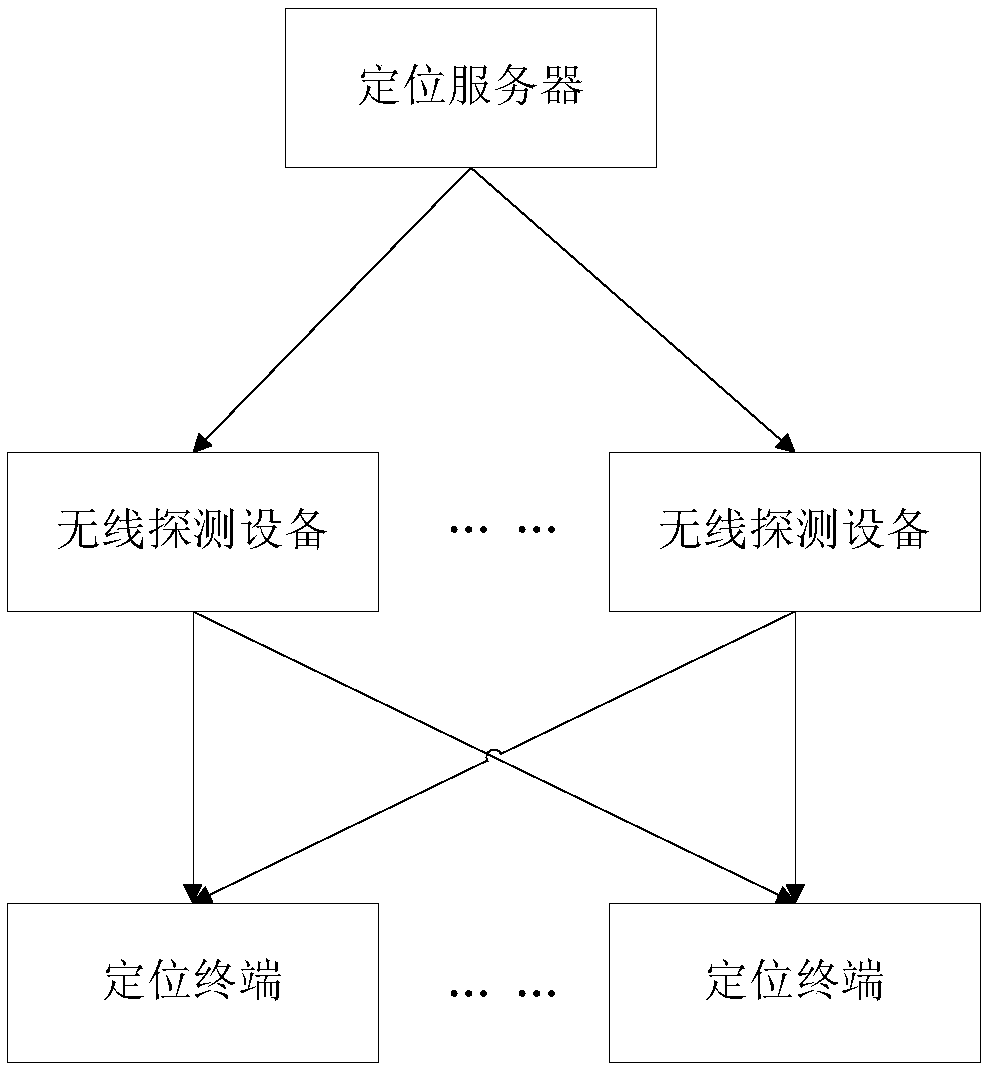

Wireless signal collecting and processing method and system used for indoor positioning

PendingCN109239655AReduce positioning errorsEase of noise reductionPosition fixationWireless communicationProcess mechanismComputer terminal

The invention records a wireless signal collecting and processing method and system used for indoor positioning. The method comprises the following steps that: through a multidirectional collection strategy, collecting a wireless signal; carrying out continuous multi-time collection on each piece of wireless detection equipment in each direction in the multidirectional collection strategy; and transmitting the collected wireless signal data to a wireless positioning server to be stored and the like. The system comprises a positioning terminal module, a multifunctional wireless signal collection module and a positioning server, wherein the positioning terminal module is used for emitting an indoor positioning wireless signal; the wireless signal collection module is used for collecting multidirectional wireless signals through a multidirectional collection strategy; and the positioning server is used for receiving and storing the wireless signal collected by the multifunctional wirelesssignal collection module. Due to the above technology, on the basis of the change difference characteristics of the wireless signal in different directions, a multidirectional signal collection strategy is adopted. Meanw

Owner:上海中兴易联通讯股份有限公司

Short-wave spectrum sensing method and system

InactiveCN102594468BIncrease coverageImprove signal-to-noise ratioTransmission monitoringDigital signal processingMulti band

The invention discloses a short-wave spectrum sensing method and a short-wave spectrum sensing system. An RF (radio-frequency) front-end unit dynamically adjusts the center frequency of a narrow-band electric tuning filter for multi-band short-waves at an RF analog front-end, and the Q value of a tuned loop is improved through an effective impedance matching network, thereby controlling the bandwidth of a filter to be fixed at a communication channel bandwidth or slightly greater than the communication channel bandwidth; after carrying out sampling on a signal, an analog-to-digital conversion module converts an analog short-wave signal in a pass band into a digital short-wave signal, and a digital signal processing unit realizes the sensing on the power spectrum of a received signal by using an energy detection algorithm. The method and system disclosed by the invention have the characteristics that the frequency band covering of short-waves is comprehensive, no image interference is introduced, and the method and the system are easy to implement.

Owner:GUILIN UNIV OF ELECTRONIC TECH

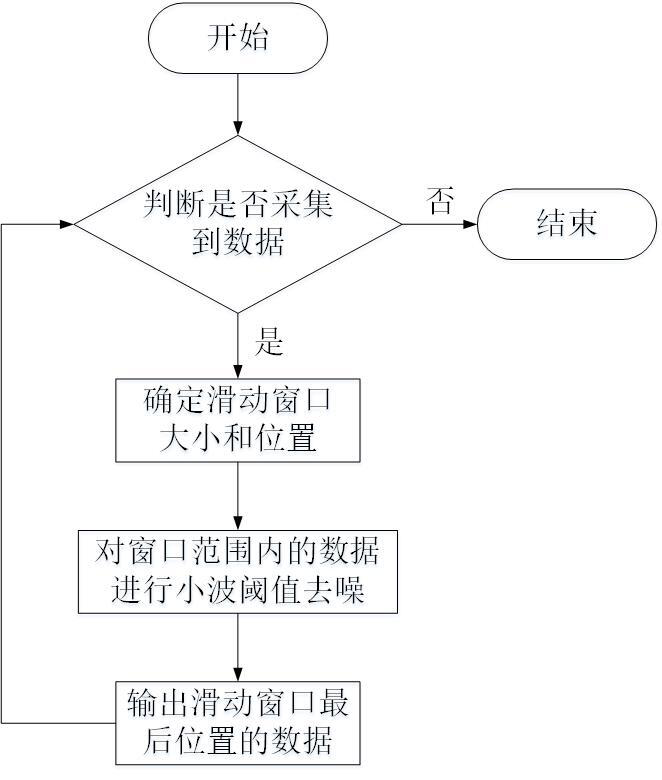

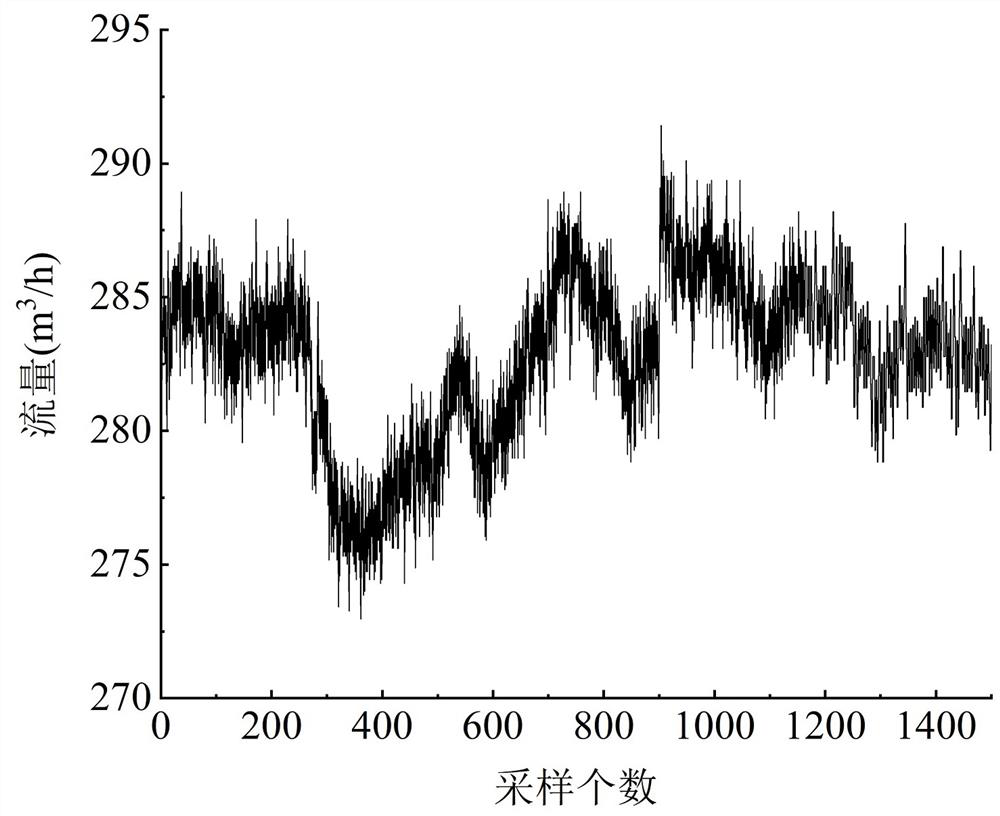

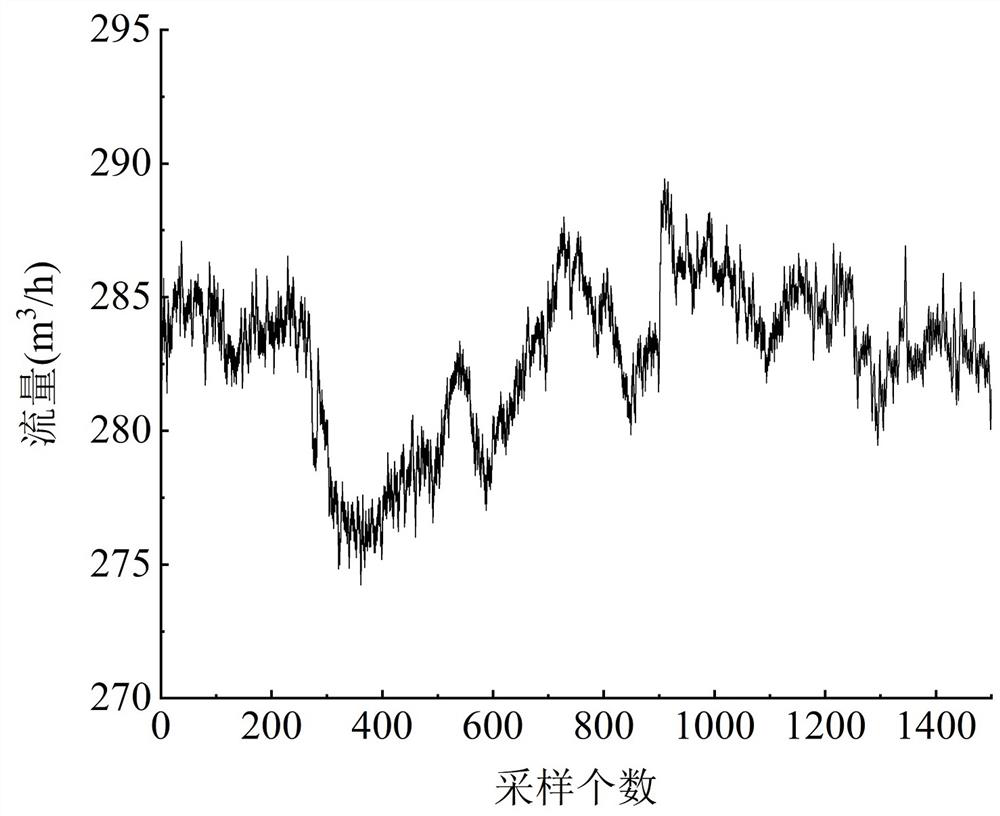

Real-time wavelet threshold denoising method for processing SCADA system data

PendingCN114298103AEase of noise reductionImplementing Online Wavelet Thresholding DenoisingCharacter and pattern recognitionSCADAWavelet decomposition

