Flue gas denitrating integral catalyst with titanium base ceramic as carrier and preparation thereof

A monolithic catalyst and catalyst technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve strong water vapor resistance, simple preparation process, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

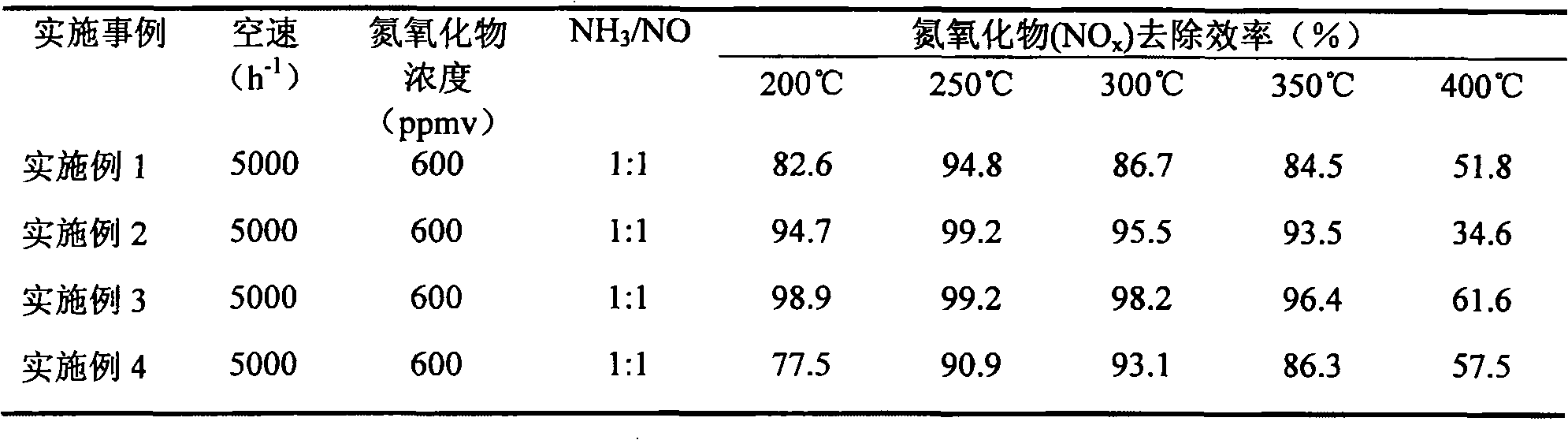

Embodiment 1

[0033] (3) Preparation of active component impregnation solution

[0034] 12gCe(NO 3 ) 3 .6H 2 Ce(NO 3 ) 3 solution;

[0035] (4) Active CeO 2 load

[0036] Coated TiO in step (2) 2 -ZrO 2The sample of the second carrier coating of the composite oxide is immersed in the solution prepared in step (3). After the immersion, the residual solution in the channel is blown out, and after 24 hours of natural shade drying, it is baked at 500° C. in a muffle furnace for 3 hours, and repeated. Impregnated, dried and calcined once until the required carrier load is reached, that is, the active CeO 2 The coating, based on the mass of the first carrier, has a mass percentage of 12.7%.

[0037] Example 2

[0038] (1) TiO 2 -ZrO 2 Composite sol preparation

[0039] First, stir 17ml butyl titanate and 25ml absolute ethanol to prepare liquid A, then add 12ml glacial acetic acid, 5ml water, and 30ml absolute ethanol in order to prepare liquid B, then add liquid A dropwise to liquid...

Embodiment 2

[0042] (3) Preparation of active component impregnation solution

[0043] 12g Ce(NO 3 ) 3 .6H 2 Ce(NO 3 ) 3 solution;

[0044] (4) Active CeO 2 load

[0045] Coated TiO in step (2) 2 -ZrO 2 The sample of the second carrier coating of the composite oxide is immersed in the solution prepared in step (3). After the immersion, the residual solution in the channel is blown away, dried in a blast drying oven at 80°C for 10 hours, and then passed through a muffle furnace at 500°C. Roast for 3 hours, repeat impregnation, drying and roasting once until the required carrier load is reached, that is, the active CeO 2 The coating, based on the mass of the first carrier, has a mass percentage of 10.5%.

[0046] Example 3

[0047] (1) TiO 2 -ZrO 2 Composite sol preparation

[0048] First, stir 17ml butyl titanate and 25ml absolute ethanol to prepare liquid A, then add 12ml glacial acetic acid, 5ml water, and 30ml absolute ethanol in order to prepare liquid B, then add liquid A...

Embodiment 3

[0051] (3) Preparation of active component impregnation solution

[0052] 12g Ce(NO 3 ) 3 .6H 2 Ce(NO 3 ) 3 solution;

[0053] (4) Active CeO 2 load

[0054] Coated TiO in step (2) 2 -ZrO 2 The sample of the second carrier coat of the composite oxide is immersed in the solution prepared in step (3). ℃ calcination for 3 hours, repeat impregnation, drying and calcination once until the required carrier load is reached, that is, the active CeO 2 The coating, based on the mass of the first carrier, has a mass percentage of 10.2%.

[0055] Example 4

[0056] (1) TiO 2 -ZrO 2 Composite sol preparation

[0057] First, stir 17ml butyl titanate and 25ml absolute ethanol to prepare liquid A, then add 12ml glacial acetic acid, 5ml water, and 30ml absolute ethanol in order to prepare liquid B, then add liquid A dropwise to liquid B , stirred for 20 minutes, then added 6.0 g of zirconium oxychloride and stirred for 40 minutes to obtain a titanium-zirconium mixed sol.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com