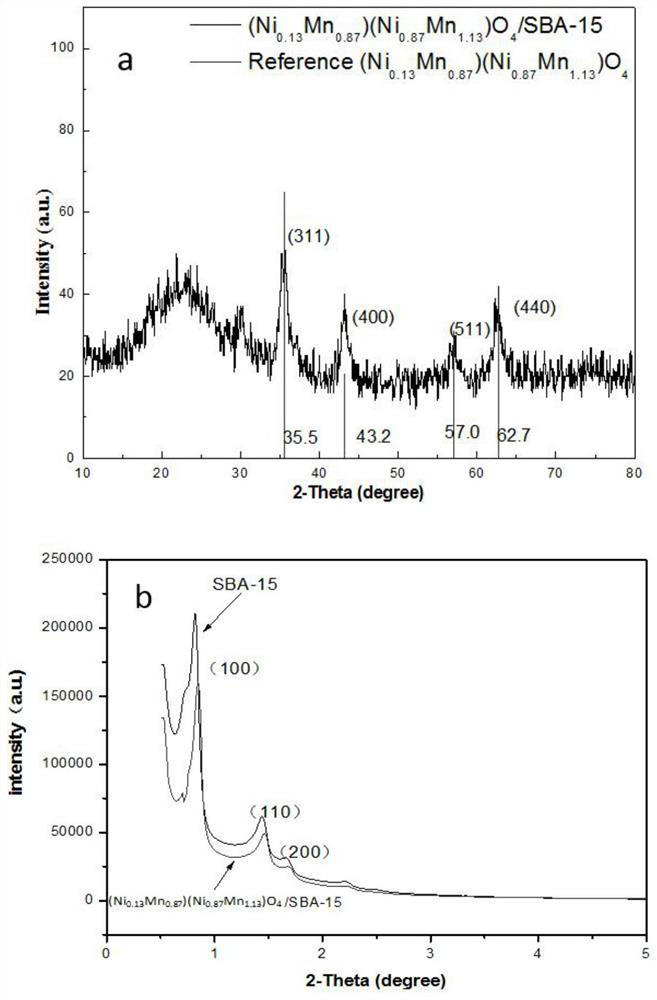

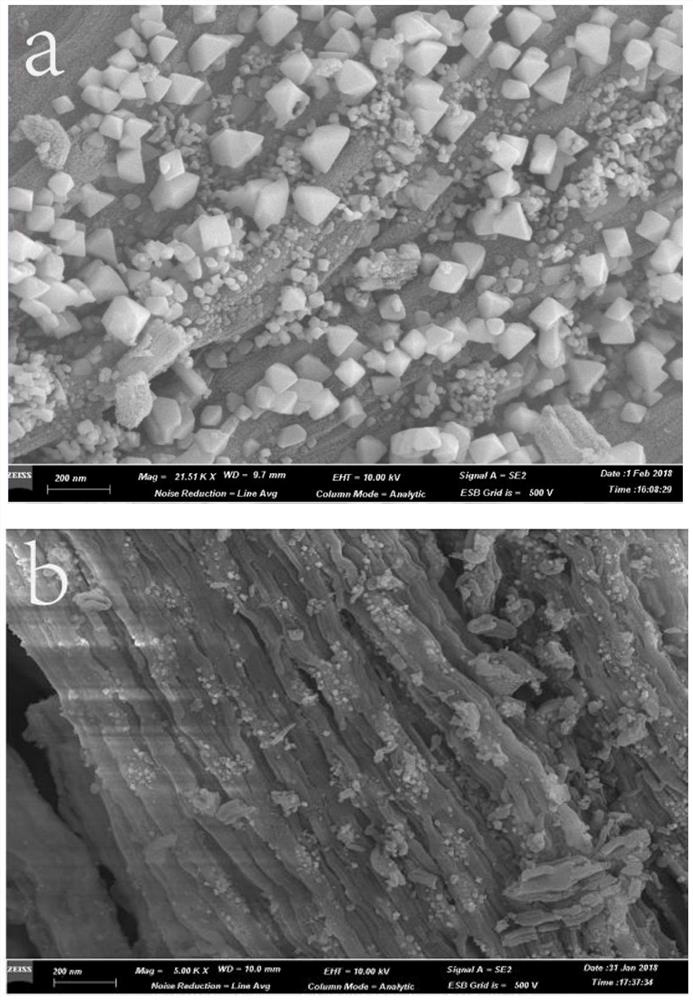

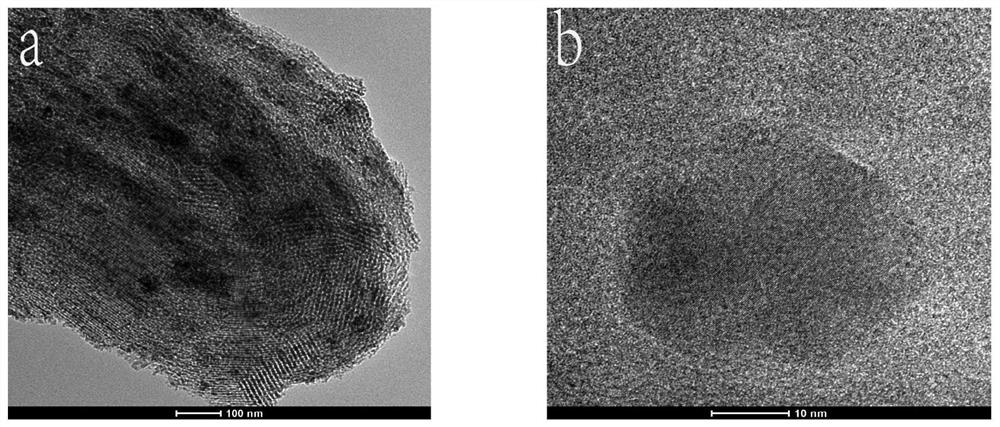

A kind of mesoporous supported catalyst material and preparation method thereof

A catalyst and composite catalyst technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of easy agglomeration, poor compatibility, inappropriate support and catalyst, and achieve good load uniformity. , The effect of repeated use with excellent and excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A preparation method for a supported composite catalyst, characterized in that, proceed as follows:

[0042] (1), Ni(NO 3 ) 2 9H 2 O and C 4 h 6 MnO·4H 2 O was dissolved in distilled water and ultrasonically dissolved for 15 minutes to form a mixed solution A, Ni(NO 3 ) 2 9H 2 O, C 4 h 6 MnO·4H 2 The consumption ratio of O and distilled water is 0.4955g:0.4456g:30mL;

[0043] (2) Add the surfactant polyethylene glycol 4000 to the mixture A while stirring, and then ultrasonicate for 5 minutes. The mass volume ratio of polyethylene glycol 4000 to the distilled water in the mixture A is 1.3:10, and then add it while stirring SBA-15, followed by ultrasonication for 45 minutes to form a mixed solution B, the stirring speed is 100r / min, and the mass volume ratio of SBA-15 to mixed solution A is 1g: 30mL;

[0044] (3) Place the mixed solution B on a magnetic stirrer at 55°C and heat and stir until the suspension becomes a paste-like material, and the stirring rate ...

Embodiment 2

[0048] A preparation method for a supported composite catalyst, characterized in that, proceed as follows:

[0049] (1), Ni(NO 3 ) 2 9H 2 O and C 4 h 6 MnO·4H 2 O was dissolved in distilled water and ultrasonically dissolved for 20 minutes to form a mixed solution A, Ni(NO 3 ) 2 9H 2 O, C 4 h 6 MnO·4H 2 The consumption ratio of O and distilled water is 0.4955g:0.4456g:30mL;