The invention provides a real-time wavelet threshold denoising method for processing SCADA (supervisory control and data acquisition) system data. According to the method, online wavelet threshold denoising is realized by adopting a sliding window, a wavelet coefficient is processed by adopting an adaptive function threshold, and wavelet decomposition of different levels is carried out under different signal lengths. According to the real-time wavelet threshold denoising method for processing the SCADA system data, calculation is simple, the denoising effect is good, the SCADA system data can be processed in real time, and basic data are provided for a long-distance pipeline online simulation technology.

Owner:SOUTHWEST PETROLEUM UNIV

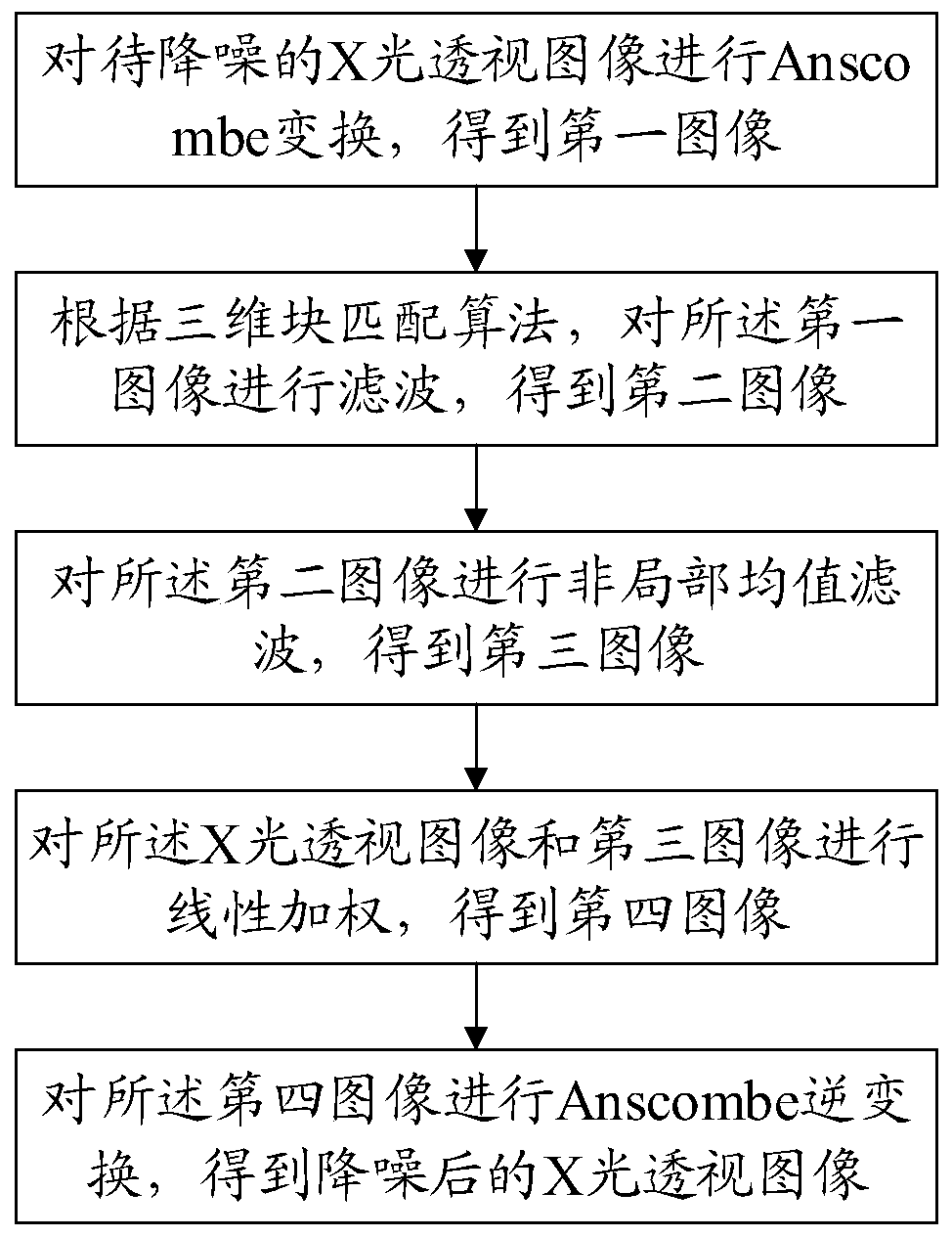

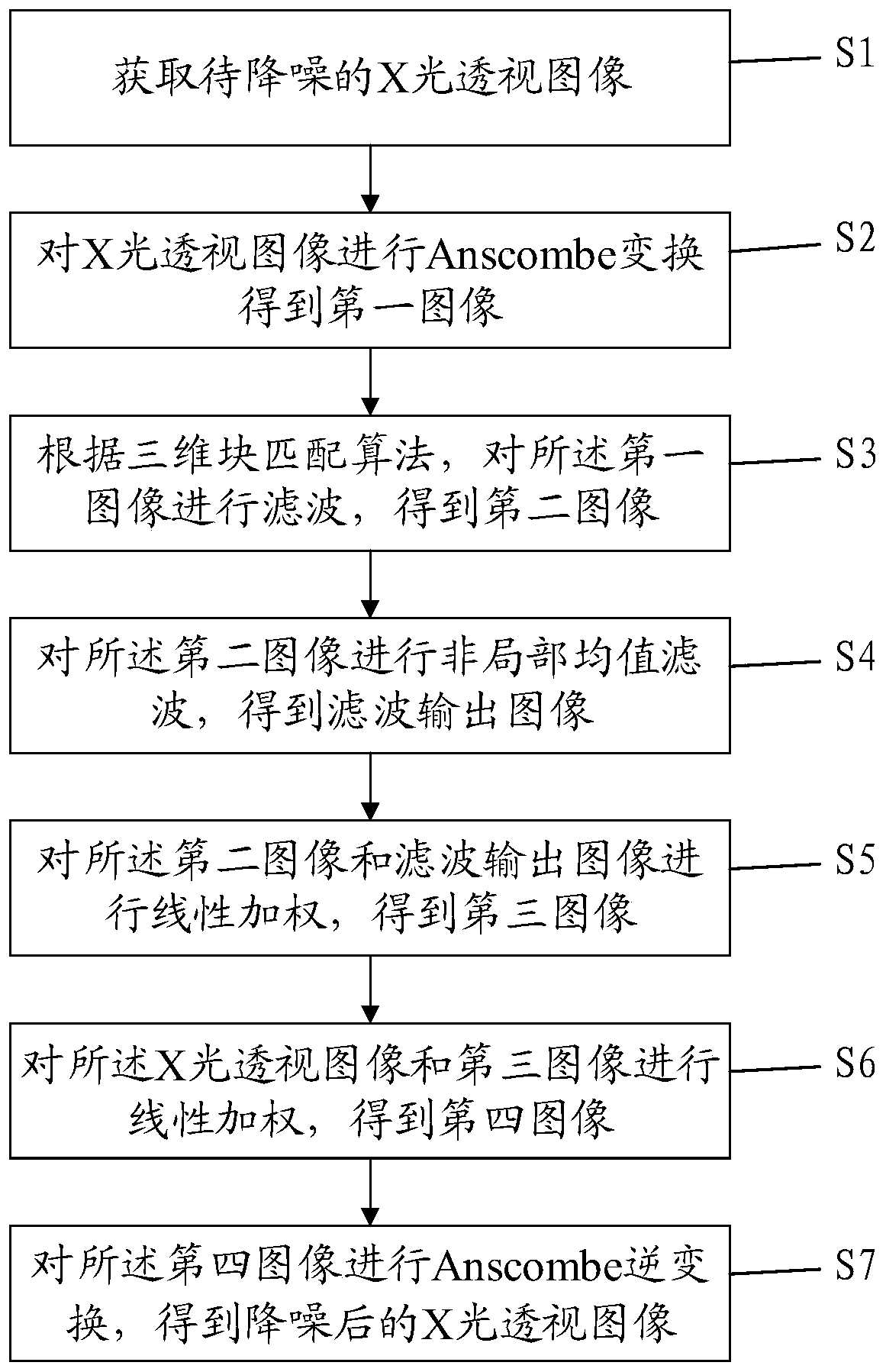

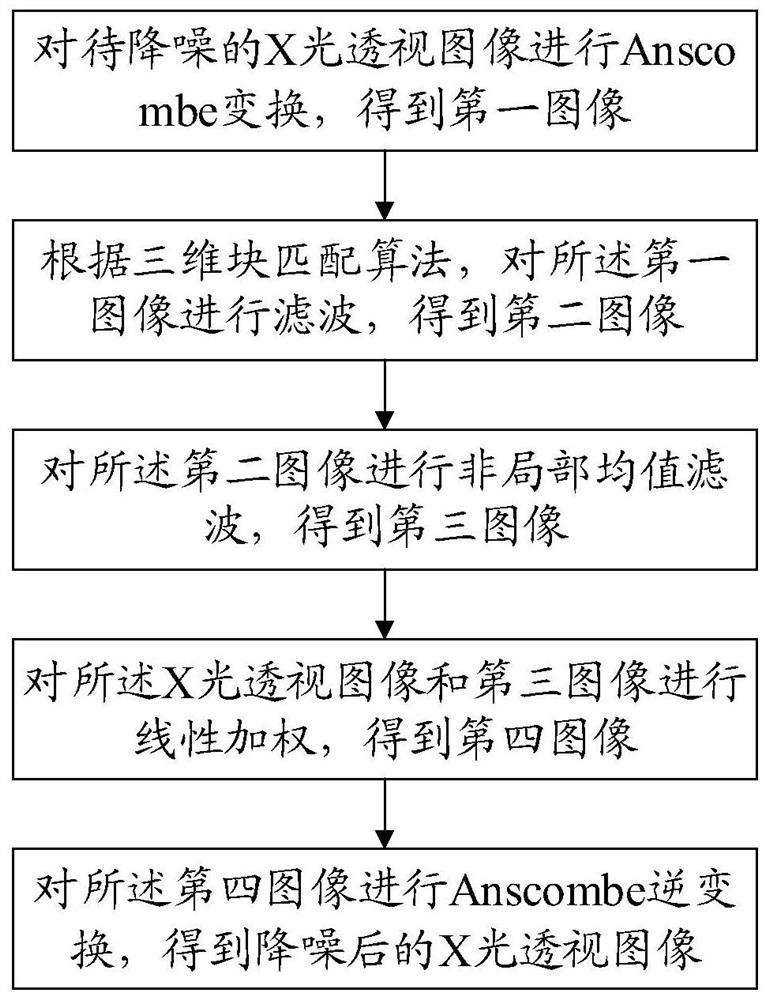

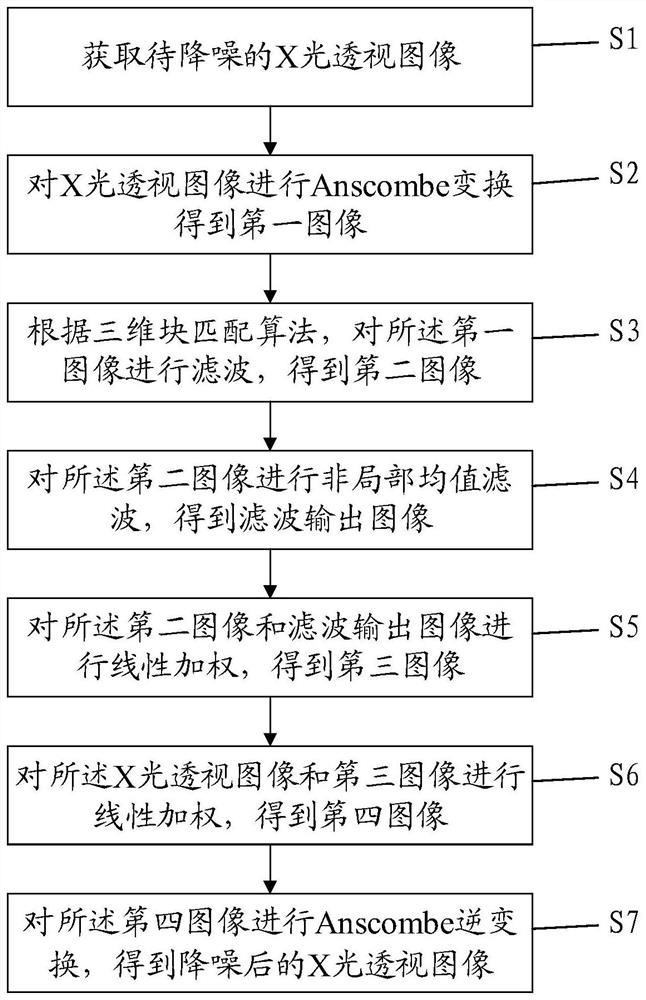

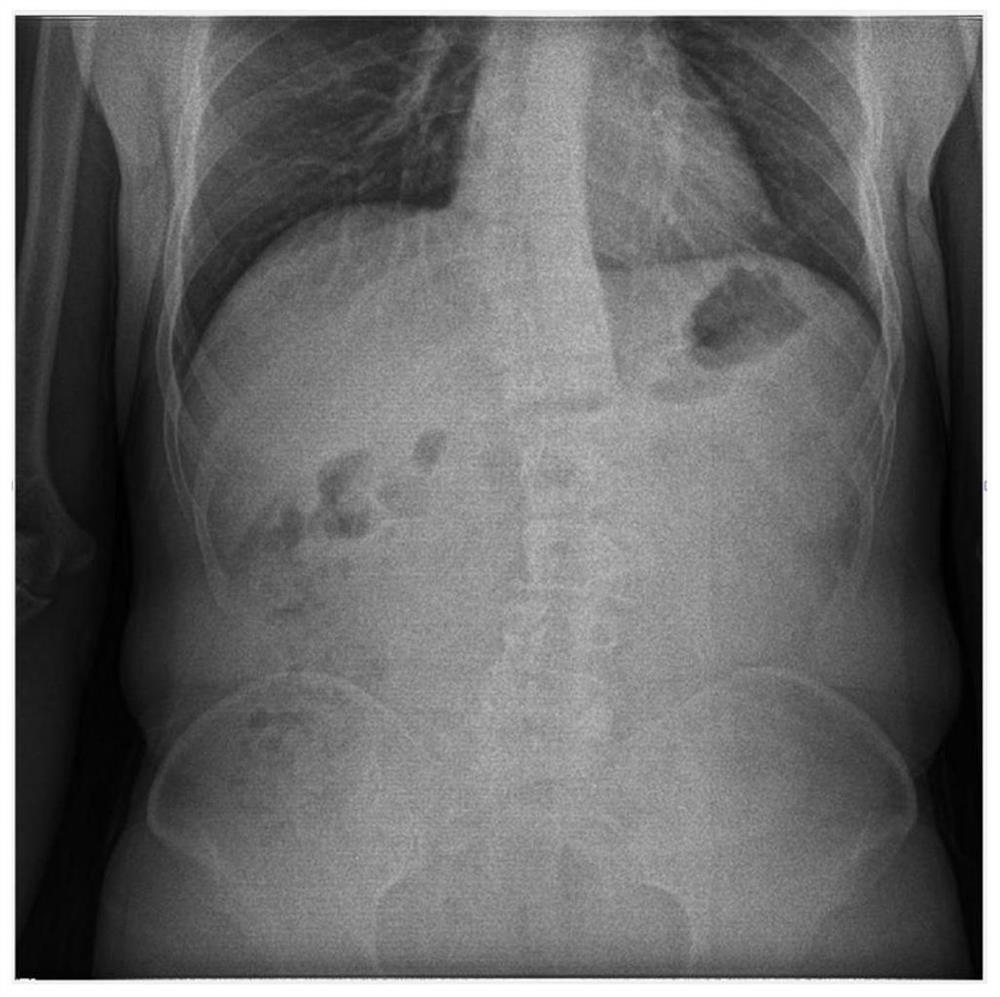

X-ray perspective image denoising method and computer readable storage medium

ActiveCN110738612AUniform brightnessKeep detailsImage enhancementImage analysisImage denoisingFluoroscopic image

The invention discloses an X-ray perspective image denoising method and a computer readable storage medium, and the method comprises the steps: carrying out the Anscombe transformation of an X-ray perspective image to be denoised, and obtaining a first image; filtering the first image according to a three-dimensional block matching algorithm to obtain a second image; carrying out non-local mean filtering on the second image to obtain a third image; performing linear weighting on the X-ray perspective image and the third image to obtain a fourth image; and performing Anscombe inverse transformation on the fourth image to obtain a denoised X-ray perspective image. The method is good in noise reduction effect, and image details can be reserved.

