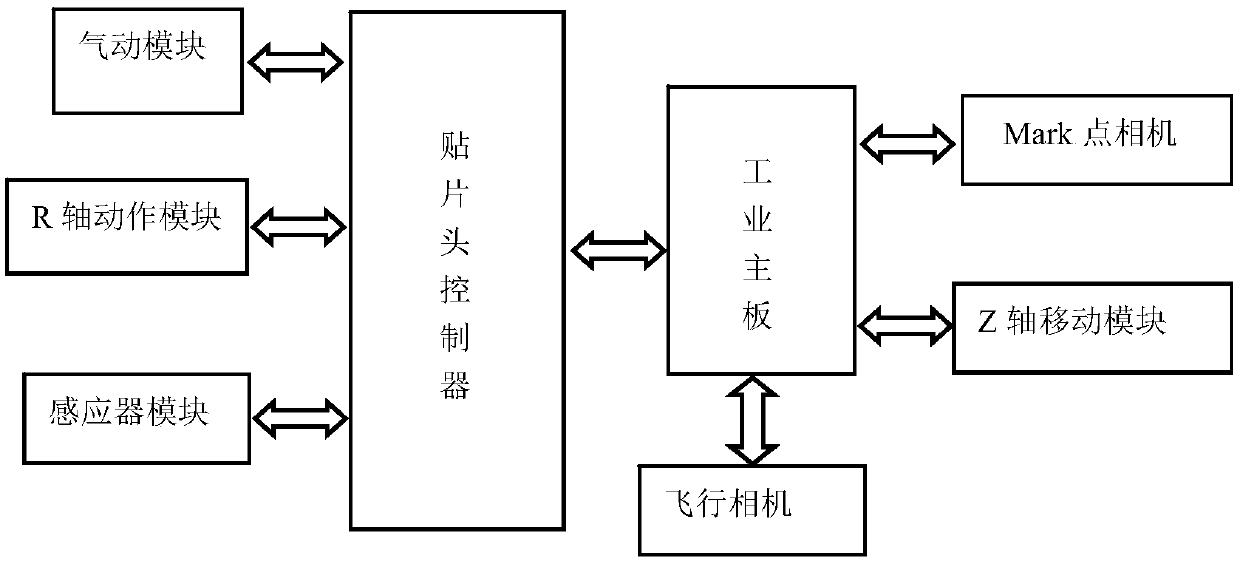

Chip head control system and method

A control system and control method technology, which is applied in the direction of assembling printed circuits with electrical components, can solve the problems of complicated control system and method, complex structure, etc., and achieve the effects of facilitating noise reduction processing, increasing suction speed, and reducing fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

