Temperature control method based on fuzzy self-adaptive controller

A temperature control method and fuzzy self-adaptive technology, applied in the direction of self-adaptive control, general control system, control/regulation system, etc., can solve the problems of uncertainty of system model parameters, nonlinearity, large lag of electric heating system, etc. The effect of industrial production efficiency, precise temperature control and flexible control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

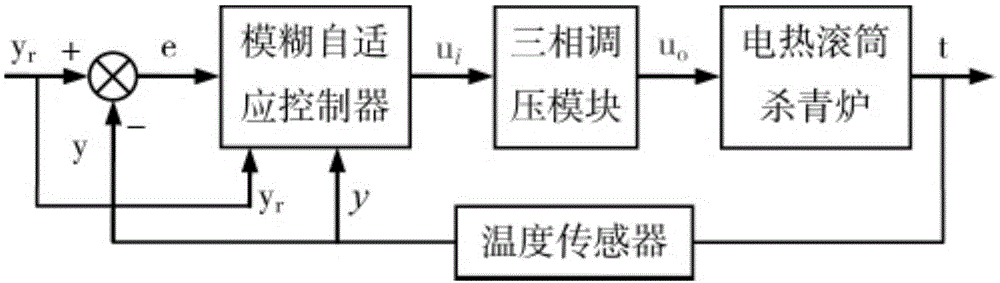

[0028] A temperature control method based on a fuzzy adaptive controller is realized by a fuzzy adaptive controller 1 , a three-phase voltage regulating module 2 , a heating module 3 , and a temperature sensor 4 .

[0029] Fuzzy adaptive controller 1 is composed of generalized predictive control 5 and fuzzy control 6 .

[0030] Fuzzy adaptive controller 1 has a soft switch E 0 , E 0 Can be a constant value, variable or function, when the error |e|≤E 0 , the switch switches to generalized predictive control 5; when the error |e|>E 0 , switch to Fuzzy Control 6.

[0031] Generalized predictive control 5 its algorithm is designed as:

[0032] Take the initial value P(0)=10 6 I, θ(0)=[0,0,0,0,0,0] T , forgetting factor λ=0.95, control its parameter N=8, control weight matrix Γ as unit matrix I 5×5 , the output softening factor α=0.7, the generalized predictive control algorithm is as follows:

[0033] 1) Sampling the current actual output y(k) and the reference output y r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com