Acidizing block remover suitable for complex lithologic reservoir

A technology of complex lithology and blocking agent, applied in chemical instruments and methods, drilling composition, etc., can solve problems such as unsatisfactory construction effect and large physical property difference, prevent secondary precipitation, prevent swelling and particles The effect of migration and increasing daily water injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

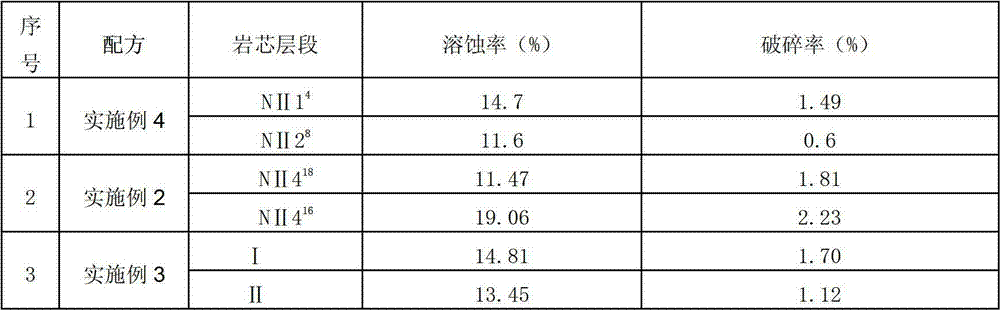

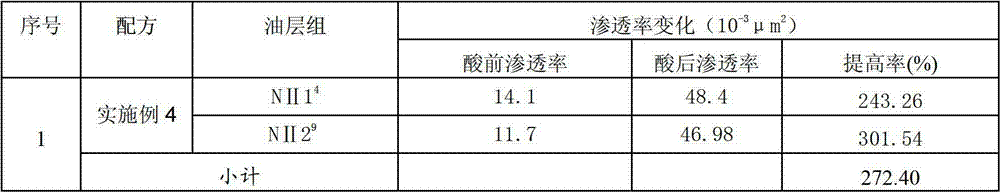

Examples

Embodiment 1

[0015] Weigh 10g of hydrochloric acid, 1g of ammonium bifluoride, 2g of boric acid, 3g of glacial acetic acid, 4.0g of corrosion inhibitor, 2.0g of mutual solvent ethylene glycol monobutyl ether, 0.5g of penetrant alkylphenol polyoxyethylene ether, and 2.0g of clay stabilizer It is mixed with 75.5g of water to prepare an acidifying plug-removing agent.

[0016] The acidifying plugging remover is suitable for the formulation of an acidizing plugging removing agent for a low-harm waterproof and sensitive compound acid liquid system. The characteristic of this acid solution system is that it can effectively dissolve formation minerals and blockages without destroying the formation framework, prevent secondary precipitation caused by sensitive minerals, prevent clay mineral expansion and particle migration, and at the same time prevent formation emulsification and enhance formation Excellent water wettability ensures acidifying effect.

Embodiment 2

[0018] Weigh 8g of sulfamic acid, 2g of ammonium bifluoride, 0.5g of citric acid, 4.0g of corrosion inhibitor, 2.0g of mutual solvent, 0.5g of penetrating agent, 2.0g of clay stabilizer and 81.0g of water to prepare an acidifying plugging remover.

[0019] The acidifying plugging remover is suitable for acid-sensitive formations prone to hydrochloric acid.

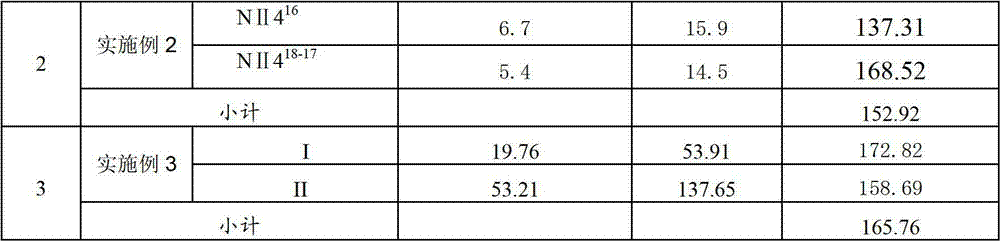

Embodiment 3

[0021] Weigh 10g of hydrochloric acid, 3g of fluoboric acid, 2g of ethanol, 1g of triethanolamine, 4.0g of corrosion inhibitor, 2.0g of mutual solvent, 0.5g of penetrant, 3.0g of clay stabilizer and 74.5g of water and mix to prepare an acidifying plugging remover.

[0022] The acidizing plug-removing agent is suitable for low-damage, anti-swelling and anti-migration compound acid system in the tuffaceous reservoirs of Xing'anling Group. The acid system is characterized by the high content of montmorillonite and tuffaceous matter in the Xing'anling oil layer, and has dual water-sensitive characteristics of water swelling and clay migration. It can effectively dissolve formation minerals and blockages, and prevent clay minerals from swelling and granules. Migration meets the acidification needs of this type of reservoir.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com