Machine vision based bamboo strip defect detection method

A defect detection and machine vision technology, applied in the field of visual inspection, can solve the problems of inability to implement targeted detection, oblique cutting, blanking, scratches cannot be effectively detected, difficult to promote, etc., to achieve rapid identification and classification , Increase the degree of automation and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

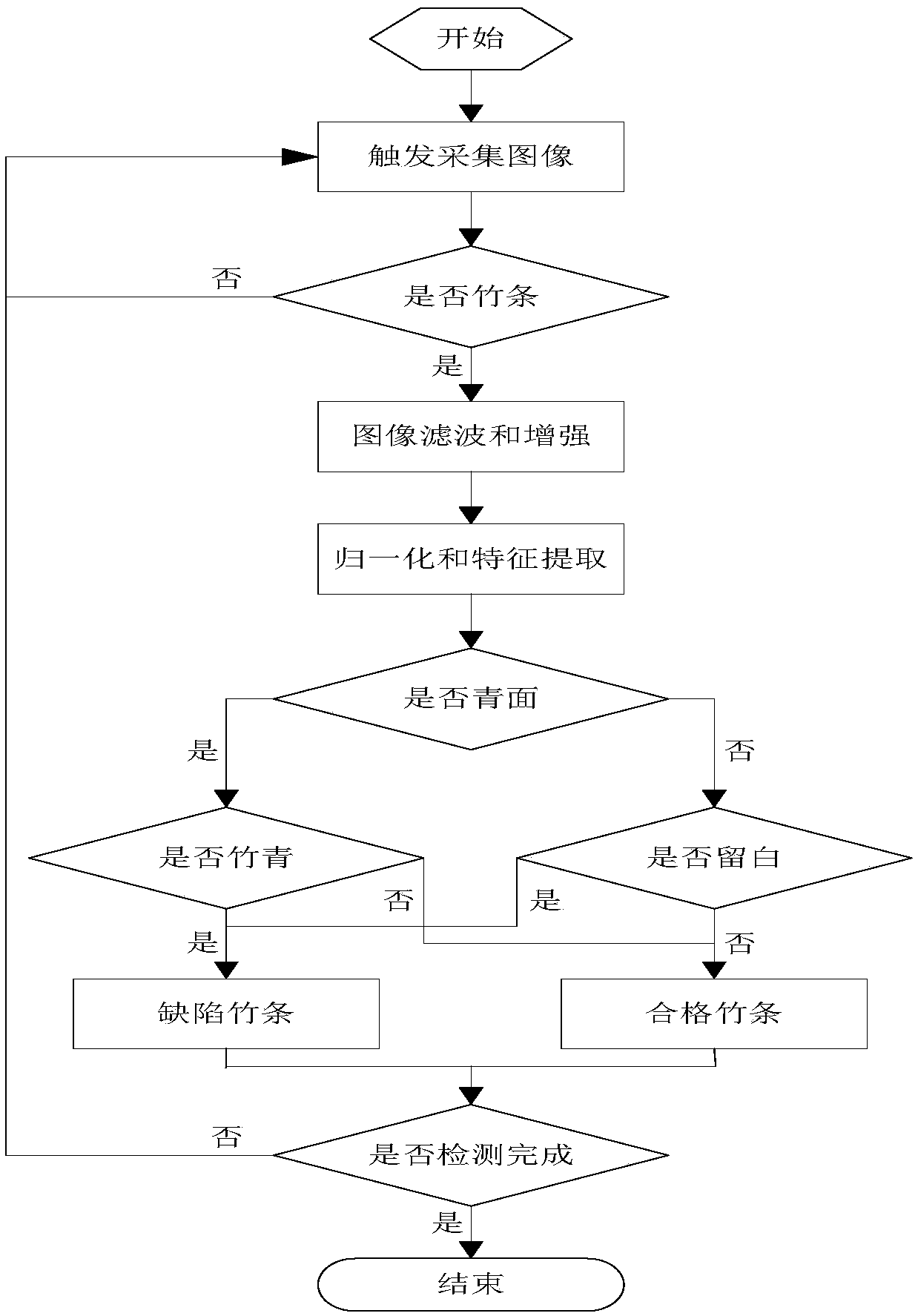

[0040] see figure 1 , the present invention proposes a kind of bamboo strip defect detection method based on machine vision, specifically comprises the following steps:

[0041] Step S1 establishes a neural network structure for recognizing bamboo strips, and obtains a recognition model for recognizing green and yellow faces of bamboo strips.

