Intelligent steel cord conveyer belt defect identification method and intelligent steel cord conveyer belt defect identification system

A wire rope core, intelligent identification technology, applied in the direction of material magnetic variables, can solve the problems of insufficient research, waste, poor real-time performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

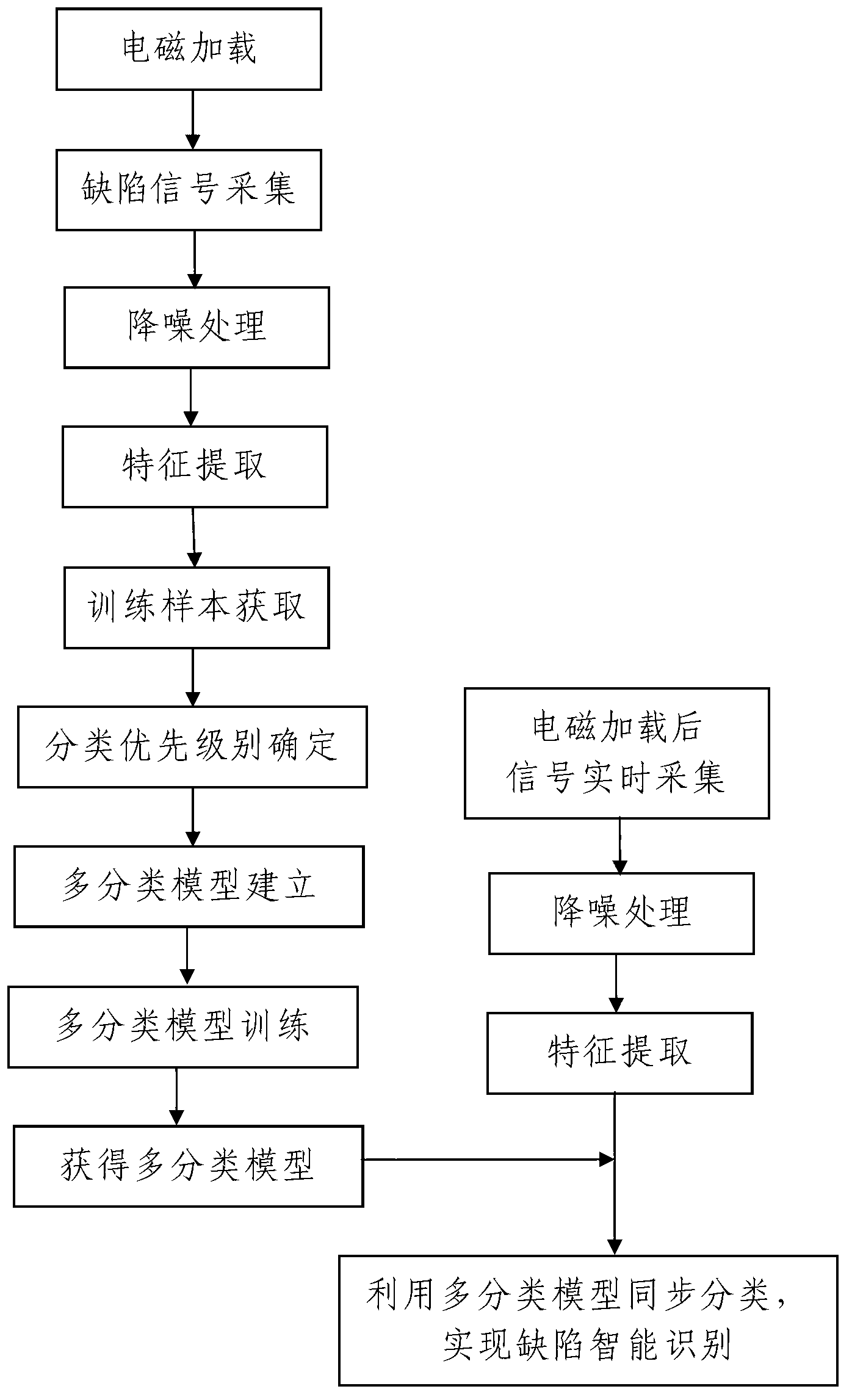

[0089] Such as figure 1 A method for intelligently identifying defects in a steel cord conveyor belt as shown, comprising the following steps:

[0090] Step 1. Electromagnetic loading: use an electromagnetic loading device to electromagnetically load the detected steel cord conveyor belt.

