Low-cost and high-strength Ti-Zr-Al-F2 alloy

A high-strength, low-cost technology, applied in the field of material science and non-ferrous metals and their alloys, can solve the problems of expensive titanium alloys, and achieve the effects of low price, good plasticity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

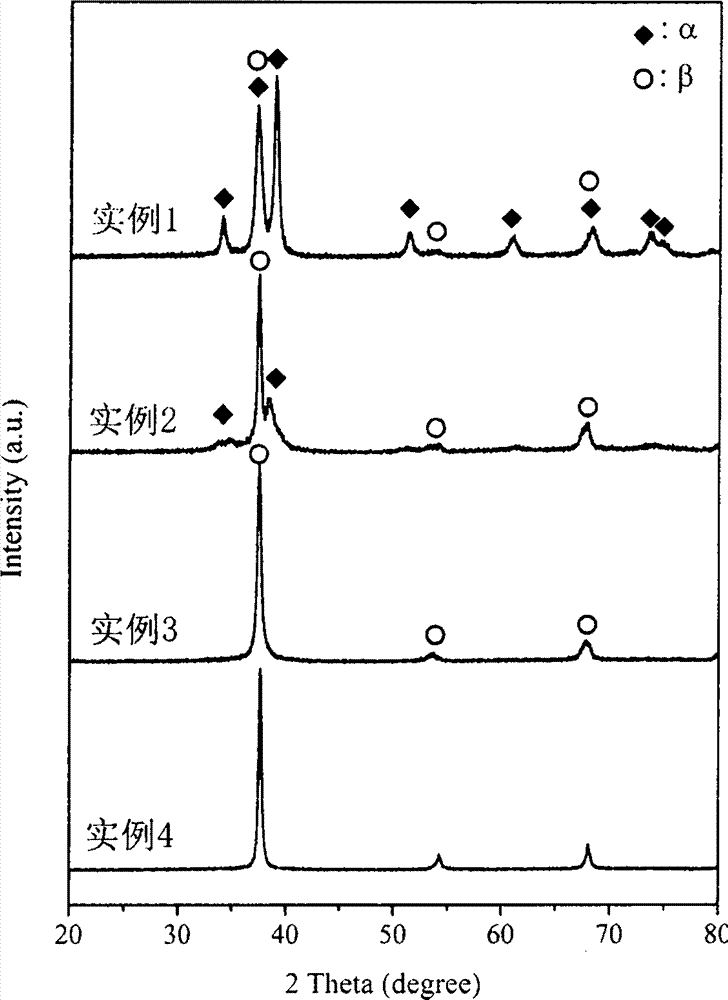

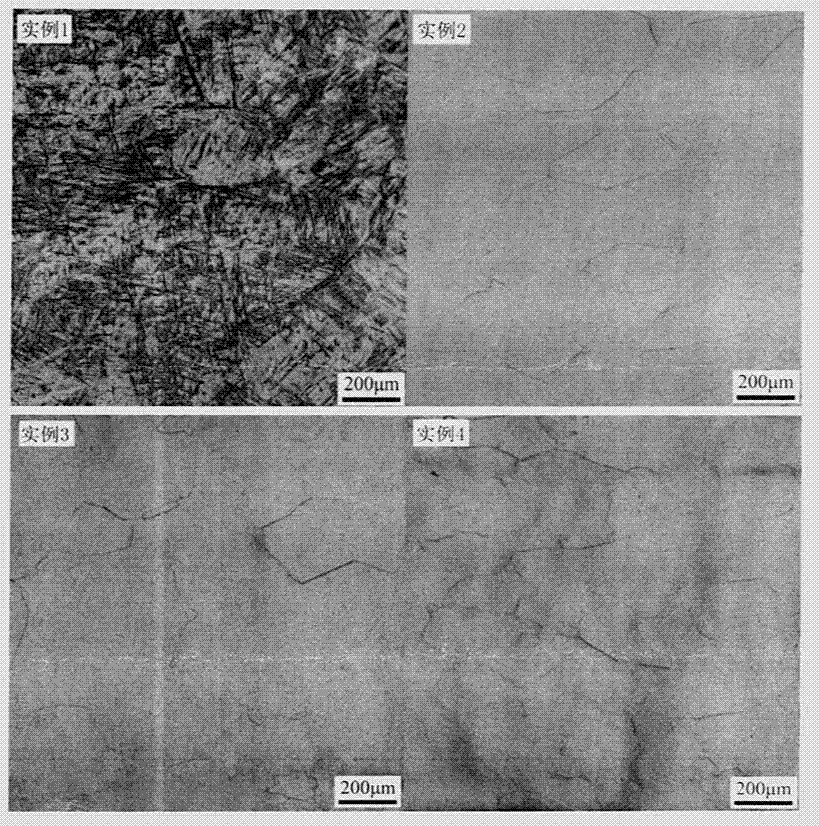

Embodiment 1

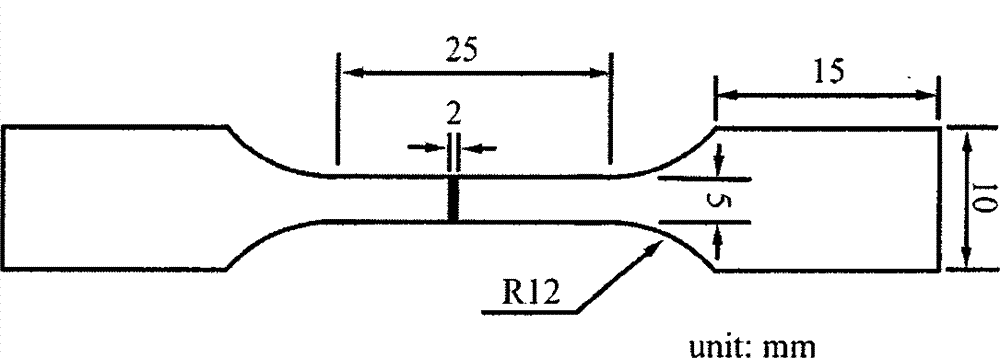

[0016] Industrial grade sponge Ti, sponge Zr, pure Al and pure Fe are used for compounding according to the composition 47.5Ti-47.5Zr-4.5Al-0.5Fe (wt%). Melt four times in a non-consumable electric arc furnace to ensure uniform composition. After holding at 750-850°C for 5-7 minutes, it is quickly transferred to a two-bar flat rolling mill for two rolling deformations. After the first rolling deformation, Re-insulate at the above temperature for 3-5 minutes and then carry out the second pass of deformation. The thickness of each pass is reduced by 4-5mm, and finally a plate-shaped sample with a thickness of about 4mm is obtained. The maximum thickness deformation of the total rolling is 65. -75%. After the last rolling pass, the sample is quickly immersed in water at room temperature (about 20°C) to cool, and the sample is taken out after it is completely cooled, and the surface of the rolled alloy sample is peeled and ground to obtain Ti-Zr -Al-Fe alloy sample. Processed in...

Embodiment 2

[0018] Industrial grade sponge Ti, sponge Zr, pure Al and pure Fe are used for compounding according to the composition 47.25Ti-47.25Zr-4.5Al-1.0Fe (wt%). Melt four times in a non-consumable electric arc furnace to ensure uniform composition. After holding at 750-850°C for 5-7 minutes, it