Boron-containing shape memory alloy and preparation method thereof

A memory alloy and alloy technology, applied in the field of shape memory alloys, can solve problems such as lattice distortion, alloy slip memory performance, and poor room temperature plastic deformation ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] Embodiments of the present invention also provide a method for preparing a boron-containing shape memory alloy according to any one of the foregoing embodiments, comprising the following steps:

[0033] S1: push the cleaned Ni raw material, Ti raw material, Zr raw material and B raw material into the smelting chamber respectively through the feeding system to obtain molten metal.

[0034] In detail, the cleaning step specifically includes removing the oxide films on the surfaces of the Ni raw material, the Ti raw material, the Zr raw material and the B raw material, respectively, and pretreatment by ultrasonic cleaning respectively. Cleaning to remove the oxide film can effectively remove surface impurities and ensure that the reaction can form a boron-containing shape memory alloy with high strength, toughness, high elasticity and good recovery performance.

[0035] Meanwhile, in an embodiment of the present invention, the vacuum degree of the smelting chamber is less ...

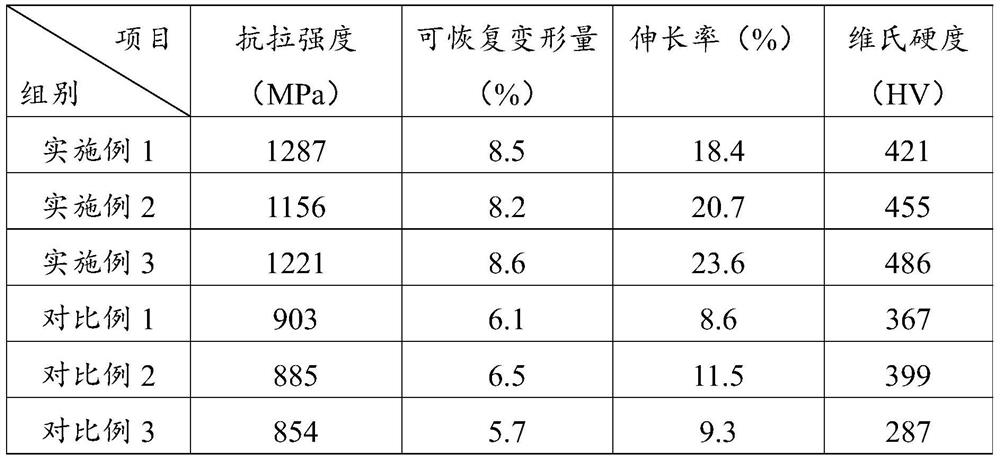

Embodiment 1

[0047] This embodiment provides a boron-containing shape memory alloy, which is prepared by the following steps:

[0048] S1: In terms of atomic percent content, the following raw materials were weighed: 50.0at% Ni, 48.0at% Ti, 1.0at% Zr and 1.0at% B;

[0049] S2: After removing the oxide film on the surface of Ni raw material, Ti raw material, Zr raw material and B raw material respectively, pretreatment by ultrasonic cleaning respectively;

[0050] S3: Push the cleaned Ni raw materials, Ti raw materials, Zr raw materials and B raw materials into the melting chamber through the feeding system respectively, and keep the vacuum degree in the melting chamber at 1×10 -2 Pa, filled with argon gas with a purity of 99.99wt%, under the irradiation of an electron beam with a voltage of 25kV and a current of 3A to obtain molten metal;

[0051] S4: A part of the molten metal is continuously irradiated by the electron beam and then dropped into the water-cooled copper bed to form a soli...

Embodiment 2

[0057] This embodiment provides a boron-containing shape memory alloy, which is prepared by the following steps:

[0058] S1: In terms of atomic percentage, the following raw materials were weighed: 50.0at% Ni, 46.0at% Ti, 3.0at% Zr and 1.0at% B;

[0059] S2: After removing the oxide film on the surface of Ni raw material, Ti raw material, Zr raw material and B raw material respectively, pretreatment by ultrasonic cleaning respectively;

[0060] S3: Push the cleaned Ni raw materials, Ti raw materials, Zr raw materials and B raw materials into the melting chamber through the feeding system respectively, and keep the vacuum degree in the melting chamber at 1×10 -2 Pa, filled with argon gas with a purity of 99.99wt%, under the irradiation of an electron beam with a voltage of 25kV and a current of 3A to obtain molten metal;

[0061] S4: Continuously irradiating a part of the molten metal to be melted by electron beam irradiation and then dripping into the water-cooled copper bed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com