A kind of konjac glucomannan-based antibacterial hydrogel fiber and preparation method thereof

A konjac glucomannan and glucomannan-based technology, which is applied in the fields of fiber chemical characteristics, rayon manufacturing, textiles and paper making, can solve the problems of untested safety and lack of antibacterial properties of hydrogel fibers, etc. Achieve the effects of easy continuous production, uniform hydrogel fiber structure, and good water absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

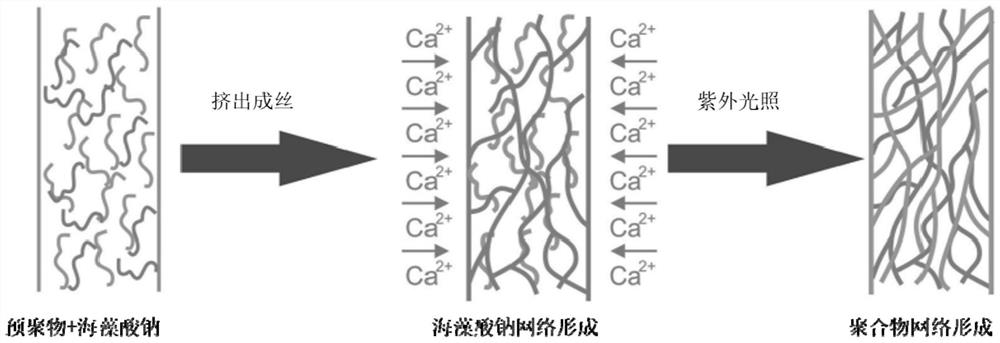

Method used

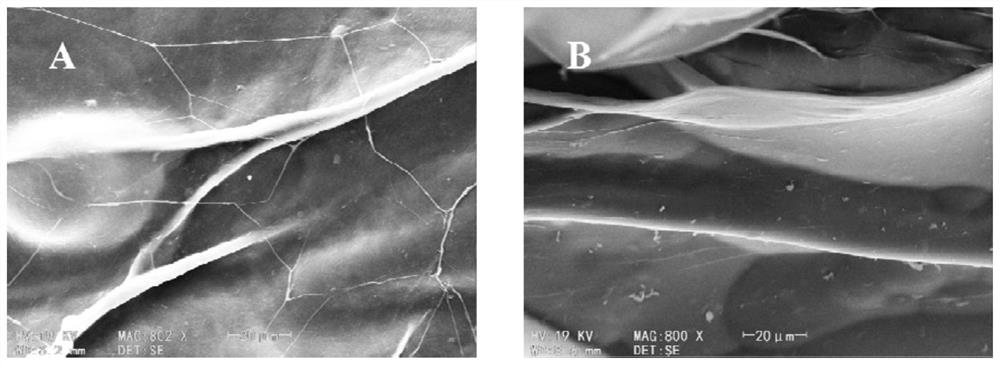

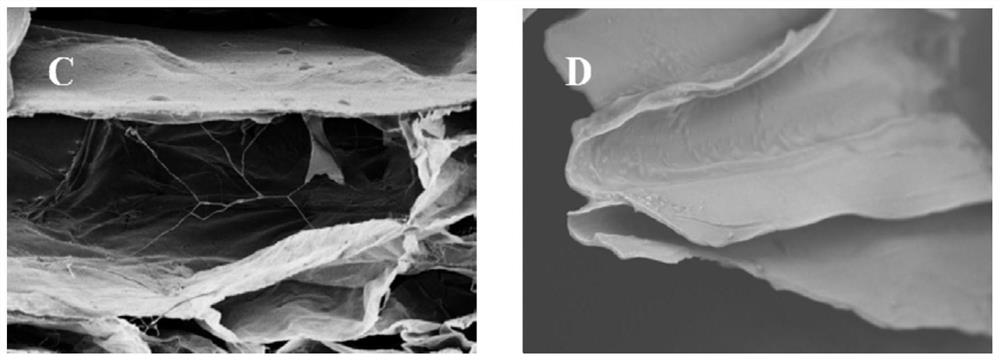

Image

Examples

Embodiment 1

[0048] This embodiment provides a kind of konjac glucomannan-based antibacterial hydrogel fiber, and the specific preparation steps are as follows:

[0049] Step 1: Preparation of konjac glucomannan polymerizable monomer and organic guanidine salt antibacterial polymerizable monomer:

[0050] a. Preparation of konjac glucomannan polymerizable monomer:

[0051] Add 0.5 g of Konjac glucomannan (KGM) into 50 mL of deionized water, adjust the pH to 7–8 with 0.1 mol / L NaOH solution, add 10 mL of methacrylic anhydride (methacrylic anhydride MA) dropwise, and Stir and react in a water bath for 24 hours. After the reaction is completed, precipitate with ethanol for 3 times, filter and dry in a vacuum oven to obtain konjac glucomannan polymerizable monomers;

[0052] b. the preparation of organic guanidine salt antibacterial monomer:

[0053] Add 5g of guanidine hydrochloride hydrochloride to 25mL of absolute ethanol, heat to 45°C until the guanidine hydrochloride is completely disso...

Embodiment 2

[0062] This embodiment provides a kind of konjac glucomannan-based antibacterial hydrogel fiber, and the specific preparation steps are as follows:

[0063] Step 1: Preparation of konjac glucomannan polymerizable monomer and organic guanidine salt antibacterial polymerizable monomer:

[0064] a. Preparation of konjac glucomannan polymerizable monomer:

[0065] Add 0.5g konjac glucomannan to 50mL deionized water, adjust the pH to 7-8 with 0.1mol / L NaOH solution, add 10mL acrylic anhydride dropwise, stir and react in an ice-water bath for 24 hours, and precipitate with ethanol after the reaction is complete 3 times, drying in a vacuum oven after filtration to obtain konjac glucomannan polymerizable monomer;

[0066] b. the preparation of organic guanidine salt antibacterial monomer:

[0067] Add 5g of guanidine hydrochloride to 25mL of absolute ethanol, heat to 45°C until the guanidine hydrochloride is completely dissolved, then add 10mL of acrylic anhydride dropwise, raise th...

Embodiment 3

[0074] This embodiment provides a kind of konjac glucomannan-based antibacterial hydrogel fiber, and the specific preparation steps are as follows:

[0075] Step 1: Preparation of konjac glucomannan polymerizable monomer and organic guanidine salt antibacterial polymerizable monomer:

[0076] a. Preparation of konjac glucomannan polymerizable monomer:

[0077] Add 0.5g konjac glucomannan to 50mL deionized water, adjust the pH to 7-8 with 0.1mol / L NaOH solution, add 10mL methacrylic anhydride dropwise, stir and react in an ice-water bath for 24 hours, and use Precipitate with ethanol for 3 times, filter and dry in a vacuum oven to obtain konjac glucomannan polymerizable monomer;

[0078] b. the preparation of organic guanidine salt antibacterial monomer:

[0079] Add 5g of guanidine hydrochloride hydrochloride to 25mL of absolute ethanol, heat to 45°C until the guanidine hydrochloride is completely dissolved, then add 10mL of methacrylic anhydride dropwise, raise the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com