Comprehensive utilization method for vanadium-titanium-magnetite concentrate

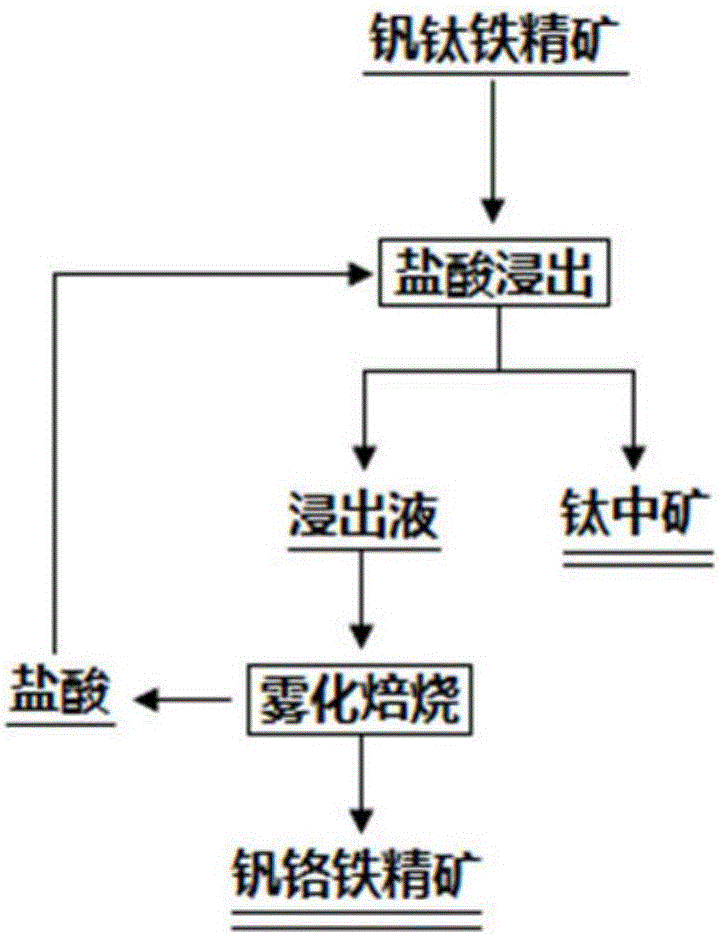

A technology of vanadium-titanium magnetite concentrate and vanadium-titanium iron concentrate, which is applied in the smelting field of vanadium-titanium magnetite, can solve the problems of unstable product quality, waste of titanium resources, long heat preservation time, etc., and achieve good application and market prospects , Realize the effect of recycling and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Vanadium Titanite Concentrate TFe 58wt%, V 2 o 5 0.54wt%, Cr 2 o 3 0.42wt%, TiO 2 10wt%, grind the vanadium-titanium magnetite concentrate to -200 mesh 85%; mix the ground vanadium-titanium magnetite concentrate with 18wt% hydrochloric acid, the liquid-solid mass ratio is 8:1, leaching at 80°C for 60min to obtain acid The leaching solution and the titanium medium ore, the TiO2 grade in the titanium medium ore is 34wt%; the leaching solution is adopted atomization roasting process, the roasting temperature is 500 ℃, adopts compressed air atomization, the spray pressure is 0.2MPa, and the gas-liquid volume ratio is 0.5, Obtain vanadium chromite concentrate and hydrochloric acid, hydrochloric acid recovery is used for the acid leaching of vanadium chromite concentrate, TFe 60wt% in the vanadium chromite concentrate, V 2 o 5 0.65wt%, Cr 2 o 3 0.54wt%; Hydrochloric acid leaching process titanium recovery rate in titanium ore is 93%, and the recovery rate of iron, ...

Embodiment 2

[0043] Vanadium Tiferon Concentrate TFe 60wt%, V 2 o 5 0.6wt%, Cr 2 o 3 0.5wt%, TiO 212wt%, grind the vanadium-titanium magnetite concentrate to -200 mesh 90%; mix the ground vanadium-titanium magnetite concentrate with 20wt% hydrochloric acid, the liquid-solid mass ratio is 8:1, leaching at 85°C for 90min to obtain acid Leaching solution and titanite, TiO in titanite 2 The grade is 37wt%; the leaching solution is atomized and roasted, the roasting temperature is 600°C, the spray pressure is 0.3 MPa, and the gas-liquid volume ratio is 0.5, to obtain vanadium-chromium iron concentrate and hydrochloric acid, and the hydrochloric acid is recovered for vanadium-titanium iron concentrate Acid leaching, TFe 62wt% in vanadium chromite concentrate, V 2 o 5 0.8wt%, Cr 2 o 3 0.6wt%; Hydrochloric acid leaching process titanium in the recovery rate of titanium ore is 94%, and the recovery rate of iron, vanadium and chromium in vanadium ferrochrome concentrate is respectively: ...

Embodiment 3

[0045] Vanadium Titanite Concentrate TFe 58wt%, V 2 o 5 0.54wt%, Cr 2 o 3 0.42wt%, TiO 2 10wt%, grind the vanadium-titanium magnetite concentrate to -200 mesh 85%; mix the ground vanadium-titanium magnetite concentrate with 15wt% hydrochloric acid, the liquid-solid mass ratio is 8:1, leaching at 90°C for 90min to obtain acid Leaching solution and titanite, TiO in titanite 2 The grade is 36wt%; the leaching solution is atomized and roasted, the roasting temperature is 700°C, the spray pressure is 0.1MPa, the gas-liquid volume ratio is 0.6, and vanadium chromite concentrate and hydrochloric acid are obtained, and TFe 61.5wt in vanadium chromite concentrate %,V 2 o 5 0.65wt%, Cr 2 o 3 0.58wt%; The recovery rate of titanium in titanium ore during hydrochloric acid leaching process is 95%, and the recovery rate of iron, vanadium and chromium in vanadium chromite concentrate is respectively: the recovery rate of iron is 83%, and the recovery rate of vanadium is 76%. %,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com