Magnesium alloy extrusion deforming processing method

A technology of extrusion deformation and processing method, applied in metal extrusion, metal extrusion die, metal processing equipment and other directions, can solve problems such as long extrusion time, material cracks, and the influence of magnesium alloy forming effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

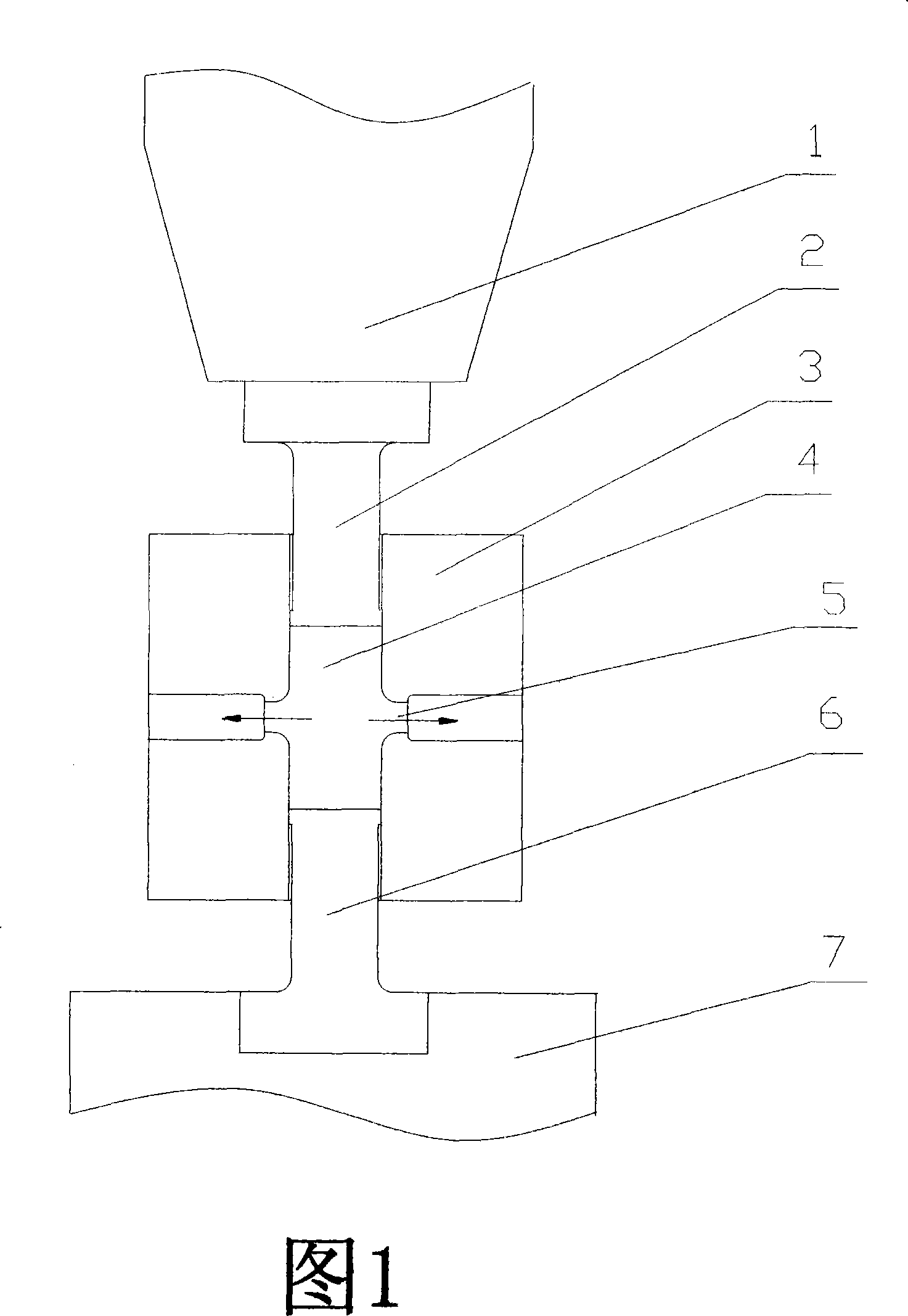

[0027]Referring to FIG. 1 , in this embodiment, an extrusion die formed by bi-directional extrusion, bi-radial flow, and diameter reduction is used in this embodiment, and AZ31 magnesium alloy rods are extruded and deformed on a vertical extruder. The concave mold 3 of the extrusion die formed by the upper and lower bidirectional extrusion double radial flow and variable diameter is provided with a bidirectional extrusion channel 4, and the middle section of the bidirectional extrusion channel 4 is symmetrically provided with two radially extending cavities Channel 5, the cavity channel 5 is perpendicular to the axis of the two-way extrusion channel 4 and runs through the wall of the die 3, the cross-sectional area of the two-way extrusion channel 4 is greater than the sum of the cross-sectional areas of the two cavity channels 5; the two punches 2 , 6 are respectively inserted into the two-way extrusion channel and the two-way extrusion channel by the opposite ends of the tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com