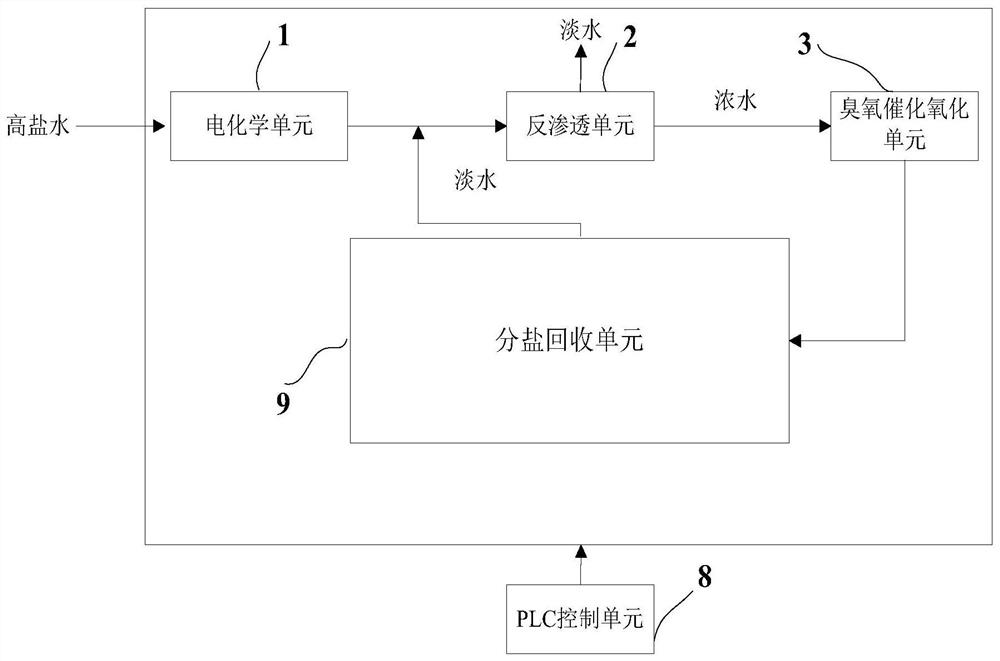

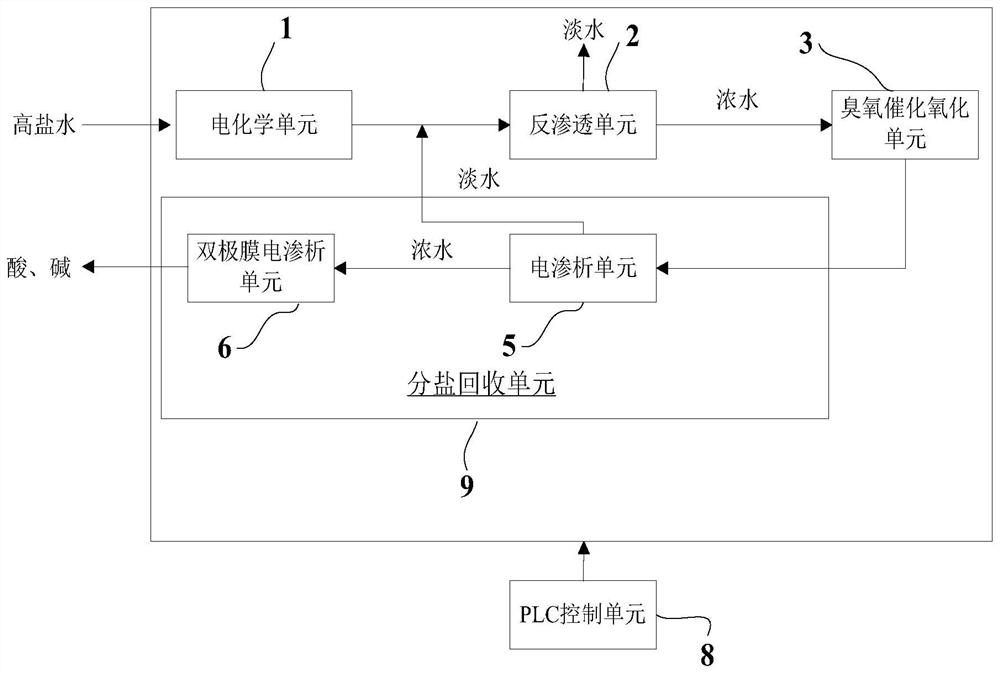

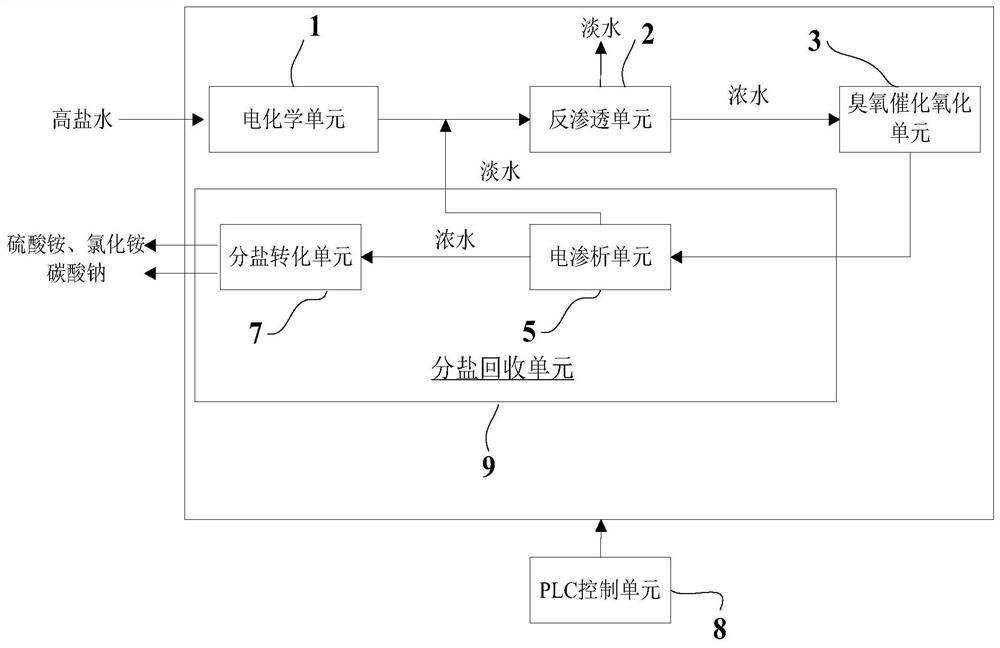

A zero-discharge treatment method and device for high-salt wastewater

A technology of high-salt wastewater and treatment device, which is applied in the field of high-salt and low-organic resource zero-discharge treatment, zero-discharge treatment method and device field of high-salt wastewater, to avoid secondary discharge, prolong service life, and realize the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0072] When the active component is selected from the combination of manganese dioxide, copper oxide, nickel oxide and cobalt oxide, the preparation method of the supported mesoporous activated carbon catalyst comprises the following steps:

[0073] a1 Put mesoporous spherical activated carbon into anhydrous nickel acetate (Ni(CH) 3 COO) 2 ), anhydrous copper acetate (Cu(CH) 3 COO) 2 ), cobalt acetate (Co(CH) 3 COO) 2 ), manganese acetate ((CH 3 COO) 2 Mn) is soaked in the immersion solution composed of 20-24h to obtain a mixed solution;

[0074] b1 Air-dry the mixed solution obtained in step a1 at normal temperature for 24-28h to obtain a semi-finished catalyst;

[0075]c1 Under a nitrogen atmosphere, the semi-finished catalyst obtained in step b1 is calcined in a resistance furnace at 1200-1400° C. for 6-8 hours to form, and then naturally cooled to room temperature.

[0076] Wherein, in step a1, the anhydrous nickel acetate (Ni(CH) 3 COO) 2 ), anhydrous copper ace...

Embodiment 1

[0114] The present embodiment provides a zero-discharge treatment method for high-salt wastewater, comprising the following steps:

[0115] 1) The high-salt wastewater is deeply dehardened by electrochemical method and organic pollutants are removed;