is quickly transferred to a two-bar flat rolling mill for two rolling deformations. After the first rolling deformation, Re-insulate at the above temperature for 3-5 minutes and then carry out the second pass of deformation. The thickness of each pass is reduced by 4-5mm, and finally a plate-shaped sample with a thickness of about 4mm is obtained. The maximum thickness deformation of the total rolling is 65. -75%. After the last rolling pass, the sample is quickly immersed in water at room temperature (about 20°C) to cool, and the sample is taken out after it is completely cooled, and the surface of the rolled alloy sample is peeled and ground to obtain Ti-Zr -Al-Fe alloy sample. Processed ...

Embodiment 3

[0020] Industrial grade sponge Ti, sponge Zr, pure Al and pure Fe are used for compounding according to the composition 47.0Ti-47.0Zr-4.5Al-1.5Fe (wt%). Melt four times in a non-consumable electric arc furnace to ensure uniform composition. After holding at 750-850°C for 5-7 minutes, it is quickly transferred to a two-bar flat rolling mill for two rolling deformations. After the first rolling deformation, Re-insulate at the above temperature for 3-5 minutes and then carry out the second pass of deformation. The thickness of each pass is reduced by 4-5mm, and finally a plate-shaped sample with a thickness of about 4mm is obtained. The maximum thickness deformation of the total rolling is 65. -75%. After the last rolling pass, the sample is quickly immersed in water at room temperature (about 20°C) to cool, and the sample is taken out after it is completely cooled, and the surface of the rolled alloy sample is peeled and ground to obtain Ti-Zr -Al-Fe alloy sample. Processed in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com