[0042] In this embodiment, the step S1 specifically includes the following sub-steps:

[0043] S11 acquires the original bamboo strip images of several frames of bamboo strips as bamboo strip samples. Specifically, the camera is triggered by the main control board to capture an 8-bit channel Bayer format image, the image format is converted into a 24-bit RGB format, and Gamma correction is performed to adjust it to a color image f suitable for human eyes.

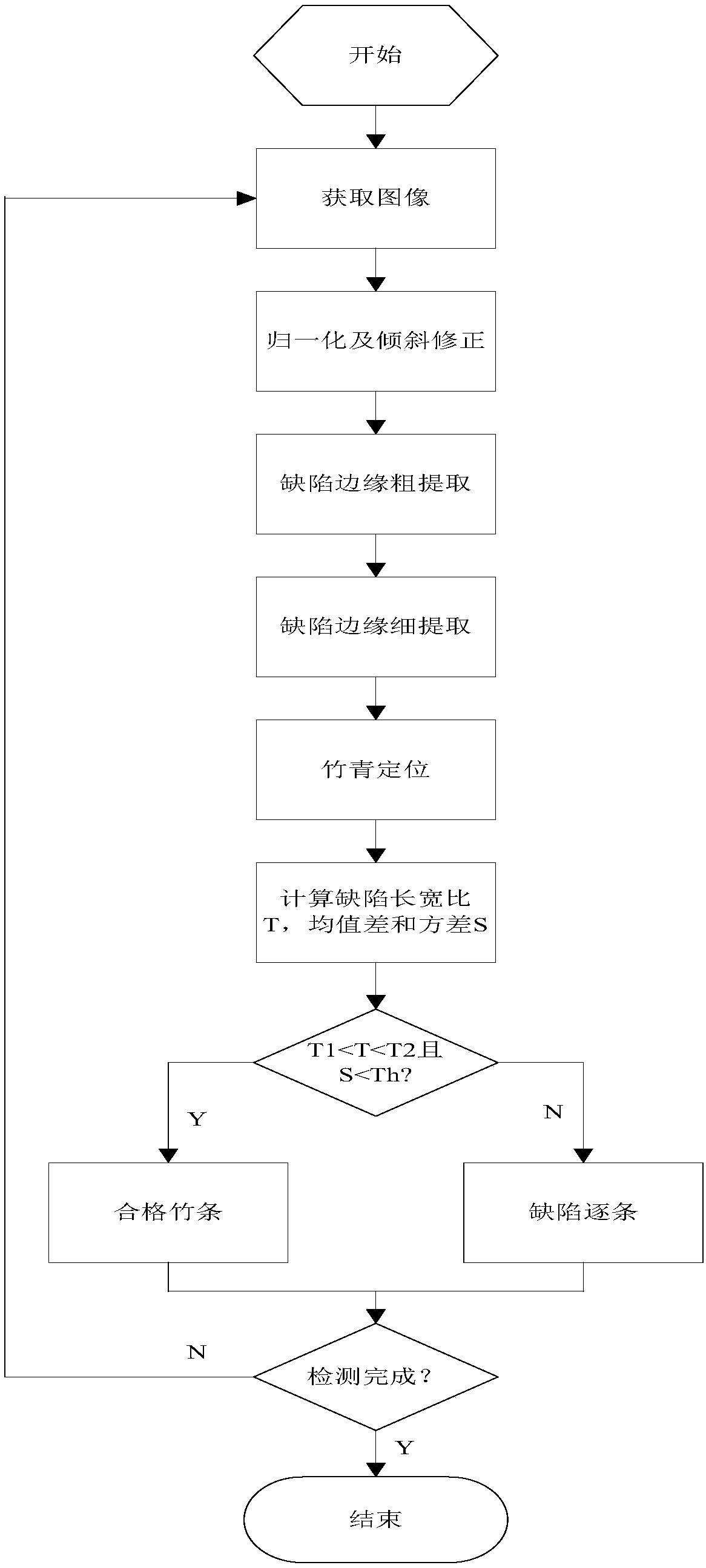

[0044] S12 Image filtering and enhancement. Specifically, the median filter is used to remove the isolated noise of the bamboo image and retain the edge detail information, the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com