Process for preparing ammonium hydrogen fluoride

A technology of ammonium bifluoride and ammonium fluoride, which is applied in the field of ammonium bifluoride preparation, can solve the problems that the product quality cannot meet the market requirements, restrict the development of the phosphate fertilizer industry, and cannot be effectively used, and achieve low equipment material requirements and easy industrial production , design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

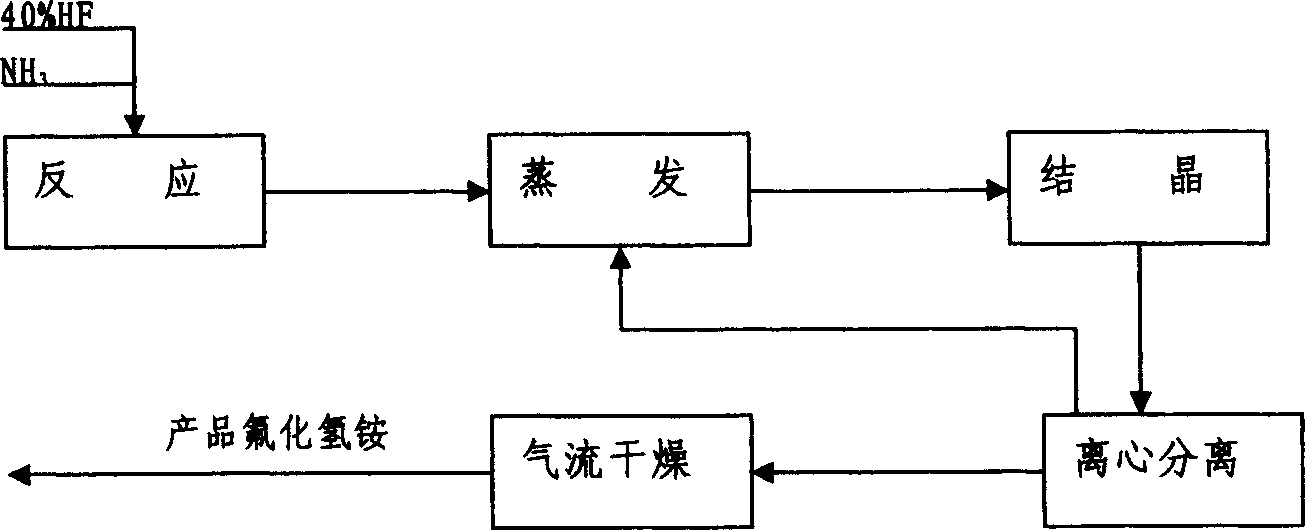

Method used

Image

Examples

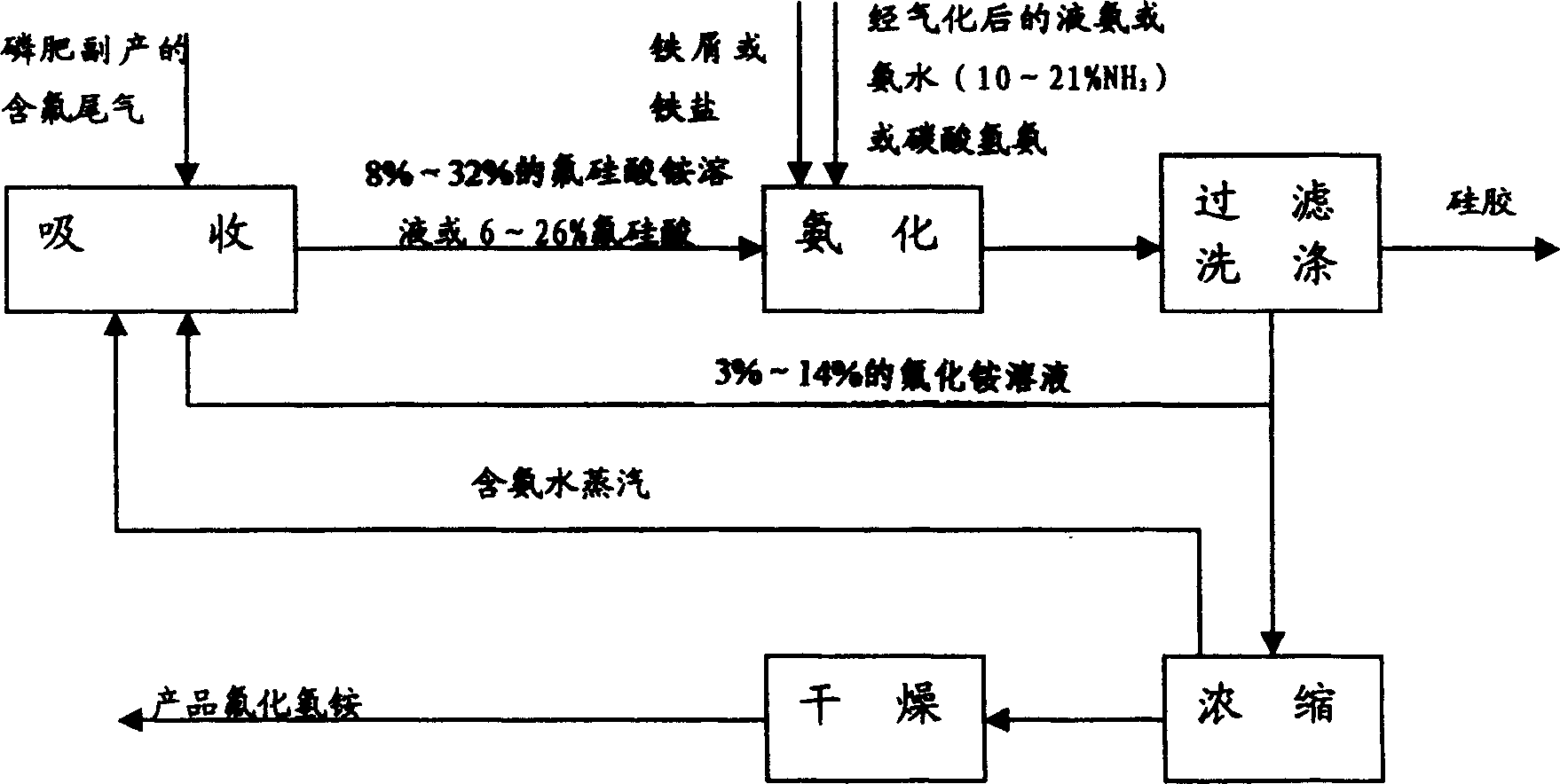

Embodiment 1

[0035] Absorb the by-product fluorine-containing tail gas of phosphate fertilizer production with 10% ammonium fluoride solution, obtain (NH 4 ) 2 SiF 6 22% ammonium fluorosilicate solution. Another by-product H in the ammonium fluorosilicate solution or phosphate fertilizer production 2 SiF 6 Iron filings or iron salts are added to fluosilicic acid with a content of 18%, and the addition amount of iron filings or iron salts is 150% of the theoretical amount; to remove phosphorus that affects product quality; then add gasified liquid ammonia or NH 3 The content is 15% ammonia water, and the pH of the control solution is 8.5. Filter and wash to remove silica precipitate; part of the ammonium fluoride solution is returned to the phosphate fertilizer absorption system, concentrated and dried to obtain the required ammonium bifluoride product. The ammonia-containing water vapor produced by concentration is absorbed by fluosilicic acid and returned to the system.

[0036] Th...

Embodiment 2

[0039] The other processes are the same as in Example 1 except that the ammonia-containing water vapor produced by concentration is absorbed by fluosilicic acid and then returned to the system, or sent to the phosphate fertilizer system to absorb fluorine-containing tail gas after condensation, or sent to other ammonia-using devices for recovery.

Embodiment 3

[0041] In addition to neutralizing 18% fluorosilicic acid (P 2 o 5 content is 0.05%) solution, while adding iron filings or iron salt (addition amount is 200% of theoretical amount). After the ammoniation reaction, the pH of the ammonium fluoride solution was controlled to be 9.0. Filter, wash (twice) to remove silica gel. The entire ammonium fluoride solution was vacuum concentrated (at 85° C.) to a water content of <4%, and dried to obtain solid ammonium hydrogen fluoride. Other processes are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com