[0116] The high-salt wastewater is coking high-salt wastewater, and the main indicators of the influent are: COD Cr : 55mg / L, Cl - : 1100mg / L, SO 4 2- : 800mg / L, Ca 2+ : 41mg / L, Mg 2+ : 20mg / L, Na + : 2168mg / L; the parameters of the electrochemical method are as follows: the current density is 20mA / cm 2 , the residence time is 20min;

[0117]2) The effluent after electrochemical removal of hard and organic pollutants is desalinated by reverse osmosis, and the fresh water after desalination by reverse osmosis is reused;

[0118] The reverse osmosis desalination adopts two-stage low-pressure reverse osmosis, and the operating pressure is 1.8MPa;

[0119] 3) Ozone catalytic oxidation is carried out to the concentrated wate...

Embodiment 2

[0135] The present embodiment provides a zero-discharge treatment method for high-salt wastewater, comprising the following steps:

[0136] 1) The high-salt wastewater is deeply dehardened by electrochemical method and organic pollutants are removed;

[0137] The high-salt wastewater is coal gasification high-salt wastewater, and the main indicators of the influent are: COD Cr : 40mg / L, Cl - : 1200mg / L, SO 4 2- : 960mg / L, Ca 2+ : 50mg / L, Mg 2+ : 43mg / L, Na + : 2052mg / L; the parameters of the electrochemical method are as follows: the current density is 15mA / cm 2 , the residence time is 30min;

[0138] 2) The effluent after electrochemical removal of hard and organic pollutants is desalinated by reverse osmosis, and the fresh water after desalination by reverse osmosis is reused;

[0139] The reverse osmosis desalination adopts two-stage low-pressure reverse osmosis, and the operating pressure is 1.8MPa;

[0140] 3) Ozone catalytic oxidation is carried out to the conce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com