A coal-based supercritical carbon dioxide Brayton cycle power generation system with intermediate preheating

A technology of Brayton cycle and carbon dioxide, applied in the direction of machines/engines, lighting and heating equipment, reducing greenhouse gases, etc., can solve the problems of high cost and difficult development, improve thermal efficiency, ensure safe operation, and solve the problem of unusable heat Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0024] The present invention is described by taking the π-type boiler as an example, but not limited to the π-type boiler.

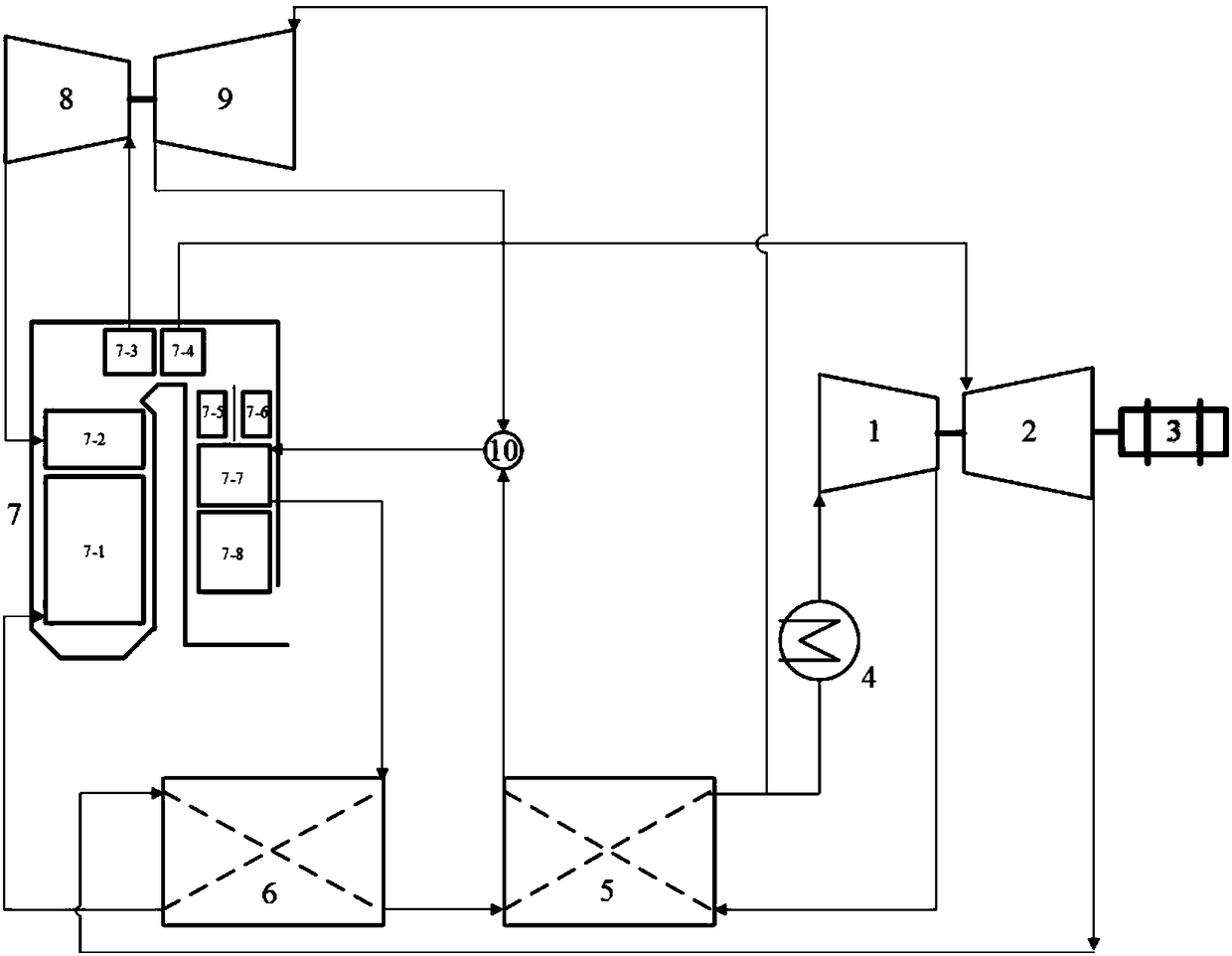

[0025] see figure 1 , the invention is a closed indirect heating intermediate preheating coal-based supercritical carbon dioxide Brayton cycle power generation system with split recompression, including a main compressor 1, a low-pressure turbine 2, a generator 3, a precooler 4, a low-temperature Regenerator 5 , high temperature regenerator 6 , boiler 7 , high pressure turbine 8 , recompressor 9 and mixer 10 .

[0026] The heat source of the power generation system is 7 boilers, and the boiler 7 includes a heating system, a reheating system, an intermediate preheater 7-7 and an air preheater 7-8;

[0027] Along the flue gas flow, the boiler 7 is sequentially equipped with a main working fluid radiation heating surface 7-1, a rehe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com