Owner:SHENZHEN ANGELL TECH

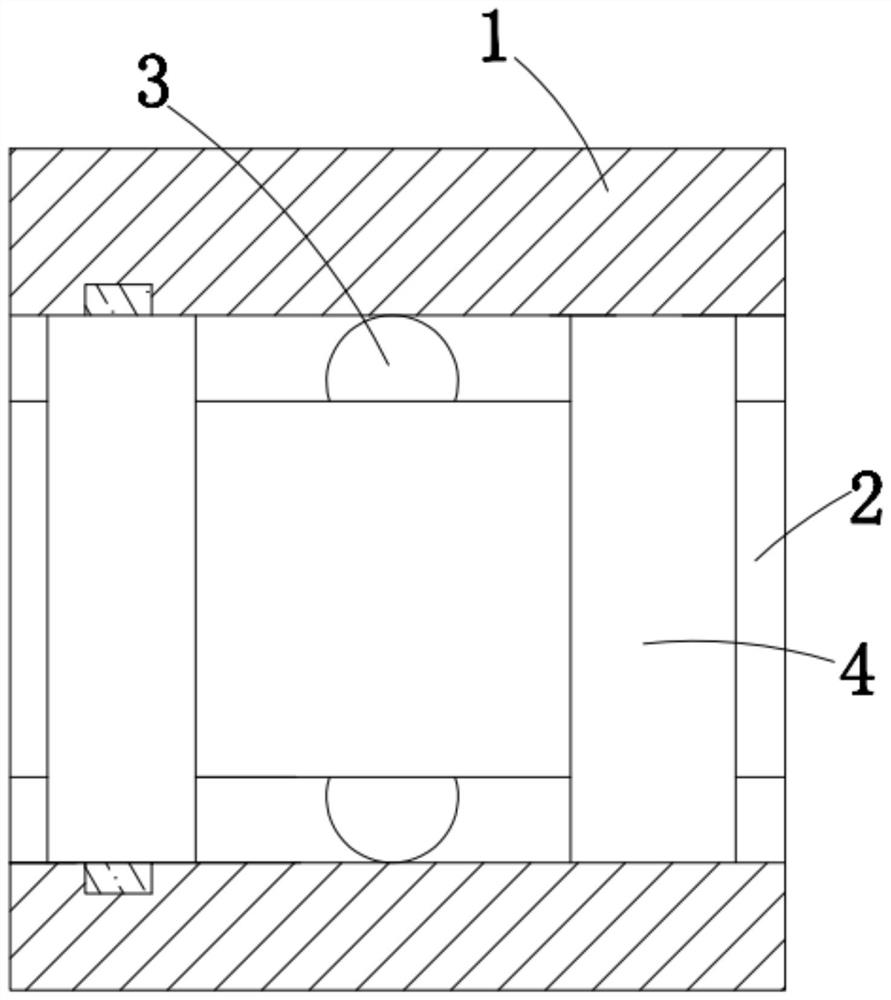

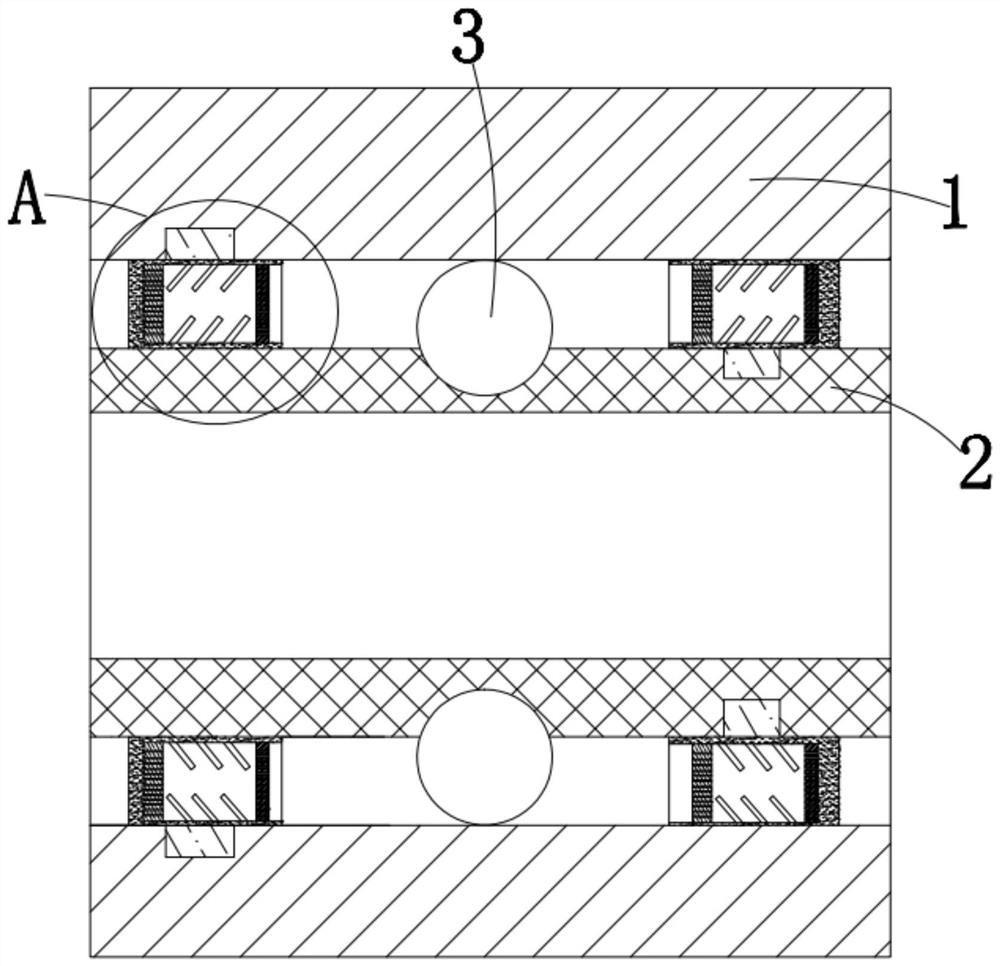

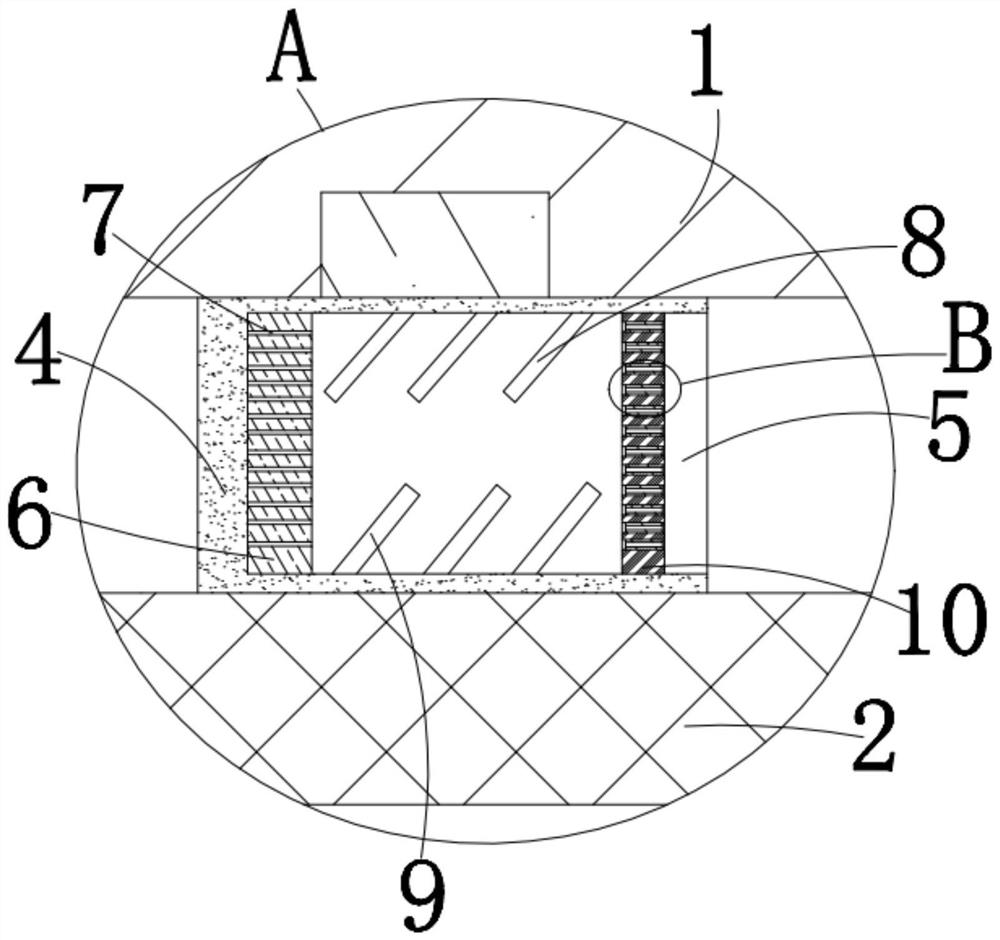

Bearing with noise reduction function

InactiveCN112524149AReduce noiseImprove the noise reduction effectBearing assemblyBall bearingsStructural engineeringNoise reduction

The invention discloses a bearing with a noise reduction function. The bearing with the noise reduction function comprises a bearing body, wherein the bearing body comprises a bearing outer ring and abearing inner ring arranged in the bearing outer ring, a plurality of balls are embedded between the bearing outer ring and the bearing inner ring, two blocking plates are arranged on the bearing inner ring in a sleeved mode, the plurality of balls are all located between the two blocking plates, one of the two blocking plates is fixedly arranged on the bearing inner ring in a sleeved mode, one blocking plate is rotationally installed on the side wall of the bearing outer