Aluminum alloy surface whitening solution and surface treatment method thereof

A technology of aluminum alloy surface and treatment method, which is applied in the direction of surface reaction electrolytic coating, anodic oxidation, electrolytic coating, etc., can solve the problems of high cost of whitening solution on aluminum alloy surface and limitation of application product range, etc., so as to reduce production cost, Effect of improving surface hardness and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0034] A kind of aluminum alloy surface whitening solution provided by the invention uses water as a solvent, and each liter of the whitening solution contains:

[0035] Ammonium chloride 8-10g;

[0036] Ammonium sulfate 40-50g;

[0037] Ammonium fluoride 50-60g;

[0038] Ammonium bifluoride 90-100g.

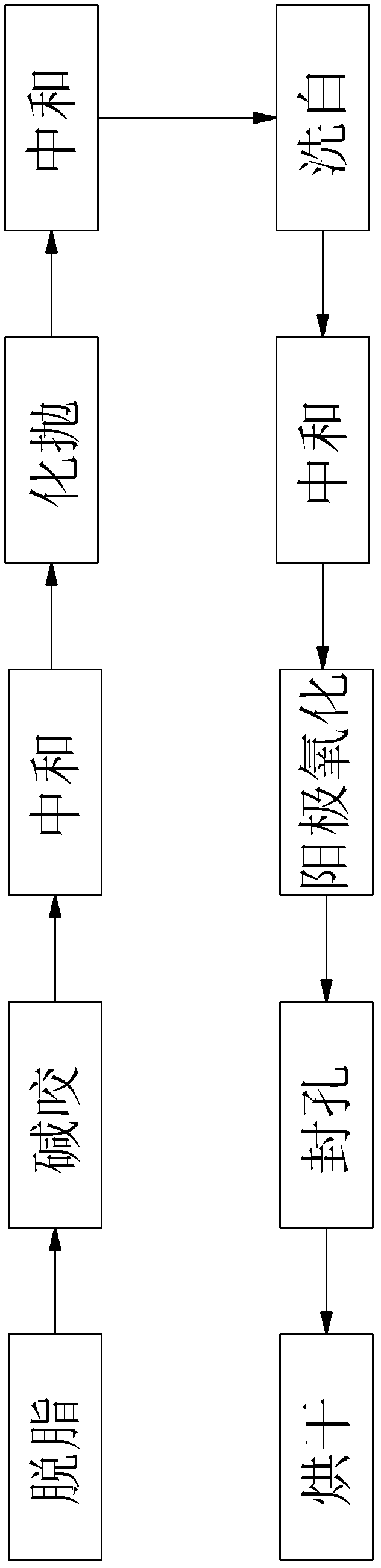

[0039] see figure 1 , which shows the process flow chart of surface treatment of aluminum alloy by using the aluminum alloy surface whitening solution of the present invention. The present invention provides a specific step of using the above-mentioned aluminum alloy surface washing solution to carry out surface treatment on the aluminum alloy surface as follows:

[0040] Degreasing: put the prefabricated aluminum alloy product into a solution containing 60g / L degreasing agent for degreasing treatment, the treatment temperature is 60°C, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com