Method for preparing titanium solution by wet-processing on vanadium-titanium magnetite concentrates

A vanadium-titanium magnetite concentrate and wet processing technology, applied in the field of hydrometallurgy, can solve the problems of high-purity titanium liquid, such as difficulty, complicated purification process, and high impurity content, and achieve high utilization rate of titanium resources, low impurity content, The effect of low impurity content in titanium liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

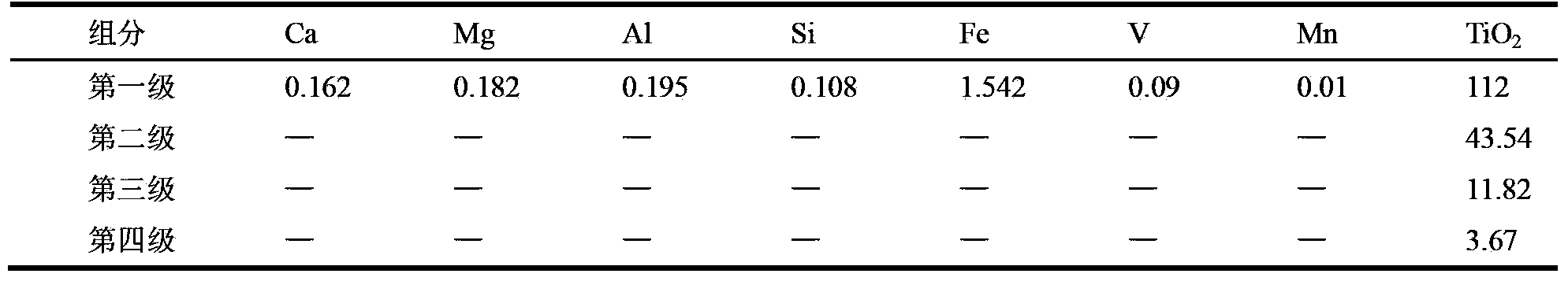

[0036] The vanadium-titanium magnetite concentrate is leached in a closed container with 30% hydrochloric acid at 150°C. The liquid-solid ratio of hydrochloric acid to the concentrate is 2:1. The liquid-solid ratio of the leaching residue is 10:1, 80°C, 20min). Washing slag and NaOH are mixed at a ratio of 1:5 and then added to a stainless steel reactor for molten salt decomposition reaction at a reaction temperature of 550°C for 5 hours to obtain a molten salt reaction material. The molten salt reaction material is washed with water (temperature 70°C, time 90min, washing liquid to solid ratio 10:1), and then pickled (sulfuric acid concentration 100g / L, temperature 70°C, time 90min, pH value of the pickling slurry is 6.7) . The pickling material is acid-dissolved with 400g / L sulfuric acid at 90°C for 3 hours to obtain the acid-dissolved material, and the liquid-solid ratio of the sulfuric acid solution to the pickling material is 1:1. Add the acid-dissolved material to 200g / ...

Embodiment 2

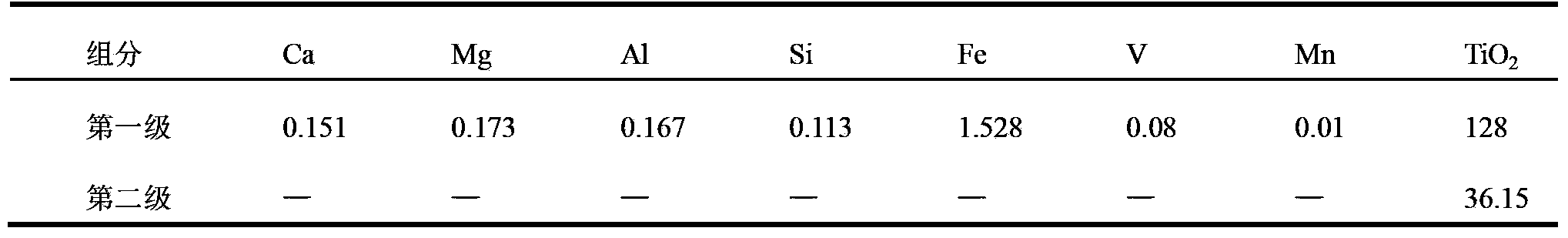

[0041] The vanadium-titanium magnetite concentrate is leached in a closed container with 10% hydrochloric acid at 130°C. The liquid-solid ratio of hydrochloric acid to the concentrate is 10:1. The liquid-solid ratio of the leaching residue is 5:1, 80°C, 30min). Washing slag and NaOH are mixed at a ratio of 1:0.5 and then added to a stainless steel reactor for molten salt decomposition reaction. The reaction temperature is 550°C and the time is 1h to obtain molten salt reaction material. The molten salt reaction material is washed with water (temperature 30°C, time 60min, washing solution to solid ratio 5:1), and then pickled (sulfuric acid concentration 80g / L, temperature 30°C, time 60min, pH value of the pickling slurry is 3.2) . The pickling material is acid-dissolved with 500g / L sulfuric acid at 40°C for 3 hours to obtain the acid-dissolved material. The liquid-solid ratio of the sulfuric acid solution to the pickling material is 0.6:1. Add the acid-dissolved material to ...

Embodiment 3

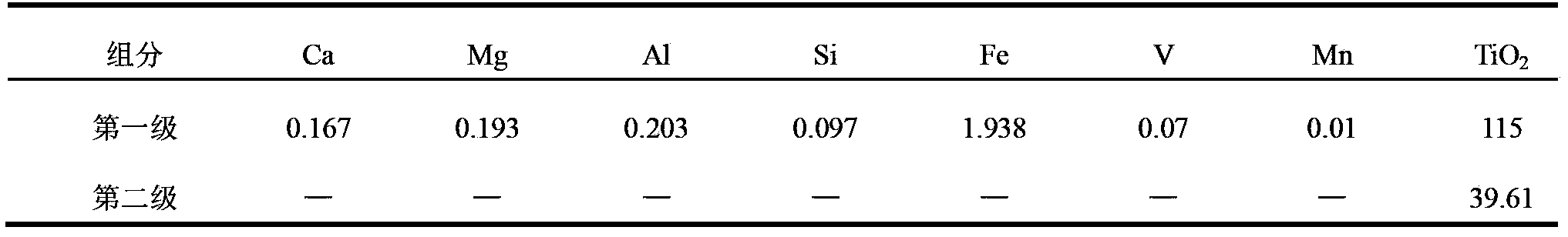

[0046]The vanadium-titanium magnetite concentrate is leached with 20% hydrochloric acid at 110°C under normal pressure. The liquid-solid ratio of hydrochloric acid and concentrate is 5:1. The liquid-solid ratio is 3:1, 30°C, 60min). Washing slag and NaOH are mixed at a ratio of 1:1 and then added to a stainless steel reactor for molten salt decomposition reaction at a reaction temperature of 400°C for 2 hours to obtain a molten salt reaction material. The molten salt reaction material is washed with water (temperature 50°C, time 30min, washing liquid to solid ratio 3:1), and then pickled (sulfuric acid concentration 200g / L, temperature 50°C, time 30min, pH value of the pickling slurry is 4.8) . The pickling material is acid-dissolved with 500g / L sulfuric acid at 40°C for 4 hours to obtain the acid-dissolved material. The liquid-solid ratio of the sulfuric acid solution to the pickling material is 1.2:1. Add the acid-dissolved material to 250g / L sulfuric acid solution for lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com