ring, the other blocking plate is rotationally arranged on the bearing inner ring in a sleeving mode, the outer side of the other blocking plate is fixedly connected with the side wall of the bearing outer ring, annular grooves are formed in the sides, close to each other, of the two blocking plates, and first aluminum plates are fixedly arranged in the annular grooves in a sleeved mode. The bearing with the noise reduction function is reasonable in design and convenient to operate, noise generated by the bearing body can be conveniently reduced, the good noise reduction purpose is achieved, disturbing of hearing of people is avoided, and the bearing is convenient to use.

Owner:常州鼎森传动科技有限公司

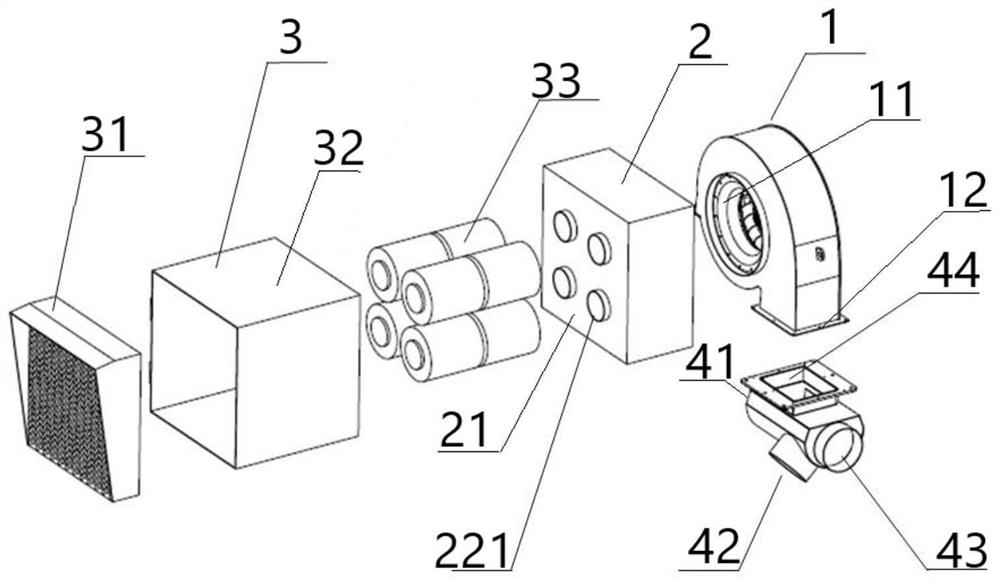

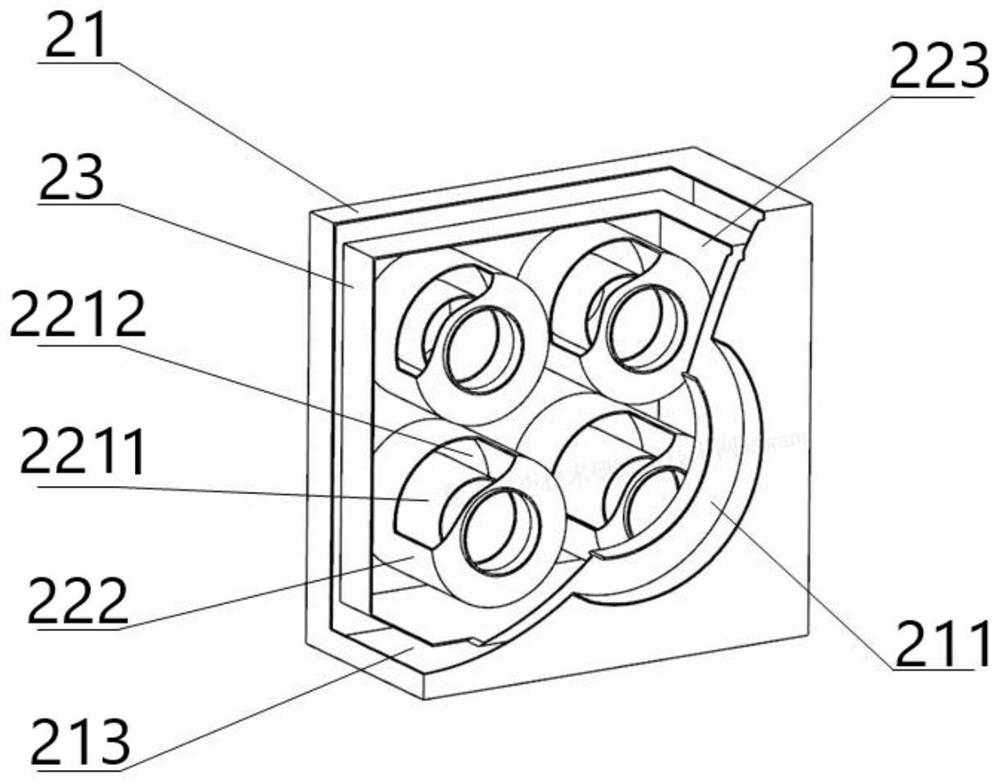

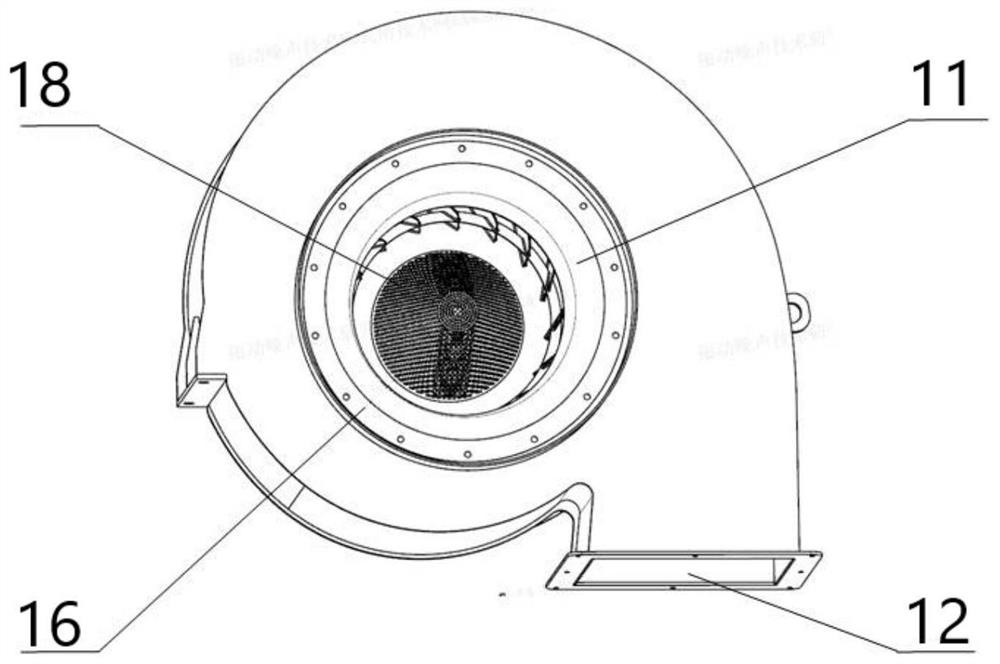

Fan components, air cooling systems and electric drive engineering machinery

ActiveCN112145463BEase of noise reductionPump componentsPump installationsEngineeringAir cooling system