[0091] In this embodiment, the electromagnetic loading device used is a weak magnetic loading module 4 . In actual loading, the TCK-GMS type magnetic field weakening loading device is specifically used, and other types of magnetic field weakening loading devices can also be used.

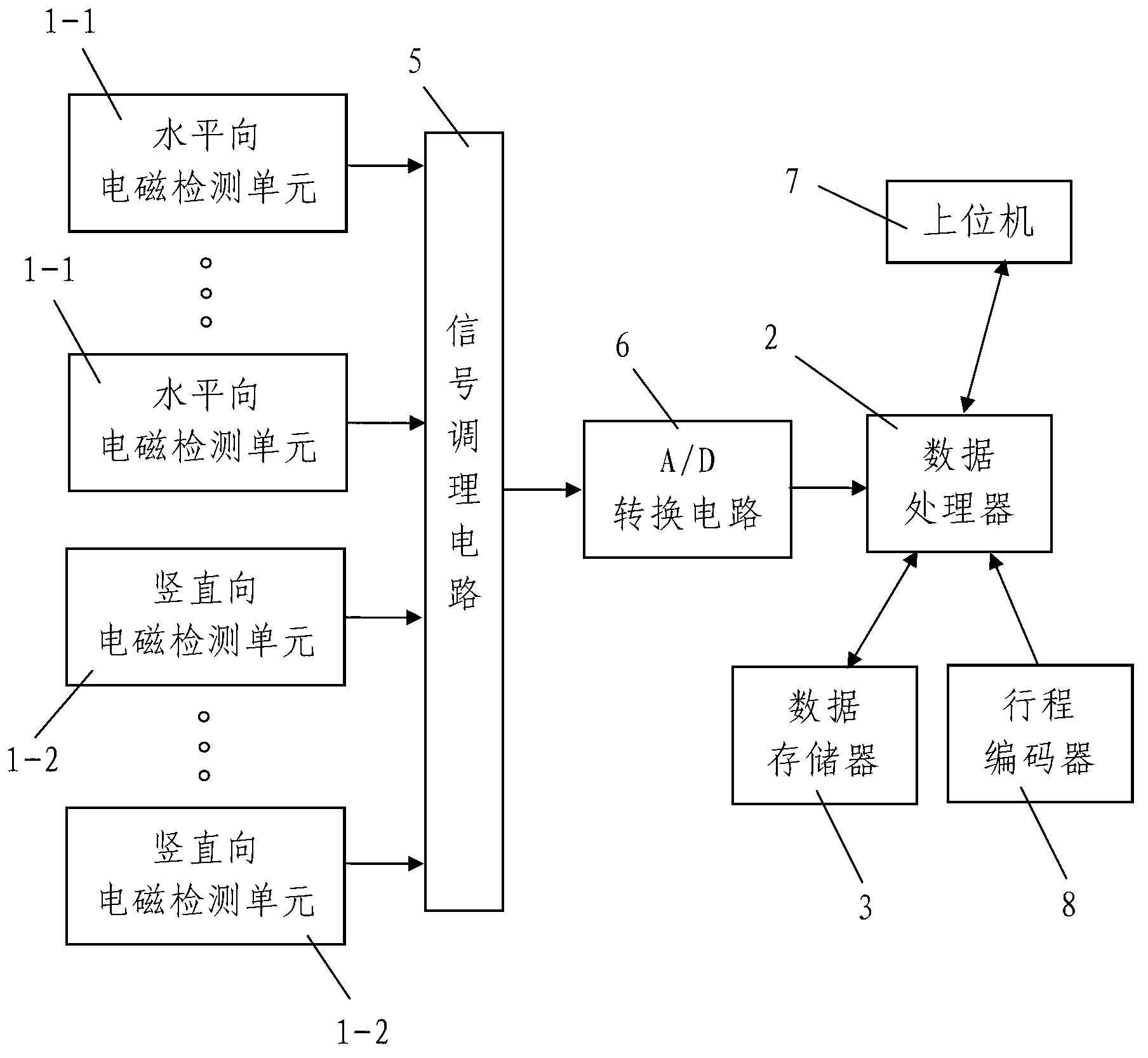

[0092] Step 2. Acquisition of defect signals: The electromagnetic detection unit is used to detect the residual magnetism in the detected steel cord conveyor belt in different defect states, and the detected signals are synchronously transmitted to the data processor 2, and correspondingly obtained and N kinds N sets of defect state detection information corresponding to different defect states, each of which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com