Method for producing anhydrous hydrogen fluoride and coproducing silica white from low-grade fluorine resources

An anhydrous hydrogen fluoride, low-grade technology, applied in fluorine/hydrogen fluoride, silicon oxide, silicon dioxide, etc., can solve the problems of low main content of hydrogen fluoride, uneconomical industrialization, incomplete conversion, etc., and achieve high utilization rate of raw materials, high price Inexpensive, cost-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

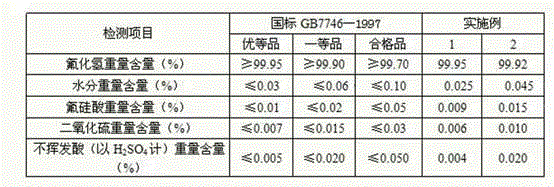

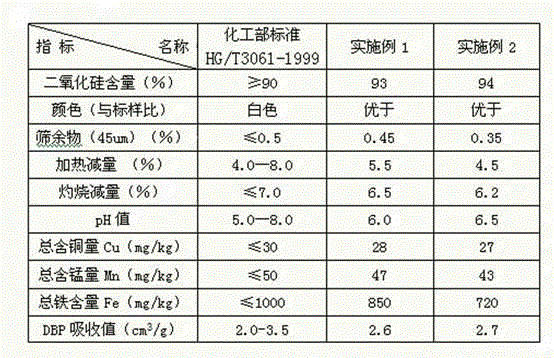

Embodiment 1

[0021] In this embodiment, the method for producing anhydrous hydrogen fluoride and co-producing white carbon black by utilizing low-grade fluorine resources comprises the following steps:

[0022] (1) Ammonium fluoride solution and silicon dioxide were obtained by ammonium lysis of 4000g of fluorosilicic acid solution with a concentration of 5% by weight of phosphate fertilizer by-products, and separated by filtration. The resulting filter cake was silicon dioxide ointment, which was washed and dried Promptly get 85g white carbon black product after the end, gained filtrate is ammonium fluoride solution;

[0023] (2) The ammonium fluoride solution obtained in step (1) is concentrated and pyrolyzed to obtain 710 g of ammonium bifluoride solution with a concentration of 20% by weight and ammonia gas, which is used in step (1) phosphate fertilizer by-product fluosilicic acid solution Ammonolysis;

[0024] (3) 710g of the obtained 710g by weight concentration of the ammonium bif...

Embodiment 2

[0027] In this embodiment, the method for producing anhydrous hydrogen fluoride and co-producing white carbon black by utilizing low-grade fluorine resources comprises the following steps:

[0028] (1) Ammonium fluoride solution and silicon dioxide were obtained by ammonium lysis of 167g of fluosilicic acid solution with a concentration of 60% by weight of phosphate fertilizer by-products, which were separated by filtration, and the obtained filter cake was silicon dioxide ointment, which was washed and dried Promptly get 45g white carbon black product after the end, gained filtrate is ammonium fluoride solution;

[0029] (2) The ammonium fluoride solution obtained in step (1) is concentrated and pyrolyzed to obtain 355 g of ammonium bifluoride solution with a concentration of 40% by weight and ammonia gas, which is used in step (1) phosphate fertilizer by-product fluosilicic acid solution Ammonolysis;

[0030] (3) 355g of the obtained 355g weight percent concentration of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com