[0050] (2) Add the surfactant polyethylene glycol 4000 to the mixed solution A while stirring, and ultrasonicate for 5 minutes. The mass volume ratio of polyethylene glycol 4000 to the distilled water in the mixed solution A is 1.5:10, and then add it while stirring SBA-15, and conduct ultrasound for 40min to form the mixed solution B, the stirring rate is 100r / min, the mass volume ratio of SBA-15 to the mixed solution A is 1g:30mL;

[0051] (3) Place the mixed solution B on a magnetic stirrer at 55°C and heat and stir until the suspension becomes a paste-like material, and the stirring rate i...

Embodiment 3

[0055] A kind of preparation method of supported composite catalyst, carries out as follows:

[0056] (1), Ni(NO 3 ) 2 9H 2 O and C 4 h6 MnO·4H 2 O was dissolved in distilled water and ultrasonically dissolved for 10 min to form a mixture A, Ni(NO 3 ) 2 9H 2 O, C 4 h 6 MnO·4H 2 The consumption ratio of O and distilled water is 0.4955g:0.4456g:30mL;

[0057] (2) Add the surfactant polyethylene glycol 4000 to the mixed solution A while stirring, and then ultrasonicate for 5 minutes. The mass volume ratio of polyethylene glycol 4000 and distilled water in the mixed solution A is 1:10, and then add it while stirring SBA-15, and conduct ultrasound for 45min to form the mixed solution B, the stirring speed is 100r / min, the mass volume ratio of SBA-15 to the mixed solution A is 1g:30mL;

[0058] (3) Add the surfactant polyethylene glycol 4000 to the mixed liquid B, then ultrasonicate for 5 minutes, place it on a magnetic stirrer at 55°C, heat and stir until the suspension ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com