The invention discloses a fan assembly, an air cooling system and an electric transmission construction machine. The fan assembly includes: a fan, including a fan inlet; An air duct and an air outlet sleeve, the air intake duct passes through the first housing and has a muffler duct section protruding from the first housing, the air outlet sleeve is installed on the first housing and covers It is arranged outside the muffler duct section and forms a first muffler cavity with the muffler duct section. The air inlet of the air inlet duct is used to input the air flow sent to the fan. The air outlet sleeve has an air outlet connected to the inlet of the fan, the air outlet of the sound-absorbing duct section is located in the air-outlet sleeve and is spaced from and communicated with the air-outlet of the air-outlet sleeve, at least two of the plurality of sound-absorbing structures The lengths of the sound-absorbing duct sections of the several sound-absorbing structures are different and / or the lengths of the air outlet sleeves of at least two sound-absorbing structures among the plurality of sound-absorbing structures are different.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

Geomagnetic aided inertial navigation method

InactiveCN102829782BImprove noise reduction efficiencySave fine matching timeNavigation by terrestrial meansNavigation by speed/acceleration measurementsNoise reductionMagnetogram

The invention relates to the navigation and guidance technologies and provides a technical scheme of a geomagnetic aided inertial navigation method. According to the scheme, at least more than one magnetic measuring apparatus is used for simultaneously measuring real-time geomagnetic information of transporters; and a geomagnetic matching navigation mode is adopted to conduct rough matching, noise reduction and precise matching on the measured real-time geomagnetic information sequentially. The magnetic measuring manner reduces the error of the apparatus and ensures the reliability of the measured value. By adopting the matching mode, the non-matching points with the reference geomagnetic map are eliminated and the range of the noise reduction and the precise matching is reduced, thereby improving the noise reduction efficiency of the real-time geomagnetic information and saving the precise matching time of the non-matching points; and meanwhile, the speed of the precise matching is improved and the precision of the navigation is ensured, thereby further promoting the quality of the geomagnetic aided inertial navigation.

Owner:BINZHOU UNIV

A high-precision patch head with flight recognition function

ActiveCN106304673BReduce deflectionGuaranteed uptimePrinted circuit assemblingAcute angleMiniaturization

The invention provides a high-precision chip mounting head capable of flight identification. The chip mounting head comprises a chip mounting head support, chip mounting shafts mounted in the chip mounting head support, a direction-Z elevation mechanism, a direction-R turning mechanism and a vacuum module group; the chip mounting head is characterized in that an integrated control assembly is mounted in the back side of the upper portion of the chip mounting head support, the vacuum module group is mounted in the front side of the upper portion of the support, a direction-R stepping motor which drives the direction-R turning mechanism and a CCD camera collecting images are mounted in the middle of the front side of the support, direction-Z driving motors are mounted in the back side of the support, and the directions of output shafts of the direction-Z driving motors are vertical to the axis-Z; and a flight camera device is mounted in the lower portion of the back side of the chip mounting head support, and comprises a light source assembly below a nozzle, a camera assembly, a camera support provided with the light source assembly and the camera assembly and a driving mechanism which enables the camera support to move along the axis-X, and an acute angle is formed between the direction of a lens of the camera assembly and the vertical direction in the XY plane. The chip mounting head is minimized and low-cost, and stable, accurate, rapid and high-precision chip mounting is realized.

Owner:江苏华志珹智能科技有限公司

Noise reduction method and computer-readable storage medium for X-ray perspective image

ActiveCN110738612BUniform brightnessKeep detailsImage enhancementImage analysisFluoroscopic imageRadiology

The invention discloses a noise reduction method for X-ray fluoroscopic images and a computer-readable storage medium. The method includes: performing Anscombe transformation on an X-ray fluoroscopic image to be de-noised to obtain a first image; Filter the first image to obtain a second image; perform non-local mean filtering on the second image to obtain a third image; perform linear weighting on the X-ray fluoroscopic image and the third image to obtain a fourth image; The fourth image is subjected to inverse Anscombe transform to obtain a denoised X-ray fluoroscopic image. The invention has good noise reduction effect and can retain image details.

Owner:SHENZHEN ANGELL TECH

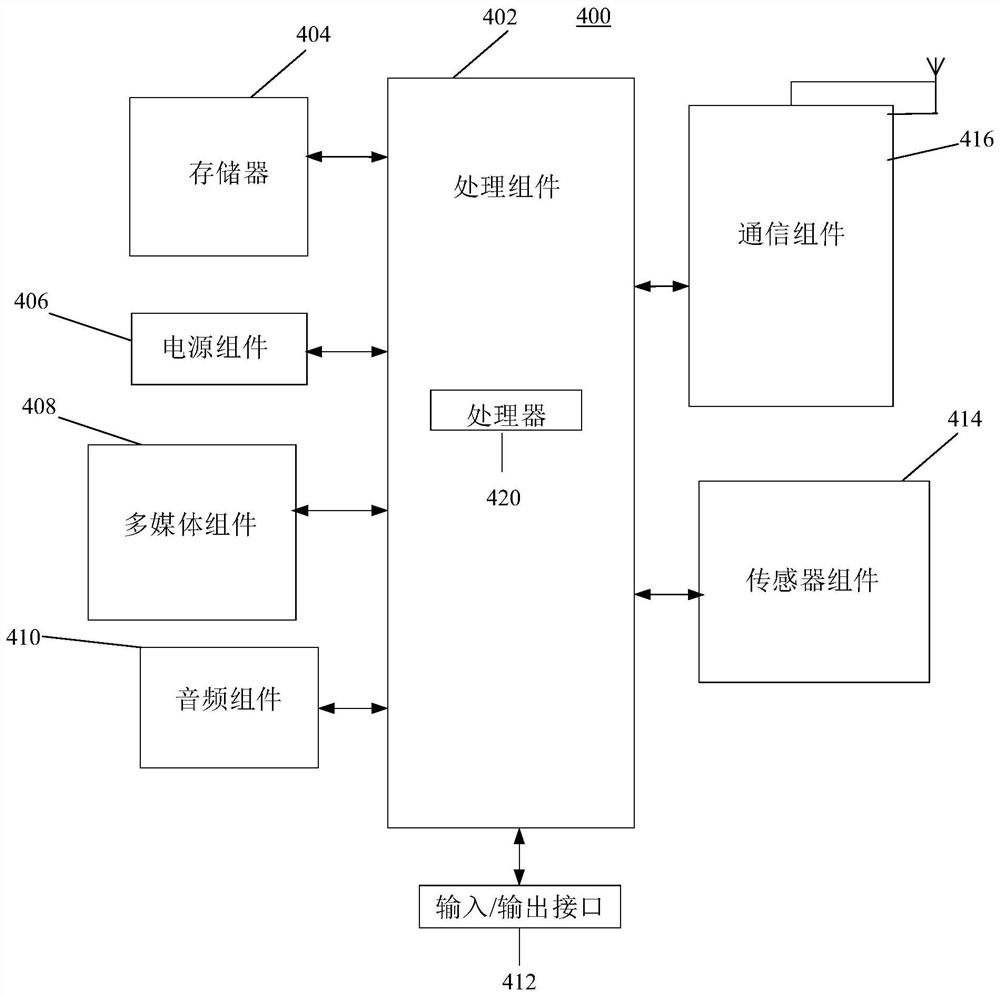

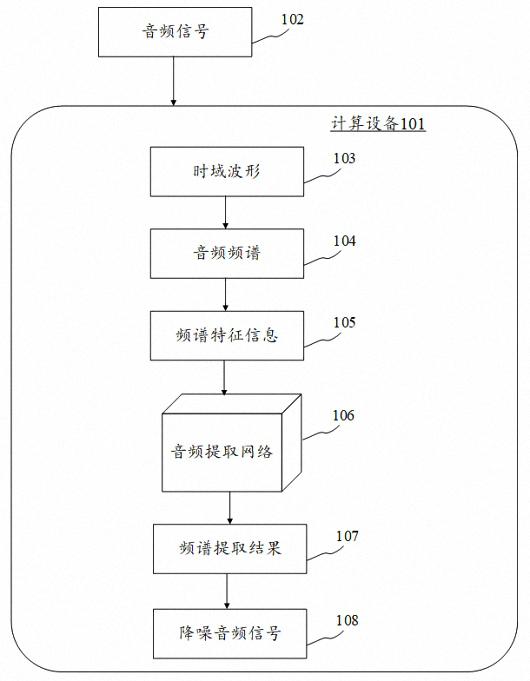

Audio noise reduction transmission method and device, electronic equipment and computer readable medium

ActiveCN112599147AImplement noise reduction processingEase of noise reductionSpeech analysisFrequency spectrumNoise

The embodiment of the invention discloses an audio noise reduction transmission method and device, electronic equipment and a computer readable medium. One specific embodiment of the method comprisesthe following steps: acquiring an audio signal acquired by a voice acquisition device; performing time domain conversion processing on the audio signal to generate a time domain waveform; performing frequency spectrum conversion processing on the time domain waveform to obtain an audio frequency spectrum; performing frequency spectrum feature extraction processing on the audio frequency spectrum to generate frequency spectrum feature information; inputting the frequency spectrum feature information into a pre-trained audio extraction network to obtain a frequency spectrum extraction result; and performing noise reduction processing on the frequency spectrum extraction result to obtain a noise reduction audio signal. According to the embodiment of the invention, the method and device achieve the noise reduction of the audio, improve the noise inhibition effect, and improve the audio transmission efficiency of the earphone.

