Treatment method on surface of magnesium alloy

A surface treatment liquid, magnesium alloy technology, applied in the direction of metal material coating process, etc., can solve the problems of environmental pollution, limited use range, etc., to achieve the effect of good corrosion resistance, avoid instability and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The specific process and steps in this embodiment are as follows:

[0032] 1. At room temperature, place the polished and washed magnesium alloy workpiece in an acetone solution for 45 seconds for ultrasonic disinfection;

[0033] 2. Put the above-mentioned clean magnesium alloy workpiece into the alkali washing solution, and carry out alkali washing under magnetic stirring; the alkali washing temperature is 65 ° C, and the time is 15 minutes;

[0034] The formula of described alkaline lotion is as follows:

[0035] Add a certain amount of various sodium salts to 1 liter of pure water solvent. The concentrations of various sodium salts are: sodium phosphate 55g / L, sodium hydroxide 20g / L, sodium silicate 25g / L and sodium carbonate 2.5g / L L; form the alkaline washing solution of mixed sodium salt;

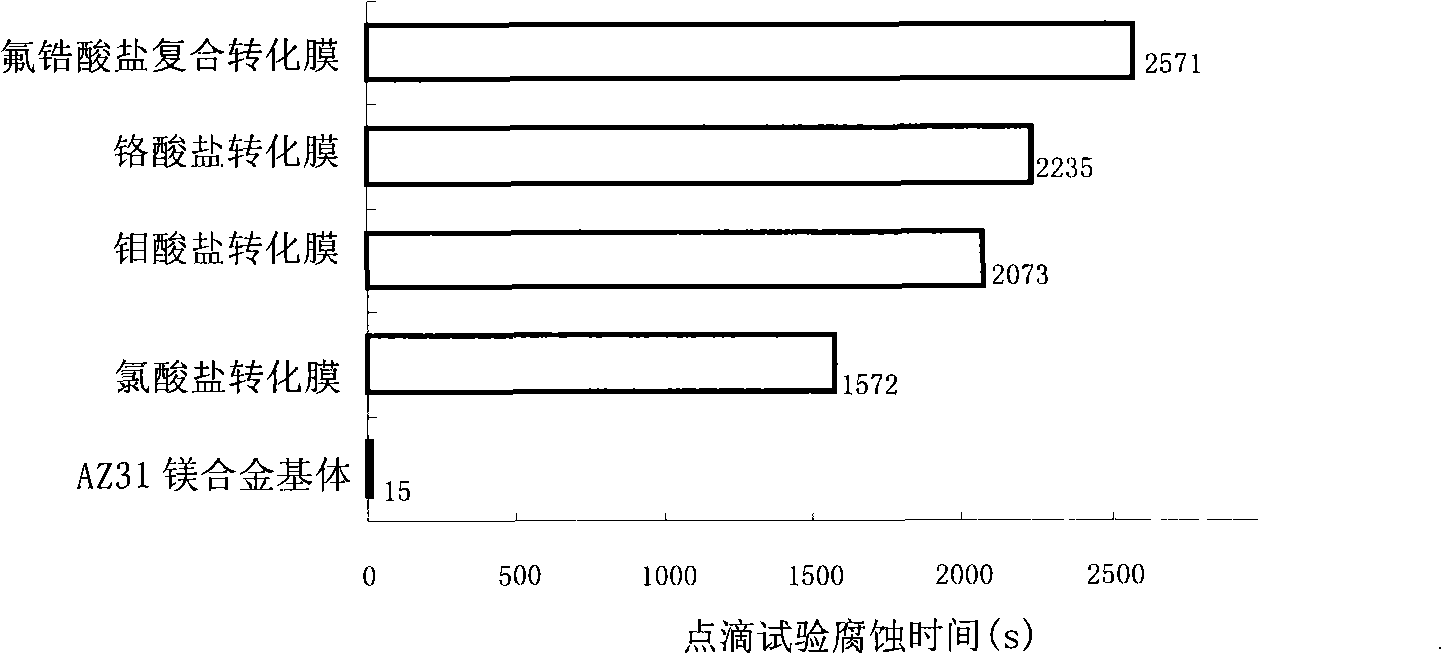

[0036] 3. Subsequently, the above alkali-washed magnesium alloy workpiece is treated with a fluorozirconate composite conversion coating surface treatment solution; the form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com