Preparation method for high-purity flaky alumina

A technology of flaky alumina and hydrated alumina, applied in the preparation of aluminum hydroxide, alumina/aluminum hydroxide, etc., can solve the problems of harsh reaction conditions, high equipment requirements, uneven doping of molten salt, etc. The particle size is uniform, the uniformity of doping is improved, and the effect of meeting application requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

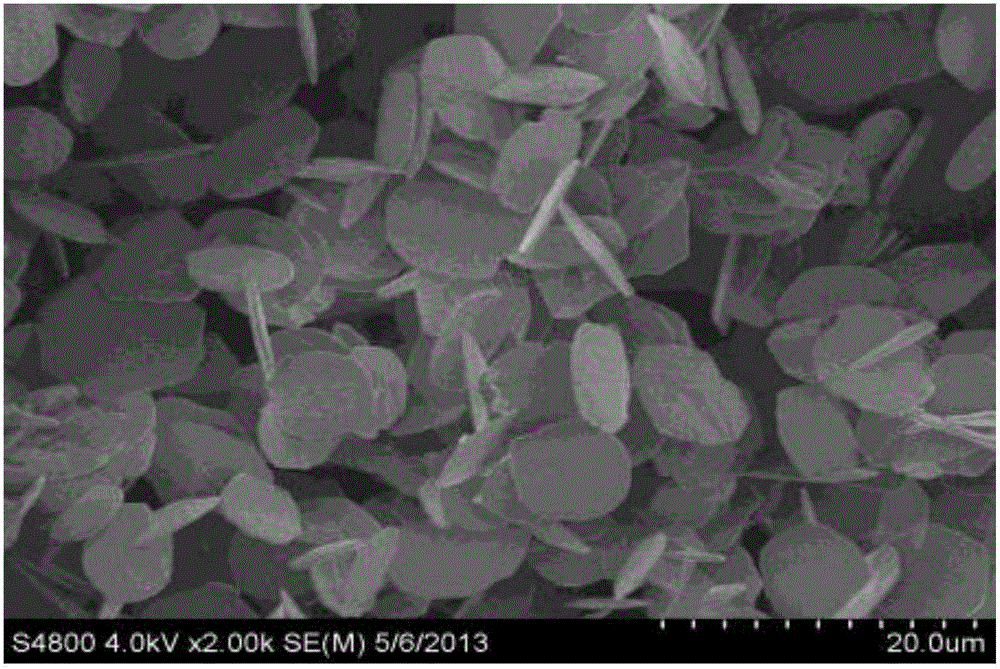

Image

Examples

Embodiment 1

[0035] Dissolve 200g of 5N grade aluminum isopropoxide in 294g of isopropanol under heating in a water bath at 80°C to make an aluminum isopropoxide solution (solution A), and place it in a funnel; mix 53g of deionized water with 236g of isopropanol Evenly, then add 10g of analytically pure ammonium fluoride, stir to make it completely dissolved in isopropanol-water solution, prepare solution B, and place it in a four-necked round-bottomed flask; put the four-necked round-bottomed flask containing solution B Put it into the water bath heater, keep the temperature of the water bath at 80°C, then install the funnel containing solution A on the four-necked round-bottomed flask, and install a reflux condenser and a stirrer on the four-necked round-bottomed flask at the same time; Add solution A to solution B gradually at a dropping speed of 1 min, and start stirring at the same time. Under the action of heating and stirring, the aluminum isopropoxide molecules in solution A and the...