Owner:北京嘉诚至盛科技有限公司

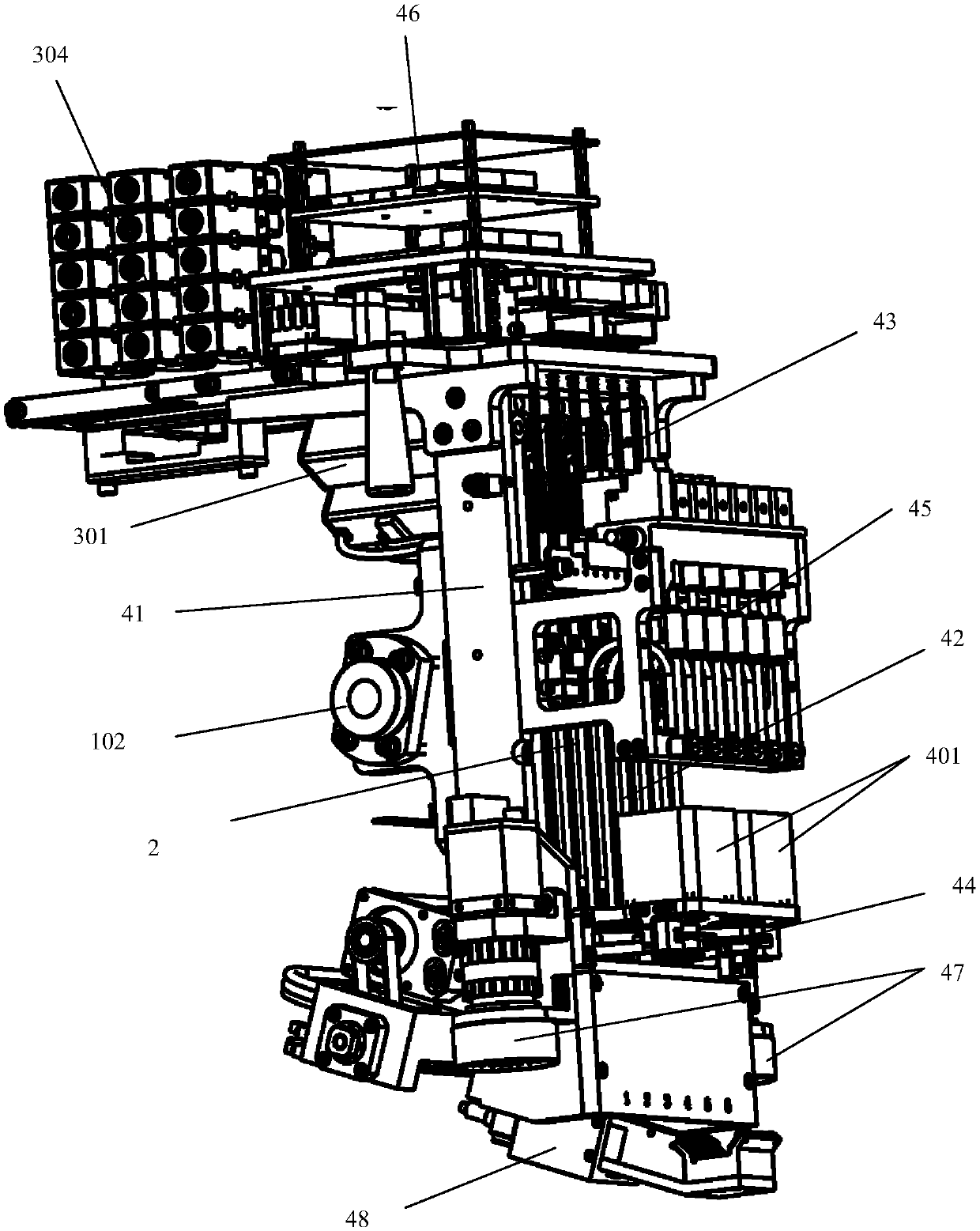

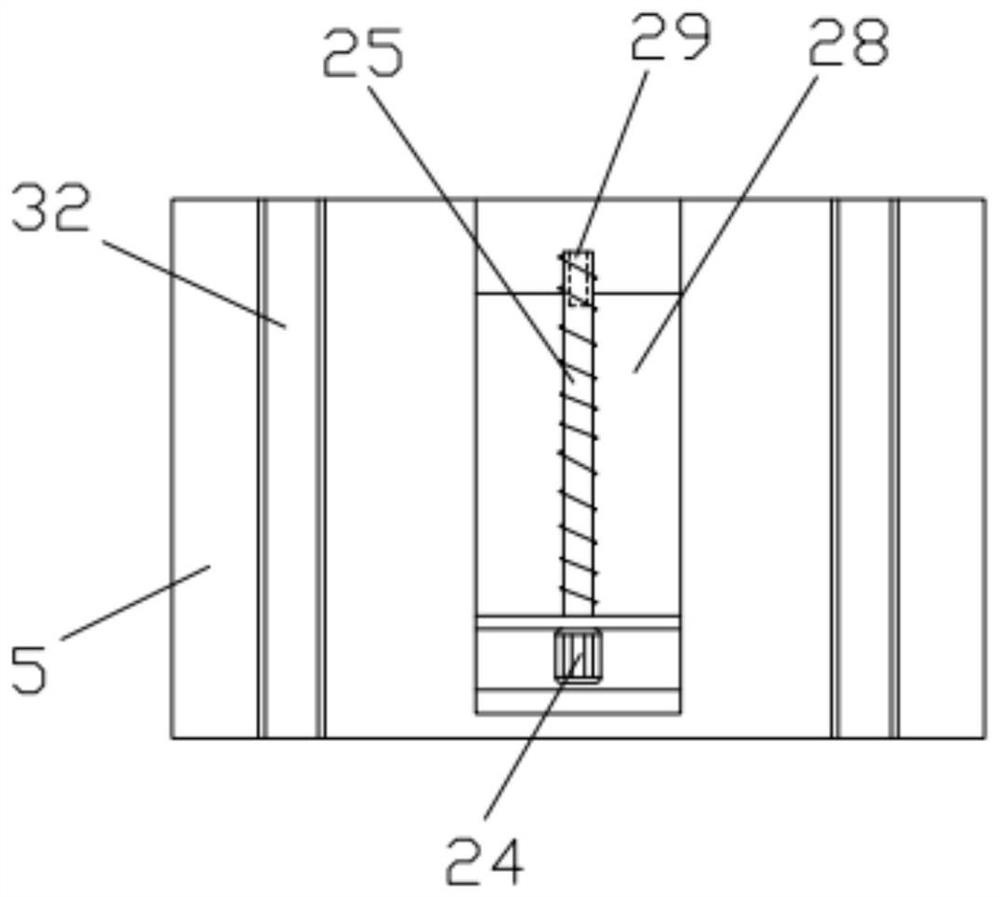

High-precision light-weight placement head

ActiveCN106304676BFine control positive pressureEase of noise reductionPrinted circuit assemblingDrive motorEngineering

The invention provides a high-precision low-weight chip mounting head. The chip mounting head comprises a chip mounting head support, chip mounting shafts mounted in the chip mounting head support, a direction-Z elevation mechanism, a direction-R turning mechanism and a vacuum module group, an integrated control assembly is mounted in the back side of the upper portion of the chip mounting head support, the vacuum module group is mounted in the front side of the upper portion of the support, a direction-R stepping motor which drives the direction-R turning mechanism and a CCD camera collecting images are mounted in the middle of the front side of the support, two vertical rows of direction-Z driving motors are mounted in the back side of the support, and the directions of output shafts of the direction-Z driving motors are vertical to the axis-Z; and a conflux packaging plate is mounted in the upper portion of a support of the vacuum module group, an air pressure detecting integrated module is mounted in the outer side surface of the conflux packaging plate, the bottom of the support of the vacuum module group is connected with a vacuum commutation plate, the upper side of the vacuum commutation plate is provided with vacuum outlets, the side surface of the vacuum commutation plate is provided with straight vacuum tubes connected to the vacuum outlets correspondingly, each straight vacuum tube is connected with one filtering assembly, and the filtering assemblies are connected with the corresponding straight vacuum tubes on the conflux packaging plate.

Owner:广州莱伦智能机械有限公司

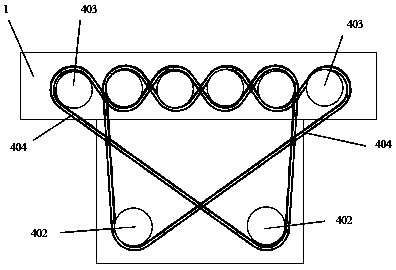

Double-arm multi-head placement machine

ActiveCN106304677BExpand the range of PCB boards that can be processedOptimization pathPrinted circuit assemblingSurface mountingHigh surface

The present invention provides a double-arm multi-head surface mount system. The double-arm multi-head surface mount system comprises two sets of single-arm multi-head surface mount devices, two Y-axis positioning arched frames, a feeding device and a plate feeding device. The double-arm multi-head surface mount system is characterized in that two Y-axis positioning arched frames are installed on a main body rack, are located at the feeding port and discharge port of the plate feeding device respectively, and are vertical to a plate feeding direction; and the two sets of single-arm multi-head surface mount devices are arranged on the Y-axis positioning arched frames respectively and can move freely above the plate feeding device; and each single-arm multi-head surface mount device is composed of a translational movement seat assembly which can move in a Y direction, a moving arm mechanism mounted on the translational movement seat assembly, and a surface mount head assembly which is mounted on the moving arm mechanism and can move in an X direction. The double-arm multi-head surface mount system of the invention has the advantages of high surface mount speed, high surface mount precision and stable and reliable surface mount quality.

