Gypsum-based composite material for self-insulation wall and preparation method of gypsum-based composite material

A composite material and gypsum-based technology, which is applied in the field of gypsum-based composite materials for self-insulating walls and its preparation, can solve the problems of limiting the high performance of wall materials and engineering applications, reducing the comprehensive performance of wall materials, and high water absorption. problems, to achieve the effect of increasing industrial profits, improving water resistance and strength, and small pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

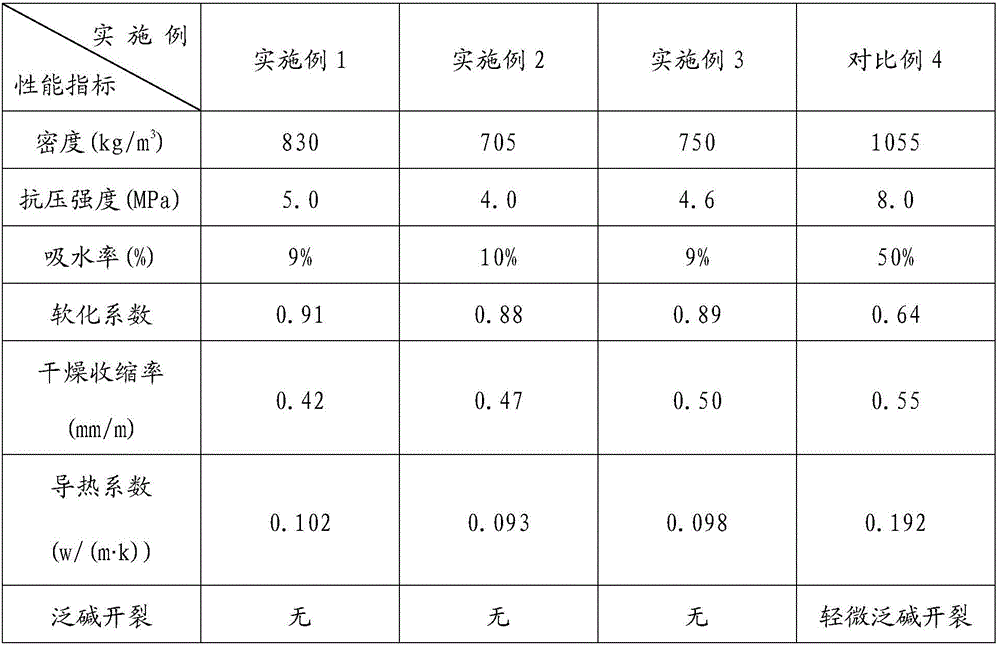

Examples

Embodiment 1

[0028] Weigh 31 parts of hemihydrate gypsum powder, 5 parts of cement, 15 parts of fly ash, 4 parts of quicklime, 2 parts of mineral powder, 3 parts of expanded silica gel, 1 part of microsilica fume, 3 parts of modified additives, and 0.05 parts of foaming agent and 36 parts of water.

[0029] The modified additives used are: in parts by weight, composed of 1 part of cellulose ether, 20 parts of water reducing agent, 9 parts of silicone water repellent, 15 parts of acrylic emulsion, 7 parts of anti-alkali agent, and 10 parts of calcium chloride , 8 parts of lithium carbonate, 11 parts of sodium oxalate, 15 parts of sodium hydroxide and 4 parts of paraffin.

[0030] A gypsum-based composite material for self-insulating walls. The micro-foaming agent used is composed of 35 parts of sodium lauryl alcohol ether sulfate and 65 parts of calcium stearate.

[0031] The water reducing agent used is: standard polycarboxylate mother liquor, without retarding components, with a solid co...

Embodiment 2

[0039] Weigh 33.4 parts of hemihydrate gypsum powder, 10 parts of cement, 12 parts of fly ash, 3 parts of quicklime, 1 part of mineral powder, 8 parts of expanded silica gel, 0.5 parts of microsilica fume, 2 parts of modified additives, and Foam agent 0.1 part and water 30 parts.

[0040] The modified additives used are: in parts by weight, 0.5 parts of cellulose ether, 19 parts of water reducing agent, 9 parts of silicone water repellent, 16 parts of acrylic emulsion, 6 parts of anti-alkali agent, 13 parts of calcium chloride , 7 parts of lithium carbonate, 10 parts of sodium oxalate, 15.5 parts of sodium hydroxide and 4 parts of paraffin.

[0041] A gypsum-based composite material for self-insulating walls, the micro-foaming agent used is composed of 40 parts of sodium lauryl alcohol ether sulfate and 60 parts of calcium stearate.

[0042] The water reducing agent used is: standard polycarboxylate mother liquor, without retarding components, with a solid content of 40%.

...

Embodiment 3

[0050]Weigh 31.5 parts of hemihydrate gypsum powder, 15 parts of cement, 10 parts of fly ash, 3 parts of quicklime, 1 part of mineral powder, 5 parts of expanded silica gel, 0.5 parts of microsilica fume, 2 parts of modified additives, and 0.08 parts of foaming agent and 32 parts of water.

[0051] The modified additives used are: in parts by weight, 1.5 parts of cellulose ether, 18 parts of water reducer, 12 parts of silicone water repellent, 15 parts of acrylic emulsion, 5 parts of anti-alkali agent, 12 parts of calcium chloride , 6 parts of lithium carbonate, 12 parts of sodium oxalate, 15.5 parts of sodium hydroxide and 4 parts of paraffin.

[0052] A gypsum-based composite material for self-insulating walls. The micro-foaming agent used is composed of 45 parts of sodium lauryl alcohol ether sulfate and 55 parts of calcium stearate.

[0053] The water reducing agent used is: standard polycarboxylate mother liquor, without retarding components, with a solid content of 40%....

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com