Method for preparing high-performance ceramic capacitor material by preparing multi-variant synergetic doped barium strontium titanate

A technology for ceramic capacitors and barium strontium titanate is applied in the field of multi-component synergistic doping of barium strontium titanate to prepare high-performance ceramic capacitor materials, which can solve the problems of low dielectric loss, large loss, and large change in dielectric constant, and achieve high dielectric constant. Low-loss withstand voltage characteristics, cost savings, and effects of high withstand voltage characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

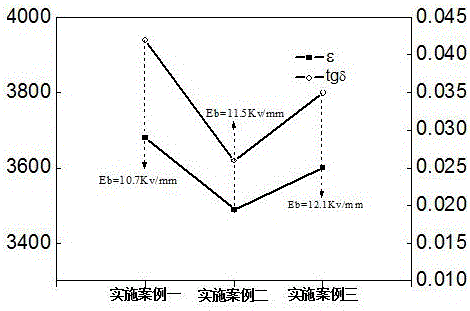

Examples

Embodiment 1

[0022] with BaCO 3 , CaCO 3 、 Bi 2 o 3 ,, ZrO 2 、TiO 2 As the main raw material, base materials such as strontium titanate and barium titanate are pre-synthesized.

[0023] (1) With 1molBi 2 o 3 , 3molTiO 2 For the standard ratio, wet ball milling to make it evenly mixed, and after press filtration, keep it at 800°C for 2 hours to obtain Bi 2 o 3 ·3TiO2 2 ; Analytical pure BaCO 3 , SrCO 3 respectively and TiO 2 Mix evenly according to the ratio of 1:1 of the amount of substances, wet ball milling to make it evenly mixed, and prepare BaTiO by 1180°C for 2.5h after pressing and other processes 3 and SrTiO 3 ; Analytical pure CaCO 3 with ZrO 2 Mix evenly according to the amount of the same substance, and cool in an electric furnace at 1250 ° C for 2 hours to obtain CaZrO 3 .

[0024] (2) Then prepare BST ceramic materials according to production design requirements, (1-z) [(Ba 1-x-y Sr x Ca y ) Ti 1-y Zr y o 3 ]·z(Bi 2 o 3 ·3TiO2 2 ), where x=0.35, y=0....

Embodiment 2

[0032] with BaCO 3 , CaCO 3 、 Bi 2 o 3 ,, ZrO 2 、TiO 2 As the main raw material, base materials such as strontium titanate and barium titanate are pre-synthesized.

[0033] (1) With 1molBi 2 o 3 , 3molTiO 2 It is the standard ratio, wet ball milling to make it evenly mixed, and after pressure filtration, keep it at 850°C for 2~3h to get Bi 2 o 3 ·3TiO2 2 ; Analytical pure BaCO 3 , SrCO 3 respectively and TiO 2 Mix evenly according to the ratio of 1:1 of the amount of substances, wet ball milling to make it evenly mixed, and prepare BaTiO by 1200°C for 2h after pressing and other processes 3 and SrTiO 3 ; Analytical pure CaCO 3 with ZrO 2 Mix evenly according to the amount of the same substance, and cool in an electric furnace at 1250 ° C for 2 hours to obtain CaZrO 3 .

[0034] (2) Then prepare BST ceramic materials according to production design requirements, (1-z) [(Ba 1-x-y Sr x Ca y ) Ti 1-y Zr y o 3 ]·z(Bi 2 o 3 ·3TiO2 2 ), where x=0.35, y=0.1, ...

Embodiment 3

[0042] with BaCO 3 , CaCO 3 、 Bi 2 o 3 ,, ZrO 2 、TiO 2 As the main raw material, base materials such as strontium titanate and barium titanate are pre-synthesized.

[0043] (1) With 1molBi 2 o 3 , 3molTiO 2 It is the standard ratio, wet ball milling to make it evenly mixed, and after pressure filtration, it is kept at 850°C for 2 hours to obtain Bi 2 o 3 ·3TiO2 2 ; Analytical pure BaCO 3 , SrCO 3 respectively and TiO 2 Mix evenly according to the ratio of 1:1 of the amount of substances, wet ball milling to make it evenly mixed, and prepare BaTiO by 1200°C for 2h after pressing and other processes 3 and SrTiO 3 ; Analytical pure CaCO 3 with ZrO 2 Mix evenly according to the amount of the same substance, and cool in an electric furnace at 1250 ° C for 2 hours to obtain CaZrO 3 .

[0044] (2) Then prepare BST ceramic materials according to production design requirements, (1-z) [(Ba 1-x-y Sr x Ca y ) Ti 1-y Zr y o 3 ]·z(Bi 2 o 3 ·3TiO2 2 ), where x=0.3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com