Owner:广东木几智能装备有限公司

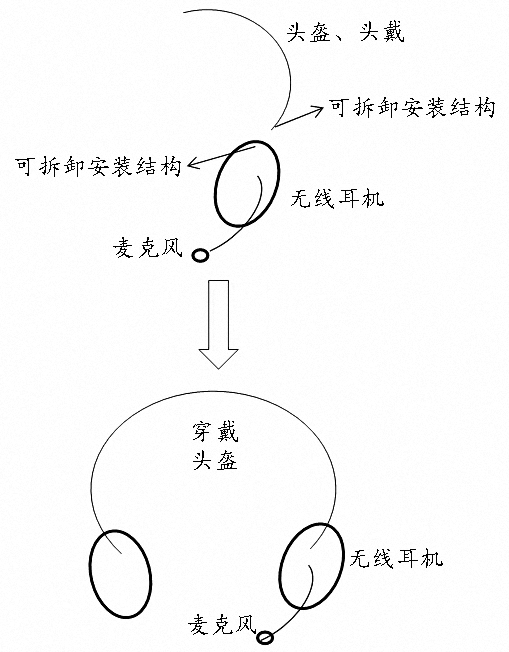

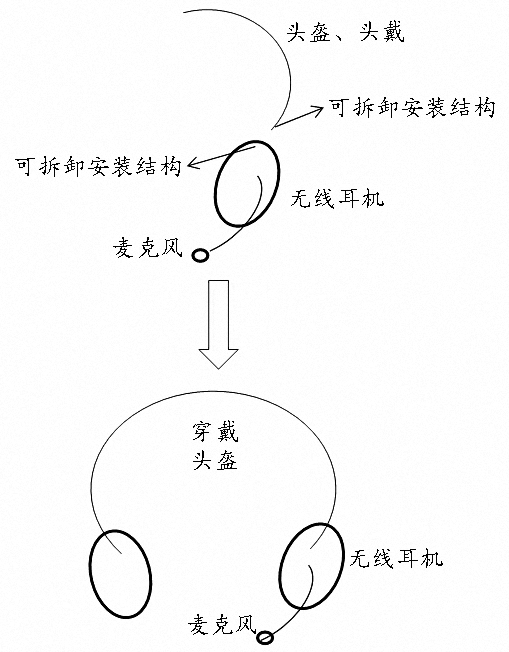

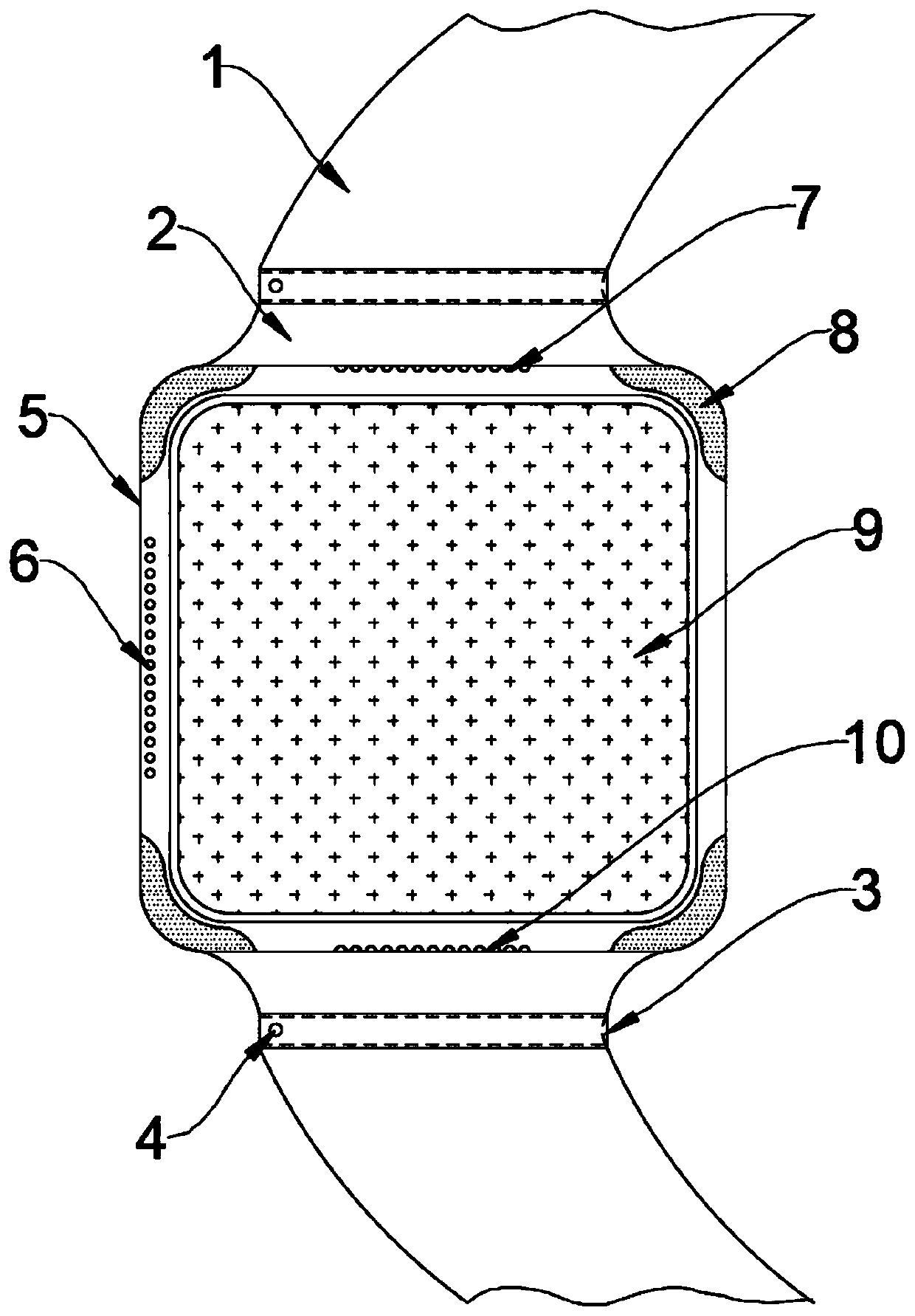

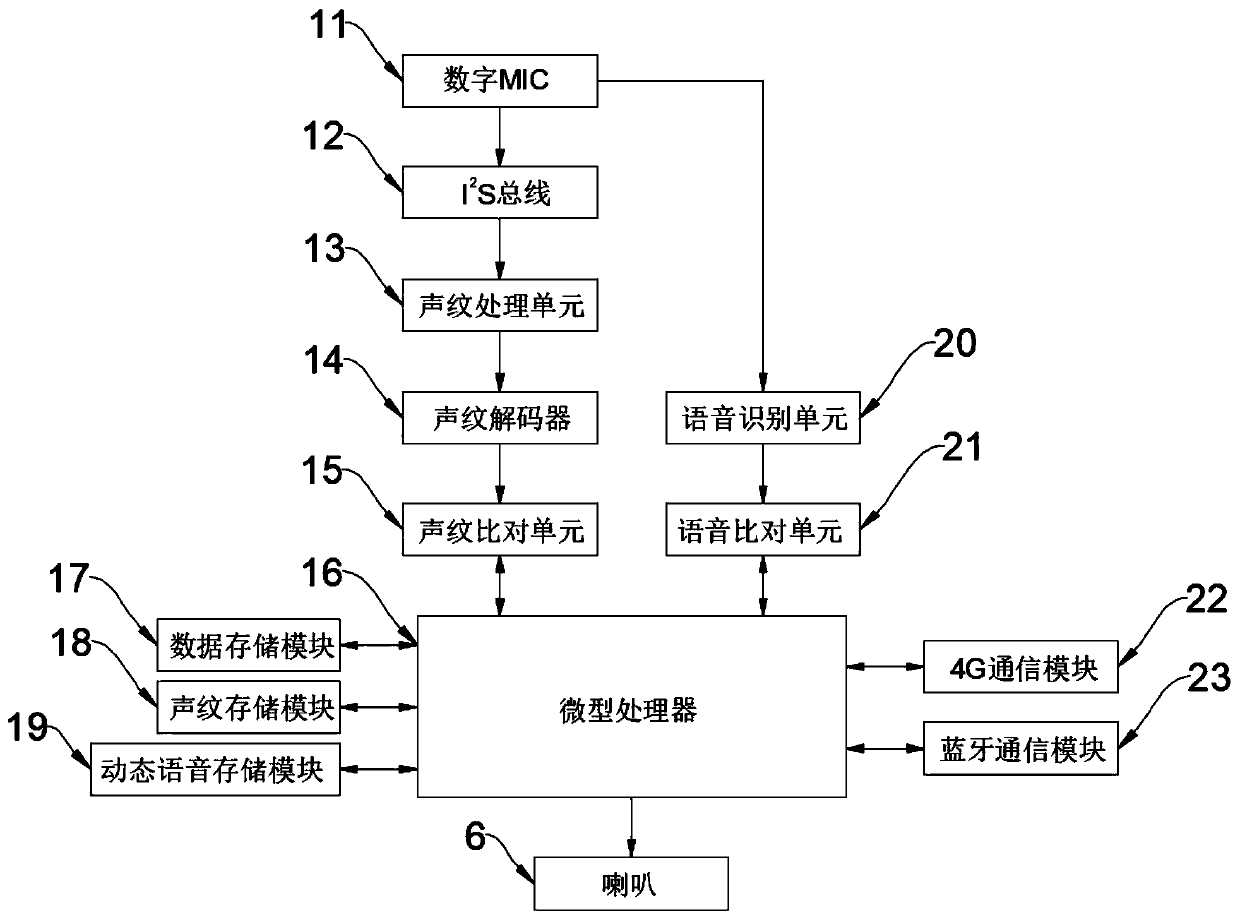

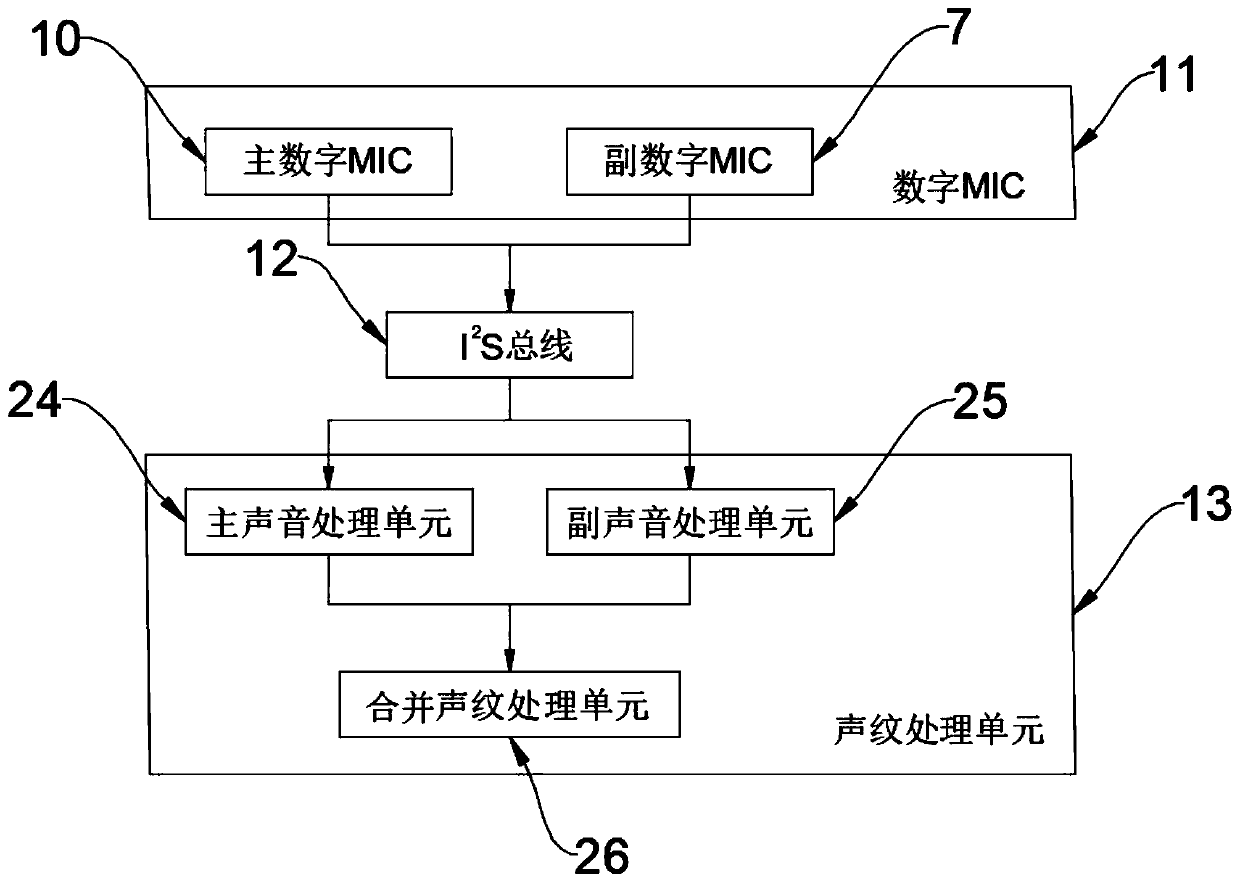

Intelligent wearing equipment with function of recognizing characteristic human voice and using method of equipment

PendingCN110060689AAccelerateGood user experienceSpeech analysisDetails for portable computersVocal soundComputer science

Owner:南京启诺信息技术有限公司

Dry-type transformer

PendingCN113130174AEasy maintenanceEasy to dissipate heatTransformers/reacts mounting/support/suspensionTransformers/inductances coolingEngineeringStructural engineering

The invention discloses a dry-type transformer. The dry-type transformer comprises a transformer body and a protective shell matched with the transformer body, a mounting seat is arranged in the protective shell, and the mounting seat is movably connected with the bottom wall of the protective shell; an opening is formed in one side of the protective shell, a cover plate is hinged to the lower edge of the opening, the surface of the cover plate and the inner bottom wall of the protective shell are located on the same horizontal plane when the cover plate is flatly laid, and a limiting plate is connected to the lower portion of the cover plate; and a heat dissipation structure and a noise reduction structure are further arranged in the protective shell. The protective shell is arranged outside the transformer body, good noise reduction treatment can be carried out in cooperation with the noise reduction structure, after the cover plate is dumped and laid flat, the surface of the cover plate and the inner bottom wall of the protective shell are located on the same horizontal plane, the mounting base movably connected with the protective shell can drive the transformer body to the cover plate, and overhaul and maintenance are convenient.

