High-precision light-weight placement head

A SMD head, lightweight technology, used in printed circuits, electrical components, printed circuit manufacturing, etc., can solve problems such as inconvenience, and achieve the effect of large design, stable air pressure, and low negative pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

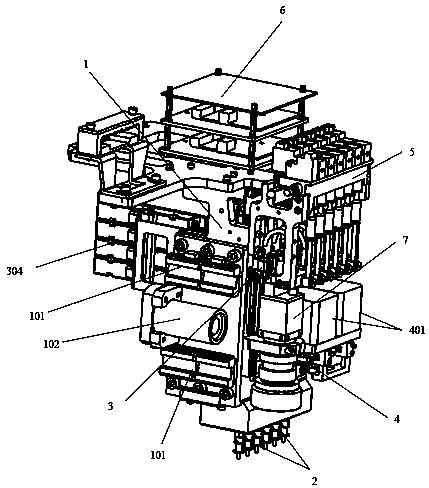

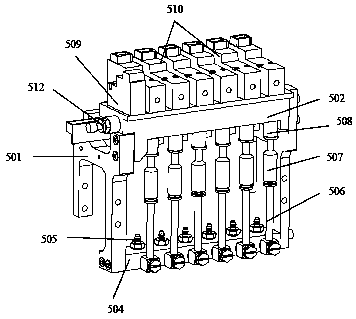

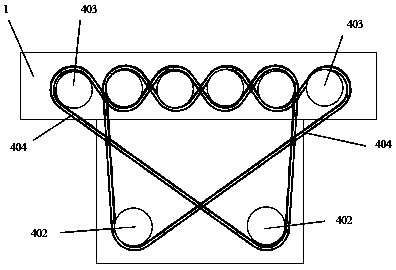

[0025] Such as Figure 1-Figure 5 As shown, a high-precision light-weight placement head includes a placement head support 1, a plurality of placement axes 2 installed in the placement head support 1, a Z-direction lifting mechanism 3, an R-direction corner mechanism 4, a vacuum mold Group 5, an integrated control component 6 is installed on the upper back of the placement head bracket 1, a vacuum module 5 is installed on the upper front, and an R-direction stepping motor 401 for driving the R-direction corner mechanism 4 is installed in the middle of the front of the mounting head. CCD camera 7, two rows of Z-direction drive motors 301 are installed on its back side, and the output shaft direction of the Z-direction drive motors 301 is perpendicular to the Z-axis; Mounting plate 502, the air pressure detection integrated module is installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com