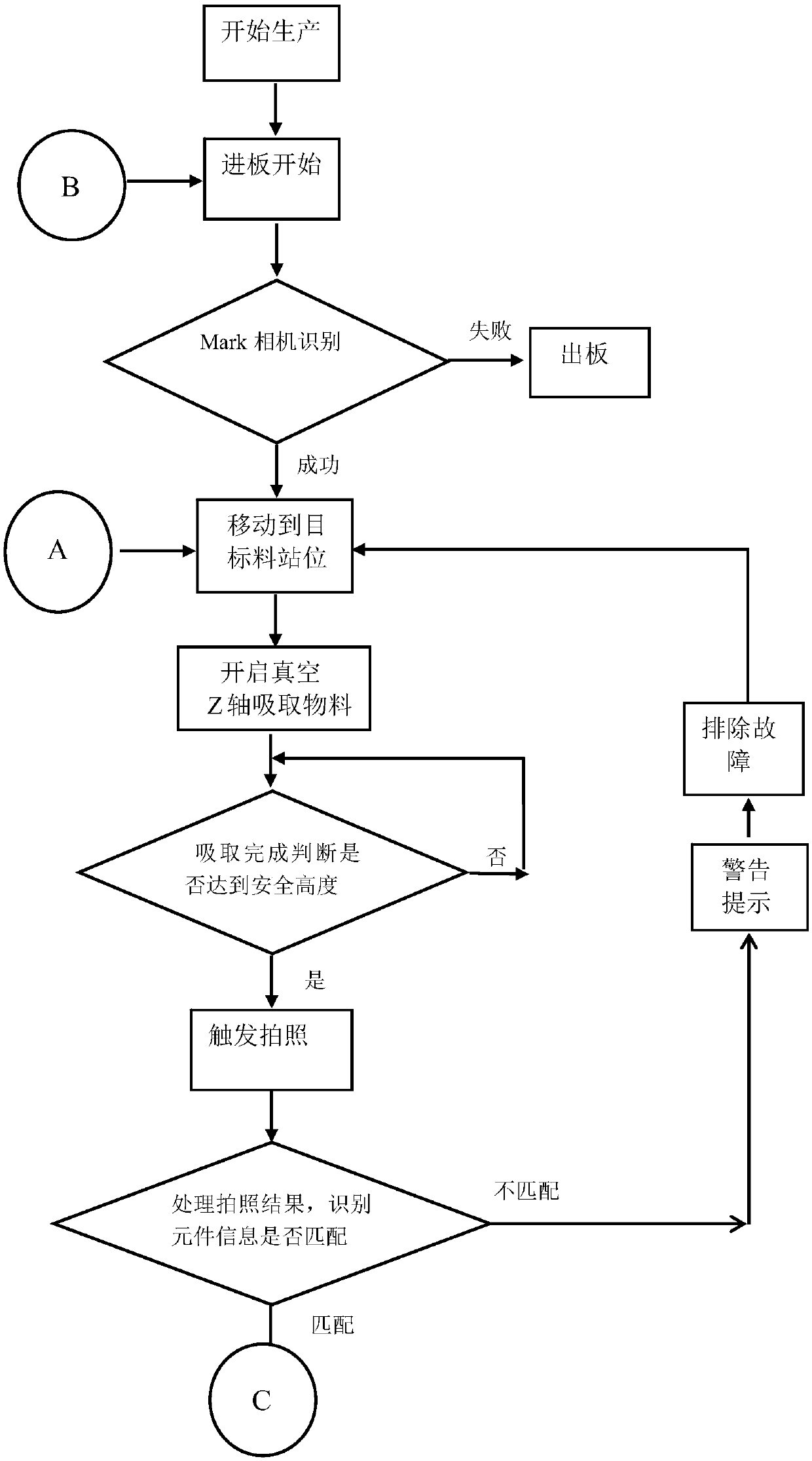

Method used

Image

Examples

Embodiment

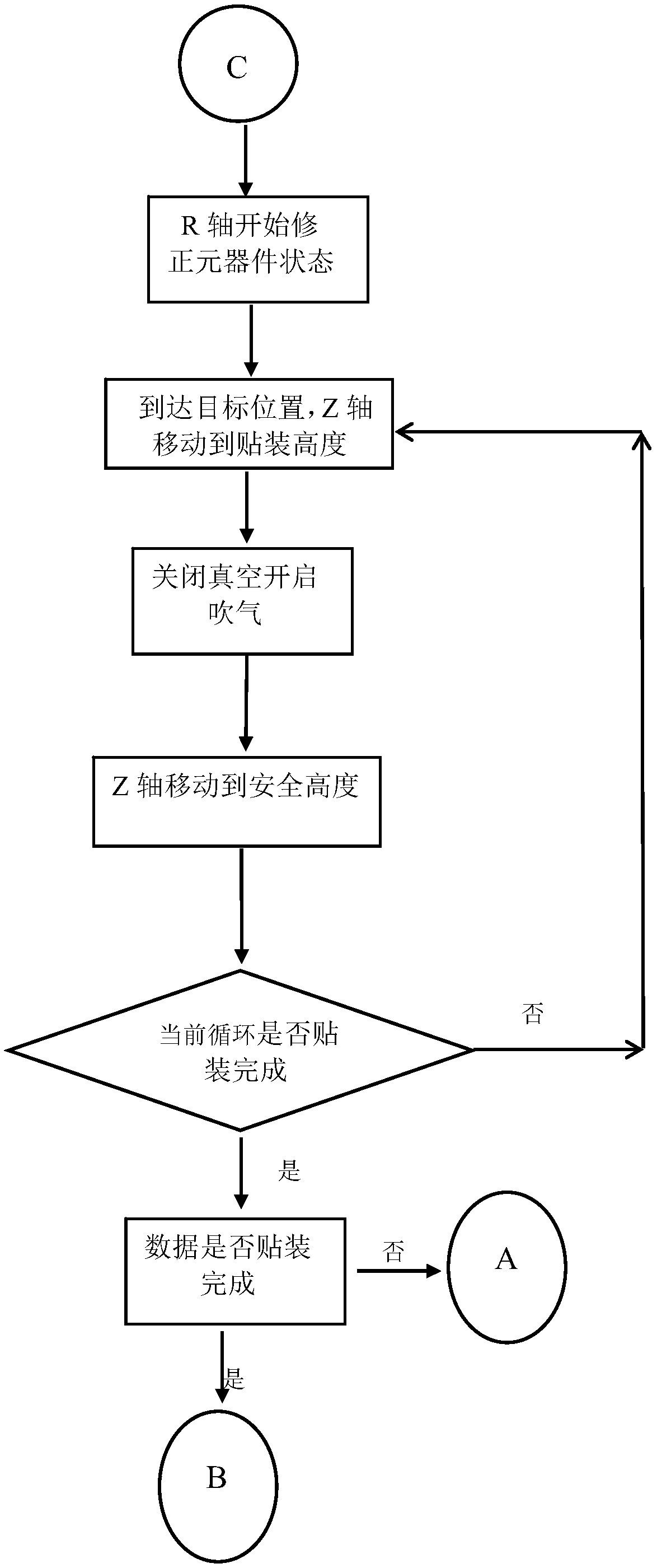

[0036] Example: There are currently 6 points, and the distances from head 1 are 21 8.9 6.2 15 5 22, so the final action is

[0037] (1) R1 starts to modify the shape of the 1-axis component, and the 1-axis starts to mount.

[0038] (2) After the 1-axis placement is completed, it starts to rise, and R2 starts to correct the shape of the 2-axis components.

[0039] (3) After the 2-axis placement is completed, it starts to rise, and R1 starts to correct the shape of the 3-axis components.

[0040] (4) After the 3-axis placement is completed, it starts to rise, and R2 starts to correct the shape of the 4-axis components.

[0041] (5) After the 4-axis placement is completed, it starts to rise, and R1 starts to correct the shape of the 5-axis components.

[0042] (6) After the 5-axis placement is completed, it starts to rise, and R2 starts to correct the shape of the 6-axis components.

[0043] (7) After the 6-axis placement is completed, it rises to a safe height, and R1R2 returns...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com