Preparation method of hydrogen fluoride

A technology of hydrogen fluoride and hydrogen fluoride gas, which is applied in the direction of fluorine/hydrogen fluoride, can solve the problems of difficult rectification separation, high water content, and low fluorine volatilization rate, and achieve the effects of safe and reliable operation, simple process, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

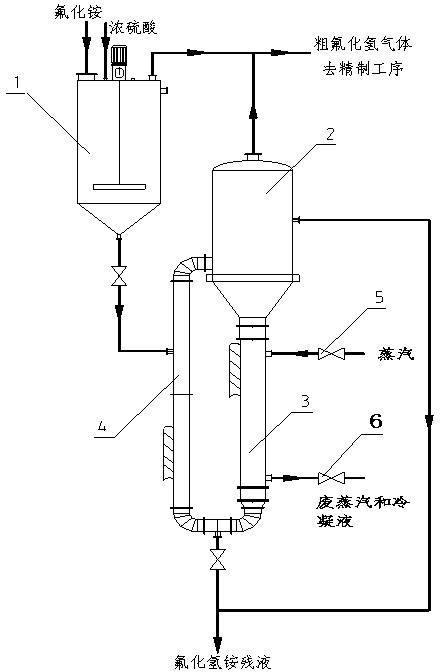

Image

Examples

Embodiment

[0018] A company's 1,000 tons / t anhydrous hydrofluoric acid industrial demonstration plant adopts this method. The raw material ammonium fluoride crystals come from the previous section with a purity of 92%. 98% concentrated sulfuric acid is used. By controlling the acid hydrolysis reaction time, temperature, and reaction feed Speed and other process conditions, the output of anhydrous hydrogen fluoride with a purity of 99.94%, the product quality meets the national first-class product standard, the actual conversion rate of fluorine per pass is increased by 60%, and the unit material consumption and energy consumption are lower than the traditional fluorite process technology. Since its completion, after repeated tests and explorations, the device has been operating continuously and stably. The product can be directly sold as a national first-class product, or further processed into downstream high value-added fluorine chemical products, and the residual liquid can be further...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com