Method for producing nitric phosphate fertilizer at low temperature under vacuum through concentrated crystallization and calcium removal as well asdevice

A concentrated crystallization, vacuum and low temperature technology, applied in fertilization devices, fertilizer mixtures, agriculture, etc., can solve the problems of increasing refrigerant separation and recovery and circulating treatment devices, inert refrigerant medium consumption, refrigerant circulation energy consumption and other problems, shortening the process, reducing The effect of investment in production equipment and increased operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

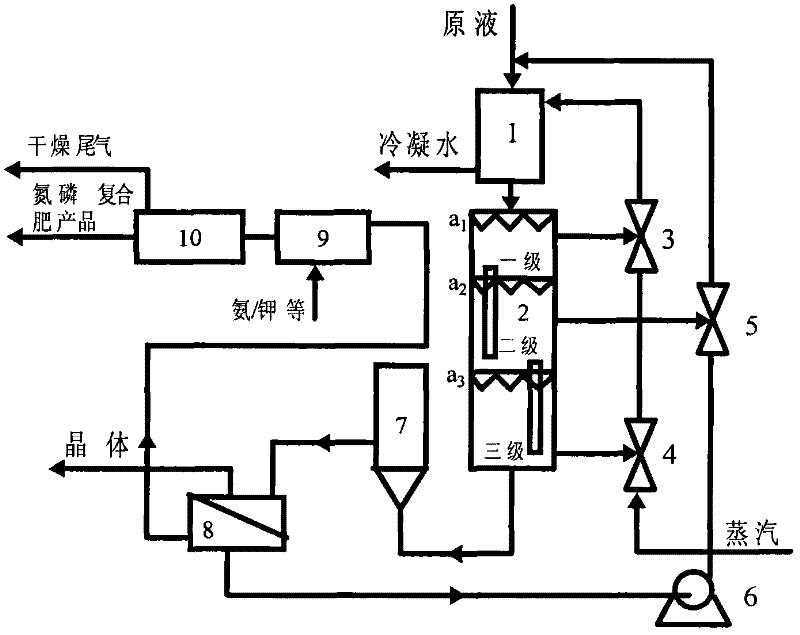

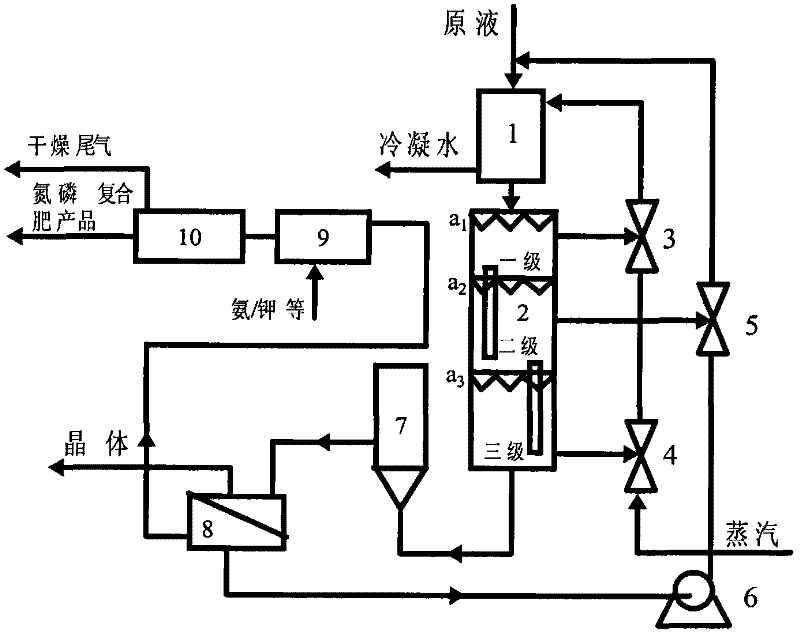

[0021] Embodiment: use 0.6MPa saturated steam to spray refrigeration, evaporate, concentrate and crystallize to remove calcium, and produce nitrogen-phosphorus compound fertilizer with water solubility ≥ 70%.

[0022] Utilize the heat exchanger 1 to heat the mixed solution of the circulating mother liquor and the newly added acidolysis solution to 40°C, and then enter the multi-stage (three-stage) vacuum evaporation, concentration and cooling supersaturation device 2 to produce the supersaturation required for calcium nitrate crystallization, The cooling temperature of the solution and the evaporative concentration process are jointly controlled by the primary steam injector 4, the secondary steam injector 3 and the circulating mother liquor injector 5, forming favorable conditions for calcium nitrate crystal growth, that is, the control of supersaturation. On the one hand, the 0.6MPa pan gas from the power plant, through the adjustment of the injection coefficient of the prima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com