Owner:天宏电力科技有限公司

Chip head control system and method

ActiveCN106304675BRealize R rotationEase of noise reductionPrinted circuit assemblingEngineeringNoise reduction

The invention provides a mounting head control system. The mounting head control system consists of a mounting head controller, an industrial mainboard, a Mark point camera, a Z axis moving module, a flight camera, a pneumatic module, an R axis motion module and an inductor module. The mounting head control system is characterized in that the Mark point camera, the Z axis moving module and the flight camera are connected to the industrial mainboard; the mounting head controller is connected to the pneumatic module, the R axis motion module and the inductor module; and the mounting head controller is connected to the industrial mainboard. The mounting head control system and method use a modularization idea and use a mounting head controller to be connected to the industrial mainboard, independently take charge for data processing of the pneumatic module, the R axis motion module and the inductor module, realize material absorbing and discharging of a mounting shaft, and member rotation in an R direction; the inductor is in charge of data collection of the pneumatic module and the R axis motion module and is in communication with the industrial mainboard through a CAN bus, which makes the whole system faster and more efficient. The mounting head control system and method effectively improve a material absorbing speed, reduce vacuum detection fluctuation and provide convenience to noise reduction processing of a detection signal of a simulation pressure sensor.

Owner:广东木几智能装备有限公司

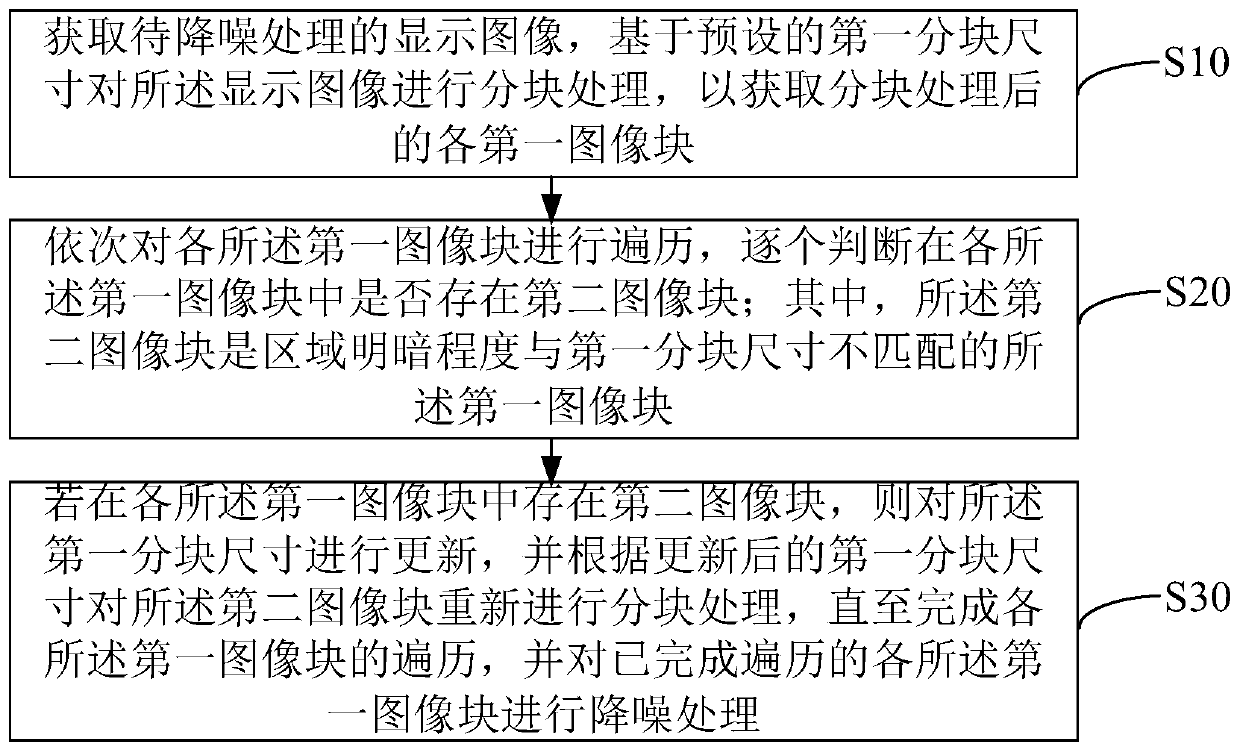

Image noise reduction processing method, mobile terminal, device and computer storage medium

PendingCN110084764AEase of noise reductionTroubleshooting Distortion-Prone Technical IssuesImage enhancementImage analysisImage denoisingPattern recognition

The invention discloses an image noise reduction processing method, a mobile terminal, a device and a computer storage medium, and the method comprises the steps: obtaining a display image to be subjected to noise reduction processing, and carrying out the block processing of the display image based on a preset first block size, so as to obtain each first image block after the block processing; traversing each first image block in sequence, and judging whether a second image block exists in each first image block one by one; wherein the second image block is a first image block of which the regional light and shade degree is not matched with the size of the first block; and if the second image block exists in each first image block, updating the size of the first block, and performing block processing on the second image block again according to the updated size of the first block until the traversal of each first image block is completed, and performing noise reduction processing on each first image block after traversal is completed. The technical problem that in the prior art is solved. After image noise reduction processing is conducted on an image, images are not prone to distortion.

Owner:NUBIA TECHNOLOGY CO LTD

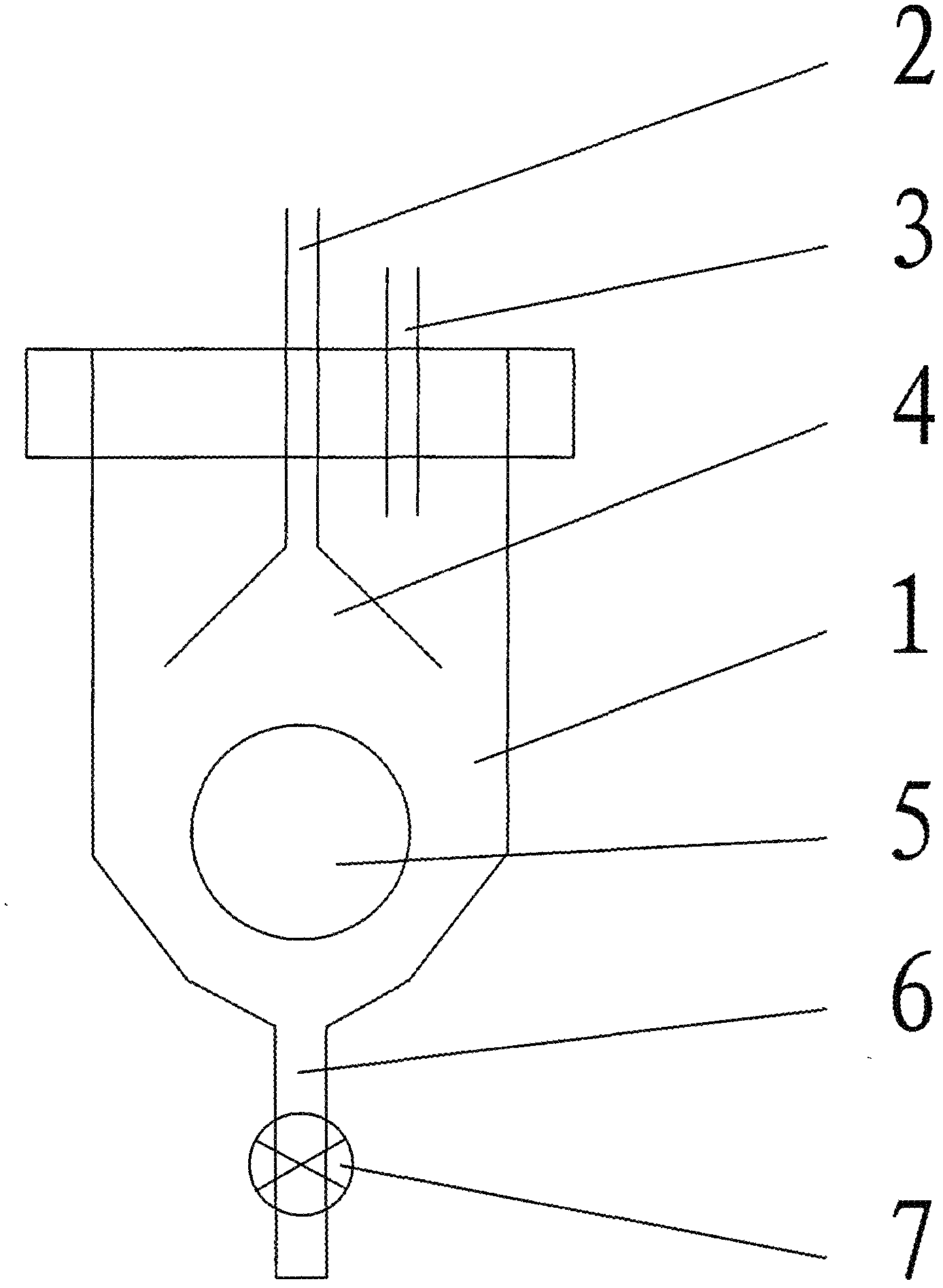

Negative pressure automatic protection device

InactiveCN102878120ASimple structureReasonable designPressure pumpsMachines/enginesOutput deviceEngineering

The invention provides a negative pressure automatic protection device, which comprises a negative pressure intake pressure regulating device and a compressor, wherein a negative pressure output device is arranged between the negative pressure intake pressure regulating device and the compressor; an isolation battle is arranged on the negative pressure output device; and an automatic drainage device is arranged in the isolation bottle. The negative pressure automatic protection device can effectively prevent liquid from being absorbed into the compressor, a pneumatic adjusting device and the like, so that great loss is avoided; and the space of an instrument is saved for a blood sample clot filtering device for noise reduction treatment of the compressor.

Owner:江苏美诚生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com