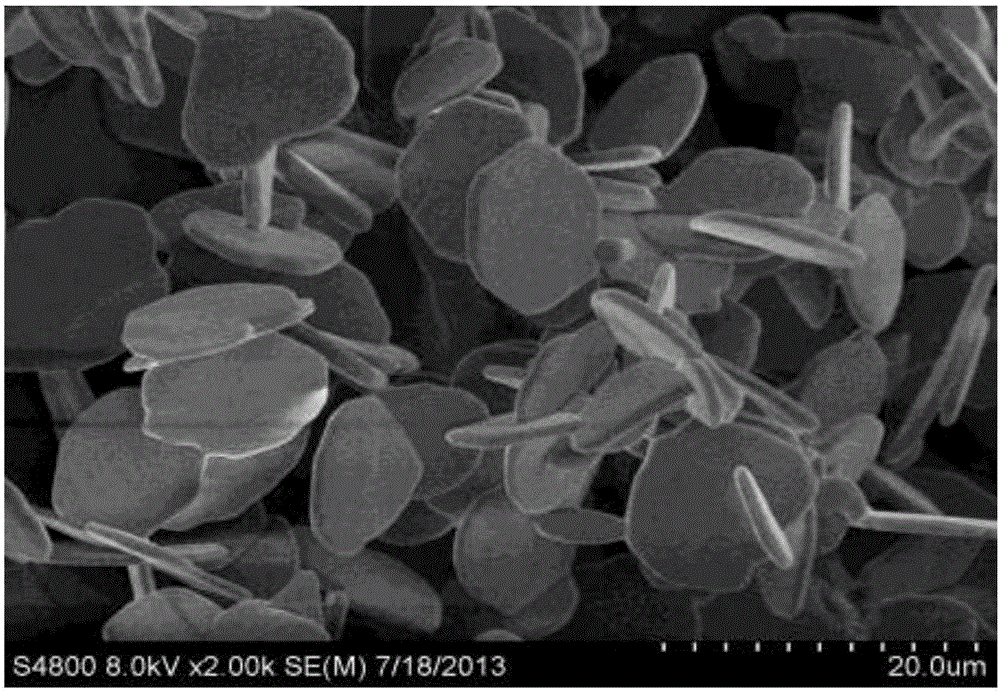

Embodiment 2

[0037] Dissolve 612g of 5N grade aluminum isopropoxide in 1080g of isopropanol to prepare aluminum isopropoxide solution (solution A), mix 216g of deionized water with 900g of isopropanol, and 30.6g of ammonium fluoride to prepare solution B, solution A is installed in a funnel, and solution B is installed in a round bottom flask; solution A is added to solution B at a rate of 12mL / min, and the temperature of the water bath is kept at 85°C. Aluminum propoxide molecules react with water molecules in solution B to produce hydrated alumina, and produce isopropanol at the same time. During the heating reaction, the volatilized isopropanol is condensed and returned to the flask; then, the hydrated alumina solution is Alumina hydrate filter cake is obtained by filtration, and the filtrate is isopropanol, which can be recycled and reused; then, the alumina hydrate filter cake is dried in an oven at 160°C to obtain hydrated alumina powder; finally, the hydrated alumina powder is Calci...

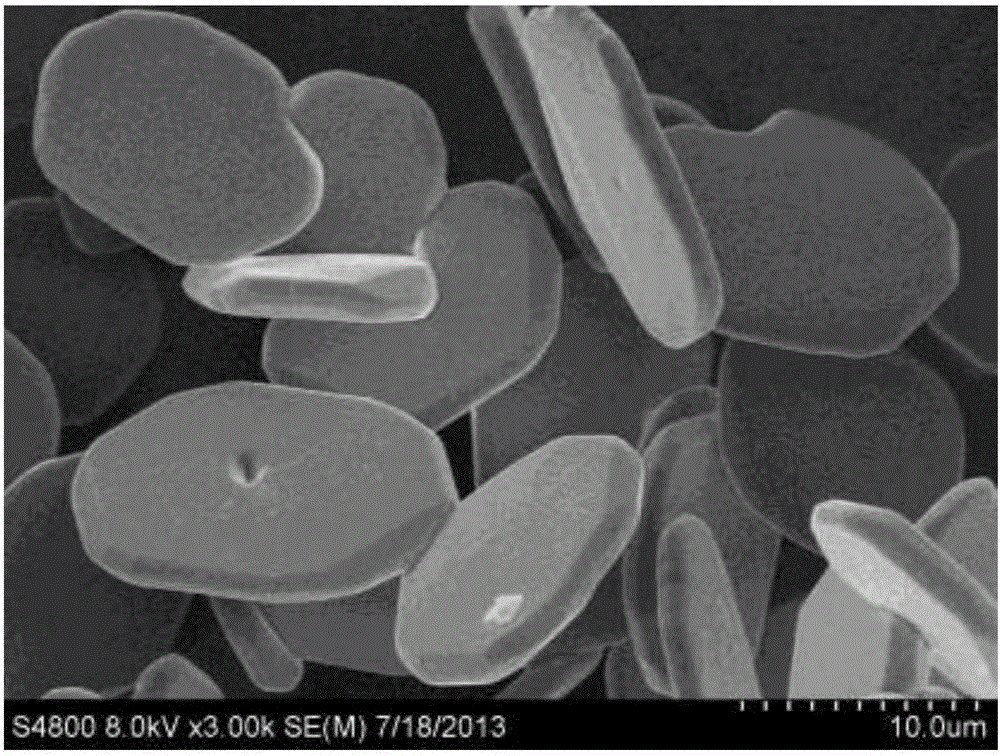

Embodiment 3

[0039] Dissolve 1244g of 5N grade aluminum isopropoxide in 1080g of isopropanol to prepare solution A, mix 162g of deionized water with 900g of isopropanol and 61.2g of ammonium bifluoride to prepare solution B, put solution A in a funnel, and solution B Put it in a round bottom flask; add solution A to solution B at a rate of 18mL / min, keep the temperature of the water bath at 65 ° C, under the action of heating and stirring, the aluminum isopropoxide molecules in solution A and solution B The water molecules in the hydrolyzed reaction generate alumina hydrate, and produce isopropanol at the same time, and the isopropanol volatilized during the heating reaction is condensed and returned to the flask; then, the alumina hydrate is filtered to obtain a filter cake, and the filtrate is isopropanol Alcohol, to be recovered and reused; then, put the hydrated alumina filter cake in a vacuum oven and dry at 150°C to obtain hydrated alumina powder; finally, put the hydrated alumina pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com