A high-precision patch head with flight recognition function

A high-precision, patch head technology, used in printed circuits, electrical components, printed circuit manufacturing, etc., can solve the problems of limiting the number of identifiable nozzles, complex optical path matching, and large patch head volume, so as to facilitate noise reduction processing. , The effect of large design and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

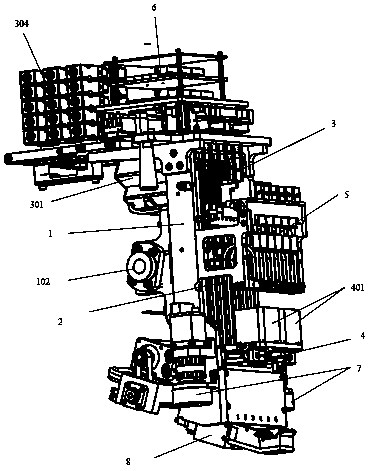

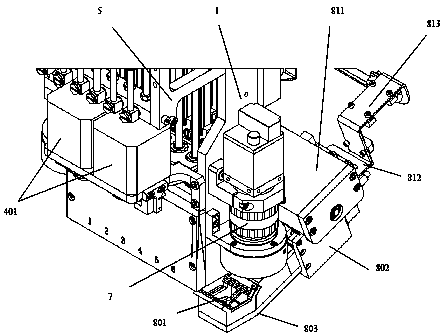

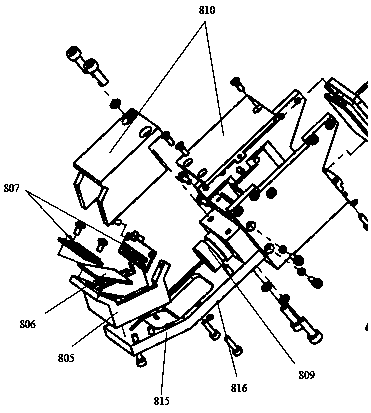

[0028] Such as Figure 1-7As shown, a high-precision placement head with flight recognition function includes a placement head support 1, a plurality of placement axes 2 installed in the placement head support 1, and a Z-direction lift that drives the placement axis 2 to rise and fall. Mechanism 3. The R-direction corner mechanism that drives the placement shaft 2 to rotate in a circle. The front is equipped with a vacuum module 5, and its front middle part is equipped with an R-direction stepper motor 401 for driving the R-direction corner mechanism 4 and a CCD camera 7 for collecting images, and a Z-direction drive motor 301 is installed on its back top, and the Z-direction The direction of the output axis of the drive motor 301 is perpendicular to the Z axis; the lower part of the back of the mounting head bracket 1 is equipped with a flying c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com