Method for preparing nanometer aluminum or nanometer aluminum coating in low-temperature electro-deposition form by using ion liquid/additive system

A nano-aluminum coating and ionic liquid technology, which is applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of low reaction temperature, high cost, low energy consumption, etc., and achieve low material requirements , low cost, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The ionic liquid 1-butyl-3-methylimidazole chloride was vacuum-dried at 50°C for 24 hours, and in the glove box, under the protection of inert gas argon, the 1-butyl-3-methylimidazole chloride was filled with imidazole and a jacketed electrolytic cell with a thermometer installed on a magnetic stirrer to keep the temperature constant, and gradually add anhydrous aluminum trichloride to the electrolyte to change the composition of the system until aluminum trichloride and 1-butyl chloride - The molar ratio of 3-methylimidazole is 2:1. After reaching thermal equilibrium and mixing uniformly, stir at 50°C for 2 to 3 hours. Add lanthanum chloride and cyclohexane with a mass fraction of 0.1% of the ionic liquid and a molar ratio of 1:1, and continue stirring to ensure that the electrolyte is evenly mixed to obtain an ionic liquid / additive electrolyte system. After polishing and polishing the copper sheet of the base electrode with sandpaper, it is used as a deposition cathod...

Embodiment 2

[0026] The ionic liquid 1-ethyl-3-methylimidazole chloride was vacuum-dried at 50°C for 24 hours. In the glove box, under the protection of inert gas argon, the 1-ethyl-3-methylimidazole chloride was filled with imidazole and a jacketed electrolytic cell equipped with a thermometer is placed on a magnetic stirrer to keep the temperature constant, and anhydrous aluminum trichloride is gradually added to the electrolyte to change the system composition until aluminum trichloride and 1-ethyl chloride - The molar ratio of 3-methylimidazole is 1.1:1. After reaching thermal equilibrium and mixing uniformly, stir at 50°C for 2 to 3 hours. Lithium chloride with a mass fraction of 0.01% of the ionic liquid is added, and stirring is continued to ensure that the electrolyte is evenly mixed to obtain an ionic liquid / additive electrolyte system. After the base electrode stainless steel is polished with sandpaper, it is degreased, acid soaked, washed with water, acetone ultrasonically clean...

Embodiment 3

[0028]The ionic liquid 1-propyl-3-methylimidazole chloride was vacuum-dried at 50°C for 24 hours. In the glove box, under the protection of inert gas argon, the 1-propyl-3-methylimidazole chloride was filled with imidazole and a jacketed electrolytic cell with a thermometer installed on a magnetic stirrer, keeping the temperature constant, adding anhydrous aluminum trichloride to the electrolyte solution to change the system composition until aluminum trichloride and 1-propyl chloride - The molar ratio of 3-methylimidazole is 3:1. After reaching thermal equilibrium and mixing uniformly, stir at 50°C for 2 to 3 hours. Add benzene with a mass fraction of 10% of the ionic liquid, and continue stirring to ensure that the electrolyte is evenly mixed to obtain an ionic liquid / additive electrolyte system. After the base electrode low-carbon steel is polished with sandpaper, it is degreased, acid soaked, washed with water, acetone ultrasonically cleaned, and dried as the deposition ca...

PUM

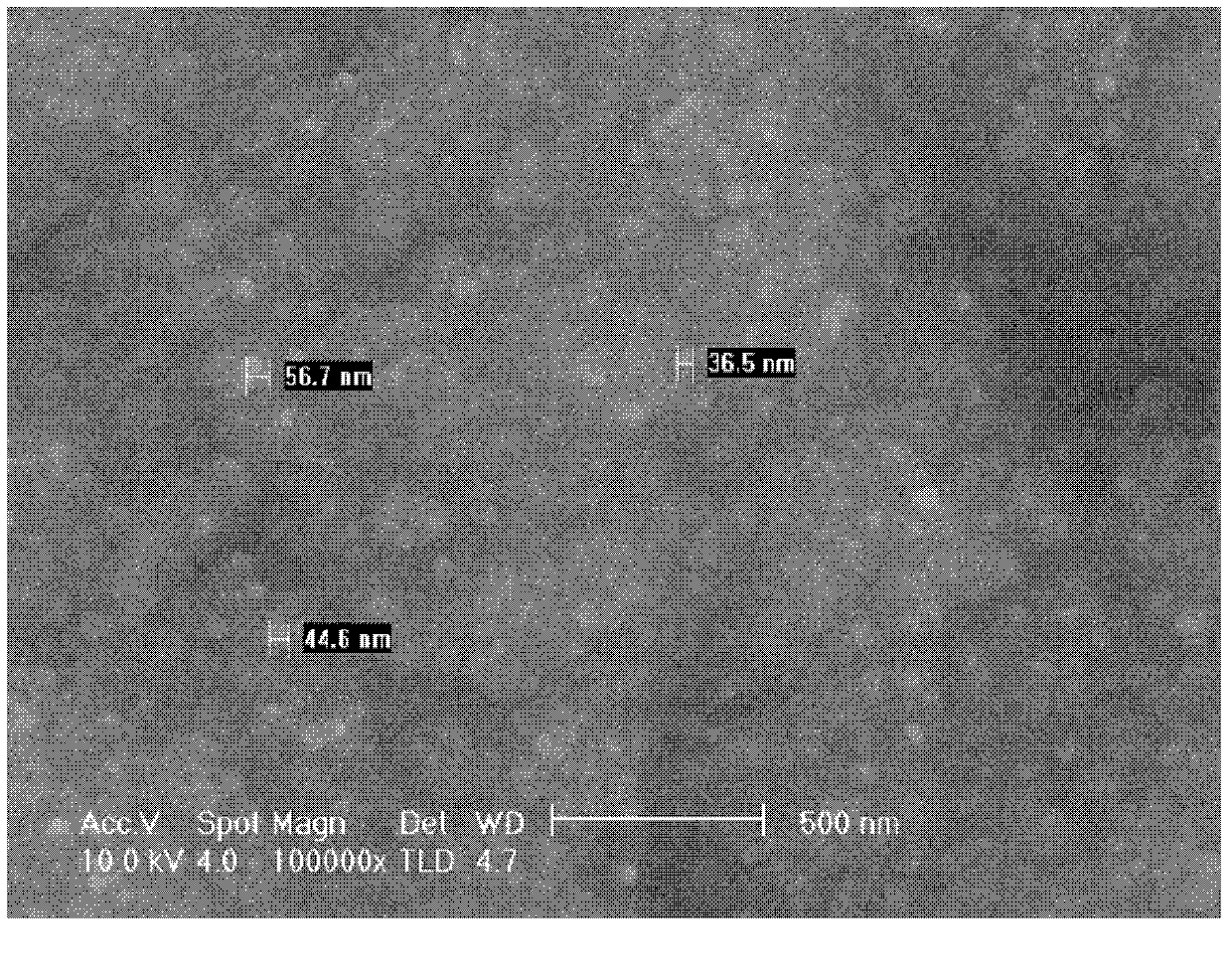

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com