Method for catalyzing dynamic kinetic resolution of arylamine via racemization catalyst

A racemization catalyst, a technology for catalyzing arylamines, applied in organic chemistry methods, organic chemistry, chemical recovery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Add p-chlorophenol, p-chlorophenyl valerate, dicyclohexylcarbodiimide and 4-dimethylaminopyridine with a molar ratio of 1:1:1:0.03, stir for 7 hours, filter, and dry the filtrate Bathing, concentrating, and passing through the column to obtain p-chlorophenyl propionate as an acyl donor for subsequent use;

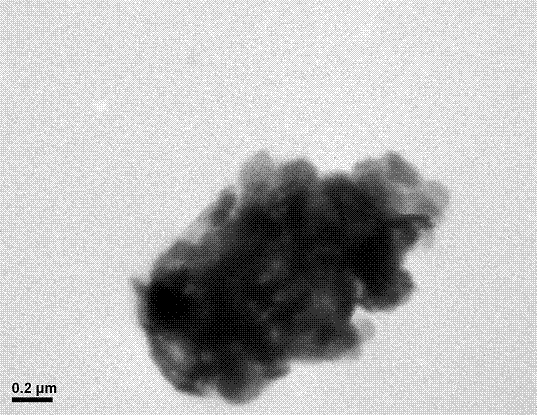

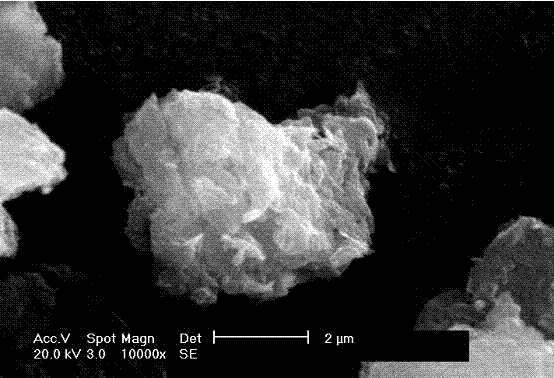

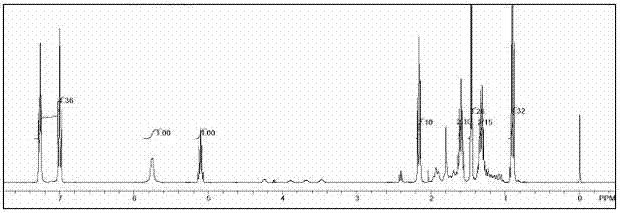

[0024] 2) Under vigorous stirring, add 10 mL of an aqueous solution of magnesium chloride and aluminum chloride with a molar percentage of 3:1 to 200 mL of 3 mol / L sodium hydroxide solution, and stir for 10 minutes under nitrogen protection. Centrifuge, wash twice with deionized water, and disperse in 40 mL of deionized water. Placed in a 60 mL stainless steel reactor, at 100 o C hydrothermal treatment for 10 hours to prepare chloride ion intercalated hydrotalcite. Add it to 100 mL of 2 mol / L sodium lauryl sulfate aqueous solution, 80 o C for 12 hours at reflux. Cooling, centrifugation, filtration, washing with water, washing with acetone, 80 o Dried for 4 ho...

Embodiment 2

[0028] 1) Add p-chlorophenol, n-valeric acid, dicyclohexylcarbodiimide, and 4-dimethylaminopyridine in a molar ratio of 1: 2: 2: 0.05, stir for 7 hours, filter, dry the filtrate, concentrate, pass column, obtain p-chlorophenyl valerate as an acyl donor for subsequent use;

[0029] 2) Under vigorous stirring, add 15 mL of an aqueous solution of magnesium chloride and aluminum chloride with a molar percentage of 4:1 to 250 mL of 3 mol / L sodium hydroxide solution, and stir for 30 minutes under nitrogen protection. Centrifuge, wash with deionized water three times, and disperse in 40 mL of deionized water. Placed in a 60 mL stainless steel reactor, at 100 o C Hydrothermal treatment for 16 hours prepared chloride ion intercalated hydrotalcite. Add it to 100 mL of 2 mol / L sodium lauryl sulfate aqueous solution, 80 oC for 12 hours at reflux. Cooling, centrifugation, filtration, washing with water, washing with acetone, 80 o Dried for 4 hours at C to obtain dodecyl sulfate interc...

Embodiment 3

[0033] 1) Add p-chlorophenol, n-valeric acid, dicyclohexylcarbodiimide and 4-dimethylaminopyridine in a molar ratio of 1:2:2:0.05, stir for 3 hours, filter, dry the filtrate, concentrate, Go through the column to obtain p-chlorophenyl valerate as an acyl donor for subsequent use;

[0034] 2) Under vigorous stirring, add 10 mL of an aqueous solution of magnesium chloride and aluminum chloride with a molar percentage of 3:1 to 200 mL of 3 mol / L sodium hydroxide solution, and stir for 10 minutes under nitrogen protection. Centrifuge, wash twice with deionized water, and disperse in 40 mL of deionized water. Placed in a 60 mL stainless steel reactor, at 100 o C hydrothermal treatment for 10 hours to prepare chloride ion intercalated hydrotalcite. Add it to 100 mL of 2 mol / L sodium lauryl sulfate aqueous solution, 80 o C for 12 hours at reflux. Cooling, centrifugation, filtration, washing with water, washing with acetone, 80 o Dried for 4 hours at C to obtain dodecyl sulfate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com