Polishing solution and polishing method

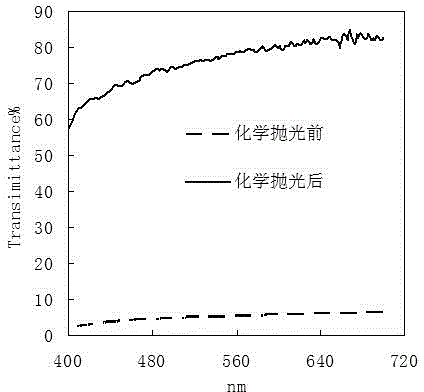

A technology of polishing liquid and hydrofluoric acid, which is applied in the field of optical processing and manufacturing, can solve the problems that the surface roughness is only 260nm, the crystal nucleus dissolution of glass-ceramics is not considered, and the chemical polishing of glass-ceramics is less, so as to achieve high polishing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

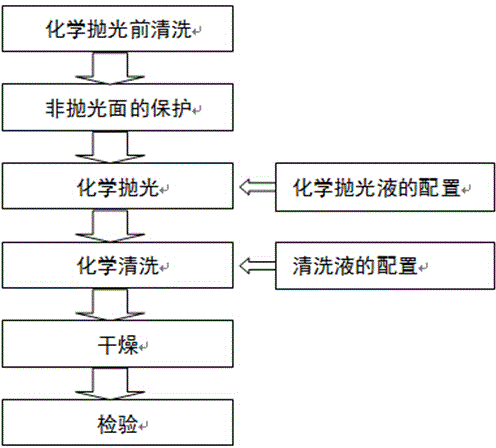

[0032] A kind of polishing liquid, the mass ratio of each component is ammonium bifluoride: hydrofluoric acid: hydrochloric acid: nitric acid: glycerol: ethylene glycol: hexadecyltrimethylammonium chloride=26~29:24~28: 9~10: 4~5: 20~22: 8~10: 0.1~0.5.

[0033] The preparation steps are: a), prepare each component according to the above mass ratio, b), weigh the solid substance ammonium bifluoride and cetyltrimethyl ammonium chloride with a balance according to the formula; c), measure hydrogen with a graduated cylinder Fluoric acid, hydrochloric acid, nitric acid, glycerol, ethylene glycol, all poured into the polytetrafluoroethylene tank and mixed; d), slowly add all the solid mixture in step b) to the mixed solution in step c), during the adding process Stir well in the medium to form a transparent chemical polishing solution.

Embodiment 2

[0035] The difference from Example 1 is that the mass ratio of each component is ammonium bifluoride: hydrofluoric acid: hydrochloric acid: nitric acid: glycerol: ethylene glycol: cetyltrimethylammonium chloride = 28:26 :10:4:22:10:0.1.

Embodiment 3

[0037] A polishing liquid, the mass ratio of each component is: ammonium fluoride: hydrofluoric acid: hydrochloric acid: nitric acid: glycerol: ethylene glycol: cetyltrimethylammonium chloride = 32~35: 24~ 26: 9~10: 4~5: 18~20: 6~8: 0.1~0.5.

[0038] During preparation, a) prepare the components according to the above mass ratio, b) weigh the solid ammonium fluoride and cetyltrimethylammonium chloride with a balance according to the formula; c) measure hydrofluoride with a graduated cylinder Acid, hydrochloric acid, nitric acid, glycerol, ethylene glycol, all poured into a polytetrafluoroethylene tank and mixed; d), slowly add all the solid mixture in step b) to the mixed solution in step c), during the addition process Stir well to form a transparent chemical polishing solution.

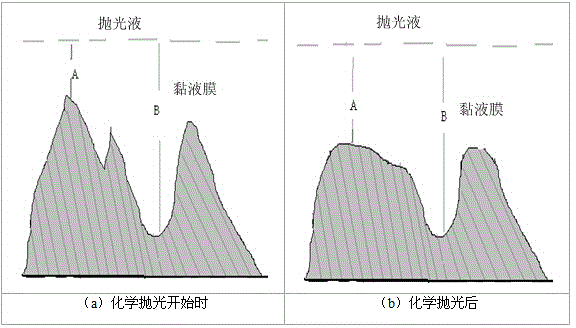

[0039] The technical principle of the present invention is: in the chemical polishing liquid HF2-, F- and HF coordination are identical, the concentration of HF in the chemical polishing liquid can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com