Preparation method of double-net hydrogel fiber and product thereof

A gel fiber and hydrogel technology, which is applied in fiber treatment, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of poor toughness of water-absorbing gel fibers, difficult fiber processing, and brittle compression, etc., to achieve strong water absorption and Water retention capacity, good toughness in dry state, and fast crosslinking speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A method for preparing dual-network hydrogel fibers includes the following steps:

[0029] (1) Preparation of spinning dope:

[0030] Dissolve one or more water-soluble natural polysaccharides and water-soluble acrylamide polymers in water, stir them evenly, and then filter and defoam to obtain natural polysaccharides with a certain viscosity and containing 1-8% (mass percentage). The mixed spinning dope of polysaccharide and 4-30% (mass percentage) of acrylamide polymer, wherein the mass ratio of natural polysaccharide to propionamide polymer is 1:1-1:10;

[0031] Wherein, the natural polysaccharide is alginate, carrageenan (kappa type carrageenan, Iota carrageenan), agar, or konjac flour, etc. The number average molecular weight of the acrylamide polymer is 50000-6000000; the acrylamide polymer is any one of anionic polyacrylamide, cationic polyacrylamide, nonionic polyacrylamide or amphoteric polyacrylamide.

[0032] The anionic polyacrylamide mainly includes: acrylamide an...

Embodiment example 1

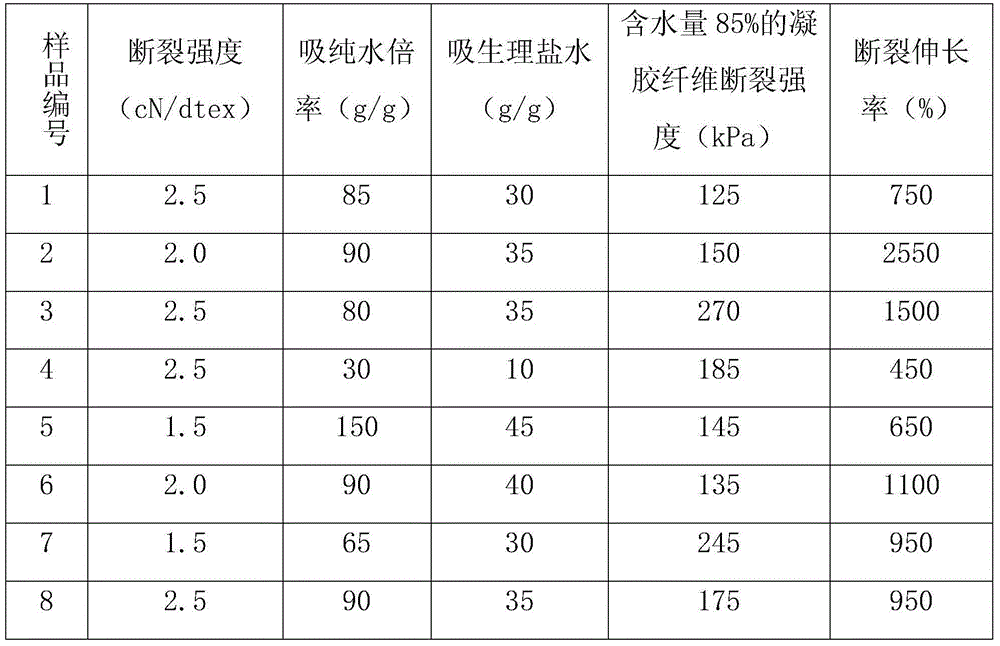

[0043] Weigh a certain amount of sodium alginate and polyacrylamide (molecular weight 2,000,000-2,500,000), quickly stir and dissolve in water at room temperature, filter, and defoam under reduced pressure to obtain a spinner containing 2% sodium alginate and 12% polyacrylamide. Silk dope, in which the mass ratio of sodium alginate to polyacrylamide is 1:6. Through dry-wet spinning, the spinning dope is spun into an 80%wt ethanol aqueous solution containing 5%wt calcium sulfate at a speed of 30m / min to coagulate into nascent fibers, where the air layer distance is 2cm, and the barrel temperature is maintained At about 70°C, the coagulation bath temperature is about 25°C, and the ratio of drawing speed to spinning speed is 1.5:1. Then, the nascent fiber bundle is drawn into the cobalt source ( 60 Co) Irradiation device, continuous irradiation cross-linking, the total irradiation dose is 50kGy. After subsequent drawing, heat setting and winding processes, a high tenacity double ...

Embodiment example 2

[0045] Weigh a certain amount of Iota-type carrageenan and polyacrylamide (molecular weight 5,000,000-6,000,000), quickly stir and dissolve them in 70℃ water, filter, and defoam under reduced pressure to obtain 2% Iota-type carrageenan and 8% polyacrylamide. The spinning dope of acrylamide, wherein the mass ratio of carrageenan to polyacrylamide is 1:4. Through gel spinning, the spinning stock solution is spun into a 50%wt ethanol aqueous solution at a speed of 30m / min to coagulate into nascent fibers. Among them, the barrel temperature is maintained at about 70°C, the coagulation bath temperature is about 0°C, and the ratio of the pulling speed to the spinning speed is 1.5:1. Then, the nascent fiber bundle is drawn into the electron beam irradiation device for continuous irradiation cross-linking, and the total irradiation dose is 10 kGy. Finally, a high tenacity double network hydrogel fiber was prepared through subsequent drawing, heat setting, and winding processes, and it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com